Introduction

1. Iteration and effects of shale oil and gas development technologies in the United States

1.1. Iterative advances in drilling technology

1.1.1. Breakthrough to cluster horizontal well drilling technology

1.1.2. Integrated application of super one-trip drilling technology

1.1.3. Automatic drilling technology

1.2. Iterative upgrades in fracturing technology

| Fracturing parameters | Horizontal section length/m | Number of sections | Number of perforation clusters | Cluster spacing/m | Fracturing fluid/(m3•m−1) | Proppants/ (t•m−1) | Duration/ (sections•d−1) |

|---|---|---|---|---|---|---|---|

| First generation | 1 300‒1 600 | 8‒16 | 2‒4 | 15‒30 | 10‒18 | 1.0‒2.3 | 2‒4 |

| Second generation | 1 600‒1 800 | 20‒26 | 6‒9 | 10‒19 | 15‒27 | 2.0‒2.5 | 6‒8 |

| Third generation | 1 800‒4 800 | 50‒80 | 12‒15 | 3‒12 | 28‒57 | 4.0‒6.0 | 12‒18 |

1.2.1. Staged fracturing technology

1.2.2. Volumetric fracturing technology

1.2.3. Dense cutting volume fracturing technology in long horizontal wells

1.3. Upgrade of well pattern

2. Technological iterations for shale oil development in Jiyang continental rifted lake basin

2.1. Geological characteristics of Jiyang shale oil

Table 2. Comparison of Jiyang shale oil with North American shale oil |

| Origin | Sedimentary facies | Lithology | Burial depth | Ro/% | Crude oil density/(g•cm−3) | Pressure coefficient | Viscosity/ (mPa•s) | GOR/ (m3•m−3) |

|---|---|---|---|---|---|---|---|---|

| Jiyang Depression | Lacustrine facies | Muddy limestone, limy mudstone | 3 000‒5 500 | 0.5‒1.0 | 0.82‒0.94 | 1.20‒2.00 | 16.80 | 40‒1 300 |

| Permian Basin | Marine facies | Sandstone, muddy limestone | 2 200‒3 000 | 0.6‒1.5 | 0.82 | 1.50 | <1.00 | 40‒1 600 |

| Bakken Formation in Williston Basin | Silty and fine sandstone, felsic shale | 2 100‒3 300 | 0.7‒1.3 | 0.82 | 1.20‒1.60 | 0.45 | 89‒249 | |

| Eagle ford shale in the Gulf Coast Basin | Muddy limestone | 1 000‒3 400 | 0.5‒2.0 | 0.84 | 1.30‒1.80 | <1.10 | 240 |

2.2. Development technology

2.2.1. Precise sweet spot evaluation is the foundation of beneficial development

Table 3. Geological-engineering dual-sweet spot evaluation criteria for shale oil in the Jiyang Depression |

| Sweet Spots | Geological factors | Engineering factors | ||||||

|---|---|---|---|---|---|---|---|---|

| Ro/% | Pressure coefficient | Favorable lithofacies percentage/% | Favorable lithofacies thicknesses/m | Brittle mineral content/% | Elastic modulus/GPa | Poisson's ratio | Interbed/barrier thicknesses/m | |

| I | 0.7‒1.0 | >1.4 | >60 | >30 | >60 | >20 | <0.3 | <3 |

| II | 0.6‒0.7 | >1.4 | 30‒60 | >30 | >50 | 15‒20 | 0.3‒0.4 | <5 |

| III | 0.6‒0.7 | 1.2‒1.4 | 10‒30 | 10‒30 | >50 | <15 | >0.4 | >5 |

2.2.2. Optimizing well pattern to increase the control on shale oil reserves

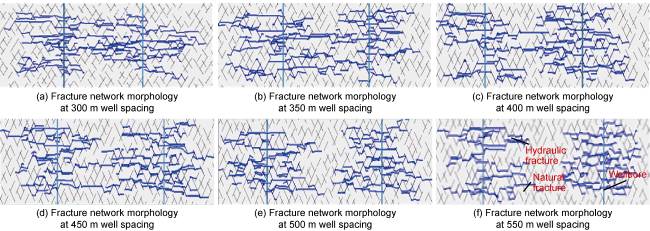

Fig. 1. Simulation results of fracture network morphology at different well spacings. |

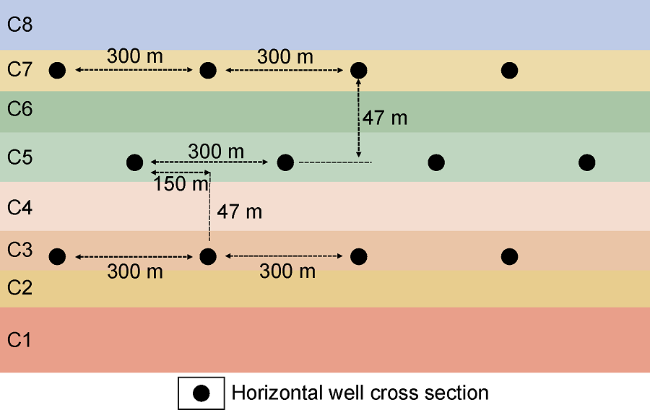

Fig. 2. Schematic diagram of a staggered well pattern for shale oil development in Jiyang Depression (C1-C8 are sublayer SNs). |

Table 4. Reasonable well spacing and layer spacing for different shales |

| Shale types | Well spacing/m | Layer spacing/m | Recoverable reserves per well/104 t |

|---|---|---|---|

| Matrix | 300‒310 | 50‒65 | 4.2 |

| Laminated | 300‒360 | 45‒55 | 5.0 |

| Naturally fractured | 350‒410 | 65‒85 | 6.5 |

2.3. Iteration of drilling technology

Table 5. Iterative process of drilling technology for Jiyang shale oil |

| Iterative stages | Time | Iterative direction | Measures | Results |

|---|---|---|---|---|

| Technological exploration | 2011-2020 | Optimization of well structure | Three-section well structure; selected bit and casing series; optimization of wellbore trajectory | Achievable drilling |

| Innovative breakthrough | 2021‒2022 | Enhancement of drilling fluid system | Composite salt drilling fluid; synthetic drilling fluid; rotary steerable system + LWD | Fast drilling |

| Integration and enhancement | 2023 to present | Development of high-end tools and equipment | Precise pressure control; temperature resistant rotary steerable system + cooling equipment; discharge/pumping parameters; and high-end automatic equipment | Excellent drilling |

2.3.1. Optimizing well structure for achievable drilling

Table 6. Comparison of the first-generation and the second-generation well structures |

| Drilling technology iteration | Well structures | Application effects | Representative wells |

|---|---|---|---|

| First-generation | Φ339.7 mm+Φ244.5 mm (blocking Es3U)+Φ139.7 mm | The formation leaked at the casing shoe after the drilling fluid density of the third section reached 1.7 g/cm³ | NY1-1HF |

| Second- generation | Φ339.7 mm+Φ244.5 mm (blocking Es3M)+Φ139.7 mm | The final drilling density was 1.80-1.95 g/cm3, with no leakage detected through the upper casing shoe | FY 1-1HF and NY1-2HF |

2.3.2. Enhancing drilling fluid system for “fast drilling”

Table 7. Performances of different drilling fluid systems |

| Drilling fluid | Formula | Specific performance and indicators | Effects |

|---|---|---|---|

| Water-based drilling fluid | 1%‒3% Bentonite slurry + 0.5%‒2% CaCl2 + 5%‒10% NaCl + 2%‒5% KCl + 1%‒2% Fluid Loss control agent + 2%‒5% Lubricant + 0.5%‒1.0% Rheology modifier + 2%‒3% Graded filler | Density: 1.05‒1.15 g/cm³; Viscosity: 30‒35 s; Plastic viscosity: 8‒15 mPa·s; Yield point: 1‒3 Pa; Gel strength: 0‒2 Pa or 4‒6 Pa; pH: 8; Radioactivity: less than or equal‒0.9 Bq | Mechanical ROP during the second spud section increased by over 80%. |

| Low-solid synthetic drilling fluid | 80% Synthetic base fluid + 20% CaCl2 Aqueous solution + 3%‒4% Complex emulsifier + 1%‒3% Wetting agent + 3%‒5% Alkalinity adjuster + 0.5%‒1.0% Organic clay + 1%‒2% Fluid loss control agent | Base mud specifications: Oil-water ratio: 80:20; Plastic viscosity: 10‒20 mPa·s; Dynamic shear stress: 2‒4 Pa; Gel strength: 1‒2 Pa or 2‒4 Pa; Demulsification voltage: 350‒550 V; Density: 1.85 g/cm³ Wellbore mud specifications: Plastic viscosity: less than or equal 40 mPa·s; Dynamic shear stress: greater than or equal 8 Pa; Gel strength: 3‒5 Pa or 6‒10 Pa | Discharge rate increased from 30 L/s to 35‒ 37 L/s |

2.3.3. Developing high-end tools and equipment for “excellent drilling”

2.3.3.1. Precise pressure control drilling equipment

Table 8. Comparison of parameters of precise pressure control drilling equipment for shale oil in the Jiyang Depression |

| Drilling system | Drive type | Pressure level/ MPa | Pressure error/ MPa | Equipment volumes/ m3 | Equipment weight/t | Numbers of pipelines | Pipeline size/ mm | Choke size/ mm | Execution accuracy/ mm | Opening/ closing time/s | API standard |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Electro-hydraulic precise pressure control | Electro- hydraulic control drive | 35 | ±0.25 | 36.50 | 13 | 4 | 103 | 65 | 0.50‒1.00 | 20 | API Spec 6A |

| Fully electric precise pressure control | Integrated electric linear drive | 35 | ±0.10 | 11.97 | 6 | 4 | 103 | 80 | 0.03 | 7 | API Spec 6A, 16C |

2.3.3.2. Supporting equipment for drilling long horizontal sections

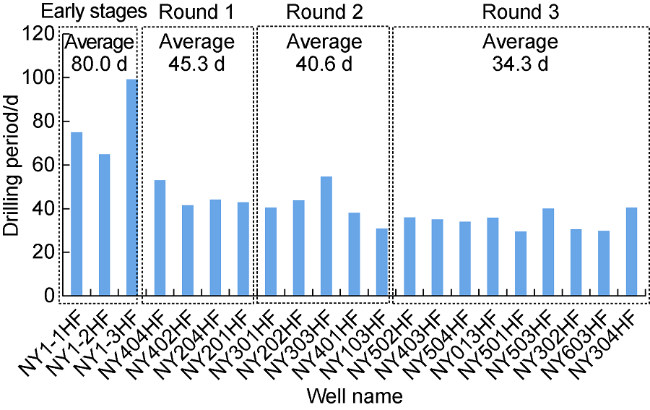

Fig. 3. Change of drilling circle of pilot well group in NY1 area. |

2.4. Fracturing technology iteration

Table 9. Iterative process of fracturing technology for Jiyang shale oil |

| Generation | Period | Fracturing technology | Technology series | Facility | Field application | Result |

|---|---|---|---|---|---|---|

| First- generation | 2018‒ 2020 | Fracture network fracturing + horizontal well | Reducing breakdown pressure by pre- set acidizing wormhole; energizing and promoting fracture and enlargement by CO2, multi-stage fracturing, high- conductivity fracturing | 2000-type diesel-driven equipment | Production capacity breakthrough in YYP 1 and FYP 1 wells | Achievable fracturing |

| Second- generation | 2021‒ 2022 | Dense cutting volume fracturing + horizontal well | Multi-size, fully-supported, dense cutting volume fracturing, balanced expansion; multi-well, coordinated fracturing | 5000-type fully electric-driven equipment | Successful implementation in NY1 experimental well group | Fast fracturing |

| Third- generation | 2023 to present | Extremely limited entry dense cutting volume fracturing + horizontal well | Extremely limited entry + tip temporary blocking; non-uniform perforation | Electric-driven automatic equipment | Smooth progressing on large platforms and small well groups in Minfeng Sag | Excellent fracturing |

Table 10. Iteration of fracturing parameters for Jiyang shale oil |

| Generation | Horizontal section length/m | Fracturing section length/m | Cluster spacing/m | Sand-adding intensity/(t•m−1) | Comprehensive sand ratio/% | Stimulated reservoir volume per stage/ 104 m3 |

|---|---|---|---|---|---|---|

| First-generation | <1 500 | 75 | 20‒30 | 1.2 | 4 | 20‒35 |

| Second-generation | 1 500‒3 500 | 60‒70 | 10‒20 | 3.8 | 6 | 40‒50 |

| Third-generation | 3 000‒4 800 | 50‒60 | 3‒8 | 4.5 | 9 | 50‒70 |

2.4.1. Breakthrough in single-well productivity made by fracture network fracturing technology

2.4.2. Increasing SRV through dense cutting volume fracturing

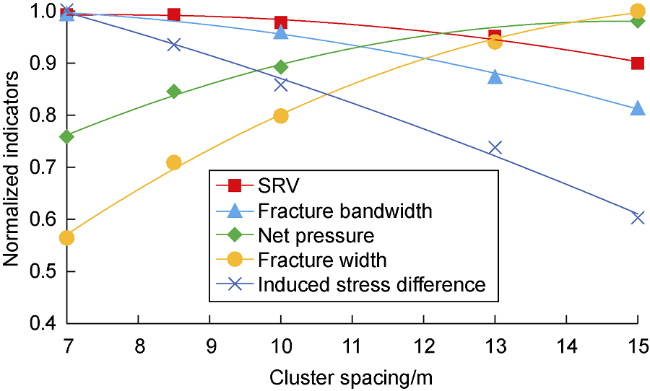

Fig. 4. Dense cutting volume fracturing parameters chart for horizontal wells in shale oil reservoirs. |

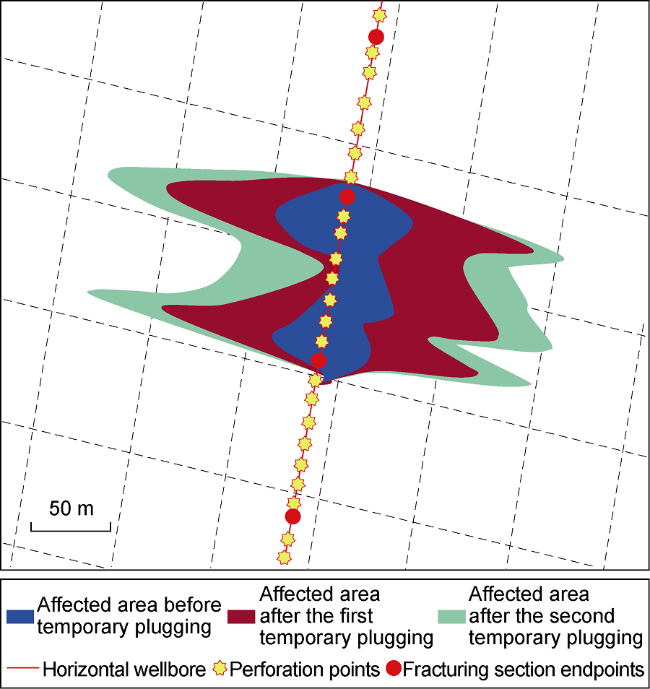

Fig. 5. Fracture shapes before and after temporary plugging and diverting. |

2.4.3. Maximizing fracture-controlled reserves through extremely limited entry dense cutting volume fracturing

Table 11. Statistics of casing deformation in NY-1 pilot well group, Jiyang Depression |

| Stages | Fracturing fluid/(m3•m−1) | Proppants/ (t•m−1) | Deformed casing per 100 sections |

|---|---|---|---|

| Enhanced stimulation | 35.4‒40.4 | 3.0‒3.6 | 1.5‒8.0 |

| Safe stimulation | 29.9 | 2.5 | 4.0 |

| Optimized stimulation | 30.9 | 2.8 | 0.8 |

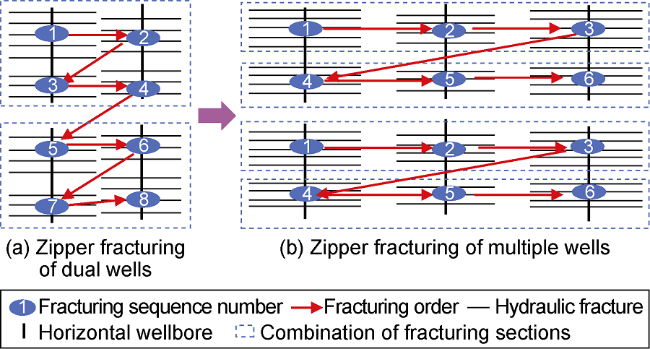

Fig. 6. Schematic diagram of multi-well zipper fracturing. |