Introduction

Polymer flooding technology has been widely used as a way to enhance oil recovery, and achieved good results in increasing oil production and decreasing water cut[1,2,3,4,5]. But for strongly heterogeneous reservoirs, the development effect of polymer flooding becomes worse in the late stage. This is because the reservoir heterogeneity and polymer retention characteristic can cause “entry profile inversion”, not favorable for enhancing the producing degree of low permeability layers and further expanding the swept volume, consequently, the contradiction between layers would become more serious, and the development effect of polymer flooding become worse[6,7]. To solve this problem, Wu Xingcai et al.[8,9] proposed synchronous diversion-flooding EOR theory and method. In this method, a new particle-type polymer SMG (Soft Microgel), a type of dispersive system in water, is used as displacing phase, to adjust the permeability of different parts of reservoir, improve sweep efficiency and enhance oil recovery by working jointly with water. After entering into porous media, the SMG particles would plug large pores while leave small ones open”. In order to qualitatively and quantitatively analyze this characteristic of SMG, and compare the oil displacement mechanisms of continuous and dispersed phase flooding agents, the particle phase separation of SMG was modeled by using microfluidic technology. Theoretically guided by the tree fork concentration distribution of red blood cells in biological fluid mechanics, the concentration distribution mathematical model of SMG dispersion in different pores was established. On this basis, the micro and macro physical simulation experiments of continuous and dispersed phase flooding agents were carried out to compare their performances. Furthermore, these were verified by field test.

1. Comparison of micro oil displacement mechanisms of continuous and dispersed phase flooding agents

1.1. Particle phase separation of SMG

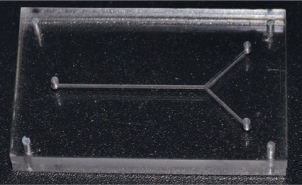

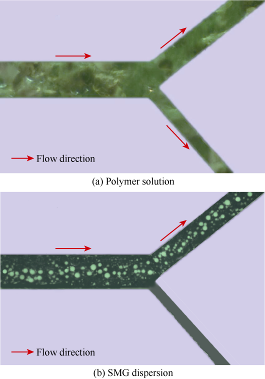

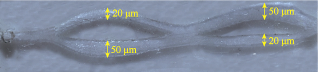

Polymer solution is a high viscosity fluid prepared by adding water-soluble polymer into water and is a continuous phase flooding agent. In contrast, SMG dispersion fluid is made up of SMG particles and carrier fluid (water), and is a dispersed phase flooding agent. Based on the shear diffusion principle and Fahraeus-Lindqvist effect of blood cells, the microfluidic technology (Lab on a chip) can be used to separate blood plasma and blood cells[10,11,12,13]. Therefore, according to the same principle, the migration characteristics of continuous and dispersed phase flooding agents in different sizes of pores were observed by the microfluidic technology in this study. The visual microfluidic chip is shown in Fig. 1. The dynamic images of polymer solution and SMG dispersion in microfluidic chip are shown in Fig. 2.

Fig. 1.

Fig. 1.

Visual microfluidic chip.

Fig. 2.

Fig. 2.

Microfluidic experiment of continuous and dispersed phase flooding agents.

When the polymer molecular coil is less than 1 μm in diameter, the concentration of polymer solution entering into pores of different sizes is the same due to the action of Brown force. When larger than 1 μm, the SMG particles would likely to deform elastically after hydration expansion under the effect of shear stress, and are prone to gather in the axis of the pore. Carried by fluid, they would enter large pores with low resistance and high flow velocity preferentially, while the carrier fluid would enter small pores with low flow velocity, which results in the particle phase separation phenomenon of SMG[14,15]. The above phenomena can be observed from Fig. 2.

There are obvious differences between the migration of continuous and dispersed phase flooding agents in pores of different sizes. The continuous phase flooding agent enters pores of different sizes evenly. While due to the particle phase separation, the SMG particles gather in the larger pores to form bridge block, and the carrier fluid displace oil in the small pores, so comes the feature of “plugging large pores without plugging small ones”. This is also the primary cause for the different effects of the two agents on the “entry profile inversion”.

1.2. Mathematical model of SMG concentration distribution

In order to analyze the plugging properties of SMG from a quantitative perspective, the tree fork concentration distribution expression of red blood cells in biological fluid mechanics was introduced and modified to establish the concentration distribution mathematical model of SMG dispersion in pores of different sizes.

Assume that a large pore has N exits, and the shunt volume of each exit is given as follows:

Based on the mass conservation law, the following formulae are obtained:

In biological fluid mechanics, there are many empirical equations describing the particle phase separation of red blood cells in the blood flow process. And the concentration calculation method of red blood cells in different pores is given. Thus the tree fork concentration distribution expression of red blood cells was introduced and modified[16,17] to get the particle concentration of SMG in each exit:

If the particle concentration yi=0, then the corresponding shunt volume xi is defined as the critical shunt volume xi*. According to the formula (4), if the outlet shunt volume xi≤xi*, then the corresponding particle concentration yi=0. Otherwise, if the outlet shunt volume xi>1-xi*, then the formula (3) is no longer satisfied. Therefore, the formula needs to be further modified, and the expression of SMG particle concentration distribution is given as follows:

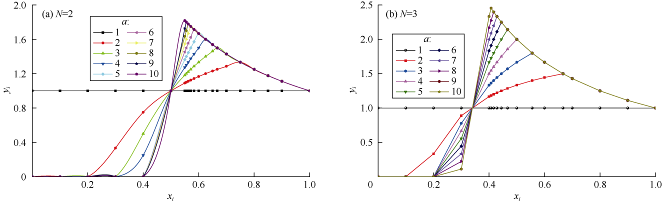

When N=2 and N=3, the relationship between particle concentration of SMG and fluid shunt volume is calculated according to the formula (5), which is shown in Fig. 3. It can be seen that from the figure the parameter a in the formula (5) has a great impact on the particle concentration distribution of SMG in different pores. The larger the particle size, and the larger the a, the larger the shear stress effect exerting on SMG and the higher the particle phase separation degree will be. On the contrary, when a =1, the polymer concentration in different pores is equal to the average concentration. That is the uniformly distribution of polymer concentration in pores of different sizes. Taking N=2 for example (Fig. 3a), the critical shunt volume xi* gets larger with the increase of the parameter a, namely the intersection point between the curve and the horizontal axis moves right. If xi≤xi*, then yi=0, namely no particles enter the pores; if xi<0.5, then the particle concentration in the pores is smaller than the average concentration; if xi=0.5, then the particle concentration is equal to the average concentration; if xi>0.5, the particle concentration entering pores is larger than the average concentration.

Fig. 3.

Fig. 3.

Particle concentration vs shunt volume.

1.3. Fluid diversion mechanism of SMG

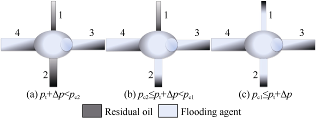

In order to further analyze the oil displacement mechanism of SMG dispersion, the conceptual model of pore throat structure was built, which is shown in Fig. 4. The additional pressure generated by SMG particles plugging at pore throat and the displacement pressure work jointly to divert the fluid flow, so the residual oil in the small capillary tubes can be displaced. When the pressure rises to a certain value, the SMG particles start to deform and move forward after passing this throat[18,19,20,21].

Fig. 4.

Fig. 4.

Schematic diagram of SMG plugging.

As shown in Fig. 4, SMG particles preferentially move along the direction with the minimum resistance, so they first enter the capillary tube 4, then the capillary tube 3 and generates a blocking effect, which makes the fluid divert. The SMG works at the inlet of capillary tube 3 to generate an additional pressure with the maximum value of pt. When the additional pressure is larger than pt, SMG will deform elastically, and continue to migrate through the capillary tube 3. During the process, the displacement pressure and additional pressure act jointly on the pore throat model to facilitate fluid diversion, which is beneficial for the displacement of residual oil in capillary tube 1 and 2.

The critical condition for the displacement of residual oil in capillary tube 2 is as follows:

The critical condition for initiating displacement of residual oil in capillary tube 1 and 2 is as follows:

When pt+Δp<pc2, that is the combined force of displacement pressure and additional pressure is less than the capillary force of pc2, the flooding fluid will not enter the capillary tube 2 and the residual oil in the capillary tube 1 cannot be displaced either. The residual oil pattern is shown in Fig. 4a.

When pc2≤pt+Δp<pc1, the combined force of displacement pressure and additional pressure is larger than the capillary force pc2. But it is smaller than the capillary force pc1. Thus the flooding fluid can enter the capillary tube 2. But the residual oil in the capillary tube 1 still cannot be displaced. The residual oil pattern is shown in Fig. 4b.

When pc1≤pt+Δp, the combined force of displacement pressure and additional pressure is larger than the capillary force pc1. The flooding fluid can enter the capillary tube 1 and 2 to displace the residual oil. The residual oil pattern is shown in Fig. 4c.

It is difficult for the traditional polymer solution to distinguish high and low permeability layers. And due to the adsorption and mechanical trapping, the retention amount of polymer solution in medium and low permeability layers increases, which would make the starting pressure gradient of medium and low permeability layers rise, and the increase magnitude of medium-low permeability layers is much larger than that of high permeability layers. Consequently, subsequent injection into medium-low permeability layers would become more difficult, while the water absorption amount of the high permeability layer would increase, causing serious “entry profile inversion”. However, this phenomenon will not occur during the SMG injection. Due to the properties of “plugging large pores but not the small ones”, SMG particles can preferentially enter high permeability layers and large pores. In the course of migration, the SMG particles expand and effectively plug the larger pores, forcing the subsequent flooding fluid to turn into the low permeability layers to displace the residual oil. Therefore, the SMG particles can work jointly with water to improve the sweeping efficiency and achieve remarkable effect of increasing oil and decreasing water production.

2. Comparison of the performance between continuous and dispersed phase flooding systems

2.1. Experimental conditions

2.1.1. The materials

The dispersed phase flooding agent (SMG(W)-micron, SMG(Y)-submillimeter) was provided by the Oilfield Chemistry Institute of PetroChina Research Institute of Petroleum Exploration & Development. Its effective content is 100%. The continuous phase flooding agent (polymer solution) was partially hydrolyzed polyacrylamide (HPAM) powder with a relative molecular mass of 2 500×104 and solid content of 90%. The dyeing agent was sodium fluorescein produced by Tianjin Damao chemical reagent factory. The simulated oil was prepared by mixing kerosene and degassed crude oil from No.1 Production Plant of Daqing Oilfield, with a viscosity of 9.8 mPa·s at 45 °C. Water in the experiment was also from Daqing Oilfield, with ionic composition shown in Table 1.

Two kinds of cores were used in the experiment: (1) The artificial microfluidic simulation model (Fig. 5) of 1 cm×4 cm, with 20-50 μm pores. (2) The “five-spot” simulation model of quartz sand cemented by epoxy resin[22,23,24,25,26,27] of 4.5 cm×30 cm×30 cm, with three layers of 1.5 cm thick each with permeabilities of 2 400×10-3 μm2, 800×10-3 μm2 and 300×10-3 μm2 from top to bottom.

Table 1 Ionic composition of water used in the experiment.

| Ion type | Ion content/ (mg·L-1) | Ion type | Ion content/ (mg·L-1) |

|---|---|---|---|

| Na++K+ | 1 265.0 | SO42- | 9.6 |

| Ca2+ | 32.1 | CO32- | 210.1 |

| Mg2+ | 7.3 | HCO3- | 1 708.6 |

| Cl- | 780.1 | Total salinity/(mg·L-1) | 4 012.7 |

Fig. 5.

Fig. 5.

The microfluidic chip model.

2.1.2. The apparatuses

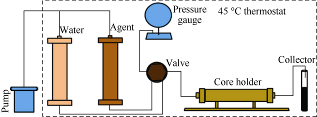

The size of SMG particles was tested by the three mesh metallographic microscope (Germany Leica Company DM1750 m). The polymer molecular coil size was tested by the dynamic/static light scattering apparatus. The experimental equipment and process is shown in Fig. 6.

Fig. 6.

Fig. 6.

The experimental equipment and process.

2.2. The method

2.2.1. Experimental procedures of microscopic oil displacement mechanism

The experimental procedures of the two agents are given as follows: (1) Evacuate the microfluidic chip model; (2) Saturate the model with water; (3) Saturate the model with simulated oil; (4) Water flood the model until the water cut reaches 98%, and record the images during the displacement process; (5) Inject the continuous or dispersed phase flooding agent of a certain PV (pore volume) into the model respectively at the injection rate of 0.01 mL/min and record the images during the displacement process.

2.2.2. Experimental scheme for fluid diversion ability evaluation

The experimental scheme of the two agents is shown in Table 2. The mass concentration of SMG solution was 0.3%. The injection rate in Run 1-1 and 1-2 was 0.5 mL/min and the pressure recording interval was 30 min during the experiment.

Table 2 Experimental scheme for fluid diversion ability evaluation.

| Run No. | Injection mode | Phase 1 | Phase 2 | Phase 3 |

|---|---|---|---|---|

| 1-1 | Constant speed | Water flood the core until the water cut reaches 98% | (0.83 PV & Cp=1 000 mg/L) polymer solution+(0.50 PV& Cp=2 000 mg/L) polymer solution | Subsequently, water flood the core until the water cut reaches 98% |

| 1-2 | Constant speed | 0.30 PV SMG(Y) +0.53 PV SMG(W) +0.30 PV SMG(Y) +0.20 PV SMG(W) | ||

| 2-1 | Constant pressure | (0.83 PV & Cp=1 000 mg/L) polymer solution +(0.50 PV & Cp=2 000 mg/L) polymer solution | ||

| 2-2 | Constant pressure | 0.30 PV SMG(Y)+0.53 PV SMG(W)+0.30 PV SMG(Y)+0.20 PV SMG(W) |

2.3. Results and discussion

2.3.1. Experimental results of micro oil displacement mechanism

2.3.1.1. Polymer solution

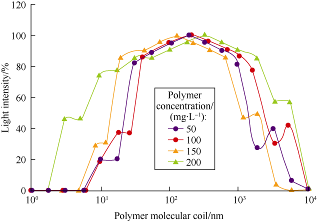

The test results of polymer molecular coil size is shown in Fig. 7. It can be seen that polymer solution is an extremely heterogeneous continuous phase system. The polymer molecular coils vary widely in size from several nanometers to thousands of nanometers. Under the action of Brown force, polymer solution enters different sizes of pores indiscriminately, resulting in irreversible blockage of small pores.

Fig. 7.

Fig. 7.

The size distribution curve of polymer molecule coils.

The polymer flooding experiment was carried out on the microfluidic chip model. The dynamic images during water flooding and polymer flooding are shown in Fig. 8. It can be seen that the residual oil after water flooding mainly exists in small pores (Fig. 8c). On the one hand, the flow resistance increases due to the high viscosity of polymer solution; on the other hand, the pore cross section decreases because of adsorption and retention of polymer in the pores. According to the mathematical model of concentration distribution, the polymer concentration in each pore is equal to the average concentration, so polymer solution enters different sizes of pores indiscriminately (Fig. 8d-8g), increasing the flow resistance in them equally. The retention of polymer solution is the primary cause for the “entry profile inversion” phenomenon during polymer flooding.

Fig. 8.

Fig. 8.

Dynamic images of polymer flooding.

2.3.1.2. SMG dispersion

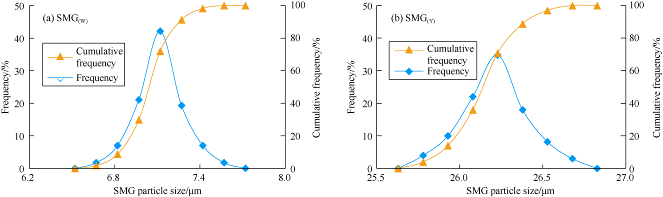

According to the statistics principle, the three mesh metallographic microscope (Germany Leica Company DM1750 m) was used to draw particle size distribution curve of SMG(W) and SMG(Y), which is shown in Fig. 9.

Fig. 9.

Fig. 9.

The particle size distribution curve of SMG.

As shown in Figs. 7 and 9, compared with the size distribution of polymer molecular coils, the size distribution of SMG(W) and SMG(Y) particles is narrow and relatively concentrated. SMG particles enter the large pores that match their sizes, and the carrier fluid enters the small pores to displace oil. The median value of initial particle size of SMG(W) and SMG(Y) were 7.16 μm and 26.25 μm respectively. After expansion, the median values of particle size of SMG(W) and SMG(Y) were 36.01 μm and 122.13 μm, expanding 5.03 and 4.65 times respectively. Furthermore, experimental results show that the matching coefficients between rock pore size and particle sizes of SMG(W) and SMG(Y) are 0.79-0.84 and 1.73-1.78 respectively[15].

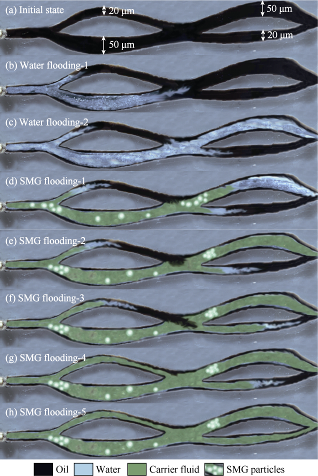

The SMG dispersion flooding experiment was carried out on the microfluidic chip model. The dynamic images during water flooding and SMG dispersion flooding are shown in Fig. 10. It can be seen that the injected water first enters the large pores with low seepage resistance during water flooding, and the residual oil exists in small pores. The particle phase separation phenomenon occurs during SMG dispersion injection. The SMG particles enter and migrate in the dominant big pores, stacking and bridge blocking the big pores to make the flow cross section decrease and seepage resistance and injection pressure increase. As the injection pressure increases, the carrier fluid would turn into small pores to displace the residual oil. When SMG particles enter the next pore throat, they gather and form the bridge block again due to the expansion of SMG particles. They repeat the accumulation, blockage and fluid diversion process, to achieve the goal of deep fluid diversion. At the same time, the experimental results partly prove the correctness of the concentration distribution mathematical model of SMG dispersion in different pores. When the particle size is large and the shunt volume in the small pores is less than the critical shunt volume xi*, the concentration of SMG particles in the small pore is zero (that is no particles enter the small pore).

Fig. 10.

Fig. 10.

The dynamic images of SMG flooding.

SMG particles and the carrier fluid play the role of “profile control” and “flooding” respectively. After getting into porous media, SMG particles show the motion feature of “gathering, deformation, migration, re-gathering, re-deformation and re-migration” and the property of “plugging large pores but not small ones”, so they plug the large pores effectively and change the flow direction of the carrier fluid. Therefore, SMG dispersion can improve the producing degree of the residual oil and greatly enhance oil recovery.

2.3.2. Experimental results of fluid diversion ability evaluation

2.3.2.1. Constant speed experiment

In run 1-1 and 1-2, the experimental results of oil recovery of the continuous and dispersed phase flooding systems under constant injection speed are shown in Table 3. It can be seen that the ultimate EOR of polymer flooding in run 1-1 is 34.07%, while the ultimate EOR of SMG dispersion flooding in run 1-2 is 16.78%. The former is larger than the latter.

Table 3 The experimental results of recovery rate under constant speed injection.

| Run No. | Total injection pore volume | Oil saturation/% | Oil recovery rate of waterflood/% | Oil recovery rate of chemical flooding/% | EOR/ % |

|---|---|---|---|---|---|

| 1-1 | 1.33 | 62.9 | 30.78 | 64.85 | 34.07 |

| 1-2 | 1.33 | 63.2 | 31.14 | 47.92 | 16.78 |

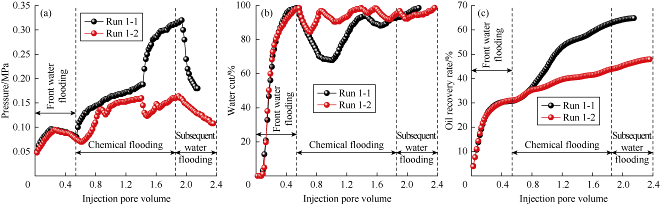

The dynamic characteristic curves of run 1-1 and 1-2 are shown in Fig. 11. It can be seen that the injection pressure of polymer flooding is higher than that of SMG dispersion flooding (Fig. 11a). This is because polymer solution has strong retention ability in core pores, which makes the injection pressure increase significantly. The magnitude of water cut reduction and oil production increment also are larger (Fig. 11b, 11c). However, according to the regulation of stimulation, the injection pressure must not exceed the reservoir rock fracturing pressure, and is also limited by the rated working pressure of injection equipment. For instance, the reservoir rock fracturing pressure of Daqing Oilfield is about 12-14 MPa. Usually, the injection pressure during water flooding is 6-7 MPa. The fracturing pressure is about 2 times the injection pressure. Therefore, the injection pressure and oil recovery rate of polymer flooding in run 1-1 are difficult to realize in the field practice. As a result, the constant pressure injection can objectively evaluate the oil increment and water reduction effect of continuous and dispersed phase flooding systems.

Fig. 11.

Fig. 11.

Relationship between injection-pressure (a), water cut (b), oil recovery rate (c) and pore volume under constant speed injection.

2.3.2.2. Constant pressure experiment

In run 2-1 and 2-2, the experimental results of oil recovery of the continuous and dispersed phase flooding systems under constant pressure injection are shown in Table 4. It can be seen that the ultimate EOR of polymer flooding in run 2-1 is 26.14%, while the ultimate EOR of SMG dispersion flooding in run 2-2 is 33.11%. The former is smaller than the latter, which is contrary to the constant speed experiment.

Table 4 The experimental results of recovery rate under constant pressure injection.

| Run No. | Total injection pore volume | Oil saturation/% | Oil recovery rate of waterflood/% | Oil recovery rate of chemical flooding/% | EOR/ % |

|---|---|---|---|---|---|

| 2-1 | 1.33 | 63.1 | 30.09 | 56.23 | 26.14 |

| 2-2 | 1.33 | 62.2 | 30.97 | 64.08 | 33.11 |

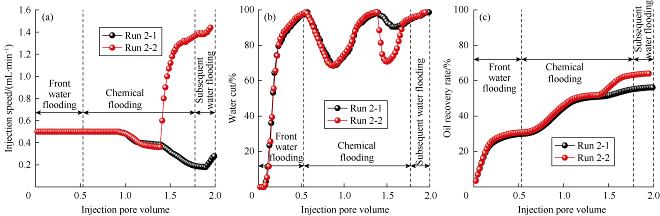

The dynamic characteristic curves of run 2-1 and 2-2 are shown in Fig. 12. It can be seen that under the same conditions of injection pore volume, the oil increment and water reduction effect of SMG dispersion is much better than that of polymer flooding. The constant pressure experimental condition is closer to the actual situation of field practice. Therefore, it can reflect the field test effect of continuous and dispersed phase flooding systems more accurately. When adopting the constant pressure injection mode, due to the strong retention ability of polymer solution in core pores, the flow cross section decreases and flow resistance increases. This causes the injection speed to decrease greatly (Fig. 12a), and the magnitude of water cut reduction and oil production increment are smaller (Fig. 12b, 12c).

Fig. 12.

Fig. 12.

Relationship between injection-speed (a), water cut (b), oil recovery rate (c) and pore volume under constant pressure injection.

3. Comparison of field test results of continuous and dispersed phase flooding systems

According to the references [28-30], the reservoir conditions that SMG dispersion has been successfully applied are summarized as follows: the reservoir permeability (50- 3000)×10-3 μm2, permeability variation coefficient of less than 0.75, crude viscosity of less than 350 mPa·s, injection water salinity of less than 200 000 mg/L, the content of two valence ions in injected water of less than 2 000 mg/L, and the reservoir temperature of less than 130 °C.

Field tests of continuous and dispersed phase flooding systems were carried out in different areas of the same reservoir[28]. In the test area of continuous phase flooding agent, the crosslinked polymer gel (LPG) was taken as the main chemical agent, considering the developed preferential channels and high oil viscosity, the high viscosity LPG was employed, rather than the low viscosity polymer solution. For the preset plugging slug, pregelled swellable particle (SLG) was used. The following LPG slugs were continuous injected, but with viscosity gradually decreasing. In the test area of dispersed phase flooding agent, SMG dispersion was the main chemical. The preset plugging slug was the same with the former, and followed by 4 times of alternate injection of SMG slug and small LPG slug.

The field test results of two flooding systems are shown in Table 5[28]. It can be seen that, in the test area of dispersed phase flooding agent, the daily oil production increases by 2.9 times during the chemical injection. While that in the test area of continuous phase flooding agent the daily oil production increases 1.1 times. The maximum water cut drops of the two agents during chemical injection are 46.2% and 32.2% respectively. Due to continuous injection of viscous fluid, both oil and water flowing resistance greatly increase, which results in the low liquid supplying capacity of the producers. Therefore, it is difficult to displace the residual oil in low permeability area, and the oil production increase and water cut reduction could not be further improved or sustained for a long period. On the contrary, due to the properties of “plugging large pores but not small ones”, a large amount of SMG particles continuously and alternately inhibiting the flow in high permeability area or large pores, and the water is diverted into low permeability area or small pores, to efficiently displace the remaining oil there, which obtained better oil increment and water reduction effect than the continuous phase flooding system.

Table 5 Comparison of field test results of continuous and dispersed flooding systems.

| Flooding agent | Maximum oil increase multiple in chemical injection | Maximum oil increase multiple in subsequent waterflooding | Maximum water cut decrease extent in chemical injection/% | Maximum water cut decrease extent in subsequent waterflooding/% | EOR effective time/Month |

|---|---|---|---|---|---|

| Continuous phase | 1.1 | 0.9 | 32.2 | 34.1 | 37 |

| Dispersed phase | 2.9 | 2.1 | 46.2 | 56.3 | 46 |

4. Conclusions

The continuous flooding system enters the larger and small pores indiscriminately. On the contrary, the particle phase separation phenomenon occurs during the injection process of dispersed flooding system. The SMG particles gather in the larger pores to form bridge block, while the carrier fluid displace oil in the small pores, realizing the property of “plugging large pores but not the small ones”.

Under the constant pressure mode, the same pore volume of polymer solution and SMG dispersion were injected into the core with three layers of different permeabilities, which is closer to the actual reservoir flooding process, the results show that the latter has better oil production increment and water reduction effect than the former. That is the dispersed phase flooding system can achieve better flooding effect. The laboratory results are consistent with the field test results.

Nomenclature

a—the parameter related to particle size, dimensionless;

i—the exit No.;

N—total number of exits;

pc1, pc2—the capillary force of capillary tube 1 and 2 respectively, MPa;

Δp—the displacement pressure, MPa;

pt—the maximum value of additional pressure generated by the SMG acting on the capillary tube, MPa;

qi—the flow of exit i, mL/s;

xi—the shunt volume of exit i, dimensionless;

xi*—the critical shunt volume of exit i, dimensionless;

yi—the particle concentration of exit i, dimensionless.

Reference

Application of polymer flooding technology in Daqing Oilfield

According to the results of the research in the laboratory and field tests, the experiences of polymer flooding in Daqing Oilfield in seven years are analyzed. The actual recovery in the field and the major factors influencing recovery efficiency are investigated. The methods for enhancing recovery efficiency, the measures to obtain a uniform polymer flooding front and ways to lower the costs for producing crude oil by polymer flooding are discussed. The effectiveness of polymer flooding technology applied in Daqing Oilfield can provide some references for further application of polymer flooding in China.

Experimental study on the mechanism of enhancing oil recovery by polymer - surfactant binary flooding

Experimental investigation of the novel phenol-formaldehyde cross-linking HPAM gel system: Based on the secondary cross-linking method of organic cross-linkers and its gelation performance study after flowing through porous media

DOI:10.1021/ef101334y

URL

[Cited within: 1]

The use of a polymer gel is an effective method for water shutoff in mature oilfield development. As for fractured reservoirs, in order to mitigate the filtration of gelant (fluid solution of cross-linker and polymer that exists before gelation) to matrix and increase the enduring erosion ability of mature gel, chromium(III) acetate, and phenol ormaldehyde cross-linking, the HPAM gel system of a secondary cross-linking method is used more often. Chromium(III) salt is often used as the first cross-linker. However, the cross-linking mechanism is achieved by an ion bond, which is less stable than a covalent bond when used as an organic cross-linker. Resorcinol and phenol-formaldehyde used as the first and secondary cross-linker, respectively, are discussed in this paper. Results showed that resorcinol can quickly cross-link with HPAM at room temperature. Gelant formulated with a combination of 0.3 wt % HPAM added to 10-30 mg/L resorcinol can increase its viscosity from 10.2 to 150 mPa s within 2 h. SEM results show that the microstructure of the first cross-linking gel appears in typical dendritic shape, with branched chains diffused in arbitrary directions. The high shearing tolerant ability of the first cross-linking gel can be achieved by these branched chains. However, a tight 3-D network structure is formed in the microstructure of the secondary cross-linking gel. This is the benefit of the stability of the skeleton structure of gel enhancing. The main factors, including temperature and total dissolved solids (TDS). to affect the gelation performance of this secondary cross-linking gel are also discussed. Results show that gelation time decreased and gel strength increased with increasing temperature and TDS. Especially for TDS, the adverse law of the gelation performance with PEI/PAtBA or PEI/HPAM gel systems is shown. The gelation performance of a resorcinol/phenol ormaldehyde/HPAM gel system of a first cross-linking state after flowing through porous media is studied. Atomic force microscopy (AFM) scanning results show that in comparison to the original gel, the structure of the weak cross-linking (code B) gels has a certain degree of damage after flowing through porous media. However, the final gel strength of both gels do not show an apparent difference. This demonstrated that the first cross-linking achieved by resorcinol can guarantee the effectiveness of secondary cross-linking. This study suggests that a resorcinol/phenol formaldehyde/HPAM secondary cross-linking gel system can be used for water shutoff in fractured reservoirs.

New insights into the gelation behavior of polyethyleneimine cross-linking partially hydrolyzed polyacrylamide gels

DOI:10.1021/ie301818f

URL

[Cited within: 1]

Using polymer gel is still the mainstream technique of the chemical method for water shut-off in mature oilfield development. The gelation performance of polyethyleneimine (PEI) cross-linking partially hydrolyzed polyacrylamide (HPAM) gel was systematically investigated in this paper by using three types of molecular weight (Mw) HPAM. Results show that the gelant solution (the fluid solution of cross-linker and polymer that exists before gelation) can slightly gel even at room temperature and form a rudimentary 3D network structure for protecting the subsequent gelling. The main factors, including HPAM, PEI concentrations, HPAM Mw, and total dissolved solids (TDS) to affect the gelation performance are also discussed. The gelation time is around 18 72 h at 65 C, which is much longer than the commonly used chromium(III)-acetate cross-linking HPAM gel system. The gelation performance of the PEI/HPAM gel system is improved after flowing through porous media and shows the adverse law for a porous media shear...

Research on the gelation performance of low toxic PEI cross-linking PHPAM gel systems as water shutoff agents in low temperature reservoirs

DOI:10.1021/ie100888q

URL

[Cited within: 1]

Using gel as the water shutoff agent has been widely reported in the aspect of enhanced oil recovery (EOR) of the development of mature oil fields. Cross-linkers such as chromium(III) acetate and phenol61formaldehyde are commonly used, but they are toxic. Today, use of low toxic polyethyleneimine (PEI) cross-linking a copolymer of acrylamide and tert-butyl acrylate (PAtBA) as the water shutoff gel is reported more but is mainly focused on its theoretical research and applications in high temperature reservoirs. Because of the defects of the chromium(III) acetate and phenol61formaldehyde cross-linkers, the gelation performance of PEI/partially hydrolyzed polyacrylamide (PHPAM) gel systems at low temperature (40 °C) is discussed in this paper. The results show that the gelation time and strength of the PEI/PHPAM gel system can be perfectly controlled by adjusting the PHPAM concentration, the molecular weight, the PEI concentration, and the total dissolved solids. The polymer concentration and molecular weight...

Research on the mechanism of “fluid entry profile reverse” during polymer flooding

Polymer flooding has been widely applied in China,and has made a great contribution to EOR. However,in some blocks with relatively severe heterogeneity,the phenomenon of "the reverse of fluid entry profile" has occurred,that is the high permeability zone absorbs more than in water flooding stage,while the middle and low permeability zones absorb less than in water flooding stage. Physical experiments have been conducted to study the factors affecting oil recovery efficiency. The results show that reservoir permeability contrast,relative molecular weight of polymer and the injection time of polymer solution will all have impact on the phenomenon of "the reverse of fluid entry profile". This study is helpful to improving displacement efficiency of polymer flooding.

A novel particle-type polymer and IOR/EOR property evaluation

Oil displacing mechanism of soft microgel particle dispersion in porous media

The formation heterogeneity causes uneven sweeping of waterflooding.Different degrees of prevailing water flowing are generated due to different sizes of pores and throats.During the middle-late stage of water flooding,it is hard to move the remaining oil since it is scattered in the pores and throats.The EOR(enhanced oil recovery)study is mainly concerned with methods both to inhibit different sized prevailing flowing channels,and to keep oil flowing path free of plugging,which can ensure production efficiency of remaining oil.In this study,the pore-scale microscopic heterogeneous models with real pore structure were established,and different oil displacing mechanisms were compared between continuous phase viscous fluid,such as conventional polymer and crosslinked polymer gel,and micro-nano soft microgel particle dispersion.Results show that the traditional polymer flooding cannot differentiate between high and low permeability or big and small pore,because it relies on viscosity to increase the flowing resistance of all the swept area and it is hard to move the remaining oil when the viscosity is high to some extent.The soft microgel particle dispersion is a type of low viscosity dispersion fluid,and the particles have priority to access relatively big pore and throat,to temporarily inhibit the flowing,and at the same time,the water can be diverted into the relatively small pore and throat,to push the remaining oil out as a piston.The process is repeated continuously.The lab results were ana-lyzed from the view of mobility adjustment in this paper,and it is concluded that the conventional continuous phase driving fluid modified mobility by increasing injection water viscosity,while the soft microgel particle dispersion achieved efficient mobility adjustment by decreasing the relative permeability of injection water and accordingly increased the oil permeable ability.

Monodisperse double emulsions generated from a microcapillary device

DOI:10.1126/science.1109164

URL

PMID:15845850

[Cited within: 1]

Double emulsions are highly structured fluids consisting of emulsion drops that contain smaller droplets inside. Although double emulsions are potentially of commercial value, traditional fabrication by means of two emulsification steps leads to very ill-controlled structuring. Using a microcapillary device, we fabricated double emulsions that contained a single internal droplet in a core-shell geometry. We show that the droplet size can be quantitatively predicted from the flow profiles of the fluids. The double emulsions were used to generate encapsulation structures by manipulating the properties of the fluid that makes up the shell. The high degree of control afforded by this method and the completely separate fluid streams make this a flexible and promising technique.

Effects of core structure and clay mineral on gel-forming performance of chromium polymer

DOI:10.1016/j.colsurfa.2018.01.002

URL

[Cited within: 1]

Cr 3+ polymer gel flooding, an effective EOR technique, has been tested in some reservoirs (LDT-1, LDF-2 and NBTF-2) of Bohai oilfield--an offshore oilfield in China. Its performance demonstrates that this technique can significantly increase oil production and reduce water cut. However, the comprehension of this technique is still insufficient to satisfy its application requirements, which restrains its further application and improvement. As a result, this paper studies the comprehensive effects of core structure and clay mineral on gel-forming performance of chromium polymer, on the basis of reservoir and fluid properties of Bohai Oilfield. The results indicate that at static conditions, cross-linking reaction between Cr 3+ and polymer molecular chain occurred at reservoir condition, and formed polymer gel with intramolecular cross-linking structure. Gel-forming performance is better with higher reservoir permeability and looser cementation, lower clay content and oil saturation. Also, clay type determines the degree of damage. From kaolinite, montmorillonite to illite, their damage gets bigger. Moreover, gel-forming performance at dynamic condition is much poorer than that at static condition. And a suspension of injection after alternate injection of Cr 3+ and polymer solution could promote cross-linking reaction.

Research on configuration of polymer molecular aggregate and its reservoir applicability

DOI:10.1080/01932691.2015.1073599

URL

[Cited within: 1]

This article researches the effect of configuration of polymer molecular aggregate on the performance of polymer solution and its reservoir applicability, taking configuration of polymer molecular aggregate, first normal stress difference, resistance coefficient, residual resistance coefficient, and oil recovery as the evaluation indexes, guided by physical chemistry, polymer materials science, and reservoir engineering, by means of chemical analysis, instrument detection, and physical simulation. Results show that the apparent viscosity of polymer solution is closely related to the configuration of molecular aggregate. However, that reflects neither the transporting and migrating ability of molecular aggregate in porous media nor the applicability of polymer solution for reservoir core pore. Compared with “linear-branched chain” polymer, network polymer has a regional “laminated-net” structure, which has a stronger ability to adsorb and wrap hydrone, when deformation occurs, internal friction of which is larger, and apparent viscosity of which is higher with isoconcentration. Changing the configuration of molecular aggregate can enhance the tackify performance of polymer, but crosslinking or association degree must be controlled properly. Otherwise, the applicability of polymer solution for reservoir core pore will become poor, thus influencing the oil incremental effect of polymer flooding. GRAPHICAL ABSTRACT

Research on the influence factors of weak-base ternary compound system on oil incremental effect and its action mechanism

This paper researches the seepage characteristics and oil displacement effect of polymer solution and weak-base ternary compound system,taking the reservoir geology and fluid from Daqing Oilfield as research object,taking injectionpressure and oil recovery as the evaluation indexes.Results show that,under the condition of the same oil displacement agent viscosity and slug size,the oil recovery increment of weak-base ASP flooding is larger than that of polymer flooding.Because there are emulsification and Jamin effect during weak-base ASP flooding,which can increase seepage resistance and injectionpressure,and its oil sweep efficiency is also higher.Compared with ternary compound system with scale-removal water,there are carbonate micro particles in the sewage ternary compound system,which can be detained in porous media.This can increase seepage resistance and cause fluid diversion effect,which eventually leads to a large increase in oil recovery.Compared with constant-speed experiment,it is early for constant-pressure experiment to adopt peak-pressure,which accelerates the forward speed of agent in the core high permeability layer and shortens the breakthrough time.As a result,the sweep efficiency and oil displacement efficiency of constant-pressure experiment is lower.

Network model for deep bed filtration

DOI:10.1063/1.1359747

URL

[Cited within: 1]

We study deep bed filtration, where particles suspended in a fluid are trapped while passing through a porous medium, using numerical simulations in various network models for flow in the bed. We first consider cellular automata models, where filtrate particles move in a fixed background flow field, with either no-mixing or complete-mixing rules for motion at a flow junction. The steady-state and time-dependent properties of the trapped particle density and filter efficiency are studied. The complete mixing version displays a phase transition from open to clogged states as a function of the mean particle size, while such a transition is absent in the (more relevant) no-mixing version. The concept of a trapping zone is found to be useful in understanding the time-dependent properties. We next consider a more realistic hydrodynamic network model, where the motion of the fluid and suspended particles is determined from approximate solutions of the time-dependent Stokes equation, so that the pressure field constantly changes with particle movement. We find that the steady-state and time-dependent behavior of the network model is similar to that of the corresponding cellular automata model, but the long computation times necessary for the simulations make a quantitative comparison difficult. Furthermore, the detailed behavior is extremely sensitive to the shape of the pore size distribution, making experimental comparisons subtle.

The profile control and displacement mechanism of continuous and discontinuous phase flooding agent

DOI:10.1080/01932691.2016.1242076

URL

[Cited within: 2]

In order to further explore the profile control and displacement mechanism of continuous and discontinuous phase flooding agent, the concentration distribution mathematical model of microsphere dispersion system in different branch channels is established, and its particle phase separation is simulated by using microfluidic technology. On this basis, in order to research the migration and plugging characteristics of microspheres, the visualization experiments on micro oil displacement mechanism of polymer solution and microspheres are carried out. And the experiment on the injection, migration, and plugging performance of microspheres in the multi-point core is performed. Results indicate that microspheres are in the axis of the channel due to the effect of fluid shear stress, and preferentially enter the large channel with low resistance and high flow velocity, which results in no particle or few particles in the small aperture and low flow velocity channel. The microspheres have better migration and retention capacity in the core and their migration shows the characteristic of 090008fluctuating pressure change090009. Compared with polymer solution, the alleviation of 090008entry profile inversion090009 and the better migration and plugging performance of microsphere dispersion system can realize deep fluid diversion and expand sweep volume.

Nonuniform red cell distribution in 20 to 100 micrometers bifurcations

DOI:10.1016/0026-2862(85)90010-X

URL

PMID:2580216

[Cited within: 1]

Several potentially important parameters influencing the disproportionate distribution of red cell flux and blood flow at a bifurcation are examined. These include parent vessel hematocrit, vessel diameter, suspending medium, cell distensiblity, parent vessel blood flow rate, and local geometry. Measurements were performed on 20 to 100 m bifurcations, fabricated such that all vessels of a given bifurcation have the same diameter. Suspensions of human red cells, hardened red cells, and mixtures of each in albumin-saline, Dextran 75, or plasma were flowed through the bifurcations and determinations of flow rates and discharge hematocrits were made for each of the channels. For the 20- m channels, hematocrits were found using videophotometric techniques, and for the larger channels, hematocrits were measured directly from the exit streams. Flow rates for both were measured by meniscus travel downstream in small-diameter glass tubes. Within the limits of the present experiments, three of the variables proved to be of major importance: (i) feed hematocrit, (ii) tube diameter, and (iii) flow-rate distribution. It was clearly demonstrated that red cell flux varies nonlinearly with fractional flow rate. Critical flow rates, at which all or none of the cells entered one of the branches, were found to vary with diameter and hematocrit as has been reported in other studies. The data were analyzed with a theoretical model which assumes that the parent vessel contains a core of uniformly distributed red cells surrounded by a marginal gap of suspending medium; in the parent vessel lumen, the flows to the two daughter branches were assumed to be separated by a chord. The marginal gap widths and tube hematocrits deduced from the data with this model are of reasonable magnitudes.

Study on in-depth profile control and flooding of pore-scale elastic microspheres under heterogeneous condition

Due to the particularity of design principle for pore-scale elastic microspheres profile control and flooding technology, the particle-pore size matching factor was introduced and through heterogeneous parallel sandpack experiments, the plugging property of elastic microspheres under different particle-pore size matching relationship and the effect of permeability ratio on the ability of profile improvement were studied. Based on this, field test of pore-scale elastic microspheres under heterogeneous condition was carried out. Indoor experimental results show that in a better particle-pore size matching factor range, the residual resistance factor and plugging rate of sandpacks are the maximum as well as plugging effect; elastic microspheres can prefer to plug high permeability layer selectively so as to make the diversion rate of high and low permeability tube all tend to 50%,which indicates that elastic micro- spheres have significant selectivity on permeability; permeability ratio has an important effect on profile control an flooding performance of elastic microspheres and under condition of better particle-pore size matching factor range and lower permeability ratio, the profile improvement of elastic microspheres is better. Field test results show that when the particle-pore size matching factor is 1. 52 and the permeability ratio is 3.1,the elastic microspheres can control the water injection profile effectively and the profile improve ability of target layer 65 and 67 is up to 98% ; it is scientific to guide the field test of elastic microspheres profile control and flooding using particle-pore size matching factor and permeability ratio.

Effects of crude oil composition on the ASP flooding

The potential of using Cr 3+/salt-tolerant polymer gel for well workover in low-temperature reservoir: Laboratory investigation and pilot test

Using DSC technique to investigate the non-isothermal gelation kinetics of the multi-crosslinked Chromium acetate (Cr 3+)-Polyethyleneimine (PEI)-Polymer gel sealant

DOI:10.1016/j.petrol.2018.01.082 URL [Cited within: 1]

Analysis of reservoir applicability of hydrophobically associating polymer

DOI:10.2118/174553-PA URL [Cited within: 1]

Study of action mechanisms and properties of Cr 3+ cross-linked polymer solution with high salinity

DOI:10.1007/s12182-012-0185-x

URL

[Cited within: 1]

Performance characteristics of partially hydrolyzed polyacrylamide (HPAM) and cross-linked polymer (CLP, Cr 3+ as the cross linker) solutions have been investigated. A Brookfield viscometer, rheometer, dynamic light scattering system, and core flow device have been used to measure the viscosity, viscoelasticity, polymer coil dimensions, molecular configuration, flow characteristics, and profile modification. The results show that, under conditions of high salinity and low HPAM and Cr 3+ concentrations, cross-linking mainly occurred between different chains of the same HPAM molecule in the presence of Cr 3+ , and a cross-linked polymer (CLP) system with a local network structure was formed. Compared with an HPAM solution of the same concentration, the apparent viscosity of the CLP solution increased slightly or remained almost unchanged, but its viscoelasticity (namely storage modulus, loss modulus, and first normal stress difference) increased, and the resistance coefficient and residual resistance coefficient increased significantly. This indicates that the CLP solution exhibits a strong capability to divert the sequentially injected polymer flood from high-permeability zones to low-permeability zones in a reservoir. Under the same HPAM concentration conditions, the dimensions of polymer coils in the CLP solution increased slightly compared with the dimensions of polymer coils in HPAM solution, which were smaller than the rock pores, indicating that the cross-linked polymer solution was well adapted to reservoir rocks. Core flood experiments show that at the same cost of reagent, the oil recovery by CLP injection (HPAM-1, Cr 3+ as the cross linker) is 3.1% to 5.2% higher than that by HPAM- 2 injection.

Mechanism and gelling effects of linked polymer solution in the core

DOI:10.1016/S1876-3804(13)60065-8

URL

[Cited within: 1]

By using Bush viscometer, dynamic and static laser scatter instrument, scanning electron microscope and core flow experimental apparatus, experiments were conducted to study the viscosity, molecular coil dimensions, molecular configuration and static gelation of amphoteric polymer solution and linked amphoteric polymer solution in porous media and affecting factors, and to analyze the gelation mechanism of linked polymer solution in the core. The results showed that with the increase of solvent water salinity, the cross-linking reaction rate increases; with increase of aging time, the gelling effect gets stronger and stable; with the increase of shear time, the lineation of polymer molecules gets more obvious, the gelling effect in pores gets worse; under the condition of low permeability, the cross-linking reaction mainly is intramolecule cross-linking; with the increase of core permeability, i.e. the increase of pore size, the gelling effect gets better in the core, and inter-molecular cross linking reaction is more likely to take place. The experimental data and theoretical analysis showed that in the linked amphoteric polymer solution, the cross-linking reaction occurs between the different branched-chain of the same molecule firstly (intra-molecular cross-linking), then the cross-linking reaction extends to different polymer molecules (i.e. inter-molecular cross-linking).

Analysis of dynamic imbibition effect of surfactant in microcracks of reservoir at high temperature and low permeability

An innovative EOR method for waterflooding heterogeneous oilfield-graded diversion flooding technology and verification by field comparison tests

Successful sweeping control technology test for offshore heavy oilfield: Case study of QHD32 reservoir in Bohai Bay

A new IOR method for mature waterflooding reservoirs: “Sweep control technology”