In order to explore the propagation law of multi-fractures after TPDF, numerous scholars have conducted laboratory experiments and theoretical research. They have found that the effectiveness of temporary plugging is influenced by reservoir conditions (such as in-situ stress state, beddings/natural fractures, etc.) and operational parameters (such as temporary plugging agent (TPA) type, TPA particle size, TPA concentration, displacement, and fracturing fluid viscosity, etc.)

[14⇓⇓⇓⇓⇓-20]. Zou et al.

[21], Zhou et al.

[22], and Chen et al.

[23] suggested that the horizontal stress difference and inter-cluster stress difference are the primary controlling factors determining the diversion effects of HF by temporary plugging within fractures and within segments. The larger the horizontal stress difference or inter-cluster stress difference, the more difficult it is for fractures to divert, requiring more TPAs, earlier plugging timing and more plugging cycles. Tang et al.

[24] indicated that the higher the density or the azimuth angle of NFs, the later the optimal timing for temporary plugging. Lu et al.

[25] proposed that the efficiency of NF opening is influenced by the plugging strength and the approaching angle of NFs. Forming an effective plugging zone is crucial for inducing HF diversion. Guo et al.

[26] proposed that the primary controlling factors affecting the formation mode of the plugging zone are the ratio of particle size to fracture width, and the displacement and viscosity of carrying fluid. Li et al.

[27] pointed out that under the influence of TPA particle concentration, the plugging zone exhibits different bridging modes, with high concentration conditions tending towards dual-particle bridging and low concentration conditions tending towards single-particle bridging. Different diverted fractures are formed in different plugging positions. Li et al.

[28] found that the larger the horizontal stress difference, the closer the initiation position to the fracture tip. Yuan et al.

[29] proposed a method based on the normal width of the fracture to describe the characteristics of the plugging position, suggesting that the narrow region inside the fracture is the characteristic plugging position. Wang et al.

[30] discovered that when the plugging occurs at the fracture tip, the diverted fracture is perpendicular to the main fracture; and when the plugging occurs in the middle of the fracture, the fracture morphologically exhibits a "S" shape. Hu et al.

[31] found that the closer the plugging position is to the fracture mouth, the more balanced the overall propagation of multi-cluster fractures. Zhang et al.

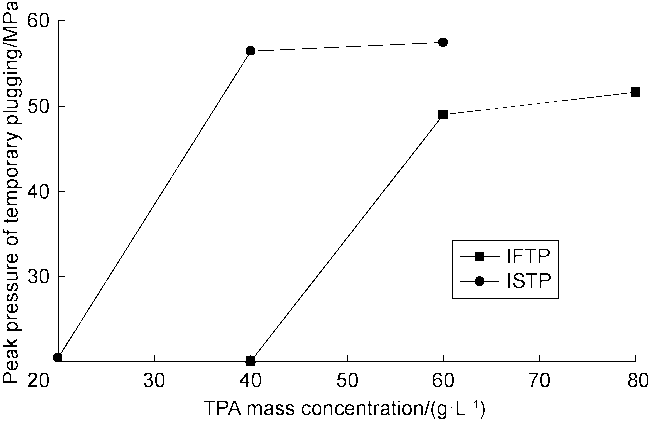

[32] suggested that the primary controlling factor influencing the plugging position and the propagation of diverted fractures is TPA concentration. Regarding the mechanism of temporary plugging for pressure buildup, Wang et al.

[33] and Shi et al.

[34] qualitatively pointed out that plugging at the fracture mouth changes the circumferential stress around the wellbore, plugging inside the fracture changes the closure stress of the fracture, and plugging at the fracture tip hinders the conduction of fluid stress and achieves fracture arrest.