Introduction

1. Experiments

1.1. Materials and equipment

1.2. Experimental procedures

1.2.1. Preparation of structure stabilizers

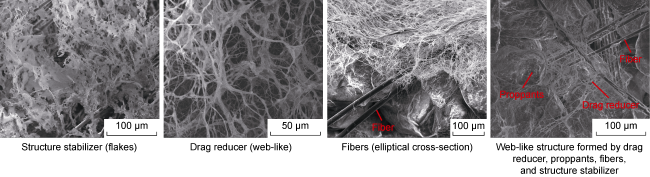

1.2.2. Microstructure observation

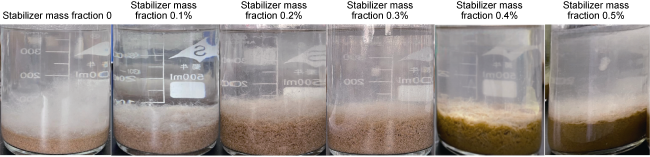

1.2.3. The effect of structure stabilizers on fiber escape rate

1.2.4. Evaluation of proppant placement height

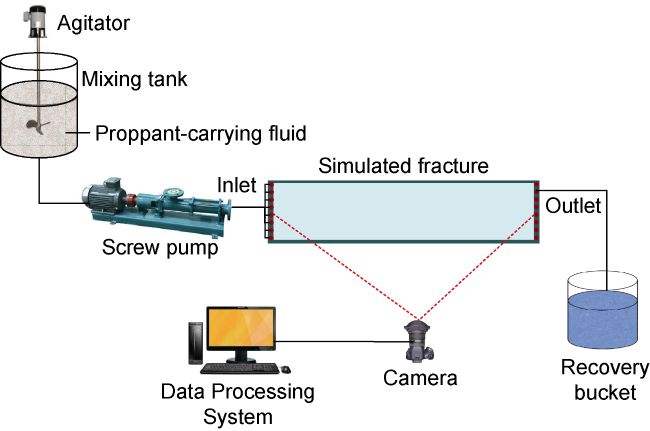

Fig. 1. Photograph of the visualized proppant sedimentation device. |

1.2.5. Flow conductivity test

1.2.6. Critical sand production flow rate test

1.2.7. Proppant transport capability testing

Fig. 2. Proppant transport capability experiment system. |

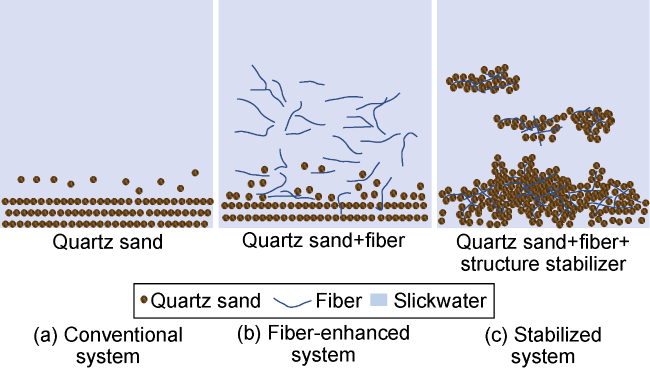

2. The mechanism of efficient placement of proppants

2.1. The mechanism of structure stabilizer

Fig. 3. Schematic diagrams illustrating the interaction among structure stabilizer, fibers, and quartz sands. |

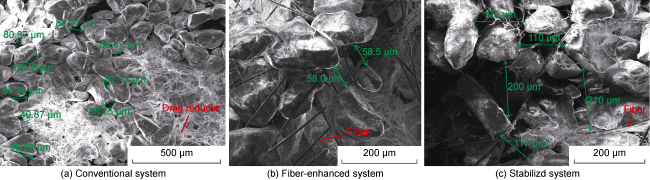

Fig. 4. SEM photos of proppant systems. |

2.2. Forces on proppants

3. Experimental results and discussion

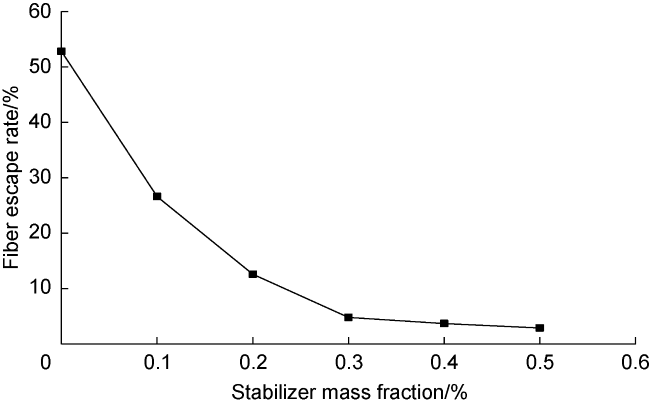

3.1. Fiber escape rate variation

Fig. 5. Experimental results of escapable fiber at different mass fractions of structure stabilizer. |

Fig. 6. Structure stabilizer mass fraction vs. fiber escape rate. |

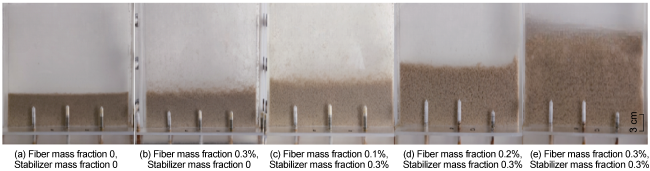

3.2. Proppant placement height variation

Fig. 7. Experiment result of different formula proppants after 1 h of sedimentation in a visualized settling device. |

Fig. 8. Schematic diagrams of proppant settling. |

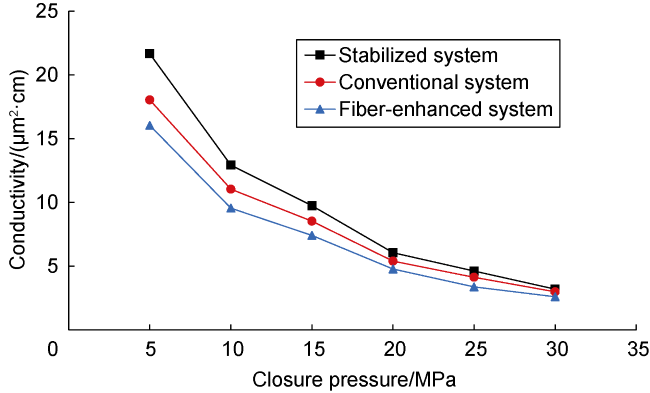

3.3. Variation of proppant conductivity

Fig. 9. Impact of closure pressure on the conductivity of different types proppant systems. |

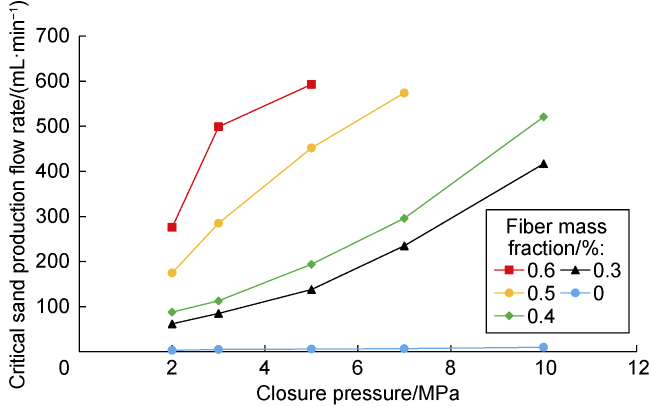

3.4. Variation of critical sand production flow rate

Fig. 10. Influence of closure pressure on the critical sand production flow rate. |

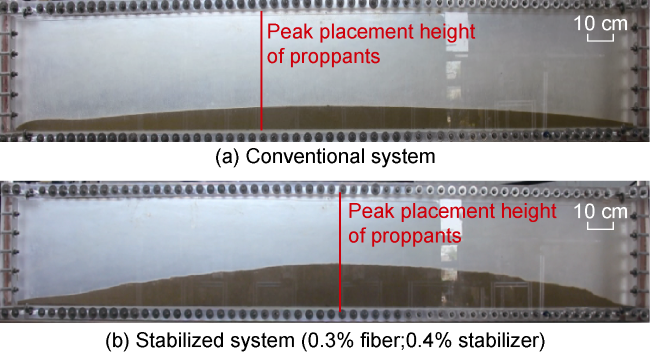

Fig. 11. Proppant placement shapes from experiments on critical sand production flow rate. |

3.5. Proppant transport capability

Fig. 12. Proppant placement profiles of different proppant systems. |

4. Field application

4.1. Application in tight gas wells

Table 1. Initial and steady production after fracturing by using different proppant systems in tight gas wells on the same well pad |

| Well | Density of drilling fluid/ (g·cm−3) | Poro- sity/% | Perme- ability/ 10−3 μm2 | Water saturation/% | Intensity of sand injection/ (m3·m−1) | Intensity of fluid injection/ (m3·m−1) | Propped fracture volume/ 104 m3 | Single fracture length/m | Initial dality gas production/ 104 m3 | Initial daily oil production/t | Sand production rate/ % | Cumulative gas production after 362 d/ 104 m3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ZM220- 5HF | 1.83-1.88 | 7.7 | 0.06 | 39.7 | 2.27 | 15.7 | 240.21 | 232.62 | 9.9 | 5.0 | 0.73 | 2 725.2 |

| ZM220- 4HF | 2.00-2.06 | 7.5 | 0.10 | 44.0 | 2.62 | 16.5 | 211.10 | 216.82 | 2.8 | 2.3 | 2.72 | 1 067.5 |

4.2. Application in shale oil wells

Fig. 13. Oil production contribution rates of fractured stages in Well YY1HF. |

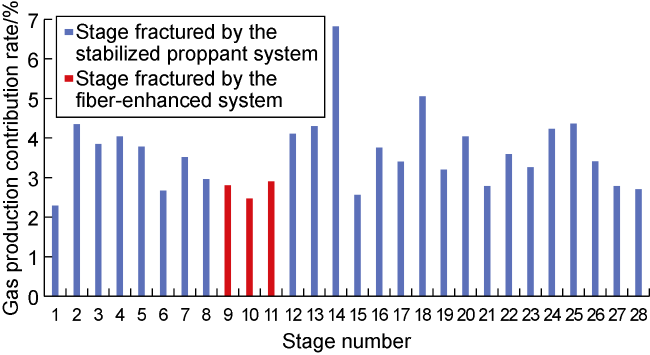

4.3. Application in shale gas wells

Table 2. Reservoir and fracturing parameters of 4 wells on well pad X in the Southern Sichuan Basin |

| Well | TOC/% | Porosity/ % | Reservoir gas content/ (m³•t−1) | Brittle mineral/% | Stage length/m | Number of stages | Displacement/ (m3•min−1) | Intensity of proppant injection/(t•m−1) | EUR/ 108 m3 |

|---|---|---|---|---|---|---|---|---|---|

| X-1HF | 5.4 | 5.5 | 6.0 | 68 | 1 371 | 20 | 18 | 3.29 | 1.18 |

| X-2HF | 6.0 | 5.7 | 6.0 | 67 | 1 328 | 19 | 18 | 3.29 | 1.09 |

| X-3HF | 6.3 | 5.7 | 6.2 | 68 | 1 372 | 20 | 18 | 3.39 | 1.08 |

| X-4HF | 5.7 | 5.9 | 6.5 | 68 | 1 497 | 17 | 18 | 3.22 | 1.21 |