The dynamic permeability model serves as the foundation for fluid-solid coupling analysis. Researchers both domestically and internationally have extensively explored this topic, proposing numerous models. These models can be categorized into two types based on independent variables. The first type characterizes the relationship between permeability and either pore pressure or effective stress

[1-2]. From a functional perspective, they fall into categories such as power model, exponential model, binomial model, and logarithmic model

[3]. These models are derived from the deformation of structures such as flat fractures, circular tube bundles, elliptical tube bundles, and star-like tube bundles based on the hypothesis of uniaxial strain. Under the assumption of constant overburden pressure

[4], dynamic permeability can be directly calculated as pore pressure changes and can be extensively used in traditional reservoir numerical simulation

[5] and well testing interpretation

[6]. The second type characterizes the relationship between permeability and porosity, resulting in various equations that link permeability with other parameters like porosity, particle radius, specific surface area, and tortuosity based on the Kozeny-Carman equation

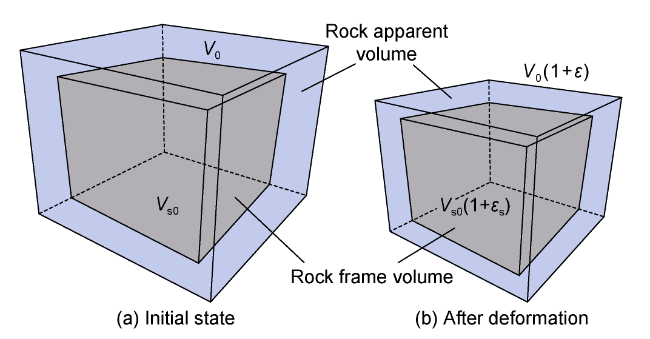

[7⇓-9]. Therefore, the relationship between permeability and volumetric strain can be obtained due to the direct and clear relationship between porosity and volumetric strain during rock deformation

[10]. As the understanding of the fluid-solid coupling deformation process deepens, it has become evident that the surrounding rocks outside the reservoir exert a constraining effect on deformation. Furthermore, there is a significant error in the assumptions of constant overburden pressure and uniaxial deformation

[11]. Fluid-solid coupling calculations have gradually developed into mechanical calculations, where stress, strain, and displacement fields are determined using a volume much larger than the seepage area. Subsequently, dynamic physical parameters are deduced based on the mechanical calculation results

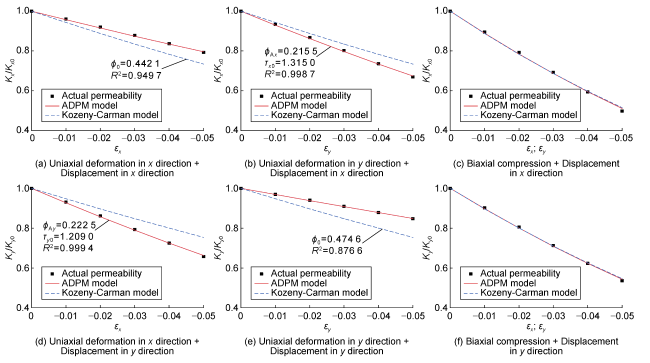

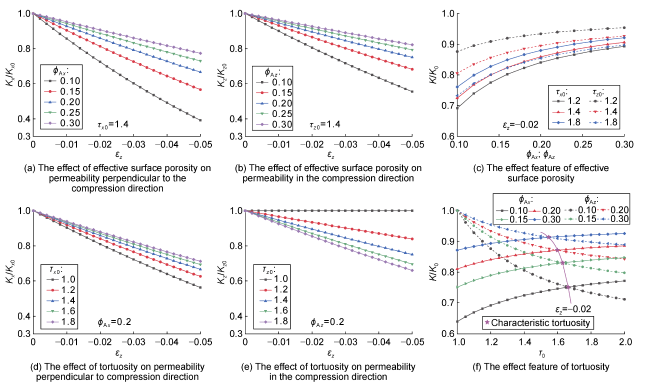

[12⇓-14]. The second type of dynamic permeability models, represented by the Kozeny-Carman equation, has gained widespread use in modern geomechanical calculations due to its compliance with the theoretical basis of three-dimensional deformation

[15-16].