Introduction

Underground gas storage is an important way to store natural gas[1]. Depleted oil and gas reservoirs, aquifers and salt domes are the main types of reservoirs used for underground gas storage[2, 3]. Natural gas storage in saline aquifers is complicated and challenging[4], all aspects of the process should be considered[5]. Parameters affecting the process include flow characteristics of fluid in porous media, gas and water phase behavior, and reservoir conditions throughout the process[6], but they have not been studied thoroughly[7]. Among them, salinity of formation water and temperature of the aquifer may not vary during natural gas storage[8], but gas injection pressure and flow rate are controllable and need further investigation. Sohrabi et al.[9] investigated multiphase flow behavior and gaseous phase sweeping efficiency by injecting methane and water alternately. Pini et al.[10] studied heterogeneity effect on CO2 injection process by performing experiments on high and low permeability cores. They found that gas saturation was high at core entry and reduced through the core length, and gas saturation was much higher at high flow rate in both of the cores. Lorenz and Muller[11] tested nitrogen injection at temperatures below 100 °C. They found that salt precipitation due to gas injection occurred near wells, also retention time and pressure loss during production resulted in more precipitation. Golghanddashti et al.[12] investigated salt precipitation by injecting natural gas into core plug at atmospheric pressure. The results showed that natural gas injection flow rate didn’t affect salt precipitation whereas thermodynamic condition was the main factor affecting the amount of salt precipitation. Torabi and Asghari[13] studied the effect of pressure on immiscible CO2 displacement of oil in porous media by conducting core flood experiment. Oh et al.[14] studied CO2-alternate-water displacement by simulation and experiment. They observed that by enhancing the injection rate, gas saturation at the inlet of the core increased. Peysson et al.[15] injected CO2 into brine saturated core and found gas flow rate had a strong impact on salt precipitation. Sadirli[8] studied natural gas storage in aquifer through numerical simulation.

Obviously, natural gas storage in a low permeability saline aquifer has not been studied through core scale experiments. In this work, core flooding experiment is carried out on a real aquifer limestone core. The aquifer is a gas storage reservoir candidate and located in the center of Iran. The interaction between gas, water and rock in the low permeability aquifer is tested to find out the effects of gas injection rate, pressure and retention time on gas storage capacity.

1. Materials and methods

1.1. Rock sample

At first, 5 limestone cores were gathered from this aquifer. The core was taken from the depth of 1 041.15 m. The aquifer mainly consists of limestone and dolomite with micro-fractures in some sections. The core with the highest permeability and porosity was used in the experiments. The core is 7.62 cm long, 3.81 cm in diameter, 8.32% in porosity, 0.02×10-3 μm2 in permeability, and 7.22 cm3 in pore volume.

1.2. Fluid properties

Synthetic brine used in the experiments was made of various salts according to brine analysis of the aquifer. From measurement, the brine has a density of 1.095 g/cm3 and viscosity of 0.75 mPa·s at the experiment temperature (46 °C). The concentrations of Ca2+, Na+, Mg2+, K+, Cl- and SO42- in the brine were 45.240, 30.270, 1.580, 0.641, 130.820 and 0.400 g/L, respectively, and the TDS (total dissolved solids) was 208.41 g/L. As the salinity of aquifer increases, the possibility of salt precipitation increases, which in turn could lower the gas storage capacity of the reservoir. In our experiments, core sample was washed after every experiment and the same brine was injected into the rock sample in each experiment.

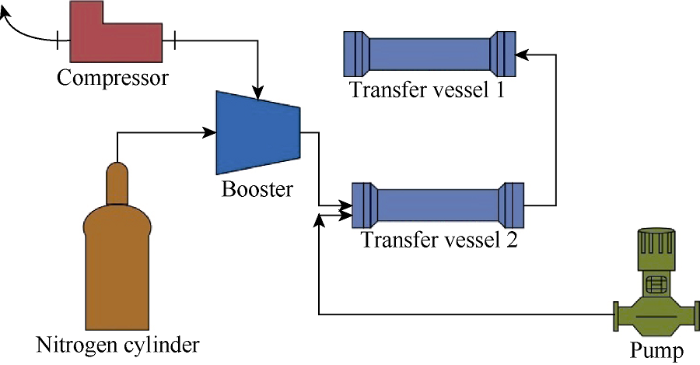

The natural gas used was taken from domestic gas pipe line. In order to gather sufficient amount of gas for the experiments, the natural gas needed to be stored and pressurized in a vessel. As domestic gas has a pressure of about 0.1 MPa, it was pressurized in several steps before storage. At first it passed through compressor and pressurized to 0.35 MPa, and the process was repeated for several times to till the pressure reached 8.0 MPa. The designed setup for gas pressurizing is shown in Fig. 1. Gas phase components were measured by gas chromatography (GC) and TCD detector. The results showed methane makes up about 98.98% of the gas and CO2 about 1.02%.

Fig. 1.

Fig. 1.

Schematic of gas pressurizing setup.

1.3. Experimental setup

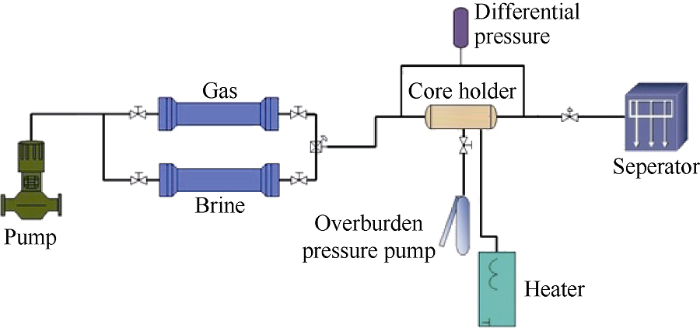

The core flooding setup is shown in Fig. 2. It consists of two transfer vessels, one for brine and the other for gas, a positive displacement pump displaces the fluids in the transfer vessels. The pump operates at a maximum pressure of 35 Mpa and flow rate range between 0.01-30.00 cm3/min. The accuracy of the pump is very important in this process, so it was measured before tests. The core plug was placed inside a stainless steel core holder which can hold cores up to 12 cm long and 3.81 cm in diameter. A back pressure regulator was used to maintain outlet pressure. Two transducers were placed at both ends of the core to measure pressure accurately at core faces. A separator was connected to the outlet line to separate produced liquid and gas. A hydraulic pump was used for applying overburden pressure.

Fig. 2.

Fig. 2.

Schematic of experimental setup for gas storage process.

1.4. Experimental procedure

The experimental procedure is: (1) Rock sample was washed by injecting two pore volumes of methanol then, the core was dried inside the oven at 90 °C for 12 hours and weighed. (2) The dry core was wrapped inside aluminum foil and put in a rubber sleeve then placed inside the core holder and heated to 46 °C. In the course, the gas permeability was measured at 0.09×10-3 μm2. (3) The core plug was vacuumed before saturated by brine. Two pore volumes of the prepared synthetic brine were injected at low rate. (4) The core permeability was measured and core plug was removed and weighted. Then it was put into the core holder for gas injection. (5) The core was pressurized to the desired pressure and natural gas was injected at a constant flow rate till there was no brine produced any more. (6) The core was weighed after the test, and the stored natural gas was calculated with core weight difference before and after the experiment.

The experimental design was based on central composite design (CCD), which is a perfect type of response surface methodology (RSM). In this method, the simultaneous effects of parameters on the process and each other can be investigated by fewer experiments compared with traditional methods. CCD introduces optimum condition in to the operational framework[16]. Even highly coupled processes can be investigated through experimental design[17]. In this study, injection flow rate and pressure were selected and their upper and lower limits were introduced to CCD. These limits are based on the real aquifer operational condition. The flow rate was set between 0.01 and 0.09 cm3/min and pressure was held between 8 and 16 MPa. For each parameter, five values were taken, and 12 experiments in total were carried out. Four experiments were done at the center point (that is, gas injection flow rate of 0.05 cm3/min and pressure of 12 MPa) to lower the errors.

2. Results and discussion

The results of 12 experiments are presented in in Table 1.

Table 1 Results of experiments.

| Experiment No. | Q/ (cm3·min-1) | P/ MPa | Storage volume/cm3 | Percentage of gas storage volume to pore volume/% |

|---|---|---|---|---|

| 1 | 0.03 | 10 | 1.125 | 15.58 |

| 2 | 0.07 | 10 | 1.152 | 15.94 |

| 3 | 0.03 | 14 | 1.367 | 18.94 |

| 4 | 0.07 | 14 | 1.502 | 20.79 |

| 5 | 0.01 | 12 | 0.838 | 11.6 |

| 6 | 0.09 | 12 | 1.261 | 17.47 |

| 7 | 0.05 | 8 | 0.417 | 5.78 |

| 8 | 0.05 | 16 | 0.913 | 12.64 |

| 9 | 0.05 | 12 | 0.470 | 6.51 |

| 10 | 0.05 | 12 | 0.507 | 7.02 |

| 11 | 0.05 | 12 | 0.500 | 6.92 |

| 12 | 0.05 | 12 | 0.552 | 7.64 |

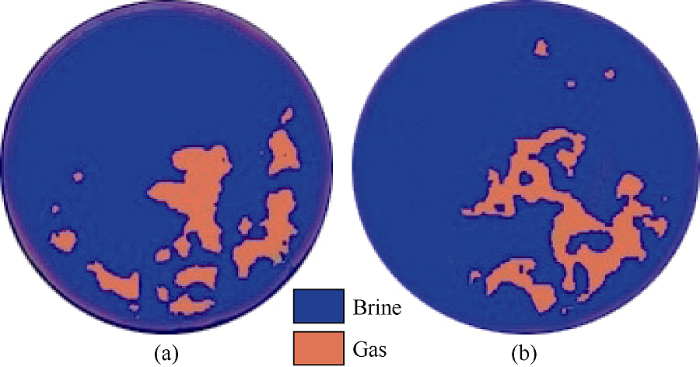

The actual operation of gas storage shows retention time can affect the gas storage process. Therefore, the effect of time on gas storage process was studied by two experiments, one of 1 day and the other 5 days long. These experiments had nearly the same results, so the rest of experiments were all done in 1 day. Fig. 3 shows cross sections of the middle part of the core plug extracted from CT scan analysis. Table 2 shows the results of the 1-day and 5-day long experiments. From Fig. 3 and Table 2, there are few differences between two experiments, so the gas storage time is designed by 1 day in 12 experiments in Table 1.

Fig. 3.

Fig. 3.

CT scan cross sections of middle part of the core (a) 1 day, (b) 5 days.

Table 2 Results of 1-day and 5-day long experiments.

| Retention time/d | Q/ (cm3·min-1) | P/ MPa | Stored gas/cm3 | Recovered gas/cm3 |

|---|---|---|---|---|

| 1 | 0.05 | 16 | 0.913 | 0.867 |

| 5 | 0.05 | 16 | 0.987 | 0.926 |

2.1. Effect of injection rate

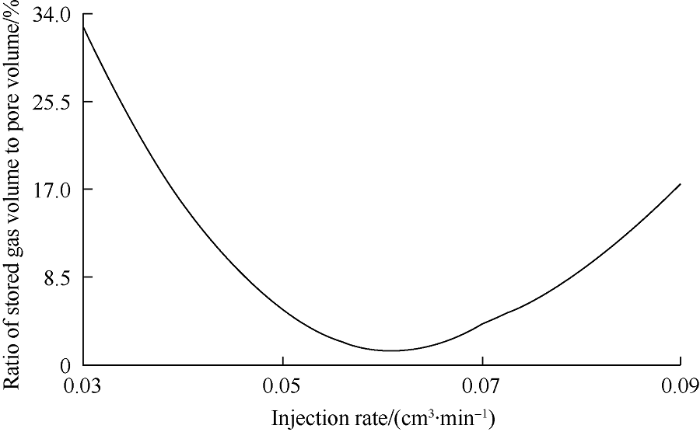

The effect of injection rate on storage is shown in Fig. 4. It can be seen from the figure that when the injection rate is low, the gas storage capacity decreases with the rise of injection rate, but when the injection rate is high, the gas storage capacity increases with the rise of injection rate. It is expected to have an ascending trend at even higher flow rate, but the applicability of different types of rock to high flow rate should be considered[18]. The process of gas injection in this core was under capillary control. The calculated values of capillary number (Nc) for these experiments were around 10-10-10-11, therefore, capillary pressure is the major force driving flow of natural gas-water. Also Reynolds number of the experiments ranged from 0.049 to 0.117, indicating there were Darcy flow in all the experiments.

Fig. 4.

Fig. 4.

Stored gas volume vs. flow rate at the pressure of 12 MPa.

2.2. Effect of pressure

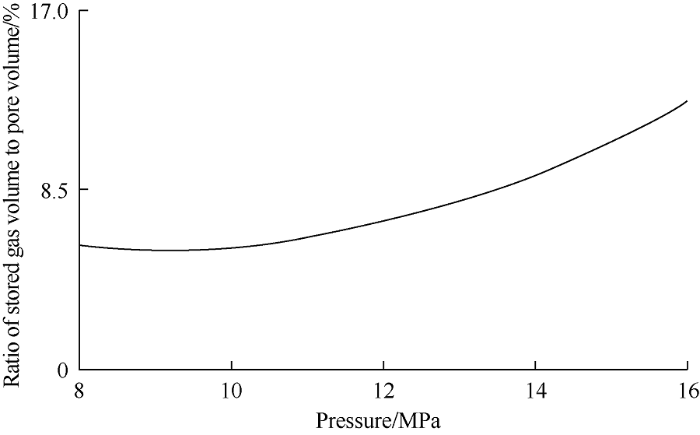

Pressure plays a major role in behaviors of multi-phase systems flow including gas[13]. Here, gas and water act as immiscible phase displacement. Increase of pressure would make the gas density and viscosity rise, so the displacing phase performance would improve. Fig. 5 shows that gas storage capacity increases significantly with the rise of pressure. As shown in the figure, by increasing pressure from 8 to 16 MPa, gas saturation in the core goes up from 5.78% to 12.64%.

Fig. 5.

Fig. 5.

Relationship between stored gas volume and pressure at gas injection rate of 0.05 cm3/min.

2.3. Statistical analysis

Statistical approach was adopted to figure out the effects of gas injection rate and pressure on gas storage capacity and their interaction. It should be noted that experiment no.5 was ignored in the statistics because the p-value of the model was not acceptable. A cubic model for gas storage percentage (S) was obtained through analysis of variance (ANOVA) (see equation (1)). This analysis predicted model results by 95% confidence and implied p-values < 0.05 as significant terms[19]. The model R2 (complex correlation coefficient) is 0.998, confirming the model is reliable. The other statistical index is F value. F value represents the importance of a parameter[20]. Table 3 shows ANOVA of the model. It can be seen from the table P-value of this model is 0.000 5, which confirms the model significance with 95% confidence. Injection rate and pressure are two important parameters, which have P-values of less than 0.05 (0.000 1 and 0.001 9, respectively). The injection rate has a F-value of 657.09, indicating it is more important than pressure with F-value of 107.86. The term AB stands for the interaction of the injection rate and pressure and its P-value (0.209 0) shows there is no significant correlation between them.

Table 3 ANOVA for the gas storage capacity results.

| Source | Sum of squares | Degree of freedom | Mean square | F-value | P-value |

|---|---|---|---|---|---|

| Model | 320.94 | 7 | 45.85 | 210.16 | 0.000 5 |

| A: Flow rate | 143.35 | 1 | 143.35 | 657.09 | 0.000 1 |

| B: Pressure | 23.53 | 1 | 23.53 | 107.86 | 0.001 9 |

| AB | 0.56 | 1 | 0.56 | 2.54 | 0.209 0 |

| A2 | 248.70 | 1 | 248.70 | 1 140.01 | <0.000 1 |

| B2 | 6.38 | 1 | 6.38 | 29.25 | 0.012 4 |

| A2B | 0.30 | 1 | 0.30 | 1.39 | 0.323 1 |

| AB2 | 133.39 | 1 | 133.39 | 611.46 | 0.000 1 |

| A3 | 0.000 | 0 | 0 | ||

| B3 | 0.000 | 0 | 0 | ||

| Pure error | 0.65 | 3 | 0.22 | ||

| Total dispersion | 321.59 | 10 |

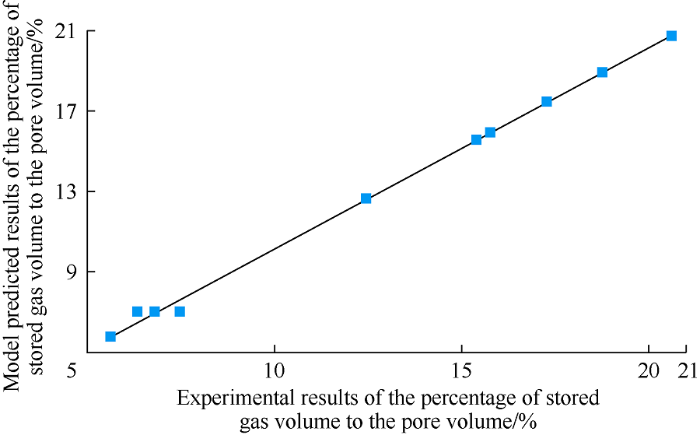

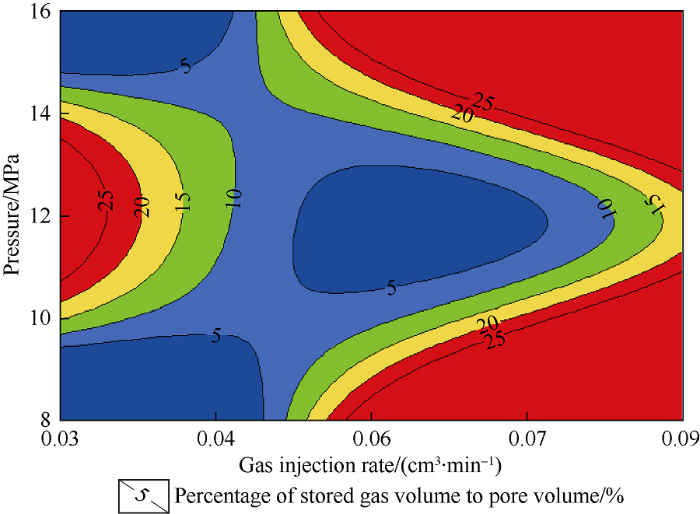

Fig. 6 shows that the predicted results by the model are in good agreement with the experimental results. Fig. 7 shows that pressure has less impact on gas storage capacity than flow rate. This shows that the gas storage capacity is mainly affected by gas injection rate, which is consistent with the results of variance analysis.

Fig. 6.

Fig. 6.

Model prediction results and experimental results of the percentage of stored gas volume to the pore volume.

Fig. 7.

Fig. 7.

Contour diagram of percentage of stored gas volume to pore volume at different gas injection rates and pressures.

The optimum condition for obtaining maximum gas storage capacity was sorted out by using ANOVA, namely the flow rate of 0.07 cm3/min and pressure of 14.354 MPa. A confirmation experiment was done under the optimum condition, the stored gas volume predicted by the model was 27.66% and the experimental value was 21.32%, which are in good agreement with each other.

2.4. Effect of retention time

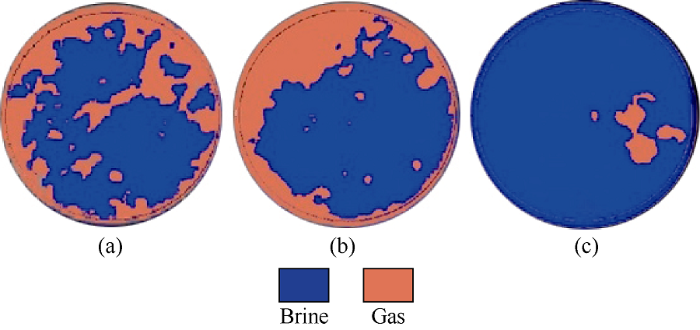

Two experiments (1 day and 60 days, respectively) were performed to find out the effect of retention time on storage process under the optimum condition (0.07 cm3/min and 14.354 MPa). The interaction between water and gas lasted for 6 months in field scale operation[21], but experiments were done in shorter periods due to limitations of experimental study. Gas was injected into the core under the optimal condition. The gas storage volume to pore volume measured was 18.93% and the residual gas saturation was about 13.07%. This shows retention time affects storage process significantly. In fact, much of the stored gas is trapped during the process and about 6% can be recovered. This is one of the consequences of gas contacting with water inside the porous medium. In aquifer gas storage reservoirs, the stored gas can flow more easily than water due to lower gravity than water. The displacement is taking place in a heterogeneous porous medium, and as a result, the water and gas can’t separate normally. There is usually trapped gas in water-bearing gas storage. Previous researchers have also found low recovery of aquifer gas storage reservoirs[22]. Therefore, this issue needs to be considered when selecting gas storage reservoirs.In order to investigate the interactions between rock and fluids, CT scanning, atomic absorption spectroscopy and gas chromatography were done on core plug and the fluid. Fig. 8 shows the inlet, middle and outlet cross sections of the core after 60 days. It can be seen clearly in the picture that at higher flow rate, the pressure difference between inlet and outlet of the core increases and may overcome capillary force in smaller pores, resulting in higher gas saturation at high flow rate. Also pressure drops and the saturation of gas gets small along the core’s length.

Fig. 8.

Fig. 8.

CT scan cross sections of core (a) inlet, (b) middle, (c) outlet.

In order to figure out the effect of gas storage on brine, atomic absorption spectroscopy (AAS) analysis was done on a Shimadzu aa-670 device. It can be seen from Table 4 that the concentrations of all of the ions increased in the produced brine, thus the salinity of produced water is higher than that of injected water. Water evaporation during gas injection may lead to over saturation and precipitation of salt in the solution[23]. The drying effect is also common in gas injection/producing wells, which causes salt precipitation in water and reduction of rock permeability and well injectivity[24].

Table 4 Ion concentrations of injected and produced brine.

| Ion | Injected brine/ (mg•L-1) | Produced brine/ (mg•L-1) | Change rate/% |

|---|---|---|---|

| Ca2+ | 45240 | 49390 | 9.17 |

| Na+ | 30270 | 38413 | 26.90 |

| Mg2+ | 1580 | 1795 | 13.61 |

| K+ | 641 | 710 | 10.76 |

Gas chromatography (GC) analysis was done to find out gas composition variation during the storage process. Gas samples after 1 and 60 days were gathered for GC analysis. The injected gas is mainly methane including a small amount of CO2. Methane is insoluble in water whereas CO2 tends to dissolve and interact with water. It can be seen from Table 5 that dissolution of CO2 leads to rise of methane concentration in the produced gas, and this effect gets stronger as time goes on.

Table 5 Results of GC analysis.

| Component | Injected/% | 1st day/% | 60th day/% |

|---|---|---|---|

| Methane | 98.98 | 99.06 | 99.85 |

| CO2 | 1.02 | 0.94 | 0.15 |

In reservoir scale operation much attention should be paid to petrophysical properties of the aquifer. Existence of fractures in the reservoir will affect gas and brine migration. Also reservoir pressure limitations and cap rock failure strength should be considered. In real operation, the retention time is longer and there may be more gas-water-rock interactions, but as natural gas does not take part in any major chemical reaction, the gas-water-rock interactions will not be as great as carbon dioxide storage process.

3. Conclusions

This study investigated the interactions between rock and fluids and parameters affecting natural gas storage capacity in saline aquifers. First, injection rate and pressure, two main parameters controlling gas storage capacity were examined. It is found that higher injection rate and pressure can enhance the gas storage capacity, and the injection rate has a stronger impact on gas storage capacity than pressure. After two months of storage, the gas recovery rate low, showing the retention effect after long storage. The atomic adsorption spectrum analysis shows drying effect occurs when natural gas is injected into brine-saturated core, so during long term gas storage, the interactions between rock and fluid should be considered. Gas chromatography analysis shows after storage in core, the concentration of CO2 in the natural gas reduces while that of methane increases. Petrophysical characteristics and lithology of the reservoir should be considered when selecting an aquifer as and during injection/withdrawal cycles of gas storage.

Reference

Natural gas storage engineering

Natural gas engineering: Production and storage. New York:

Potential capacity of gas storage caverns in rock salt bedded deposits in Poland

DOI:10.1016/j.jngse.2017.03.028

URL

[Cited within: 1]

The subject of this article is an estimation of the initial capacity of a gas storage cavern, depending on the thickness and the depth of a bedded salt deposit, and the cavern's capacity decrease in time due to its convergence. It was assumed that the relative rate of convergence depends on the depth, the range of the storage pressure and the cavern diameter to height ratio. The discussion will consider the shape of the cavern and the pressure range of natural gas storage. Also, potential locations in Poland for natural gas storage in bedded rock salt deposits in terms of geological and mining criteria are presented in this article. Based on Zechstein isopach maps, as well as maps of its top depth, potential storage capacity maps per unit area were developed. Presented examples will cover two potential regions i.e., bedded salt deposit in the Zatoka Gda艅ska region and Fore-Sudetic Monocline. These maps will be the basis for the analysis of the suitability of the bedded rock salt Zechstein deposit for natural gas storage.

Pressure transients to characterize cavities dissolved for natural gas storage

DOI:10.1016/j.jngse.2016.03.082

URL

[Cited within: 1]

61Characteristics of pressure wave inside a submerged pipe significantly change responding to its boundary conditions.61They include diameter of a conduit containing the pipe and an interface between contrasting fluids in the conduit.61Pressure transient can be a useful tool for characterization of subsurface structures.

Tightness and suitability evaluation of abandoned salt caverns served as hydrocarbon energies storage under adverse geological conditions (AGC)

DOI:10.1016/j.apenergy.2016.06.086

URL

[Cited within: 1]

in China, the storage of hydrocarbon energies is extremely insufficient partially due to the lack of storage space, but on the other side the existence of a large number of abandoned salt caverns poses a serious threat to safety and geological environments. Some of these caverns, defined as abandoned caverns under adverse geological conditions (AGC), are expected to store hydrocarbon energies (natural gas or crude oil) to reduce the risk of potential disasters and simultaneously support the national strategic energy reserve of China. Herein, a series of investigations primarily related to the tightness and suitability of the caverns under AGC is performed. Laboratory measurements to determine the physical and mechanical properties as well as porosity and permeability of bedded salt cores from a near target cavern are implemented to determine the petro-mechanical properties and basic parameters for further study. The results show that the mechanical properties of the bedded rock salts are satisfactory for the stability of caverns. The interface between the salt and interlayers exhibits mechanical properties that are between those of rock salt and interlayers and in particular is not a weak zone. The silty mudstone interlayers have relatively high porosity and permeability, likely due to their low content of clay minerals and the presence of halite-filled cracks. The conditions for evaluating the tightness and suitability of a cavern for storing hydrocarbons are proposed, including “No tensile stress,” “Factor of Safety” and “A threshold of leakage amount”. Three-dimensional numerical geomechanical models are developed to indicate how gas seepage evolves around the caverns. The results show that the permeability of the interlayers is a key factor in influencing gas seepage in the vicinity of the caverns and that interlayers form primary channels for gas migration. By evaluating the fluid seepage around the cavern by the above conditions, the upper-threshold permeability of the interlayers is suggested to be no more than 10-1665 10-17m2to guarantee tightness when storing natural gas and no more than 10-16m2when storing oil. In principle, this work provides references for alternate uses of abandoned caverns for hydrocarbon storage under adverse geological conditions.

Using underground gas storage to replace the swing capacity of the giant natural gas field of Groningen in the Netherlands: A reservoir performance feasibility study

DOI:10.1016/j.petrol.2016.03.010

URL

[Cited within: 1]

61We estimate reservoir performance of natural gas reservoirs in onshore Netherlands.61We identify 72 best candidates with a total working volume of 122±30 billion Sm3.61Current UGS (Norg & Grijpskerk) yield amongst lowest working:cushion volume ratios.61UGS will have to compete with cheaper pipelines and liquefied natural gas imports.61We recognized 19 most economically favorable candidates with wv:cv ratios >0.9.

Study on fluids flow characteristics of water-gas mutual flooding in sandstone underground gas storage with edge water.

Simulation and investigation of effective parameters in aquifer gas storage.

Visualization of oil recovery by water-alternating-gas injection using high-pressure micromodels

DOI:10.1109/ELECO.2013.6713897

URL

[Cited within: 1]

Keratoconus is an eye disease characterized by progressive thinning of cornea which is the front based transparent layer of the eye. In other words, it is a progressive distortion of corneal layer and at least getting conical shape that should be like a dome camber. The vision reduces more and more while cornea gets shape of cone which should be like a sphere normally. The aim of this study is to define a new classification method for detecting keratoconus based on statistical analysis and to realize the prediction of these classified data with intelligent systems. 301 eyes of 159 patients and 394 eyes of 265 refractive surgery candidates as the control group have been used for this study. Factor analysis, one of the multivariate statistical techniques, has been mainly used to find more meaningful, easy to understand, and independent factors amongst the others. Later, a new classification method has been defined using clustering analysis techniques on these factors and finally estimated by using artificial neural networks and support vector machines.

Modelling of halite formation in natural gas storage aquifers

Effect of operating pressure, matrix permeability and connate water saturation on performance of CO2, huff-and-puff process in matrix-fracture experimental model

DOI:10.1016/j.fuel.2010.05.020

URL

[Cited within: 2]

The main objective of study is to examine the performance and efficiency of CO huff-and-puff process for improving oil recovery and subsequent storage of CO in light-oil fractured porous media through designing and conducting targeted experiments.The experimental set-up consisted of a high-pressure stainless steel cell made specially to hold a cylindrical core with spacing around it, simulating a matrix and its surrounding fracture environment. The matrix was saturated with normal decane, which was used as oil during the experiments. A total of six separate sets of huff-and-puff experiments, using CO as solvent, were conducted under operating pressures of 250, 500, 750, 1000, 1250, and 1500 psi. The temperature was kept constant (35 掳C) during all tests. Each set of the huff-and-puff experiments was conducted by injecting CO in the fracture system surrounding the core (injection step). Then, the system was shut-in for a period of 24 h to allow CO to diffuse from fracture into the oil in matrix (soaking period step). At the end of the soaking period, the pressure was released and the oil production was measured (production step). The above cycle was repeated until no more oil was produced.The results obtained show that when CO was injected at 1500 psi through a huff-and-puff process, it recovers more than 95% of oil from a fracture-matrix experimental model saturated with normal decane. Also indicates that at such a pressure, 45% of initial oil-in-place can be recovered during the first cycle. However, when CO was injected at pressures below CO minimum miscibility pressure (MMP), the maximum recovery factor achieved was less than 50%. Similarly, recovery factor of the first cycles performed at pressures below MMP were much lower (less than 30%) compare to those conducted at miscible condition. This indicates that miscible huff-and-puff process is a viable option for fractured porous media.As part of this study, effects of matrix permeability, and connate water saturation on the performance of huff-and-puff process in fracture-matrix core set-up at both immiscible and miscible conditions were studied. Results indicate that presence of connate water saturation is beneficial to immiscible CO huff-and-puff process while it has almost negligible effect on the performance of this process when performed at miscible conditions. In presence of connate water saturation more than 70% of oil-in-place was recovered at immiscible condition compare to a maximum of 45% recovered when matrix was 100% saturated with normal decane. Results of the tests performed in a core with permeability about 10 times higher than the original core shows similar production trends. However, recovery factor in the high permeable core was slightly less than twice of that in low permeable core at immiscible condition. According to this study, effect of core permeability was less pronounced when CO was injected at miscible conditions.

Experimental and numerical study on supercritical CO2/brine transport in a fractured rock: Implications of mass transfer, capillary pressure and storage capacity

DOI:10.1016/j.advwatres.2013.03.007

URL

[Cited within: 1]

This study presents the impact of fractures on CO2 transport, capillary pressure and storage capacity by conducting both experimental and numerical studies. A series of laboratory experiment tests was designed with both a homogeneous and a fractured core under CO2 storage conditions. The experimental results reveal a piston-like brine displacement with gravity override effects in the homogeneous core regardless of CO2 injection rates. In the fractured core, however, two distinctive types of brine displacements were observed; one showing brine displacement only in the fracture whereas the other shows brine displacement both in the fracture and matrix with different rates, which were dependent on the magnitude of the pressure build-up in the matrix. The injectivity in the fractured core was twice of the homogeneous core, while the amount of calculated CO2 in the homogeneous core was over 1.5 times greater than the fractured core. Salt precipitation, which is likely to occur near injection wells, was observed in the experiments; X-ray images enabled the observation of salt-precipitation during CO2-flooding tests. Finally, numerical simulations predict free-phase CO2 transfer between fracture and matrix in a fracture-matrix system. Pressure gradients between the fracture and matrix enforced CO2 to transfer from the fracture into matrix at the front of the CO2 plume, whereas, the reversal of pressure gradients at the rear zone of the CO2 plume reversed the transfer process. The variation of CO2 saturation within the fracture was caused by fracture aperture variations, and local variations of fracture permeability control the free-phase CO2 transfer between the fracture and matrix.

Well injectivity during CO2, storage operations in deep saline aquifers: Part 1: Experimental investigation of drying effects, salt precipitation and capillary forces

DOI:10.1016/j.ijggc.2013.10.031

URL

[Cited within: 1]

Carbon Capture and Storage (CCS) is a technique than can potentially limit the accumulation of greenhouse gases in the atmosphere. Well injectivity issues are of importance for CCS because the gas injection rate must be maintained at a high level (a million tonnes of CO2 per year and per site) during the industrial operation period (30鈥40 years). The risk of altered permeability must therefore be determined in order to guarantee the sustainability and the security of the CO2 geological storage. Injection of dry gas in deep saline aquifers might lead to near wellbore drying and salt precipitation. The solid salt might then reduce the rock permeability by clogging pores or by pore throat restriction. The objective of this paper is to present new experimental results on the drying of rocks induced by continuous injection of large amount of dry gas (N2). The main goal of the study was to understand and model the physical processes that govern the decrease in water saturation in reservoir rocks. Two types of sandstone were used to study slow and fast drying rates and capillary effects on drying. The experimental results evince the main physical parameters that control the key mechanisms. In a companion paper in this issue (Andr茅 et al., 2013), we show that the continuous approach in the context of a compositional two-phase flow model can fairly well predict the saturation evolution in the near wellbore and the alteration in permeability due to salt precipitation.

Design of experiments for engineers and scientists

The tools and technique used in the Design of Experiments (DOE) have been proved successful in meeting the challenge of continuous improvement over the last 15 years. However, research has shown that applications of these techniques in small and medium-sized manufacturing companies are limited due to a lack of statistical knowledge required for their effective implementation. Although many books have been written in this subject, they are mainly by statisticians, for statisticians and not appropriate for engineers.overcomes the problem of statistics by taking a unique approach using graphical tools. The same outcomes and conclusions are reached as by those using statistical methods and readers will find the concepts in this book both familiar and easy to understand. The book treats Planning, Communication, Engineering, Teamwork and Statistical Skills in separate chapters and then combines these skills through the use of many industrial case studies. Design of Experiments forms part of the suite of tools used in Six Sigma.Key features:* Provides essential DOE techniques for process improvement initiatives* Introduces simple graphical techniques as an alternative to advanced statistical methods 聳 reducing time taken to design and develop prototypes, reducing time to reach the market* Case studies place DOE techniques in the context of different industry sectors* An excellent resource for the Six Sigma training programThis book will be useful to engineers and scientists from all disciplines tackling all kinds of manufacturing, product and process quality problems and will be an ideal resource for students of this topic.is Senior Teaching Fellow at the International Manufacturing Unit at Warwick University. He is also a trainer and consultant in DOE and has worked as such for a number of companies including Motorola, Vickers, Procter and Gamble, Nokia, Bosch and a large number of SMEs. * Provides essential DOE techniques for process improvement initiatives* Introduces simple graphical techniques as an alternative to advanced statistical methods - reducing time taken to design and conduct tests* Case studies place DOE techniques in the context of different industry sectors

Design of experiments in chemical engineering: A practical guide

DOI:10.1002/3527604162

URL

[Cited within: 1]

While existing books related to DOE are focused either on process or mixture factors or analyze specific tools from DOE science, this text is structured both horizontally and vertically, covering the three most common objectives of any experimental research: * screening designs * mathematical modeling, and * optimization. Written in a simple and lively manner and backed by current chemical product studies from all around the world, the book elucidates basic concepts of statistical methods, experiment design and optimization techniques as applied to chemistry and chemical engineering. Throughout, the focus is on unifying the theory and methodology of optimization with well-known statistical and experimental methods. The author draws on his own experience in research and development, resulting in a work that will assist students, scientists and engineers in using the concepts covered here in seeking optimum conditions for a chemical system or process. With 441 tables, 250 diagrams, as well as 200 examples drawn from current chemical product studies, this is an invaluable and convenient source of information for all those involved in process optimization.

Geologic carbon storage is unlikely to trigger large earthquakes and reactivate faults through which CO2 could leak

DOI:10.1073/pnas.1413284112

URL

PMID:25902501

[Cited within: 1]

Zoback and Gorelick [(2012) Proc Natl Acad Sci USA 109(26):10164-10168] have claimed that geologic carbon storage in deep saline formations is very likely to trigger large induced seismicity, which may damage the caprock and ruin the objective of keeping CO2 stored deep underground. We argue that felt induced earthquakes due to geologic CO2 storage are unlikely because (i) sedimentary formations, which are softer than the crystalline basement, are rarely critically stressed; (ii) the least stable situation occurs at the beginning of injection, which makes it easy to control; (iii) CO2 dissolution into brine may help in reducing overpressure; and (iv) CO2 will not flow across the caprock because of capillarity, but brine will, which will reduce overpressure further. The latter two mechanisms ensure that overpressures caused by CO2 injection will dissipate in a moderate time after injection stops, hindering the occurrence of postinjection induced seismicity. Furthermore, even if microseismicity were induced, CO2 leakage through fault reactivation would be unlikely because the high clay content of caprocks ensures a reduced permeability and increased entry pressure along the localized deformation zone. For these reasons, we contend that properly sited and managed geologic carbon storage in deep saline formations remains a safe option to mitigate anthropogenic climate change.

Cr and Ni recovery during bioleaching of dewatered metal-plating sludge using Acidithiobacillus ferrooxidans

DOI:10.1016/j.biortech.2014.05.107

URL

PMID:24971945

[Cited within: 1]

This study determined the optimal conditions required to attain maximum metal recovery in the bioleaching process of dewatered metal-plating sludge using Acidithiobacillus ferrooxidans (A. ferrooxidans). Adaptation of this strain was carried up to 1% (w/v) of the sample. Three factors including initial pH, initial Fe3+ concentration and pulp density were selected as the effective factors and were optimized using a central composite design of response surface methodology. An initial pH of 1, pulp density of 9g/l and initial Fe3+ concentration of 1g/l were determined to be optimum values by the statistical models. The highest extractions for Cr and Ni under optimal conditions were 55.6% and 58.2%, respectively. Bioleaching kinetics was investigated using a modified shrinking core model to better understand the mechanism of the leaching reaction. The model predictions indicate that the diffusion step controlled the overall dissolution kinetics and is the rate controlling step.

Comparison of submerged and solid state fermentation systems effects on the catalytic activity of Bacillus, sp. KR-8104 α-amylase at different pH and temperatures

Geological storage: Underground gas storage.

Salt precipitation due to supercritical gas injection: I. Capillary-driven flow in unimodal sandstone

DOI:10.1016/j.ijggc.2015.01.005

URL

[Cited within: 1]

Drying and salt precipitation in geological formations can have serious consequences for upstream operations in terms of injectivity and productivity. Here we investigate the consequences of supercritical CO2 injection in sandstones. The reported findings are directly relevant for CO2 sequestration and acid as injection operations, but might also be of interest to a broader community dealing with drying and capillary phenomena. By injecting dry supercritical CO2 into brine-saturated sandstone, we investigate the drying process and the associated precipitation of salts in a capillary-pressure-dominated flow regime. Precipitation patterns were recorded during the drying process by means of 渭CT scanning. The experimental results and numerical simulations show that under a critical flow rate salt precipitates with an inhomogeneous spatial distribution because of brine and solutes being transported in counter-current flow upstream where salt eventually precipitates. A substantial impairment of the absolute permeability has been found, but despite high local salt accumulation, the effective CO2 permeability increased during all experiments. This phenomenon is a result of the observed microscopic precipitation pattern and eventually the resulting K() relationship. The findings in this paper are related to unimodal sandstone. In a companion paper (Ott et al., 2014) we present data on the distinctly different consequences of salt precipitation in dual- or multi-porosity rocks.

Evaluation of water evaporation and salt precipitation due to flow in gas reservoirs.