CO

2 enhanced oil recovery (EOR) has been extensively applied in the United States, with an annual oil production reaching the scale of 1 500×10

4 t

[29]. However, the continental sedimentary reservoirs in China differ significantly from the marine sedimentary reservoirs in the United States. While the CO

2 flooding mechanisms, technologies, and practices from the United States can serve as a reference, they cannot be directly copied. By using the established "multi-dimensional, multi-scale, dynamic- static combined, quantitative characterization" CO

2 injection physical simulation method and platform, the CNPC research team proposed some new insights into the mechanisms of CO

2 miscible flooding in continental sedimentary reservoirs

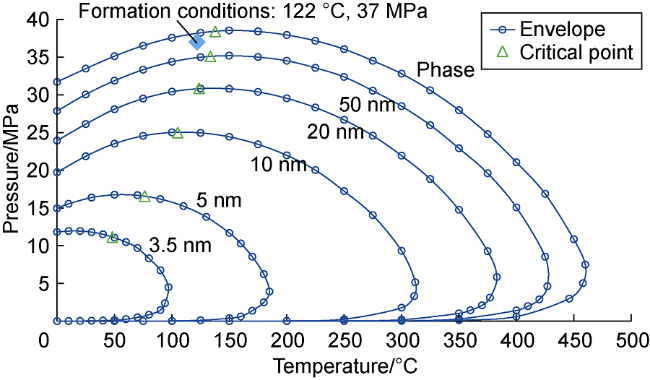

[29⇓⇓⇓-33]. These insights involve four aspects. First, the mass transfer and miscibility between CO

2 and C₇-C₁₅ fractions, which are abundant in continental oil, are also strong. This finding challenges the prevailing foreign notion that only C₂-C₆ fractions have strong mass transfer and miscibility with CO

2, significantly enhancing the potential for CO

2 miscible flooding in continental sedimentary reservoirs. Second, after CO

2 dissolves into crude oil, the cyclic and branched hydrocarbons contribute more to oil swelling, even though these components are present in smaller quantities. These hydrocarbons are crucial for oil swelling. Third, large hydrocarbon pore volume (HCPV) injection of CO

2 could multiply contact with oil and extract hydrocarbons to achieve miscibility. This highlights that a large HCPV cyclic gas injection strategy can significantly increase recovery rates. Fourth, the microscopic pore-throat displacement mechanism of gas flooding was elucidated, clarifying the displacement rules and limits of the matrix-fracture system during CO

2 flooding. Continuous gas injection into matrix core samples can effectively displace micro pores smaller than 0.1 μm, while sustained gas injection into microfractured core samples can effectively utilize small pores ranging from 0.1 μm to 1.0 μm.