c—operating conditions such as pulling out of hole and running in hole;

d—dual-string structure, wellbore trajectory, downhole tools and other design parameters;

d2—inner diameter of the outer string, m;

D1—inner string diameter, m;

D2—outer string diameter, m;

E—elastic modulus of string, Pa;

F—axial tension of downhole string, N;

Ff—friction per unit length of the downhole string, N/m;

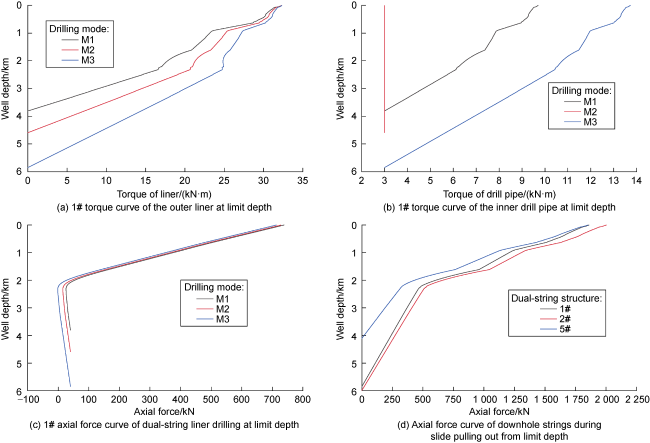

Fobj—objective function of extension limit of dual-string liner differential rotary drilling in horizontal well;

g—gravity acceleration, m/s2;

h—hydraulic constraints such as drilling fluid performance, hydraulic circulating pressure and critical flow velocity of rock debris migration;

i—well section element number;

I—moment of inertia of pipe cross-section, m4;

k—number of screen pipe elements;

kf—flow coefficient, dimensionless;

L—downhole string length, m;

Lh—hydraulic extension limit of dual-string liner drilling of horizontal well, m;

Li—length of well section i, m;

Lm—mechanical extension limit of dual-string liner drilling in horizontal well, m;

Lmax—maximum extension limit of dual-string liner drilling in horizontal well, m;

Lo—open hole extension limit of dual-string liner drilling in horizontal well, m;

MT1—inner string torque, N·m;

MT2—outer string torque, N·m;

n—rheology index, dimensionless;

nt1—normal force of the inner string acting on the outer string, N;

nt2—normal force of the dual-string acting on borehole wall, N;

N—element number of completion string, and $1\le i\le k\le N$;

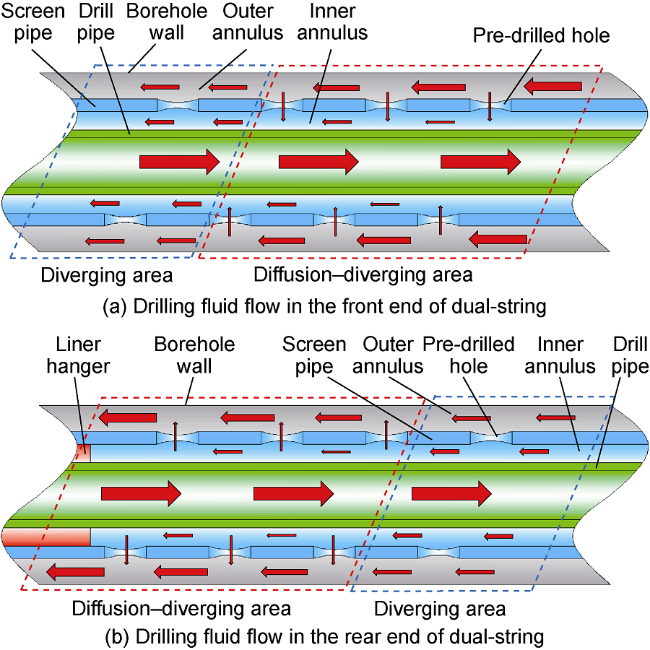

pca—hydraulic loss in the annulus between downhole dual- string and borehole wall in the casing completion section, Pa;

pca1, pca2—hydraulic loss in annulus of casing-borehole wall and casing-drill pipe, Pa;

pf—reservoir fracture pressure, Pa;

pla—annulus pressure between the first-grade reaming bit at the front end of screen pipe and the borehole wall, Pa;

pla1, pla2—outer and inner annulus pressure, Pa;

pla1_b—outer annular circulation pressure of the well section with large deviation (greater than 30°), Pa;

pla1_h—outer annular circulation pressure of horizontal well section, Pa;

pla1_v—outer annular circulation pressure of the well section with small deviation (less than and equal to 30°), Pa;

pmax—the maximum hydraulic loss of downhole dual-string, Pa;

pmax,1—the maximum circulating hydraulic loss of downhole dual-string with the screen pipe and liner connected by screw thread, Pa;

pmax,2—the maximum circulating hydraulic loss of the downhole dual-string with the screen pipe hanging on the inner wall of the casing, Pa;

pp—hydraulic loss of downhole string, Pa;

P—mechanical parameters such as lifting system load, rotary system load and pipe failure limit;

∆p—pressure difference between outer annulus and inner annulus, Pa;

qw—gravity of downhole string per unit length in drilling fluid, N/m;

Qa—total drilling fluid flow rate in double-annulus, L/s;

Qa1—drilling fluid flow rate in outer annulus, L/s;

Qa2—drilling fluid flow rate in inner annulus, L/s;

Qc—critical drilling fluid displacement of wellbore cleaning, L/s;

va—drilling fluid flow velocity, m/s;

va1, va2—drilling fluid flow velocity in outer and inner annulus, m/s;

Y—allowable region of the constraint parameter, that is the constraint condition;

${{\kappa }_{\text{b}}}$—borehole curvature, m−1;

μ1—friction coefficient between inner string and outer string, dimensionless;

μ2—friction coefficient between borehole wall and outer string, dimensionless;

ρf—drilling fluid density, kg/m3.

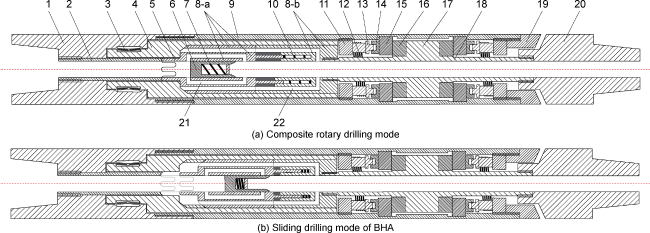

kp—if kp=1, the inner and outer strings are small-size drill pipe and liner, respectively; if kp=2, the inner and outer strings are large-size drill pipe and intermediate casing, respectively.