Introduction

Reservoir classification is the key to reservoir evaluation. Reservoir classification methods commonly used now can be divided into three categories: The first category is to establish a cross-plot by using effective reservoir thickness, physical parameters, pore structure and other parameters or introduce mathematical parameters to select the characterization parameters that have a greater impact on reservoir quality[1,2,3]. The second category is to classify the reservoirs according to the effects of sedimentary microfacies, lithologic lithofacies and diagenetic facies on the pore structure of reservoirs[4]. The third category is to evaluate reservoir quantitatively on the basis of comprehensive evaluation, by using fractal dimension, grey theory, fuzzy theory, clustering analysis and BP neural network methods etc[5,6,7]. Although the current reservoir grading evaluation methods can qualitatively and quantitatively evaluate reservoirs from the aspects of reservoir evaluation parameters, petrophysical facies and mathematical methods, but they are mainly applied to clastic reservoirs and seldom used in carbonate reservoirs[8,9].

The gas reservoir in Cambrian Longwangmiao Formation of Moxi area, Sichuan Basin at a buried depth of more than 4500 m had proven reserves of more than 4 000×108 m3 in 2013. It is the largest marine carbonate monolithic gas reservoir ever discovered in China and also the largest Cambrian gas reservoir found in the world[10]. At present, in line with the fine description of reservoir in the stage of gas reservoir development, the following two problems need to be solved urgently: First, according to the classification criterion of carbonate reservoirs in oil and gas industry criterion[11], the reservoirs with porosity greater than 12% and permeability greater than 10 000 μm2 are classified as grade I reservoirs, the reservoirs with porosity of 6%-12% and permeability of 100-10 000 μm2 are grade II, the reservoirs with porosity of 2%-6% and permeability of 1-100 μm2 are grade Ⅲ, and the reservoirs with porosity of less than 2% and permeability of less than 1 μm2 are grade Ⅳ. According to this criterion, the grade I high-quality reservoir hardly exists in the study area, but more than 30 gas wells have obtained commercial gas flows of more than one million cubic meters in formation testing. Therefore, the classification criterion in the former industry criterion is not suitable for reservoir grading evaluation in the study area. Second, due to the unclear criterion for reservoir grading evaluation, the distribution of high-quality reservoirs is not delicate enough to meet the demand of gas reservoir productivity supplement construction and deployment. Therefore, it is urgent to establish a new and applicable grading standard for deep marine carbonate reservoirs and predict reservoirs by grade.

The gas reservoir in Longwangmiao Formation of Moxi area is dominated by fracture-cavity carbonate reservoirs with complex configuration of fractures and vugs, and rich small- scale dissolved pores and micro-fractures. The reservoirs are characterized by strong heterogeneity, low porosity and medium-high permeability. In order to overcome the disadvantages of conventional grading method of low permeability clastic reservoir in grading evaluation of medium-high permeability carbonate reservoir, and the limitation that conventional methods don’t consider reservoir heterogeneity in application[5,6,7], the parameters of reservoir grading evaluation were worked out on the basis of comprehensive study of basic characteristics and internal structures of gas reservoirs in Longwangmiao Formation of Moxi area. Then, the reservoir grading criterion suitable for the study area was established, the main controlling factors of reservoir grading evaluation parameters were analyzed and the distribution of different grades of reservoirs was predicted, and the distribution rules of high-quality reservoirs were figured out, which can provide reference for further optimizing development technical indicators and realizing steady increase of production of such gas reservoirs.

1. Overview of the study area

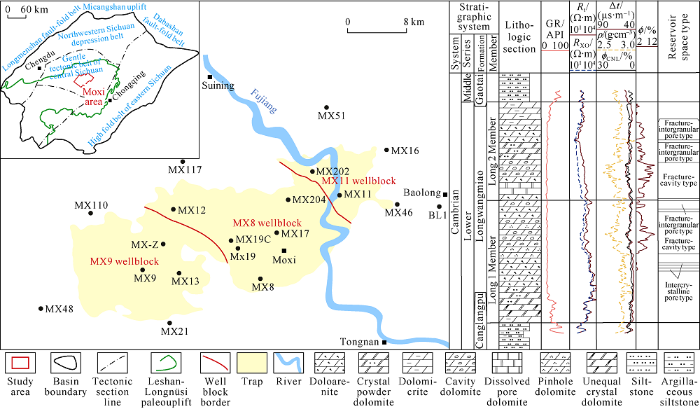

The Moxi area is located in Suining city of Sichuan Province and Tongnan county of Chongqing city. It is structurally located at the eastern Leshan-Longnüsi paleouplift of the gentle structural belt in central Sichuan Basin (Fig. 1). The Longwangmiao Formation of Moxi area is in the upper part of the lower Cambrian, and in conformable contact with the underlying Canglangpu Formation and the overlying Gaotai Formation. The stratum has low and gentle top structure, and multi-high points. The formation, 80-110 m, can be divided into the Long 1 Member and Long 2 Member from bottom up. It is dominated by residual doloarenite, sparry doloarenite and fine-medium crystalline dolomite, and is widely distributed in other areas except in the core area of Leshan-Longnüsi paleouplift[12]. Its sedimentary facies is restricted platform facies, and granular beach is the most favorable subfacies for reservoir development[13,14]. The reservoirs come in large-scale continuous pieces on the plane, and the reservoir of Long 2 Member is larger in scale than that of Long 1 Member, and tends to shift toward north and northeast[15]. Generally, the gas reservoir in Longwangmiao Formation of Moxi area is a lithologic-structural complex trap gas reservoir with large reserves, high temperature and pressure, medium H2S content and low CO2 content.

Fig. 1.

Fig. 1.

Geographical location of Moxi area in Sichuan Basin and composite columnar section of Longwangmiao Formation.

The existing exploration and development results and geological research show that the Longwangmiao Formation in Moxi experienced multi-stage tectonic movement, large strata depth, and experienced multi-stage dissolution transformation, secondary pores, cavities and fractures developed. It has the characteristics of anisotropic distribution of reservoir area, strong heterogeneity of internal structure of reservoir space, complex and changeable controlling factors of reservoir layer, large difference of reservoir thickness and uneven output of single well.

2. Basic characteristics of reservoir space

The reservoir space of Longwangmiao Formation in Moxiarea consists of dissolved pores, intergranular dissolved pores, intercrystalline dissolved pores, intercrystalline pores and fractures, which can be divided into two types of reservoir space combination: fracture-cavity type and fracture-pore type.

2.1. fracture-cavity type

The fracture-cavity reservoir is mainly residual doloarenite and doloarenite. The vertical thickness of single layer is 1.02-32.50 m, with an average of 7.43 m, and the average porosity of plunger sample is 5.21%. The reservoir space is dominated by dissolved pores and small-scale beaded dissolved pores with a diameter of 2-5 mm, followed by micro-fractures (Fig. 2a and 2d). The average cavity density of reservoir core is 25.2 pcs/m, and dominated by enlarged dissolution type of small-scale dissolved pores, accounting for 81% (Fig. 2b and 2f). There are three types of fractures: tectonic fractures, pressolution fractures and tectonic fractures enlarged by dissolution. Macroscopic fractures are underdeveloped, while late high-angle micro-fractures and reticulated micro-fractures take the majority. Effective fractures that contribute greatly to porosity and permeability mainly include tectonic fractures partially filled by dolomite and bitumen, tectonic fractures and dissolved fractures distributed along tectonic fractures (Fig. 2d). The fractures in the reservoir cores have an average density of 0.5-0.7 pics/m, average aperture of 20-100 μm, and average length of 22.4 mm.

Fig. 2.

Fig. 2.

Lithology and reservoir space photographs of all types of gas reservoirs in Longwangmiao Formation of Moxi area. (a) Well MX13, brown-gray micritic-powder crystal vug dolomite, 4 621.93-4 622.10 m, vugs partially filled with dolomite, occasional quartz, asphalt migration traces in the vugs, vug diameter: 1-50 mm; (b) Well MX204, deep-gray doloarenite, 4 651.23-4 651.36 m, rich in vugs of 2-5 mm; (c) Well MX202, gray graniphyric aplitic-powder crystal vug dolomite, 4 647.85-4 647.97 m, with dissolved pores in irregular distribution; (d) Well MX13, brown-gray powder crystal dolomite, 4 610.64-4 610.89 m, with reticulated fissures, vugs of 0.5-12.0 mm in diameter and surface porosity of 11%; (e) Well MX12, brown powder crystal dolomite, 4 639.34-4 639.50 m, with a high-angle fracture and sporadic vugs, a maximum vug diameter of 0.7 cm and a surface porosity of 3%; (f) Well MX13, residual aplitic doloarenite, 4 614.58 m, with abundant vugs partially filled by bitumen and dolomite, cast thin section, plane polarized light; (g) Well MX12, brown residual aplitic doloarenite, 4 648.43 m, with abundant intergranular dissolved pores filled by bitumen in the edge, cast thin section, plane polarized light; (h) Well MX12, brown gray fine-medium crystalline residual doloarenite, 4 639.13 m, with intergranular dissolved pores, intracrystalline pores and intracrystalline dissolved pores, cast thin section, plane polarized light; (i) Well MX12, brown aplitic residual doloarenite, 4 638.18 m, with reticulated microfractures filled by asphalt, cast thin section, plane polarized light.

2.2. Fracture-pore type

Fracture-pore type reservoirs include fracture-intergranular (dissolved) pore reservoirs and intercrystalline (dissolved) pore reservoirs. The fracture-intergranular (dissolved) pore reservoirs are dominated by residual doloarenite and doloarenite. This kind of reservoir has an average vertical thickness of 4.11 m per layer, and average porosity of 3.81% from core plug test which is lower than that of fracture-cavity reservoir. The reservoir space is dominated by intergranular dissolved pores and micro-fractures (Fig. 2c and 2e). The intergranular dissolved pores are often partially filled by late dolomite and asphalt (Fig. 2g and 2h), with a remaining pore diameter of 0.1-1.0 mm and surface porosity of 2%-10%. The fractures in this type of reservoir are similar to those in fracture-cavity reservoir, and play an important role in improving the permeability of reservoir.

The intercrystalline (dissolved) pore reservoirs are dominated by grain dolomite. The average vertical thickness per layer and the average porosity from core plug test are lower, which are 2.29 m and 3.10%, respectively. The main reservoir space includes intercrystalline dissolved pores, intercrystalline pores and micro-fractures (Fig. 2h and 2i). The intercrystalline (dissolved) pores are usually filled with asphalt, 0.1-0.3 mm in diameter and 2%-10% in surface porosity.

3. Parameters and criterion of reservoir grading evaluation

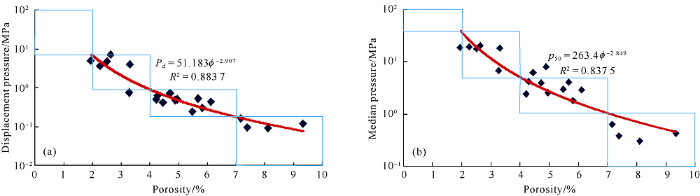

In order to characterize the micro-internal structure and physical parameters of reservoirs in the study area, laboratory analyses such as CT scanning, digital core and mercury injection test were carried out. Through analysis of the relationship between porosity and displacement pressure and median pressure from mercury injection test of 20 samples from the gas reservoir (Fig. 3), it is found that different capillary pressure curves correspond to different porosity intervals, and the porosity of the tested samples fall into four intervals with 2%, 4% and 7% as the dividing points. Samples of different porosity intervals differ widely in displacement pressure. According to this study, the reservoir space in Longwangmiao Formation can be divided into four categories: Grade I, with porosity greater than 7%; Grade II, with porosity ranging from 4% to 7%; Grade III, with porosity ranging from 2% to 4%; Grade IV, with porosity less than 2% (Table 1). Each type of reservoir space represents the corresponding reservoir type.

Fig. 3.

Fig. 3.

Relationship between displacement pressure, median pressure and porosity of samples from Longwangmiao Formation.

Table 1 Grading evaluation of pore throat structure in gas reservoir of Longwangmiao Formation.

| Reservoir space grade | Reservoir type | Porosity/ % | Displacement pressure/MPa | Median pressure/MPa | Median throat radius/μm | Maximum throat radius/μm | Maximum mercury injection/% | Ejection efficency/% |

|---|---|---|---|---|---|---|---|---|

| Grade I | 1 | >7 | <0.2 | <1 | >0.7 | >4.0 | >90 | >25 |

| Grade II | 2 | 4-7 | 0.2-0.9 | 1-5 | 0.2-0.7 | 0.8-4.0 | 85-90 | 15-25 |

| Grade III | 3 | 2-4 | 0.9-7.0 | 5-40 | 0.02-0.20 | 0.1-0.8 | 75-85 | 10-15 |

| Grade IV | 4 | <2 | >7.0 | >40 | <0.02 | <0.1 | <75 | <10 |

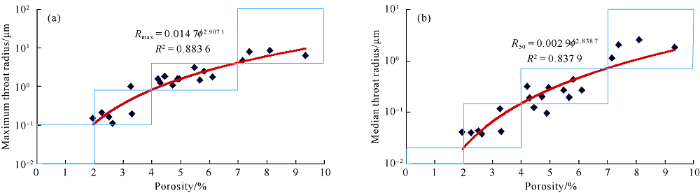

The relationship between porosity and maximum throat radius and median throat radius of 20 mercury injection samples (Fig. 4) was analyzed. It is found that the samples also fall into four districts. Different throat radii correspond to different porosity intervals, and the dividing radii basically coincide with the dividing points of porosity, 2%, 4% and 7%. The throat radius boundaries of different porosity intervals are obvious, which also confirms that there may be four types of reservoir spaces in Longwangmiao Formation with different reservoir physical properties. Comparative analysis shows that the reservoirs with porosity greater than 7% have largely fracture-cavity reservoir space, the reservoirs with porosity of 4%-7% have fracture-intergranular (dissolved) pore reservoir space, the reservoirs with porosity of 2%-4% have mainly micro-fracture and intracrystalline (dissolved) pore reservoir space, and the reservoirs with porosity of less than 2% have primarily intracrystalline pore reservoir space.

Fig. 4.

Fig. 4.

Relationship between maximum throat radius, median throat radius and porosity of Longwangmiao Formation.

The analysis of reservoir internal structure shows that under the same displacement pressure and median pressure, the larger the median pore throat radius, the larger the maximum mercury injection and ejection efficiency are, and the better the reservoir pore structure is. Therefore, median pore throat radius is an important parameter for reservoir classification. The mercury injection experiments on plug samples from the study area show that grade I and grade II reservoirs have high porosity, good pore-throat configuration, low displacement pressure and median pressure, low irreducible water saturation and high ejection efficiency (Table 1). Among them, the grade I reservoir space has the largest pore throat radius, median pore throat radius of greater than 0.7 μm, mostly fracture- cavity type space, capillary pressure curve in concave step shape, and the best permeability. The grade II reservoir has median pore throat radius of 0.2-0.7 μm, mainly fracture- intergranular (dissolved) pore space, capillary pressure curve in double step shape, and fairly high porosity and permeability. Grade III and grade IV reservoirs have lower-extra low porosity, small throat radius, high displacement pressure and median pressure, high irreducible water saturation and low ejection efficiency. Among them, the grade III reservoir has a median pore throat radius of 0.02-0.20 μm, relatively weak poroperm ability, mostly intercrystalline (dissolved) pores, and approximately linear capillary curve. The grade IV reservoir has median pore throat radius of less than 0.02 μm, very low permeability, and hardly any effective reservoir space.

Based on the analysis of geological characteristics and internal reservoir space of gas reservoir in upper Longwangmiao Formation, it is concluded that there are four parameters for reservoir grading evaluation in the study area, namely, median pore throat radius of reservoir, effective porosity and permeability of fracture-dissolved vug development zone, and development degree of fracture-dissolved vug combination.

3.1. Porosity evaluation

1 415 plunger samples from gas reservoir in Longwangmiao Formation of Moxi area have an average porosity of 4.22%, and 84.88% of the samples have a porosity from 2% to 6%. Therefore, matrix porosity is not very useful for reservoir classification, while the effective porosity of fracture and dissolved vug zones is the key factor for reservoir classification (porosity mentioned bellow is all effective porosity). Fractures, vugs and pores occur in combination in the study area, where the grade I reservoir has mainly fracture-cavity type reservoir space and small amount of fracture-pore space. The grade II reservoir has largely fracture-cavity type space and a small amount of fracture-pore type space. The grade III reservoir has a little fracture-intergranular pore type space. The grade IV non-reservoir has very poor storage capacity and permeability, and hardly any effective reservoir space. According to the porosity, the reservoirs can be divided into four grades: greater than 7%, 4%-7%, 2%-4% and less than 2% (Table 2). For example, the Well MX8 located in the zone rich in dissolved vug of the study area has higher logging interpretation porosity than Well MX19 located in the relatively low porosity and low permeability area (6.1% and 3.9% respectively).

Table 2 Grading evaluation of porosity and permeability of gas reservoir in Longwangmiao Formation of Moxi area.

| Reservoir space grade | Porosity/% | Permeability/10-3 μm2 | Average vertical thickness of Reservoir/m | Testing production/104 m3 |

|---|---|---|---|---|

| Grade I | >7 | >5.0 | 34-40 | >100 |

| Grade II | 4-7 | 0.5-5.0 | 20-34 | 30-100 |

| Grade III | 2-4 | 0.05-0.5 | 10-20 | 3-30 |

| Grade IV | <2 | <0.05 | <10 | <3 |

3.2. Permeability evaluation

The 1 245 plunger samples from gas reservoir in Longwangmiao Formation of Moxi area have an average permeability of 0.75×10-3 μm2 and a maximum permeability of 64.3×10-3 μm2. Similar to matrix porosity, the matrix permeability is useless for reservoir classification, while the effective permeability of fracture-cavity zone is the key factor for reservoir classification (permeability mentioned bellow is all effective permeability). The interpretation permeability of well testing in the study area is as high as 500×10-3 μm2, representing medium and high permeability. Therefore, the permeability index is also divided into four grades: greater than 5×10-3 μm2, (0.5-5.0)×10-3 μm2, (0.05-0.50)×10-3 μm2 and less than 0.05×10-3 μm2 (Table 2). For example, Well MX8 located in the zone with abundant dissolved vugs of the study area has a production of 78.4×104 m3/d higher than Well MX19 located in relatively low porosity and permeability zone, and the well testing interpretation shows they had a permeability of 535.3×10-3 μm2 and 0.043×10-3 μm2, respectively.

3.3. Fracture evaluation

Statistics show that the plug samples from the reservoirs of the study area are characterized by low porosity and low permeability, with an average permeability of 0.75×10-3 μm2. There is a big discrepancy between the permeability obtained from dynamic and static data, which indicates that the reservoirs may have rich micro-fractures, and the observation of cores and cast slices also confirms abundant micro-fractures. For example, in Well MX17, the reservoir has abundant fractures according to drilling, a logging interpretation porosity of 4.4% and a near wellbore permeability of 0.5×10-3 μm2 from well test, but a moderate yield of industrial gas flow was tested from the well. Therefore, fracture is important for improving the seepage capability of the gas reservoir.

3.4. Evaluation of reservoir space types

Drilling in the study area proves that the more developed the dissolved vugs are, the higher the industrial gas flow production tested, that is, there is a positive correlation between them. If the dissolved vugs and fractures are well developed in the reservoir and in good combination, the high-yield industrial gas flow is highly likely to be obtained. For example, Well MX12 located in the northern part of the gas reservoir has well-developed dissolved vugs, and the drilling rate of fracture-cavity reservoir of 60%, it was tested a high-yield industrial gas flow of over one million cubic meters.

By looking at the reservoir grading evaluation parameters and the above research, it can be concluded that the key parameters of reservoir evaluation in this area are median pore throat radius, effective porosity and permeability of dissolved vug development zone, and combination relationship between fractures and dissolved vugs, among which, the last one is the core parameter for reservoir evaluation. According to reservoir experimental data, the standard of reservoir grading evaluation parameters of the study area can be established (Table 3).

Table 3 Grading evaluation criterion for gas reservoirs in Longwangmiao Formation of Moxi area.

| Reservoir type | Reservoir grade | Porosity/% | Permeability/10-3 μm2 | Median throat radius/μm | Surface porosity/% |

|---|---|---|---|---|---|

| 1 | Grade I high-quality fracture-cavity reservoir | >7 | >5.0 | >0.7 | >6 |

| 2 | Grade II medium fracture-pore reservoir | 4-7 | 0.5-5.0 | 0.2-0.7 | 3-6 |

| 3 | Grade III intercrystalline pore poor reservoir | 2-4 | 0.05-0.50 | 0.02-0.20 | 3-5 |

| 4 | Grade IV non-reservoir | <2 | <0.05 | <0.02 | <3 |

Grade I high-quality fracture-cavity reservoir: this kind of reservoir is dominated by fracture-cavity type and includes a small number of fracture-pore type. In this kind of reservoir, multi-scale fractures widespread are in configuration with vugs (dissolved vugs) and pores (dissolved pores), with a coordination number of pore throat and vugs (dissolved vugs) of 1-5. This kind of reservoir is located in the structural high of Longwangmiao Formation top, subjected to the strongest supergene dissolution, and deposited in the main area of thick- bed beach in the middle of grain beach. Well test interpretation curves show that the reservoir near the wellbore presents good radial flow characteristic. It has high testing yield, high output in production test and small production pressure difference, representing high-yield reservoir.

Grade II medium fracture- pore reservoir: This kind of reservoir consists of mainly fracture-pore reservoirs, and a small number of fracture-cavity reservoirs and intercrystalline pore reservoirs, in which fracture-intergranular reservoirs account for more than 50%. In it, fractures occur in combination with intergranular pores (intergranular dissolved pores). They are located at the structural high of top surface of the stratum or the slope, and in the main body of the grain beach or the flank of the beach edge. Well test curves show that the reservoir relies on acidizing to improve seepage condition near wellbore, but faces the problems of limited scope of acidizing and insufficient matrix fluid supply. They have high testing yield, relatively low output in production test and large production pressure difference, representing medium-yield reservoir.

Grade III intergranular pore poor-reservoir: This kind of reservoir consists of largely intergranular pore reservoirs, and a small number of fracture-intergranular pore reservoirs, rare or no fracture-cavity reservoirs. The intercrystalline pores (intercrystalline dissolved pores) are small in size and do not occur with fractures. They are located in the low part of top surface of Longwangmiao Formation in the edge of grain beach. Well test curves show that they have very limited communication distance by acidizing and relatively low permeability. The grade III reservoir has lower testing yield, lower output in production test and higher production pressure difference than the grade I and II reservoirs, representing low-yield reservoir.

4. Geophysical characteristics of high-quality reservoir

Previous exploration and development practices show that the different types of reservoirs and non-reservoirs in the study area differ widely in geophysical response characteristics. On the basis of sedimentary facies, rock-electric experiment and geophysical data interpretation, FMI and unsupervised seismic waveform classification technology were selected to analyze the geophysical response characteristics of the reservoirs.

4.1. Log response characteristics

The FMI has high resolution for fractures and dissolved vugs. Through core observation, rock-electric experiment and imaging logging interpretation, the effective fractures in gas reservoir of Longwangmiao Formation in Moxi area can be divided into low angle fracture, oblique intersection fracture, high angle fracture and reticulated fracture according to their occurrence. The reservoir space can be divided into vug (dissolved vug), intergranular pore (intergranular dissolved pore) and intracrystalline pore (intracrystalline dissolved pore) according to diameter and diagenesis. After calibrated by core and FMI, the conventional logs, mainly natural gamma ray, resistivity and porosity curves were used to identify pores, vugs and fractures from the response characteristics, as shown in Table 4.

Fracture-cavity reservoirs in the study area mainly contain vugs (dissolved vugs) and high-angle fractures, with a high development degree of fractures and vugs. In this kind of reservoir, small vugs with a diameter of 2-5 mm account for about 80% of the total vugs, and the surface pore ratio is 4.05%. Fractures are dominated by high-angle ones, and the direction of maximum principal stress is NE-SW and NW-SE. Fracture index (FI) indicates that fracture development degree is relatively high (FI≥0.6). Imaging logging shows porphyritic characteristic, including "honeycomb" dark patches of various sizes in irregular small cone or ellipse shapes and several dark high conductivity anomalies. Some low angle and oblique fractures are covered by the characteristics of dissolved vugs. These reservoirs have AC of 138.0-156.2 μs/m, a density of generally less than 2.8 g/cm3, ϕCNL of 5%-10% and LLD resistivity of less than 4 000 Ω•m.

Fracture-intergranular (dissolved) pore reservoirs have mainly intergranular pores (intergranular dissolved pore) and high-angle fractures, with moderate fracture and vug development degree. The average surface porosity of intergranular pores (intergranular dissolved pores) is 3.04%. The fractures are mostly high-angle fractures and oblique fractures, occasionally reticular fractures and low-angle fractures. The direction of maximum principal stress is NE-SW and NW-SE, the fracture index is 0.3-0.6. These reservoirs feature blocky, dark block anomalies transited from black to bright and several dark high-conductivity anomalies in sine and approximate sine curves (with impregnated characteristics) on imaging logging. In terms of conventional logging, they have AC of 135.1-150.1 μs/m, density of 2.70-2.85 g/cm3, ϕCNL of 4%- 8% and LLD resistivity of less than 5 000 Ω•m.

Intercrystalline (dissolved) pore reservoirs have primarily intercrystalline (dissolved) pores, low fracture and vug development degree, and an average surface porosity of 2.75%. The fractures, limited or undeveloped, are mainly oblique fractures and low-angle fractures, with a fracture index of less than 0.3. These reservoirs are basically low conductivity anomalies with the same color (bright color), and high conductivity anomalies of relatively continuous dark sine curves or similar to the argillaceous bands in some intervals, with disseminated features at the edges. In terms of conventional logging, they have AC of 132.1-144.1 μs/m, density of 2.75- 2.85 g/cm3, ϕCNL of 3%-6% and LLD resistivity of less than 5000 Ω•m.

4.2. The seismic responses

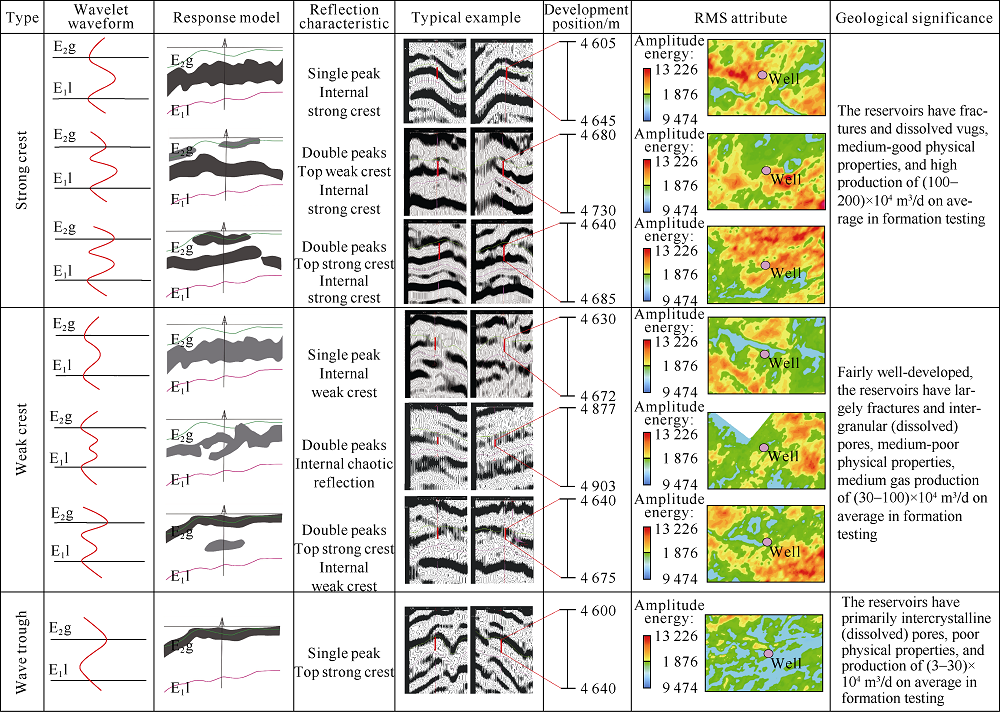

The seismic data of Longwangmiao Formation in Moxi area has main frequency of 35-40 Hz and bandwidth of 6-72 Hz. According to the forward modeling of seismic wavefield in the study area, the minimum reservoir resolution of the existing seismic data is 10 m, and the seismic reflection characteristics and amplitude energies of different grades of reservoir are also different[17,18,19,20]. Combined processing and calibration of well and seismic data show that different seismic waveform characteristics represent different reservoir development characteristics, and their plane distribution and combination reflect certain regularity of reservoir development and distribution. By using unsupervised waveform classification method, the seismic responses of gas reservoir in Longwangmiao Formation of Moxi area can be subdivided into 3 types and 7 kinds of waveforms. Through comparison with actual drilling data, the three types of seismic waveforms have a good correspondence with reservoir development degree. Combining with actual reservoir physical properties, the reservoirs in the study area can be classified and planar distribution law of the reservoirs can be interpreted comprehensively (Table 5).

Table 5 Seismic waveform classification of gas reservoirs in Longwangmiao Formation. E2g—Stratigraphic top boundary of Longwangmiao ormation; E1l—Bottom strata boundary of Longwangmiao Formation.

|

Through comparison, it can be seen that different types of waveforms have obvious different characteristics. Reservoirs with seismic waveforms featuring strong crest reflection in the stratum can be subdivided into three types: strong crest type in single peak, top weak and internal strong type in double peaks, top strong and internal strong type in double peaks. They correspond to fracture-cavity reservoir development zone in high energy beach body represented by the yellow-red area in the amplitude energy attribute map. Reservoirs with seismic waveforms featuring weak crest reflection in formation can be subdivided into three types: the one with weak crest in the middle of single event, the one with chaotic reflection in the middle of single event, and the one with two events, top strong and middle weak crest. They correspond to fracture-pore reservoir controlled by low-energy beach body mainly, i.e. the green-yellow area in the amplitude energy attribute map. Reservoirs with seismic waveforms featuring trough reflection in the formation, show top strong peak and trough inside single peak, and correspond to fracture-pore reservoir controlled by low- energy beach body of the green area in the amplitude energy attribute map.

The gas wells with strong crest type take a higher proportion than those with weak crest type and valley type, and the three types of wells account for 75.5%, 21.0% and 3.8% respectively. The reservoirs are 17.4 m, 5.5 m and 1.2 m thick, and 5.2%, 3.6% and 3.4% in porosity, and have a test production of (100-200)×104 m3/d, (30-100)×104 m3/d and (3-30)× 104 m3/d, respectively.

High-quality reservoirs with mainly vugs (dissolved vugs) and high-angle fractures, and high fracture and vug development degree, feature strong crest seismic response. That is to say, the larger the fracture index is, the more the dark patches representing vugs on the imaging logging image are. In terms of conventional logging, they have AC of 14.0-15.8 μs/m, a density of generally less than 2.8 g/cm3, ϕCNL of 5%-10%, and LLD resistivity of less than 4 000 Ω•m. The reservoir seismic response is characterized by strong crest and strong RMS amplitude energy. It has larger median pore throat, larger effective porosity and effective permeability of fracture and dissolved vug development zone, and high development degree of dissolved vugs, which is manifested as high development degree of high-quality reservoir and high-yield industrial gas flow in gas well testing.

Based on the main controlling factors of high-quality reservoir and the geophysical response characteristics of different grades of reservoirs, combined with the comparative analysis of gas well production, a set of grading evaluation criterion and comprehensive prediction methods for deep marine carbonate reservoirs have been finally established, as shown in Table 6.

Table 6 Grading evaluation criteria and prediction of reservoirs in Longwangmiao Formation of Moxi area.

| Reservoir grade | Reservoir type | Grading evaluation criterion | Main controlling factor | Geophysical response characteristics | Dynamic response characteristics | Comprehensive evaluation | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Physical parameters Pore throat parameters Development degree of dissolved vug | Tectonic location | Sedimentary environment | Diagenesis | Logging response | Seismic response | Testing characteristic Productivity characteristic | Production testing characteristics | |||

| Grade I fracture- cavity reservoir | Fracture-cavity reservoir is the main reservoir, with a few fracture-pore reservoir | Porosity > 7%, Permeability is 5×10-3 μm2, Median hole throat radius ≥ 0.7 μm, Surface porosity > 6% | The high part of structure in Longwangmiao Formation top | Dominated by the main body of grain beach | Influenced by contemporaneous to penecon- temporaneous dissolution, burial disso- lution and supergene dis- solution, the effect of super- gene disso- lution on the reservoir of Longwangmiao Formation is most obvious | With Δt of 138.0-156.2 μs/m, Density of generally less than 2.8 g/cm3; ϕCNL of 5%-10%; LLD of less than 4000 Ω•m; FMI imaging feature is patchy mode | Strong crest type | Average testing yield is greater than 100×104 m3/d Average open flow capacity is greater than 400×104 m3/d | Tubing pressure is stable; Average daily gas production is greater than 100×104 m3/d | High-yield type |

| Grade II fracture- pore reservoir | Fracture-intergranular pore reservoir is the main reservoir, with a few fracture-cavity reservoir | With a porosity of 4%-7%, Permeability of (0.5-5.0)× 10-3 μm2, Median hole throat radius of 0.2-0.7 μm, and surface porosity of 3%-6% | The structural high or slope of Longwangmiao Formation structure | Margin of grain beach and diamictic tidal flat | With Δt of 135.1-150.1 μs/m; Density of 2.7-2.85 g/cm3; ϕCNL of 4%-8%; LLD of less than 5000 Ω•m; Featuring block mode on FMI image | Weak crest type | Average testing yield is (30-100)×104 m3/d Average open flow capacity is (50-400)× 104 m3/d | Tubing pressure is stable; Average daily gas production is (30-100)×104 m3/d | Medium-yield type | |

| Grade III intercry- stalline pore reservoir | Intercrystalline pore reservoir is the main reservoir, with a few fracture-intergranular pore reservpor | With porosity of 2%-4%, Permeability of (0.05-0.50)× 10-3 μm2, Median pore throat radius of 0.02-0.20 μm, and surface porosity of 3%-5% | The lower part of structure in Longwangmiao Formation top | Lagoon and interbeach sea | With Δt of 132.1-144.1 μs/m; Density of 2.75-2.85 g/cm3; ϕCNL of 3%-6%; LLD of less than 5000 Ω•m; FMI imaging is characterized by low conductivity anomalies of basically the same color | Wave trough type | Average testing yield is less than 30×104 m3/d Average open flow capacity is less than 50×104 m3/d | Low-yield type | ||

5. Reservoir grading evaluation

5.1. Prediction of spatial distribution law of different grades of reservoirs

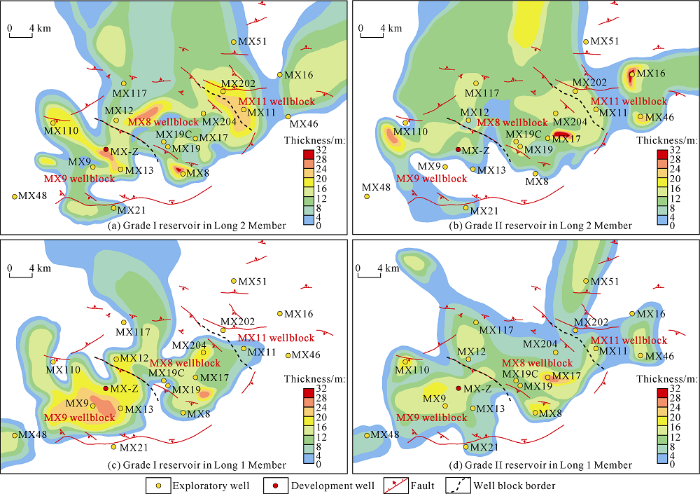

By using the above-mentioned reservoir grading evaluation criterion and prediction method, the development positions of the 3 grades of reservoirs in the study area were predicted. Based on preliminary understanding of reservoir distribution trend from previous exploration and development[21], the spatial distribution law of the 3 grades of reservoirs in local areas were accurately predicted, and the plane distribution of grades I and II reservoirs in upper and lower sub-members of Longwangmiao Formation were mapped (Fig. 5). We can see that the grade I reservoir is thick and blocky, appears as a continuous piece in Long 1 Member of MX9 well block, in bands or patches within the trap area of Long 2 Member of MX8 well block, while in thin sheet in Long 2 Member of MX11 well block with poor physical property, and hardly occurs in Long 1 Member. The grade II reservoirs are mainly medium-thick layers, continuously distributed in a large area in Long 1 Member of MX9 well block and limitedly distributed in the western Long 2 Member, while comes in bands in MX8 well block mainly distributed in the east and south side, but the thickness of the second stage is larger than that of the first stage. In MX11 wellblock, this kind of reservoir only exists in the west side of the upper and lower sub-members limitedly, and is 12-16 m thick and poorer in physical properties. The grade III reservoirs appear mostly in thin bands, are widely distributed in MX9 and MX8 wellblocks, and only exists in local part of Long1 Member and hardly occurs in Long 2 Member in MX11 wellblock. Compared with grade I and grade II reservoirs, they have smaller thickness, poorer physical properties and lower production. In summary, considering the influence of structure, sedimentation, diagenesis, physical properties, fracture-cavity development and production performance on the evaluation of deep marine low-porosity and medium-high permeability carbonate reservoirs, it is concluded that the high-quality reservoirs in Longwangmiao Formation of Moxi area are mainly distributed in the high part of MX9 wellblock and the south and north flanks of MX8 well block, and grade I and grade II reservoirs formed in the second stage are more widely distributed than the ones formed in the first stage.

Fig. 5.

Fig. 5.

Thickness distribution map of grade I and II gas reservoirs in Longwangmiao Formation of Moxi area.

5.2. Effect of grading reservoir prediction

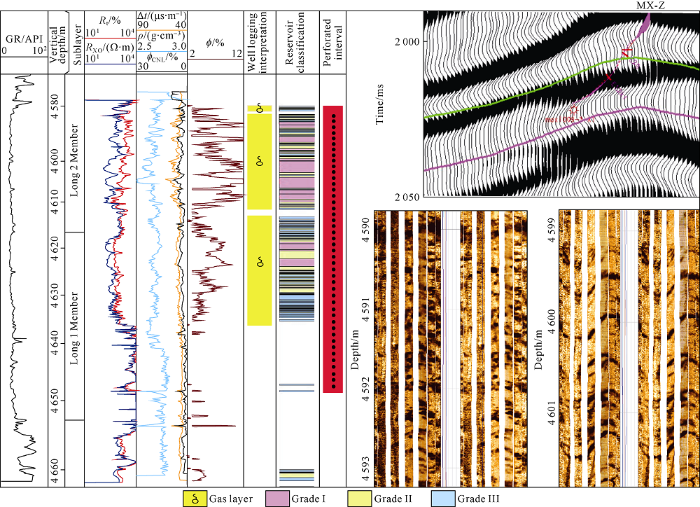

By using the above reservoir grading evaluation and prediction methods, the distribution of different grades of reservoirs have been identified effectively, guiding the lateral correlation and the anisotropy study of reservoirs, providing the target area for well location deployment, and laying a basis for development adjustment of the gas reservoir. For example, development well MX-Z was deployed to effectively produce reserves in MX9 wellblock. The well is located in relatively high structural position. Its seismic response pattern is strong crest type, i.e. weak crest at the top and strong crest in the interior. Prediction of grade I fracture-cavity high-quality reservoirs shows that the reservoirs in Long 1 Member and Long 2 Member are 16-20 m and 24-28 m thick vertically, rich in dissolved vugs and micro-fractures, and good in physical properties. If the reservoirs are classified according to the geological characteristics of carbonate gas reservoir[11], such as the porosity, permeability and pore structure parameters of the rock, the reservoirs would be grade Ⅲultra-low permeability ones only. Drilling proves that the reservoirs in this well are 54 m thick vertically and 4.7% in porosity from logging interpretation, and the industrial gas flow of the obtained product is tested. Medium yield industrial gas flow was tested in this well (Fig. 6), which further proves that the established grading evaluation criterion and prediction methods for carbonate reservoirs are effective. The criterion and prediction methods can be drawn on in fine description, grading evaluation and prediction of the same type of reservoirs.

Fig. 6.

Fig. 6.

Composite columnar section and geophysical response of Longwangmiao Formation reservoirs in Well MX-Z of Moxi area.

6. Conclusions

The reservoirs of Longwangmiao Formation in Moxi area have two types of reservoir space combinations: fracture- cavity type and fracture-pore type. The reservoir with the fracture-cavity type combination has better physical properties than the reservoir with fracture-pore type combination. The fracture-pore reservoirs include intergranular (dissolved) pore reservoirs and intercrystalline (dissolved) pore reservoirs, and the intergranular pore reservoirs have better physical properties than intercrystalline (dissolved) pore reservoirs. Through the study of grading evaluation parameters of single reservoir, four parameters, median pore throat radius, effective porosity, effective permeability and fracture-dissolved vug combination, were selected to establish a grading evaluation criterion for four grades of reservoirs. The main controlling factors of high-quality reservoir, tectonic location, sedimentary environment and diagenetic epigenesis have been sorted out, and the development conditions of high-quality reservoir have been revealed. The spatial distribution of different grades of gas reservoirs in Longwangmiao Formation of Moxi area were predicted accurately by using the main controlling geological factors of reservoir development, FMI for fracture-cavity identification, seismic waveforms response characteristics of different grades of reservoirs and the well testing dynamic data. By using the reservoir grading evaluation criterion and reservoir prediction method, good drilling results have achieved in the study area. The wells drilled later in the study area confirm that the reservoir distribution predicted in each well block is quite accurate.

Nomenclature

GR—gamma ray, API;

K—permeability, 10-3 μm2;

p50—median pressure, MPa;

pd—displacement pressure, MPa;

R—multiple correlation coefficient, dimensionless;

R50—median throat radius, μm;

Rmax—maximum throat radius, μm;

Rt—resistivity, Ω•m;

Rxo—flushed zone resistivity, Ω•m;

ρ—density, g/cm3;

ϕCNL—neutron porosity, %;

ϕ—porosity, %;

∆t—acoustic interval transit time, μs/m.

Reference

Classification of tight sandstone reservoirs based on the contribution of intergranular pores: A case study of Xujiaweizi fault depression

A grading evaluation method for low-permeability reservoirs and its application

Using multi-information to evaluate carbonate reservoir

Petrophysical facies classification of tight sandstone reservoir and high-quality reservoir prediction: A case study from the second member of Xujiahe Formation in Anyue area, central Sichuan Basin

On classification and evaluation of extra-low porosity and permeability reservoir in Yongjin Oilfield, Zhungaria Basin

Reservoir zonation based on statistical analyses: A case study of the Nubian sandstone, Gulf of Suez, Egypt

DOI:10.1016/j.jafrearsci.2016.09.021 URL [Cited within: 2]

Classification and identification of hydrocarbon reservoir lithofacies and their heterogeneity using seismic attributes, logs data and artificial neural networks

DOI:10.1016/j.petrol.2012.01.012 URL [Cited within: 2]

A study of classification evaluation criteria of TOC of carbonate gas source rocks

The present challenges of Chinese petroleum reservoir geology and research direction

Geological features of and development strategies for Cambrian Longwangmiao Formation gas reservoir in Anyue gas field, Sichuan Basin, SW China

DOI:10.1016/S1876-3804(17)30002-2 URL [Cited within: 1]

Diagenesis of the dolomite reservoir in lower Cambrian Longwangmiao Formation in Central Sichuan Basin

Characteristics and distribution of grain bank of the Lower Cambrian Longwangmiao Formation in Moxi-Gaoshiti area, Sichuan Basin

A development rule of Lower Cambrian Longwangmiao grain beaches in the Sichuan Basin

Genesis and evolution of Lower Cambrian Longwangmiao Formation reservoirs, Sichuan Basin, SW China

Distribution characteristics of dolomite reservoir pores and caves of Longwangmiao Fm gas reservoirs in the Sichuan Basin

Petrophysical characteristics and logging evaluation of asphaltene carbonate reservoirs: A case study of the giant gas reservoir of the Cambrian Longwangmiao Formation in Anyue gas field, Sichuan Basin

DOI:10.1016/S1876-3804(17)30002-2 URL [Cited within: 1]

Research progress of seismic wavelet extraction

Application of resolution improvement in seismic data processing technology to the Longwangmiao Fm gas reservoir exploration in Leshan- Longnüsi Paleouplift, Sichuan Basin

Seismic prediction on the favorable efficient development areas of the Longwang-miao Fm gas reservoir in the Gaoshiti-Moxi area, Sichuan Basin

Theoretical and technical innovations in strategic discovery of a giant gas field in Cambrian Longwangmiao Formation of central Sichuan paleo-uplift, Sichuan Basin