The resolution of reservoir stimulation: An introduction of volume stimulation

2

2011

... Volume stimulation in horizontal well has become a key technology for effective development of unconventional oil and gas reservoirs[1,2,3]. Better understanding on the theory of volume stimulation technology has important significance for optimizing design and application of fracturing in the field. In this study, we explain the core connotation, summarize the research results and key technologies and look into the future development direction of volume stimulation based on the theoretical study and field application of this technology. The ultimate goal is to promote the application of this technology in a wider range. ...

... In 2002, through micro seismic monitoring, Maxwell[4] found that the fractures generated in the staged fracturing of horizontal well showed a complex network propagation geometry in the plane and longitudinal direction, rather than the two-wing symmetric fractures stated by the traditional fracturing theory. This discovery was the starting point for the development of volume stimulation technology. In 2006, Mayerhofer[5] first proposed the concept of “stimulation of reservoir volume (SRV)”, followed by an in-depth analysis of SRV in 2010 but did not include technical aspects[6]. In 2008, our research team first proposed the concept of “fracture network” fracturing technology in the industry. After one year of research and practice, an article[7] was published in 2009 to elucidate the technology and its application effect. In January 2009, the author officially proposed the concept of “volume stimulation” technology in PetroChina. After more than one year of research and summary, the first article was published in 2011[1], which clearly stated that volume stimulation technology is a major technological breakthrough. In 2013, the theory and design method of volume stimulation technology were initially established. ...

Volume stimulation technology of unconventional reservoirs: Connotation, optimization design and implementation

1

2012

... Volume stimulation in horizontal well has become a key technology for effective development of unconventional oil and gas reservoirs[1,2,3]. Better understanding on the theory of volume stimulation technology has important significance for optimizing design and application of fracturing in the field. In this study, we explain the core connotation, summarize the research results and key technologies and look into the future development direction of volume stimulation based on the theoretical study and field application of this technology. The ultimate goal is to promote the application of this technology in a wider range. ...

The core theories and key optimization designs of volume stimulation technology for unconventional reservoirs

2

2014

... Volume stimulation in horizontal well has become a key technology for effective development of unconventional oil and gas reservoirs[1,2,3]. Better understanding on the theory of volume stimulation technology has important significance for optimizing design and application of fracturing in the field. In this study, we explain the core connotation, summarize the research results and key technologies and look into the future development direction of volume stimulation based on the theoretical study and field application of this technology. The ultimate goal is to promote the application of this technology in a wider range. ...

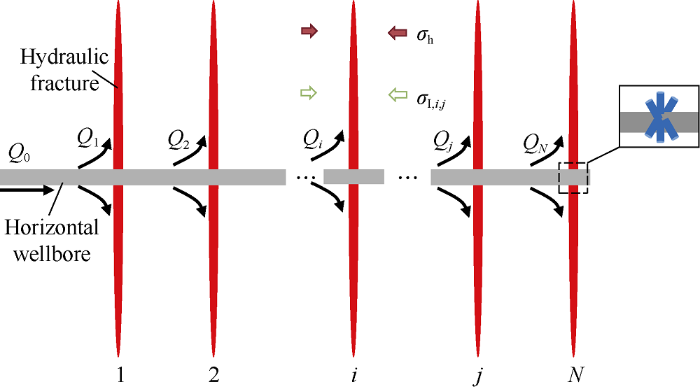

... Multi-cluster perforation is the key to the application of volume stimulation. When multiple clusters (3 clusters or more) are used for each stage, the key to ensure the initiation and growth of each cluster under constant injection rate is to limit the perforation numbers in each stage. If the total perforation number can ensure sufficient entry resistance, all the perforation clusters can be initiated[3]. In this case, it is not necessary to use the temporary blocking technique to activate the unopened clusters. Due to the influence of reservoir heterogeneity and the phase of perforation hole, how to realize the uniform stimulation of all clusters needs to be studied and analyzed from the aspect of multi-fracture propagation (Fig. 3). ...

Microseismic imaging of hydraulic fracture complexity in the Barnett shale

1

2002

... In 2002, through micro seismic monitoring, Maxwell[4] found that the fractures generated in the staged fracturing of horizontal well showed a complex network propagation geometry in the plane and longitudinal direction, rather than the two-wing symmetric fractures stated by the traditional fracturing theory. This discovery was the starting point for the development of volume stimulation technology. In 2006, Mayerhofer[5] first proposed the concept of “stimulation of reservoir volume (SRV)”, followed by an in-depth analysis of SRV in 2010 but did not include technical aspects[6]. In 2008, our research team first proposed the concept of “fracture network” fracturing technology in the industry. After one year of research and practice, an article[7] was published in 2009 to elucidate the technology and its application effect. In January 2009, the author officially proposed the concept of “volume stimulation” technology in PetroChina. After more than one year of research and summary, the first article was published in 2011[1], which clearly stated that volume stimulation technology is a major technological breakthrough. In 2013, the theory and design method of volume stimulation technology were initially established. ...

Integration of microseismic fracture mapping results with numerical fracture network production modeling in the Barnett shale

2

2006

... In 2002, through micro seismic monitoring, Maxwell[4] found that the fractures generated in the staged fracturing of horizontal well showed a complex network propagation geometry in the plane and longitudinal direction, rather than the two-wing symmetric fractures stated by the traditional fracturing theory. This discovery was the starting point for the development of volume stimulation technology. In 2006, Mayerhofer[5] first proposed the concept of “stimulation of reservoir volume (SRV)”, followed by an in-depth analysis of SRV in 2010 but did not include technical aspects[6]. In 2008, our research team first proposed the concept of “fracture network” fracturing technology in the industry. After one year of research and practice, an article[7] was published in 2009 to elucidate the technology and its application effect. In January 2009, the author officially proposed the concept of “volume stimulation” technology in PetroChina. After more than one year of research and summary, the first article was published in 2011[1], which clearly stated that volume stimulation technology is a major technological breakthrough. In 2013, the theory and design method of volume stimulation technology were initially established. ...

... Early studies[77] believed that the best cluster spacing should be 20-30 m in the case of multiple-cluster perforation in horizontal wells. If three clusters are used, the length of each fracturing stage is generally 60 to 90 m. However, Mayerhofer et al.[5] argued that when the reservoir permeability was as low as 0.000 1×10-3 μm2, if the fracture spacing was 8 m, the production could be greatly increased and the oil recovery improved. Zhu et al.[21] found through study that reducing the cluster spacing could greatly improve the ultimate recovery of the reservoir. Years of field practices have proved the tight cluster spacing can greatly shorten the distance of fluid seepage in the matrix, thus realizing volume stimulation of the reservoir with strong plasticity and large stress difference that is difficulty to form complex fractures. At present, the cluster spacing has been gradually reduced from 20 m to 4.6 m[78] in North America, and the small cluster spacing has been widely used in horizontal well staged fracturing of all unconventional reservoirs, rather than reservoirs hard to form fracture network only. ...

What is stimulated reservoir volume?

1

2010

... In 2002, through micro seismic monitoring, Maxwell[4] found that the fractures generated in the staged fracturing of horizontal well showed a complex network propagation geometry in the plane and longitudinal direction, rather than the two-wing symmetric fractures stated by the traditional fracturing theory. This discovery was the starting point for the development of volume stimulation technology. In 2006, Mayerhofer[5] first proposed the concept of “stimulation of reservoir volume (SRV)”, followed by an in-depth analysis of SRV in 2010 but did not include technical aspects[6]. In 2008, our research team first proposed the concept of “fracture network” fracturing technology in the industry. After one year of research and practice, an article[7] was published in 2009 to elucidate the technology and its application effect. In January 2009, the author officially proposed the concept of “volume stimulation” technology in PetroChina. After more than one year of research and summary, the first article was published in 2011[1], which clearly stated that volume stimulation technology is a major technological breakthrough. In 2013, the theory and design method of volume stimulation technology were initially established. ...

Fracture network stimulation technique for improving post-stimulation performance of low and ultra-low permeability reservoirs

2

2009

... In 2002, through micro seismic monitoring, Maxwell[4] found that the fractures generated in the staged fracturing of horizontal well showed a complex network propagation geometry in the plane and longitudinal direction, rather than the two-wing symmetric fractures stated by the traditional fracturing theory. This discovery was the starting point for the development of volume stimulation technology. In 2006, Mayerhofer[5] first proposed the concept of “stimulation of reservoir volume (SRV)”, followed by an in-depth analysis of SRV in 2010 but did not include technical aspects[6]. In 2008, our research team first proposed the concept of “fracture network” fracturing technology in the industry. After one year of research and practice, an article[7] was published in 2009 to elucidate the technology and its application effect. In January 2009, the author officially proposed the concept of “volume stimulation” technology in PetroChina. After more than one year of research and summary, the first article was published in 2011[1], which clearly stated that volume stimulation technology is a major technological breakthrough. In 2013, the theory and design method of volume stimulation technology were initially established. ...

... between fractures and the natural fractures[38]. During the on-site fracturing, the clustering perforation can be used to improve the complexity of fractures in far from wellbore by making use of the superposition of inter-cluster stress interference and the diverting technique in fractures[7]. In addition, reducing the cluster spacing can make multi-cluster fractures deflect away from each other, thus increasing the complexity of fractures and the lateral stimulation range[39]. For reservoirs with natural fractures susceptible to sand plugging near wellbore, a combination of “breaking up rock by gel + carrying proppant by slickwater” can be considered to reduce the risk of sand plugging and improve the complexity of fractures far from wellbore. ...

Microflows and nanoflows: Fundamentals and simulation

1

2005

... Generally speaking, the volume stimulation technology is the general fracturing technology under modern theory. The “fracture network” is the fracture geometry pursued by volume stimulation, and the “fracture network” fracturing technology is an expression of volume stimulation technology. The volume stimulation technology invented by the author’s research team is an interpretation of the classic Darcy’s law from different perspectives in the field of unconventional oil and gas exploration and development. Its core theory mainly includes the following points: (1) one method: “breaking up” the reservoir to form network fractures and artificial permeability; (2) three connotations: the maximum contact area between the fracture wall and the reservoir matrix, the shortest flow distance of fluid from the matrix to the fracture, and the minimum pressure difference for the fluid flow to the fracture; and (3) three functions: to increase single well production, improve oil recovery, and maximize the producing degree of reserves. Studies by researchers at home and abroad have shown that[8,9,10], for seepage of oil and gas in unconventional reservoir matrix, whether considering non-Darcy flow, starting pressure flow or multi-scale flow, its model of non-Darcy flow is still in the expression form of Darcy’s law, and the difference is that the model is modified by using different parameters, but the seepage characteristics are still controlled by the seepage area, flow distance, and driving pressure difference. These studies have confirmed theoretically rationality of the core idea of volume stimulation technology, that is “the maximum contact area, the shortest flow distance, the smallest pressure difference”. Therefore, it can be argued that Darcy’s law is the theoretical basis for establishing volume stimulation technology, and “the maximum contact area, the shortest flow distance, the smallest pressure difference” is a new expression of Darcy’s law in the field of reservoir stimulation. Volume stimulation technology can be applied not only to unconventional reservoirs, but also to the development of low-saturation reservoirs, heavy oil reservoirs, and even conventional reservoirs. Volume stimulation technology is also applicable to deep unconventional reservoirs. The main technical bottlenecks are the technical capability and level of deep well operation, the pressure resistance of wellheads and equipment, and greater investment. Therefore, how to reduce cost and increase efficiency is an important research direction for effective development of deep shale gas reservoirs. ...

Study on the multi-scale nonlinear flow mechanism and model of shale gas

1

2016

... Generally speaking, the volume stimulation technology is the general fracturing technology under modern theory. The “fracture network” is the fracture geometry pursued by volume stimulation, and the “fracture network” fracturing technology is an expression of volume stimulation technology. The volume stimulation technology invented by the author’s research team is an interpretation of the classic Darcy’s law from different perspectives in the field of unconventional oil and gas exploration and development. Its core theory mainly includes the following points: (1) one method: “breaking up” the reservoir to form network fractures and artificial permeability; (2) three connotations: the maximum contact area between the fracture wall and the reservoir matrix, the shortest flow distance of fluid from the matrix to the fracture, and the minimum pressure difference for the fluid flow to the fracture; and (3) three functions: to increase single well production, improve oil recovery, and maximize the producing degree of reserves. Studies by researchers at home and abroad have shown that[8,9,10], for seepage of oil and gas in unconventional reservoir matrix, whether considering non-Darcy flow, starting pressure flow or multi-scale flow, its model of non-Darcy flow is still in the expression form of Darcy’s law, and the difference is that the model is modified by using different parameters, but the seepage characteristics are still controlled by the seepage area, flow distance, and driving pressure difference. These studies have confirmed theoretically rationality of the core idea of volume stimulation technology, that is “the maximum contact area, the shortest flow distance, the smallest pressure difference”. Therefore, it can be argued that Darcy’s law is the theoretical basis for establishing volume stimulation technology, and “the maximum contact area, the shortest flow distance, the smallest pressure difference” is a new expression of Darcy’s law in the field of reservoir stimulation. Volume stimulation technology can be applied not only to unconventional reservoirs, but also to the development of low-saturation reservoirs, heavy oil reservoirs, and even conventional reservoirs. Volume stimulation technology is also applicable to deep unconventional reservoirs. The main technical bottlenecks are the technical capability and level of deep well operation, the pressure resistance of wellheads and equipment, and greater investment. Therefore, how to reduce cost and increase efficiency is an important research direction for effective development of deep shale gas reservoirs. ...

Nonlinear flow model and productivity of stimulated reservoir volume in tight oil reservoirs

1

2014

... Generally speaking, the volume stimulation technology is the general fracturing technology under modern theory. The “fracture network” is the fracture geometry pursued by volume stimulation, and the “fracture network” fracturing technology is an expression of volume stimulation technology. The volume stimulation technology invented by the author’s research team is an interpretation of the classic Darcy’s law from different perspectives in the field of unconventional oil and gas exploration and development. Its core theory mainly includes the following points: (1) one method: “breaking up” the reservoir to form network fractures and artificial permeability; (2) three connotations: the maximum contact area between the fracture wall and the reservoir matrix, the shortest flow distance of fluid from the matrix to the fracture, and the minimum pressure difference for the fluid flow to the fracture; and (3) three functions: to increase single well production, improve oil recovery, and maximize the producing degree of reserves. Studies by researchers at home and abroad have shown that[8,9,10], for seepage of oil and gas in unconventional reservoir matrix, whether considering non-Darcy flow, starting pressure flow or multi-scale flow, its model of non-Darcy flow is still in the expression form of Darcy’s law, and the difference is that the model is modified by using different parameters, but the seepage characteristics are still controlled by the seepage area, flow distance, and driving pressure difference. These studies have confirmed theoretically rationality of the core idea of volume stimulation technology, that is “the maximum contact area, the shortest flow distance, the smallest pressure difference”. Therefore, it can be argued that Darcy’s law is the theoretical basis for establishing volume stimulation technology, and “the maximum contact area, the shortest flow distance, the smallest pressure difference” is a new expression of Darcy’s law in the field of reservoir stimulation. Volume stimulation technology can be applied not only to unconventional reservoirs, but also to the development of low-saturation reservoirs, heavy oil reservoirs, and even conventional reservoirs. Volume stimulation technology is also applicable to deep unconventional reservoirs. The main technical bottlenecks are the technical capability and level of deep well operation, the pressure resistance of wellheads and equipment, and greater investment. Therefore, how to reduce cost and increase efficiency is an important research direction for effective development of deep shale gas reservoirs. ...

The Bakken: Utilizing a petroleum system based analysis to optimally exploit one of the world

1

2012

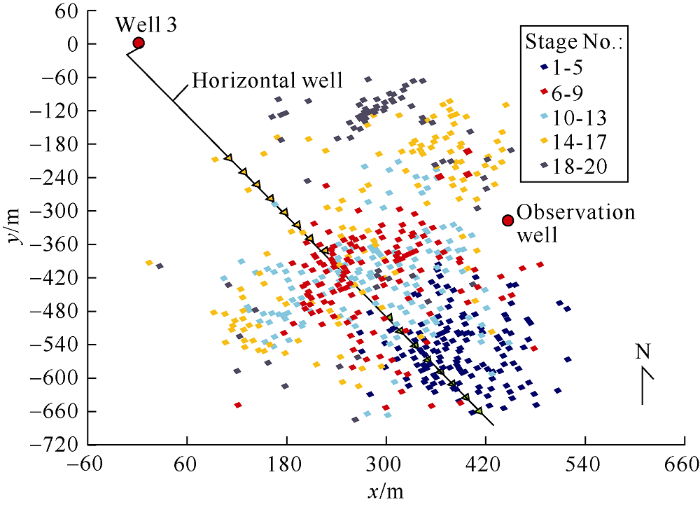

... Since the emergence of volume stimulation technology, it has not only been widely used in PetroChina, but foreign researchers[11] also agree that it is the future development direction of fracturing technology to “break up” the rock near the wellbore through multi-cluster and large-scale fracturing. Pearson et al.[12] compared the fracturing effects obtained by using different tools and techniques in the Bakken Basin and found that volume stimulation using bridge plug, clustering perforation and slick water in large-scale and large displacement has the best result. Romanson et al.[13] verified the general applicability of volume stimulation technique by monitoring the complex fractures formed by the volume stimulation in the Bakken Basin through microseismic monitoring (Fig. 1). ...

Breaking up is hard to do: Creating hydraulic fracture complexity in the Bakken central basin

1

2013

... Since the emergence of volume stimulation technology, it has not only been widely used in PetroChina, but foreign researchers[11] also agree that it is the future development direction of fracturing technology to “break up” the rock near the wellbore through multi-cluster and large-scale fracturing. Pearson et al.[12] compared the fracturing effects obtained by using different tools and techniques in the Bakken Basin and found that volume stimulation using bridge plug, clustering perforation and slick water in large-scale and large displacement has the best result. Romanson et al.[13] verified the general applicability of volume stimulation technique by monitoring the complex fractures formed by the volume stimulation in the Bakken Basin through microseismic monitoring (Fig. 1). ...

Multistage stimulation processes can help achieve and control branch stimulation and increase stimulated reservoir volume for unconventional reservoirs

1

2011

... Since the emergence of volume stimulation technology, it has not only been widely used in PetroChina, but foreign researchers[11] also agree that it is the future development direction of fracturing technology to “break up” the rock near the wellbore through multi-cluster and large-scale fracturing. Pearson et al.[12] compared the fracturing effects obtained by using different tools and techniques in the Bakken Basin and found that volume stimulation using bridge plug, clustering perforation and slick water in large-scale and large displacement has the best result. Romanson et al.[13] verified the general applicability of volume stimulation technique by monitoring the complex fractures formed by the volume stimulation in the Bakken Basin through microseismic monitoring (Fig. 1). ...

Fracture monitoring by surface tiltmeter in horizontal-well A pad in Changning, Sichuan

2

2016

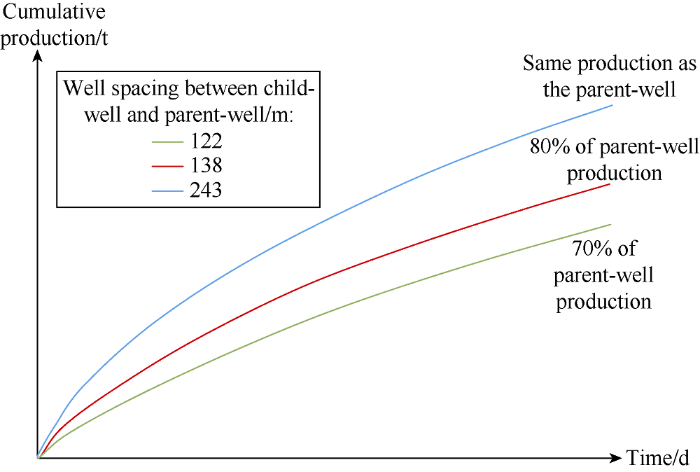

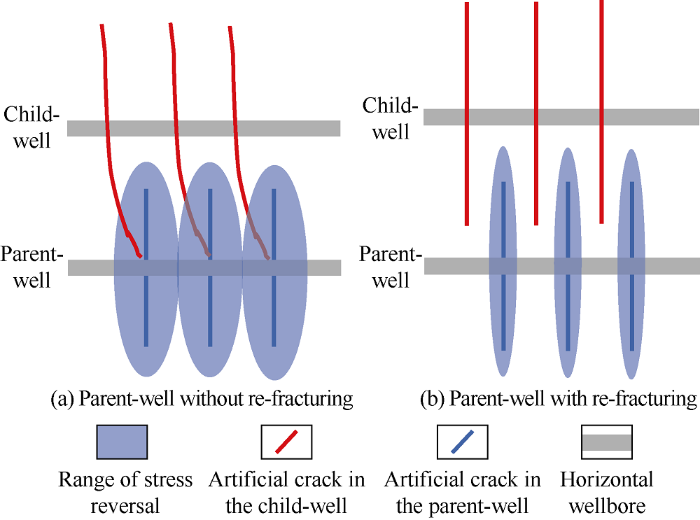

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

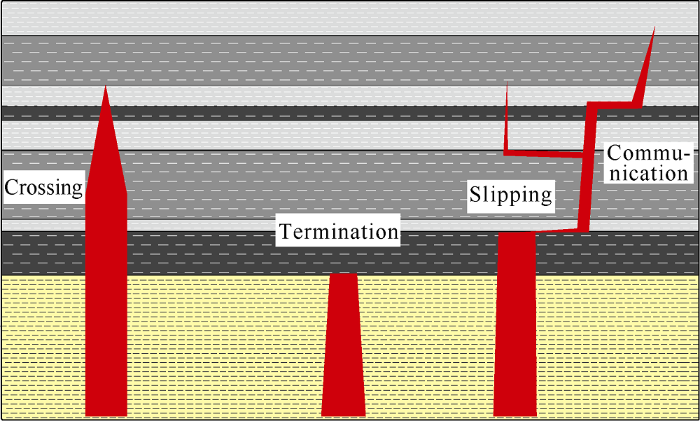

... Field practice and research have shown that the hydraulic fractures can intersect with bedding surfaces (Fig. 7) in several ways, including passing, terminating, slipping, and communicating high-angle fractures. Slipping is the main mechanism controlling fracture height propagation. When the fracturing fluid is lost along the bedding surface, the pressure in the fracture would reduce and the bedding slippage causes the flow friction of fluid to increase, both of which would make artificial fracture fail to pass through the bedding, limiting the fracture propagation in height. Similarly, in slick water fracturing, the proppant continuously settles along the direction of fracture height and rapidly deposits at the bottom of the fracture to prevent the fracture from expanding downward. Monitoring shale gas horizontal wells with inclinometer, Xiu Nailing et al.[14] found that vertical fracture volume makes up 90% of the total fracture volume at most, but for some sections, this is only 50% to 60%. The artificial fracture system consists of vertical and horizontal fractures, indicating that the artificial fractures have the characteristics of extending in the horizontal bedding. The shale gas field data of PetroChina (Table 1) shows that the position of the horizontal well section in the high-quality reservoir is closely related to the stimulation effect, and the propagation of the fracture in the height ...

Stimulated reservoir volume: A misapplied concept?

1

2014

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Utica well performance evaluation: A multiwell pad case history

1

2016

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Influencing fracture growth with stage sequencing

1

2016

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Evaluation of multistage hydraulic fracture patterns in naturally fractured tight oil formations utilizing a coupled geomechanics-fluid flow model: Case study for an Eagle Ford shale well pad

1

2016

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Determining maximum horizontal stress with microseismic focal mechanisms: Case studies in the Marcellus, Eagle Ford, Wolfcamp

1

2016

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Improving production in the Eagle Ford shale with fracture modeling, increased fracture conductivity, and optimized stage and cluster spacing along the horizontal wellbore

1

2010

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

Cluster spacing and well spacing optimization using multi-well simulation for the lower Spraberry shale in Midland basin

2

2017

... Microseismic monitoring and well test analysis show that the actual length of the hydraulic fracture is much smaller than the range of the microseismic event[14,15]. Under the condition of large well spacing (such as 400 m), the length of the artificial fracture is not enough to cover the interwell reservoir fully, so the reserve utilization rate is limited and stimulation efficiency is not maximized. So, reduction of well spacing is taken in North America[16,17,18], with well spacing shortened from 400 m in 2009 to less than 200 m, and the minimum well spacing being just 76 m[19]. Reducing the well spacing can reduce the fracture length designed and make field operation easier. By strengthening the support ability of proppant to the fractures in distal end of formation, the fractures can fully control the reserves between two adjacent wells, thus greatly reducing the volume of unstimulated reservoir far from the wells. In addition, while reducing the well spacing, it is often necessary to reduce the cluster spacing, they are closely related to each other. At present, the cluster spacing of horizontal well stimulation in unconventional reservoirs in North America has been reduced from 20-30 m[20] to 5-10 m[21]. Under the condition of small cluster spacing, it is not necessary to form network fractures between clusters. The seepage distance between oil and gas and fractures in the matrix within two fractures is only a few meters. For micro- and nano-scale permeability reservoirs, the driving pressure difference required for fluid to flow into the fracture in the matrix has been greatly reduced, which means that the oil and gas recovery in the matrix is basically no problem. “All” recovery is the core and ultimate goal of the volume stimulation technology. ...

... Early studies[77] believed that the best cluster spacing should be 20-30 m in the case of multiple-cluster perforation in horizontal wells. If three clusters are used, the length of each fracturing stage is generally 60 to 90 m. However, Mayerhofer et al.[5] argued that when the reservoir permeability was as low as 0.000 1×10-3 μm2, if the fracture spacing was 8 m, the production could be greatly increased and the oil recovery improved. Zhu et al.[21] found through study that reducing the cluster spacing could greatly improve the ultimate recovery of the reservoir. Years of field practices have proved the tight cluster spacing can greatly shorten the distance of fluid seepage in the matrix, thus realizing volume stimulation of the reservoir with strong plasticity and large stress difference that is difficulty to form complex fractures. At present, the cluster spacing has been gradually reduced from 20 m to 4.6 m[78] in North America, and the small cluster spacing has been widely used in horizontal well staged fracturing of all unconventional reservoirs, rather than reservoirs hard to form fracture network only. ...

Stacked pay pad development in the Midland Basin

2

2017

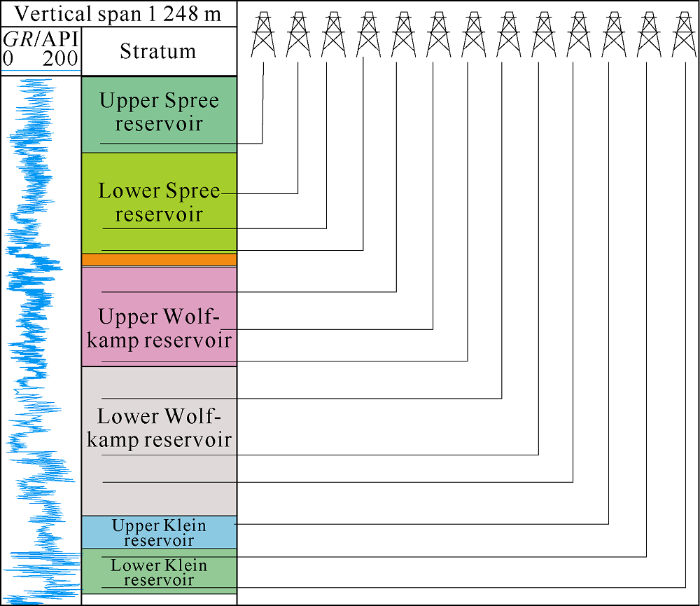

... Increasing the producing degree of longitudinal sections of layered or thick unconventional reservoirs has always been an important research topic in the field of reservoir stimulation. Multi-layer fracturing with packer sliding sleeves and coiled tubing hydraulic sand blasting in vertical well, and multi-lateral horizontal well fracturing are effective technical methods. With the development of drilling technology, the drilling speed has been greatly improved. For example, in the Eagle Ford block, for typical wells 4 853 m deep and 2 198 m long in horizontal length, it only takes 6.02 d to finish drilling from spud-in. Drilling costs have fallen from 60%-80% of the cost of completion to 21%-34%. The speed of drilling has prompted the development of spatial-mode volume stimulation technology (Fig. 2)[22], that is, a horizontal well is drilled separately for each target layer, and multi-lateral horizontal wells are no longer used. Compared with multi-lateral wells, multi-layer horizontal wells are simple in operation, high in efficiency, low in risk, and low in overall cost. This technology applies the concept of “breaking up” reservoirs from plane to vertical direction by volume stimulation. With reference to the horizontal well development model in the wellpad mode, the horizontal sections are stacked in the longitudinal direction, the fractures are placed in a staggered pattern, so network fractures can be created by the interference of effective stress generated in the longitudinal direction by the fractures height propagation to greatly increase the reserve utilization rate of the longitudinal reservoirs. Farhan et al.[22] found that when the Wolfcamp block was developed using three stacked multi-layer horizontal wells, 78% of the wells with production were of multi-layer completion. Field practice in the blocks of Eagle Ford and Niobrara shows that poor reservoirs with no economic value of development interpreted by the logging data, can reach development result similar to good reservoirs after using reservoir simulation technology[23]. ...

... [22] found that when the Wolfcamp block was developed using three stacked multi-layer horizontal wells, 78% of the wells with production were of multi-layer completion. Field practice in the blocks of Eagle Ford and Niobrara shows that poor reservoirs with no economic value of development interpreted by the logging data, can reach development result similar to good reservoirs after using reservoir simulation technology[23]. ...

2

... Increasing the producing degree of longitudinal sections of layered or thick unconventional reservoirs has always been an important research topic in the field of reservoir stimulation. Multi-layer fracturing with packer sliding sleeves and coiled tubing hydraulic sand blasting in vertical well, and multi-lateral horizontal well fracturing are effective technical methods. With the development of drilling technology, the drilling speed has been greatly improved. For example, in the Eagle Ford block, for typical wells 4 853 m deep and 2 198 m long in horizontal length, it only takes 6.02 d to finish drilling from spud-in. Drilling costs have fallen from 60%-80% of the cost of completion to 21%-34%. The speed of drilling has prompted the development of spatial-mode volume stimulation technology (Fig. 2)[22], that is, a horizontal well is drilled separately for each target layer, and multi-lateral horizontal wells are no longer used. Compared with multi-lateral wells, multi-layer horizontal wells are simple in operation, high in efficiency, low in risk, and low in overall cost. This technology applies the concept of “breaking up” reservoirs from plane to vertical direction by volume stimulation. With reference to the horizontal well development model in the wellpad mode, the horizontal sections are stacked in the longitudinal direction, the fractures are placed in a staggered pattern, so network fractures can be created by the interference of effective stress generated in the longitudinal direction by the fractures height propagation to greatly increase the reserve utilization rate of the longitudinal reservoirs. Farhan et al.[22] found that when the Wolfcamp block was developed using three stacked multi-layer horizontal wells, 78% of the wells with production were of multi-layer completion. Field practice in the blocks of Eagle Ford and Niobrara shows that poor reservoirs with no economic value of development interpreted by the logging data, can reach development result similar to good reservoirs after using reservoir simulation technology[23]. ...

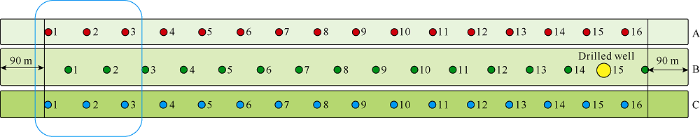

... The faster drilling in North America has made the drilling cost drop significantly. Many companies have begun to explore spatial stimulation development model, seeking to break the limitations of well trajectory and fracture height, thus improving the stimulation effect on reservoir profile. Carrizo has implemented a spatial stimulation project in the Niobrara formation[23]. The projected included 47 wells with horizontal section of 1 426 m and horizontal section space of 90-100 m. The wells are arranged in 3 layers, Fig. 8 shows a side view of the horizontal wells stacked in three layers (i.e. toe end position of horizontal section of each horizontal well). The wells of layers A and C are in the same façade in the vertical direction, and the wells in layer B are misplaced, we called this as three-dimensional staggered zipper fracturing technology. The order of fracturing is from left to right: C1—C2—B1—A1— C3—B2—A2—A3—…… The method can make the first fracturing well generate an additional stress field at the bottom. Due to the dislocation fracturing of different layers, the additional stress generated by the fracturing can increase the complexity of the adjacent layer fractures, thereby improving the stimulation effect of the longitudinal small layers. ...

1

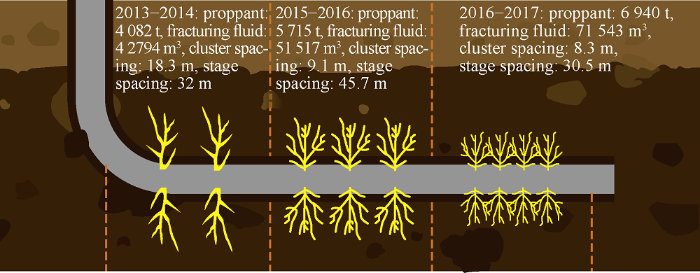

... Utra-long horizontal well fracturing technology has been attempted in North America since 2013, with the horizontal section increasing from 1 900 m at first to 5 700 m in 2016. For example, the company of Eclipse successfully implemented ultra-long horizontal well fracturing in Well Purple Hayes1H in the Utica block[24]. The well has a depth of 8 244 m, horizontal section length of 5 562 m, and vertical depth of 2307 m. It took 17.5 d to finish its drilling, and 23.5 d to finish its fracturing. The fracturing had 124 stages, with each stage being 45.72 m. 5.3 stages with 5 clusters per each stage were fractured per day. After the fracturing, the well had a natural gas production of 14.16×104 m3/d and condensate production of 190.8 m3/d. According to the production data, the EUR for 3 years would reach 2.76×108m3. The ultra-long horizontal well can reduce the drilling and completion cost per meter, improve the economic indicators of the well, reduce the cost of fracturing and drilling by 20%-30%, and increase the profit by 35%-70%, compared with the short horizontal well. By increasing the number of fractures cutting matrix and the contact area between fractures and matrix, the ultra-long horizontal well can maximize the recovery rate of reserves in the horizontal section, so as to delay the decline of the production, greatly increase the EUR, reduce cost and increase profit. ...

Analysis of the power input needed to propagate multiple hydraulic fractures

1

2013

... When the fracture expands, the energy from the injected liquid is converted into the strain energy and fracturing energy of the rock, the energy that overcomes the far-field stress and interactive stress, the perforation friction and the energy consumed by the fluid flow in the fracture[25]. Considering the case of N clusters of fractures in each stage, the energy balance equation for each fracture can be expressed as: ...

Propagation regimes of fluid-driven fractures in impermeable rocks

1

2004

... Assume that the interactive stress of ith fracture caused by the jth fracture is σI,i,j, meanwhile as the hydraulic fractures are largely viscosity-dominated fractures[26], Wc can be negligible, so the equation (1) can be simplified as: ...

Can we engineer better multistage horizontal completions? Evidence of the importance of near-wellbore fracture geometry from theory, lab and field experiments

1

2015

... The above analysis shows that in the volume stimulation of horizontal well, uniform stimulation of each cluster can be achieved by multi-cluster limited entry technique. This conclusion has been proved by Lecampion and Wu et al.[27,28] through numerical simulation. The extreme limited entry (XLE) perforating technique proposed by Somanchi et al.[29] can achieve multi-cluster simultaneous opening and uniform expansion by a greater degree of multi-cluster limited entry. The technology was tested in the Montany block, where with 3 clusters per stage and 2-3 perforation holes per cluster, the fracturing was done at the injection rate of 5 m3/min and perforation entry resistance of 8.3 MPa. Optical fiber diagnosis shows that the technology results in more balanced amount of sand per cluster and the efficiency of perforation clusters 33% higher than conventional limited entry perforating. Weddle et al.[30] reported the effect of XLE in the Bakken block: the horizontal section of the wells were 4 313 m long, and were fractured in 40-50 stage, with 12-15 perforation clusters in each stage and 2 holes in each cluster; the holes in the same cluster were perforated at 180° phase angle; the fracturing was done at the sand adding rate of 0.98-1.51 t/m, injection rate of 12.7 m3/min, and the perforating entry resistance of 10-14 MPa. Post-fracturing gamma logging shows that the efficiency of XLE is 80% to 90%, while the efficiency of limited entry perforating is often only 30% to 80%. However, the injection rate of XLE is lower, mainly because the number of holes is too few, which leads to excessive entry resistance and great increase of the injection pressure at the wellhead. But, lower injection rate often results in lower net pressure in the fractures, which is not conducive to the formation of complex fractures and increase of SRV. ...

Mechanisms of simultaneous hydraulic- fracture propagation from multiple perforation clusters in horizontal wells

1

2015

... The above analysis shows that in the volume stimulation of horizontal well, uniform stimulation of each cluster can be achieved by multi-cluster limited entry technique. This conclusion has been proved by Lecampion and Wu et al.[27,28] through numerical simulation. The extreme limited entry (XLE) perforating technique proposed by Somanchi et al.[29] can achieve multi-cluster simultaneous opening and uniform expansion by a greater degree of multi-cluster limited entry. The technology was tested in the Montany block, where with 3 clusters per stage and 2-3 perforation holes per cluster, the fracturing was done at the injection rate of 5 m3/min and perforation entry resistance of 8.3 MPa. Optical fiber diagnosis shows that the technology results in more balanced amount of sand per cluster and the efficiency of perforation clusters 33% higher than conventional limited entry perforating. Weddle et al.[30] reported the effect of XLE in the Bakken block: the horizontal section of the wells were 4 313 m long, and were fractured in 40-50 stage, with 12-15 perforation clusters in each stage and 2 holes in each cluster; the holes in the same cluster were perforated at 180° phase angle; the fracturing was done at the sand adding rate of 0.98-1.51 t/m, injection rate of 12.7 m3/min, and the perforating entry resistance of 10-14 MPa. Post-fracturing gamma logging shows that the efficiency of XLE is 80% to 90%, while the efficiency of limited entry perforating is often only 30% to 80%. However, the injection rate of XLE is lower, mainly because the number of holes is too few, which leads to excessive entry resistance and great increase of the injection pressure at the wellhead. But, lower injection rate often results in lower net pressure in the fractures, which is not conducive to the formation of complex fractures and increase of SRV. ...

Extreme limited entry design improves distribution efficiency in plug-n- perf completions: Insights from fiber-optic diagnostics

1

2017

... The above analysis shows that in the volume stimulation of horizontal well, uniform stimulation of each cluster can be achieved by multi-cluster limited entry technique. This conclusion has been proved by Lecampion and Wu et al.[27,28] through numerical simulation. The extreme limited entry (XLE) perforating technique proposed by Somanchi et al.[29] can achieve multi-cluster simultaneous opening and uniform expansion by a greater degree of multi-cluster limited entry. The technology was tested in the Montany block, where with 3 clusters per stage and 2-3 perforation holes per cluster, the fracturing was done at the injection rate of 5 m3/min and perforation entry resistance of 8.3 MPa. Optical fiber diagnosis shows that the technology results in more balanced amount of sand per cluster and the efficiency of perforation clusters 33% higher than conventional limited entry perforating. Weddle et al.[30] reported the effect of XLE in the Bakken block: the horizontal section of the wells were 4 313 m long, and were fractured in 40-50 stage, with 12-15 perforation clusters in each stage and 2 holes in each cluster; the holes in the same cluster were perforated at 180° phase angle; the fracturing was done at the sand adding rate of 0.98-1.51 t/m, injection rate of 12.7 m3/min, and the perforating entry resistance of 10-14 MPa. Post-fracturing gamma logging shows that the efficiency of XLE is 80% to 90%, while the efficiency of limited entry perforating is often only 30% to 80%. However, the injection rate of XLE is lower, mainly because the number of holes is too few, which leads to excessive entry resistance and great increase of the injection pressure at the wellhead. But, lower injection rate often results in lower net pressure in the fractures, which is not conducive to the formation of complex fractures and increase of SRV. ...

Mining the Bakken II: Pushing the envelope with extreme limited entry perforating

2

2018

... The above analysis shows that in the volume stimulation of horizontal well, uniform stimulation of each cluster can be achieved by multi-cluster limited entry technique. This conclusion has been proved by Lecampion and Wu et al.[27,28] through numerical simulation. The extreme limited entry (XLE) perforating technique proposed by Somanchi et al.[29] can achieve multi-cluster simultaneous opening and uniform expansion by a greater degree of multi-cluster limited entry. The technology was tested in the Montany block, where with 3 clusters per stage and 2-3 perforation holes per cluster, the fracturing was done at the injection rate of 5 m3/min and perforation entry resistance of 8.3 MPa. Optical fiber diagnosis shows that the technology results in more balanced amount of sand per cluster and the efficiency of perforation clusters 33% higher than conventional limited entry perforating. Weddle et al.[30] reported the effect of XLE in the Bakken block: the horizontal section of the wells were 4 313 m long, and were fractured in 40-50 stage, with 12-15 perforation clusters in each stage and 2 holes in each cluster; the holes in the same cluster were perforated at 180° phase angle; the fracturing was done at the sand adding rate of 0.98-1.51 t/m, injection rate of 12.7 m3/min, and the perforating entry resistance of 10-14 MPa. Post-fracturing gamma logging shows that the efficiency of XLE is 80% to 90%, while the efficiency of limited entry perforating is often only 30% to 80%. However, the injection rate of XLE is lower, mainly because the number of holes is too few, which leads to excessive entry resistance and great increase of the injection pressure at the wellhead. But, lower injection rate often results in lower net pressure in the fractures, which is not conducive to the formation of complex fractures and increase of SRV. ...

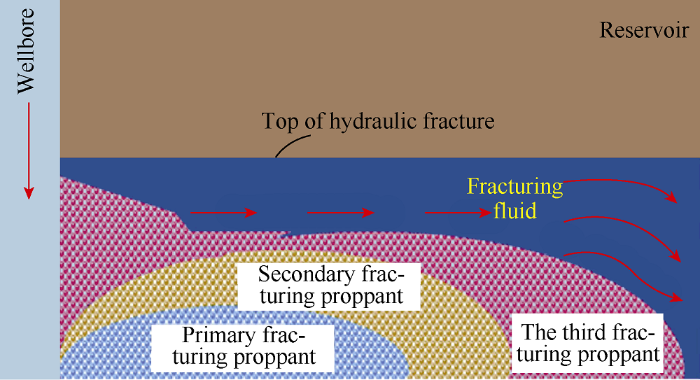

... According to the equation (6), when the particle diameter of the proppant is reduced to 1/2 of the conventional particle diameter, the setting speed of the proppant will be reduced to 1/4 of the setting speed of the conventional particle size proppant. At present, the clusters in a fracturing stage of horizontal well volume stimulation are going up from 3 to more than 10[30], so the injection rate in each cluster is greatly reduced. Since the injection rate cannot be increased indefinitely to increase the fracture width, and the limit dynamic fracture width to avoid sand screenout should ideally be 2 to 3 times the proppant particle size[40], so it is sensible to select small particle size proppant to reduce the risk of sand screenout and increase the migration distance of proppant in the fracture. ...

Hydraulic fracture complexity: Diagnosis, remediation, and exploration

1

2008

... The main purpose of volume stimulation is to increase the complexity of fractures far from well[31]. The near-well fractures should be as simple as possible in shape to avoid distortion or multiple fractures which may cause smaller fracture width and subsequently sand plugging at the perforation tunnel or near the well. Therefore, directional perforation, equal hole size perforation and other techniques can be taken to make the perforation phase as consistent as possible with the direction of the maximum principal stress, to effectively avoid the distortion of near-well fractures[32,33]. In staged fracturing from horizontal wells, the perforation spacing of the same perforation cluster should generally be less than 4 times the diameter of the wellbore[34] to ensure that the fractures at different tunnels are single. ...

Oriented perforation: A rock mechanics view

1

1994

... The main purpose of volume stimulation is to increase the complexity of fractures far from well[31]. The near-well fractures should be as simple as possible in shape to avoid distortion or multiple fractures which may cause smaller fracture width and subsequently sand plugging at the perforation tunnel or near the well. Therefore, directional perforation, equal hole size perforation and other techniques can be taken to make the perforation phase as consistent as possible with the direction of the maximum principal stress, to effectively avoid the distortion of near-well fractures[32,33]. In staged fracturing from horizontal wells, the perforation spacing of the same perforation cluster should generally be less than 4 times the diameter of the wellbore[34] to ensure that the fractures at different tunnels are single. ...

Improved hydraulic stimulation perforation efficiency observed with constant entry hole and constant penetration perforating system

1

2017

... The main purpose of volume stimulation is to increase the complexity of fractures far from well[31]. The near-well fractures should be as simple as possible in shape to avoid distortion or multiple fractures which may cause smaller fracture width and subsequently sand plugging at the perforation tunnel or near the well. Therefore, directional perforation, equal hole size perforation and other techniques can be taken to make the perforation phase as consistent as possible with the direction of the maximum principal stress, to effectively avoid the distortion of near-well fractures[32,33]. In staged fracturing from horizontal wells, the perforation spacing of the same perforation cluster should generally be less than 4 times the diameter of the wellbore[34] to ensure that the fractures at different tunnels are single. ...

Experimental study of hydraulic fracture geometry initiated from horizontal wells

1

1989

... The main purpose of volume stimulation is to increase the complexity of fractures far from well[31]. The near-well fractures should be as simple as possible in shape to avoid distortion or multiple fractures which may cause smaller fracture width and subsequently sand plugging at the perforation tunnel or near the well. Therefore, directional perforation, equal hole size perforation and other techniques can be taken to make the perforation phase as consistent as possible with the direction of the maximum principal stress, to effectively avoid the distortion of near-well fractures[32,33]. In staged fracturing from horizontal wells, the perforation spacing of the same perforation cluster should generally be less than 4 times the diameter of the wellbore[34] to ensure that the fractures at different tunnels are single. ...

Experimental hydraulic fracture propagation in a multi-fractured medium

2

2000

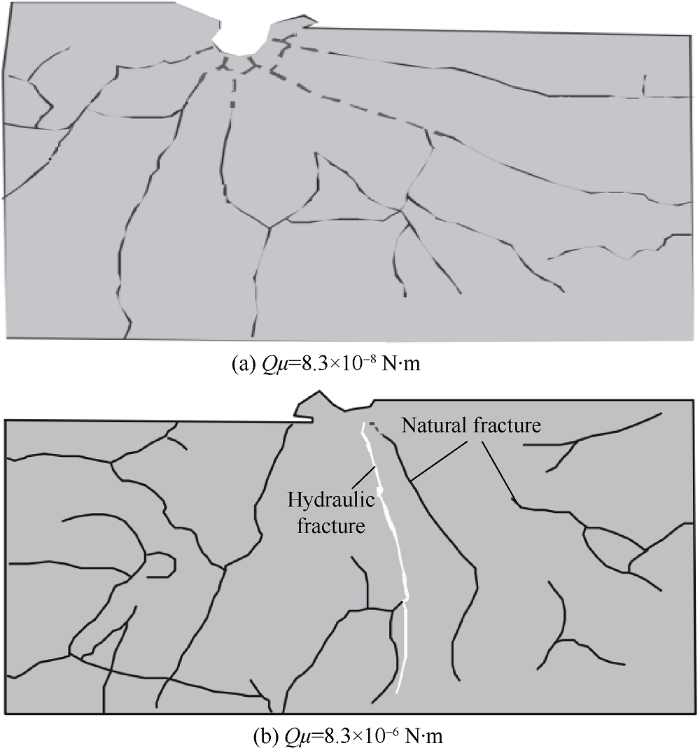

... Beugelsdijk et al.[35] studied the fracture geometry in naturally fractured formations, and pointed out that the product Qμ was the key factor affecting the natural fracture propagation and fracture propagation geometry. When Qμ was 8.3×10-8 N·m, the liquid would flow along the natural fracture and no main artificial fracture would be generated; and when Qμ was 8.3×10-6 N·m, main artificial fractures would be created and the natural fracture would not open. The study also showed that the change rate of injection rate had a significant effect on the fracture initiation, if the injection rate was increased slowly, the pressure curve would have no signs of breakdown, the injected liquid may lose along the natural fracture, causing multiple fractures near well to open (Fig. 4a); when the injection rate was increased quickly, the pressure curve would show obvious breakdown, in this case the natural fracture would not open, only a single hydraulic fracture would be created (Fig. 4b). The experiments of Fu Haifeng et al.[36] verified the function of product Qμ; Lecampion et al.[37] also found that for reservoirs with natural fractures near the wellbore, rapid increase of injection rate to establish bottom-hole pressure could avoid initiation of multiple fractures, thereby reducing the complexity of fractures near wellbore. ...

... Beugelsdijk et al.[35] studied the difficult degree of main fracture diverting and opening of natural fractures and concluded that the diverting ability of artificial fractures should be determined by dimensionless net pressure (ratio of net pressure to horizontal stress difference). The greater the dimensionless net pressure, the easier the fracture will deviate from the direction of the main fracture and form complex fractures. He also introduced a dimensionless horizontal stress difference coefficient to characterize the open ability of natural fracture: ...

Laboratory study on hydraulic fracture geometry of Longmaxi Formation shale in Yibin area of Sichuan Province

1

2016

... Beugelsdijk et al.[35] studied the fracture geometry in naturally fractured formations, and pointed out that the product Qμ was the key factor affecting the natural fracture propagation and fracture propagation geometry. When Qμ was 8.3×10-8 N·m, the liquid would flow along the natural fracture and no main artificial fracture would be generated; and when Qμ was 8.3×10-6 N·m, main artificial fractures would be created and the natural fracture would not open. The study also showed that the change rate of injection rate had a significant effect on the fracture initiation, if the injection rate was increased slowly, the pressure curve would have no signs of breakdown, the injected liquid may lose along the natural fracture, causing multiple fractures near well to open (Fig. 4a); when the injection rate was increased quickly, the pressure curve would show obvious breakdown, in this case the natural fracture would not open, only a single hydraulic fracture would be created (Fig. 4b). The experiments of Fu Haifeng et al.[36] verified the function of product Qμ; Lecampion et al.[37] also found that for reservoirs with natural fractures near the wellbore, rapid increase of injection rate to establish bottom-hole pressure could avoid initiation of multiple fractures, thereby reducing the complexity of fractures near wellbore. ...

Competition between transverse and axil hydraulic fractures of horizontal wells

1

2013

... Beugelsdijk et al.[35] studied the fracture geometry in naturally fractured formations, and pointed out that the product Qμ was the key factor affecting the natural fracture propagation and fracture propagation geometry. When Qμ was 8.3×10-8 N·m, the liquid would flow along the natural fracture and no main artificial fracture would be generated; and when Qμ was 8.3×10-6 N·m, main artificial fractures would be created and the natural fracture would not open. The study also showed that the change rate of injection rate had a significant effect on the fracture initiation, if the injection rate was increased slowly, the pressure curve would have no signs of breakdown, the injected liquid may lose along the natural fracture, causing multiple fractures near well to open (Fig. 4a); when the injection rate was increased quickly, the pressure curve would show obvious breakdown, in this case the natural fracture would not open, only a single hydraulic fracture would be created (Fig. 4b). The experiments of Fu Haifeng et al.[36] verified the function of product Qμ; Lecampion et al.[37] also found that for reservoirs with natural fractures near the wellbore, rapid increase of injection rate to establish bottom-hole pressure could avoid initiation of multiple fractures, thereby reducing the complexity of fractures near wellbore. ...

Numerical investigation of complex hydraulic fracture development in naturally fractured reservoirs

1

2015

... between fractures and the natural fractures[38]. During the on-site fracturing, the clustering perforation can be used to improve the complexity of fractures in far from wellbore by making use of the superposition of inter-cluster stress interference and the diverting technique in fractures[7]. In addition, reducing the cluster spacing can make multi-cluster fractures deflect away from each other, thus increasing the complexity of fractures and the lateral stimulation range[39]. For reservoirs with natural fractures susceptible to sand plugging near wellbore, a combination of “breaking up rock by gel + carrying proppant by slickwater” can be considered to reduce the risk of sand plugging and improve the complexity of fractures far from wellbore. ...

Stress interference calculation model and its application in volume stimulation of horizontal wells

2

2016

... between fractures and the natural fractures[38]. During the on-site fracturing, the clustering perforation can be used to improve the complexity of fractures in far from wellbore by making use of the superposition of inter-cluster stress interference and the diverting technique in fractures[7]. In addition, reducing the cluster spacing can make multi-cluster fractures deflect away from each other, thus increasing the complexity of fractures and the lateral stimulation range[39]. For reservoirs with natural fractures susceptible to sand plugging near wellbore, a combination of “breaking up rock by gel + carrying proppant by slickwater” can be considered to reduce the risk of sand plugging and improve the complexity of fractures far from wellbore. ...

... Chinese researchers have also carried out research on fracture propagation models. Chen Mian[68] deduced the controlling equations for hydraulic fracture activation and diverting in three-dimensional space and established an extended model of two-dimensional natural fractures. Zeng Qinglei et al.[69] worked out a fluid-solid coupled finite element algorithm for multi-cluster fracture propagation. His model considers perforating friction and wellbore friction. Wang Lixiang et al.[70] proposed a finite element and discrete element hybrid method for two-dimensional hydraulic fracture propagation and simulated the fracture propagation pattern of multi-cluster fracturing in the formation with natural fractures. Guo et al.[71] introduced a pore elastic bonding unit and established a two-dimensional fluid-solid coupling finite element fracture propagation model. He also studied the effect of natural fractures on the hydraulic fracture propagation morphology. Zou et al.[72] developed a finite element/discrete element model based on the random distribution of natural fractures in the formation and studied the fracture propagation pattern of shale formations. Xu Yun et al.[39] established a boundary element model for multi-cluster fracture propagation and examined the deflection law of multi-cluster fracture propagation. Chen Ming et al.[73,74] further discussed the factors controlling the deflection of fractures and how to create multi-fractures. Zhao Jinzhou et al.[75] proposed a pseudo-three-dimensional multi- cluster hydraulic fracture extension boundary element model and a perforation optimization method based on PKN model. Wu Qi et al.[76] expounded the application of geological-engineering integration technology in shale gas development and demonstrated the promising application prospect of this technology. However, the current fracture propagation simulation in China is mainly based on two-dimensional model, and there is no three-dimensional model. The research on geological-engineering integration mainly relies on foreign software. Our research team is carrying out relevant research with the help of national research projects and is expected to strengthen the construction of the volume stimulation optimization design platform for the geology-engineering integration of unconventional reservoirs in China, so as to promote the advancement of China’s unconventional reservoir simulation technology. ...

Hydraulic fracture mechanics

1

1995

... According to the equation (6), when the particle diameter of the proppant is reduced to 1/2 of the conventional particle diameter, the setting speed of the proppant will be reduced to 1/4 of the setting speed of the conventional particle size proppant. At present, the clusters in a fracturing stage of horizontal well volume stimulation are going up from 3 to more than 10[30], so the injection rate in each cluster is greatly reduced. Since the injection rate cannot be increased indefinitely to increase the fracture width, and the limit dynamic fracture width to avoid sand screenout should ideally be 2 to 3 times the proppant particle size[40], so it is sensible to select small particle size proppant to reduce the risk of sand screenout and increase the migration distance of proppant in the fracture. ...

Effect of a partial monolayer of propping agent on fracture flow capacity

1

1960

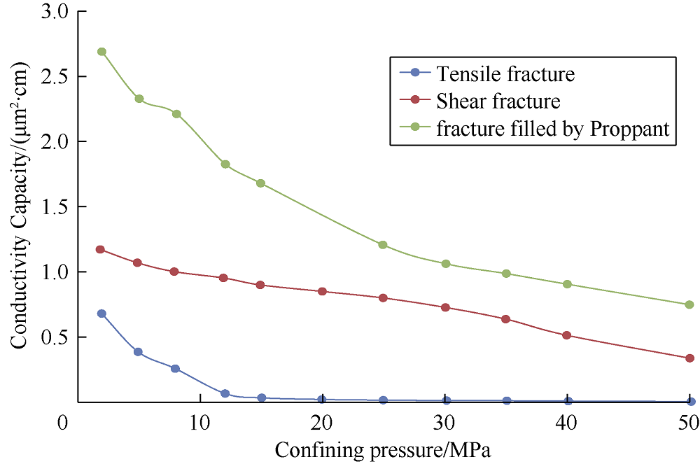

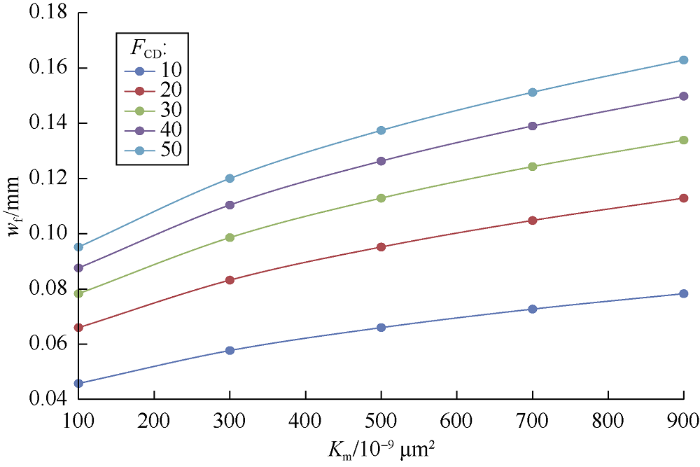

... Since slickwater volume stimulation is likely to create complex fractures, the small particle size proppant would not only settle in the main fractures, but also enter the branch fractures and micro fractures in the forms of corner support and single particle support. This type of placement manner conforms to the early research consensus, that is: “Proppant setting in single layer has the best conductivity”[41], which is an important reason why the complex fracture network has better conductivity. Ely et al.[42] compared the production of the Eagle Ford and Bakken blocks, and found that the small-size quartz sand worked better than the large-size quartz sand in fracturing. At present, the field test of smaller particle size proppant was carried out in Grassland block of Texas, North America[43,44]. In the test, 11 horizontal wells were stage fractured with 3 clusters in each stage at an average injection rate of 8.6 m3/min. The concentration of proppant of 0.150 mm (100 mesh) and 0.425/0.212 mm (40/70 mesh) were both 300 kg/m3, and that of 0.045 mm (325 mesh) micro-size silt was 12 kg/m3. Fracturing with the above method, the cumulative gas production per well over 210 days increased by 20%-30%. Through experiment and numerical simulation, Dahl et al.[43] pointed out that injecting small particle size proppants could increase the micro-fracture permeability of shale and enhance production. ...

“Slick water fracturing and small proppant” The future of stimulation or a slippery slope?

1

2014

... Since slickwater volume stimulation is likely to create complex fractures, the small particle size proppant would not only settle in the main fractures, but also enter the branch fractures and micro fractures in the forms of corner support and single particle support. This type of placement manner conforms to the early research consensus, that is: “Proppant setting in single layer has the best conductivity”[41], which is an important reason why the complex fracture network has better conductivity. Ely et al.[42] compared the production of the Eagle Ford and Bakken blocks, and found that the small-size quartz sand worked better than the large-size quartz sand in fracturing. At present, the field test of smaller particle size proppant was carried out in Grassland block of Texas, North America[43,44]. In the test, 11 horizontal wells were stage fractured with 3 clusters in each stage at an average injection rate of 8.6 m3/min. The concentration of proppant of 0.150 mm (100 mesh) and 0.425/0.212 mm (40/70 mesh) were both 300 kg/m3, and that of 0.045 mm (325 mesh) micro-size silt was 12 kg/m3. Fracturing with the above method, the cumulative gas production per well over 210 days increased by 20%-30%. Through experiment and numerical simulation, Dahl et al.[43] pointed out that injecting small particle size proppants could increase the micro-fracture permeability of shale and enhance production. ...

Application of micro-proppant to enhance well production in unconventional reservoirs: Laboratory and field results

2

2015

... Since slickwater volume stimulation is likely to create complex fractures, the small particle size proppant would not only settle in the main fractures, but also enter the branch fractures and micro fractures in the forms of corner support and single particle support. This type of placement manner conforms to the early research consensus, that is: “Proppant setting in single layer has the best conductivity”[41], which is an important reason why the complex fracture network has better conductivity. Ely et al.[42] compared the production of the Eagle Ford and Bakken blocks, and found that the small-size quartz sand worked better than the large-size quartz sand in fracturing. At present, the field test of smaller particle size proppant was carried out in Grassland block of Texas, North America[43,44]. In the test, 11 horizontal wells were stage fractured with 3 clusters in each stage at an average injection rate of 8.6 m3/min. The concentration of proppant of 0.150 mm (100 mesh) and 0.425/0.212 mm (40/70 mesh) were both 300 kg/m3, and that of 0.045 mm (325 mesh) micro-size silt was 12 kg/m3. Fracturing with the above method, the cumulative gas production per well over 210 days increased by 20%-30%. Through experiment and numerical simulation, Dahl et al.[43] pointed out that injecting small particle size proppants could increase the micro-fracture permeability of shale and enhance production. ...

... [43] pointed out that injecting small particle size proppants could increase the micro-fracture permeability of shale and enhance production. ...

Enhancement of well production in the SCOOP Woodford shale through the application of microproppant

1

2017

... Since slickwater volume stimulation is likely to create complex fractures, the small particle size proppant would not only settle in the main fractures, but also enter the branch fractures and micro fractures in the forms of corner support and single particle support. This type of placement manner conforms to the early research consensus, that is: “Proppant setting in single layer has the best conductivity”[41], which is an important reason why the complex fracture network has better conductivity. Ely et al.[42] compared the production of the Eagle Ford and Bakken blocks, and found that the small-size quartz sand worked better than the large-size quartz sand in fracturing. At present, the field test of smaller particle size proppant was carried out in Grassland block of Texas, North America[43,44]. In the test, 11 horizontal wells were stage fractured with 3 clusters in each stage at an average injection rate of 8.6 m3/min. The concentration of proppant of 0.150 mm (100 mesh) and 0.425/0.212 mm (40/70 mesh) were both 300 kg/m3, and that of 0.045 mm (325 mesh) micro-size silt was 12 kg/m3. Fracturing with the above method, the cumulative gas production per well over 210 days increased by 20%-30%. Through experiment and numerical simulation, Dahl et al.[43] pointed out that injecting small particle size proppants could increase the micro-fracture permeability of shale and enhance production. ...

Computer simulation of hydraulic fractures

1

2007

... The design of hydraulic fracturing relies on theoretical models and calculation methods. The early classic models included mainly PKN, GDK models etc.[45], and later Settari and Palmer et al.[46,47] developed them into a pseudo-three-dimensional model. The model considers the influence of the inter-layer stress difference, but the fracture height equation does not consider the vertical flow and the interlayer mechanical properties. Therefore, when the thin interbed and perforation segments are high-stress layers, the fracture height predicted by this model would have larger error. A full three-dimensional model established by Lee and Carter et al.[48,49] doesn’t use the fracture height equation but obtains the fracture width and the fluid pressure in the fracture by coupling the two-dimensional flow equation of the fluid in the fracture with the three-dimensional linear elastic mechanics model. In addition, the fracture boundary is determined by the stress intensity factor of the discrete grid element to work out the fracture length and height. ...

Three-dimensional simulation of hydraulic fracturing

1

1982