1. Basic geological features

Sulige gas field is located in the Yishan slope of the Ordos Basin. It is a monoclinic structure inclined from northeast to southwest with an exploration area of about 4.0×104 km2. Its accumulated proven natural gas reserves exceed 3×1012 m3. The reservoirs are characterized by low porosity, low permeability, low abundance, small thickness, and strong heterogeneity, representing typical tight sandstone gas reservoirs[1]. The major reservoirs, the 8th Member of Shihezi Formation and the 1st Member of Shanxi Formation are deposited in an alluvial-fluvial system and controlled by the sand bodies distributed in the S-N direction. The internal structure of channel is complex with highly developed interlayers, and the gas- bearing sandstone is mainly braided river sand bar and point bar. The reservoirs feature small thickness and scale, with single well gas-layers combined of less than 14 m thick and single layers of 2-6 m thick; the sand bodies are less than 1 000 m long and 400-800 m wide. Hence, the wells there are limited in controlled reserves and low in output[1,2]. Dominated by quartz sandstone and lithic quartz sandstone, the reservoirs have primary inter-granular pores, residual inter-granular pores and dissolved inter-granular pores as main storage space. With a porosity of 5%-10% and permeability of mostly below 0.1×10-3 μm2, the reservoirs are tight. Most of the reservoirs have a pressure gradient of less than 1.00 MPa/100 m and 0.87 MPa/100 m on average, representing low-pressure ones[3].

2. Block development background

Located in the northwest of Sulige Gas Field, Block Su10 is developed by a set of vertical wells. The basic well pattern was 600 m×1 200 m diamond pattern. Later, it was infilled between wells in the favorable area of the basic well pattern, forming 600 m×600 m infilled well pattern, and horizontal well tests were carried out. The Block Su53, located at the north of Block Su10, is developed by horizontal wells in two sets of gas-bearing layers. The well pattern adopted there is approximate diamond-shape with a well spacing of 600 m. The horizontal wells have a lateral section of 1 000-1 200 m long. With the deepening of development, on one hand, the wells in the enrichment area are gradually saturated, the number of low-yield old wells increases, and well deployment and stable production are more and more difficult. On the other hand, as the reservoirs change rapidly in vertical and lateral directions, and the single-well controlled reserves are low, there are still some areas with high gas saturation under the well-pattern above, which form scattered residual gas enrichment areas difficult to reach by conventional measures. How to improve the production of the wells, tap the remaining gas, and improve recovery is a major research issue for the continuous and stable production of the gas field. In order to find an effective way to reduce development costs and excavate reserves not produced between wells, the sidetracking horizontal well from old wells was tried first in Block Su10 and Su53[4].

3. Development history of sidetracking horizontal drilling from old wells in Sulige Gas Field

The development process of sidetracking horizontal drilling from the old well in Sulige Gas Field can be divided into four stages: test, development, breakthrough, and application.

3.1. Sidetracking horizontal well test stage

In 2011, sidetracking from the horizontal well was tested first in a well in Block Su10 and put into production in 2007 with a cumulative gas production of only 200×104 m3. The sidetracking well has a designed horizontal section of 600 m long and actual horizontal section of 528 m long, an effective reservoir drilling ratio of 53.6%, effective producing thickness of 6.4 m, and a drilling cycle of 61 d. Due to limitations in drilling and completion technologies, the drilling of the well suffered a number of accidents such as sticking and circulation lost. In the completion stage, the wellbore collapsed and the actual horizontal section was reduced to 320 m long. After three stages of fracturing, the well had an initial daily gas production of (1-2)×104 m3, equivalent to that of the vertical well. Soon it was converted to intermittent production, failing to reach the desired effect.

3.2. Development stage of sidetracking horizontal well

In 2012, another horizontal well was sidetracked from a shut-down well in Block Su10 with highly certain reservoirs. The sidetracking well has a horizontal section of 700 m long, effective reservoir drilling ratio of 39.4%, and effective producing thickness of 6 m. Due to the unstable development of sand body, many uncertain factors and tracking difficulty in drilling mudstone section, the drilling cycle of this well reached 90 d. After 7-stage fracturing, the well had an initial daily gas production of (2.5-3.0)×104 m3, which was twice that of the adjacent vertical wells. This well realized continuous production, marking major progress in sidetracking horizontal well drilling test.

3.3. Breakthrough stage of sidetracking horizontal well

Based on the advancement of sidetracking horizontal well drilling and completion technology and better understanding on geologic conditions, two old wells in Block Su10 were selected to carry out sidetracking horizontal well test in 2015. These two wells have an average horizontal section of 627 m long, a sandstone drilling ratio of 100%, an effective reservoir drilling ratio of 60.6%, effective producing thickness of 10.3 m, and average drilling cycle of 42 d, with drilling and completion technical problems all overcome successfully. After staged fracturing, they had an initial daily gas production of (3.0-5.0)×104 m3, which is 3-5 times that of adjacent vertical wells. This test marked major breakthrough in drilling ratio, drilling operation and production effect of sidetracking horizontal drilling.

3.4. Application stage of sidetracking horizontal well

After the successful sidetracking horizontal well test in Block Su10, through full demonstration in geology and engineering, it was decided to promote the technology to Block Su53. From 2016 to 2017, sidetracking drilling was successively implemented in 8 old wells in Block Su53. These sidetracking wells have an average horizontal section of 724 m long, effective reservoir drilling ratio of 65.5%, effective producing thickness of above 10 m, and average drilling cycle of 43 d (the well drilled fastest only took 21 d to complete). All eight wells were fractured and put into production. They had an average initial gas production of 5.5×104 m3, among them, the well with the highest production produced 11.0×104 m3 of gas a day. They marked the large scale application of sidetracking horizontal well in Sulige Gas Field.

4. Advantages and difficulties of old well sidetracking in Sulige Gas Field

Sidetracking horizontal wells are small-sized horizontal wells completed by window opening, sidetracking and directional deflecting in the upper part of the casing of oil and gas reservoirs, using part of the wellbore of low-yield and low-efficiency wells and casing-deformed wells in the development of oil and gas fields as well as intact ground equipment[5]. Generally, high-quality reservoirs with stable distribution but a low producing degree in old wells are selected as target layers, and sidetracking drilling and fracturing are carried out to increase the yield of old wells.

4.1. Technical advantage of old well sidetracking

4.1.1. Reduction of development costs

By sidetracking from old wells, this technology can reduce drilling footage, make full use of the original well site and surface pipe network and save pre-drilling construction, wellhead, casing pipe, and well cementation costs. The wellbore of this kind of well is smaller than that of conventional well, so its drilling fluid and drilling cuttings discharge can be reduced by 60%, saving costs for environmental protection; land requisition and road construction costs, etc. can also be reduced[6]. With the implementation of the new “Safe Production Law” and “Environmental Protection Law”, the well construction cost has increased. The number of wells corresponding to fund for 1×108 m3 productivity capacity is reduced, so the cost advantage of old well sidetracking compared with new well is particularly obvious.

4.1.2. The increase of reserves producing degree

Besides, restore production of old wells and increase efficiency, sidetracking horizontal well is also the adjustment and supplement for the existing vertical well pattern and horizontal well pattern. Under the background of confirming the regional gas-bearing characteristics, sidetracking horizontal wells can be deployed properly as infill wells to tap the remaining reserves, reduce dead gas zones and enhance recovery. Compared with vertical wells, sidetracking horizontal wells have larger control area, higher recoverable reserves, increase discharge area and recovery ratio[6]; with the stronger liquid carrying capacity, their output is 3 to 5 times that of vertical wells. Compared with conventional horizontal wells, they have a smaller lower limit of economic recoverable reserves and a shorter horizontal section, so they can be deployed more flexibly, to tap the remaining recoverable gas in poorly vertical superposed and individual layers[7].

4.1.3. Reduction of construction risk

Sidetracking horizontal wells are usually implemented in old well areas, where adjacent wells have abundant data, regional sand body development, reservoir distribution and production capacity are relatively certain, and the old wellbore can serve as a guide for sidetracking horizontal well, which provide a powerful basis for the determination of the target layer, the precise target landing and the geosteering of the horizontal section, and reduce the geological and drilling risks. In addition, Sulige Gas Field has gentle structure, few faults and clear gas and water system in old well areas[8], making it suitable for the implementation of sidetracking horizontal wells.

4.2. Technical difficulties of old well sidetracking

4.2.1. Difficult drilling operation

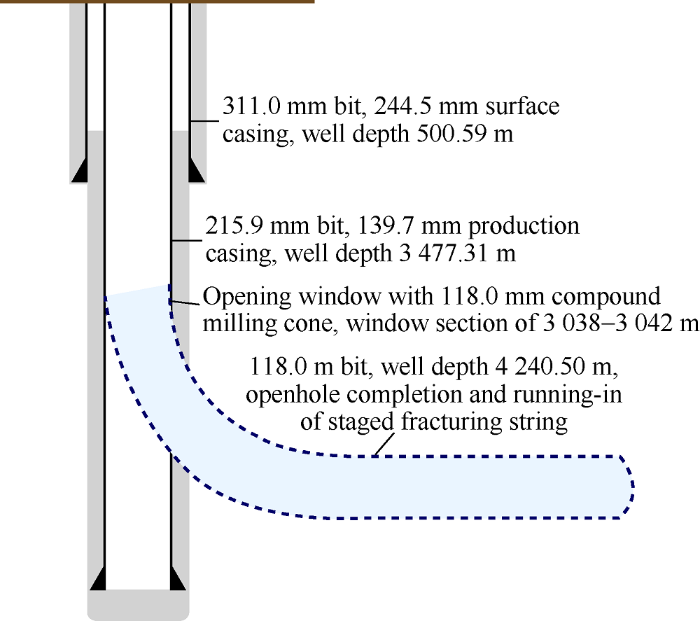

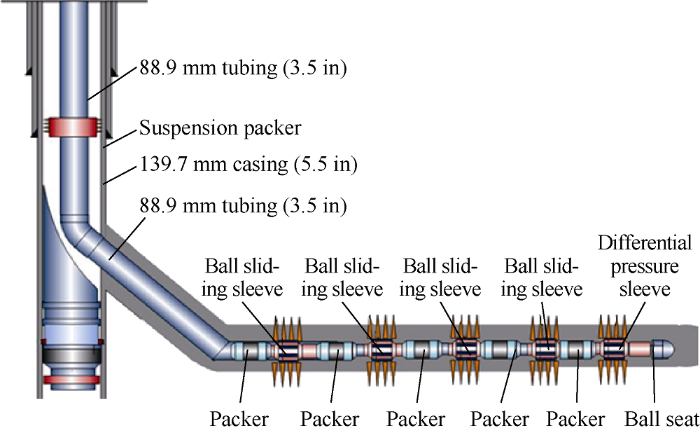

In Sulige area, the casing of most vertical cluster wells in gas reservoirs are Φ139.7 mm, and the sidetracking drilling often involves opening window with Φ118.0 mm compound milling cone in the Φ139.7 mm casing, then drilling the whole well with Φ118.0 mm PDC bit (Fig. 1), and staged fracturing with openhole packers at last[9] (Fig. 2), belonging to the small borehole drilling[10]. Sidetracking horizontal wells often have the following technical problems during the construction process: (1) Deep window opening depth, large casing wall thickness, difficult window opening process. Deflector rotation and milling cone sticking could happen if improper parameters are selected in milling window. When drilling through the window, the deflector may move down and the window may close if the operation is improper[10,11]. (2) Difficult trajectory control, flexible drilling tool combination, low orientation efficiency, large drilling tool friction and torque, insufficient drilling pressure transmission and limited ability to extend horizontal section. (3) Difficult to keep the borehole wall stable. Mudstone in Shiqianfeng and Shihezi Formations is highly hydrated and dispersed and located in the building section of the wellbore, sloughing, collapse, and leak could occur. (4) Small annular clearance, the prominent contradiction between pump pressure and displacement, limited displacement, difficult sand carrying with formation leakage. (5) During the drilling of the deep segment, the drilling fluid often returns somewhat when the pump is stopped, making it difficult to detect overflow when the gas layer is encountered, and bringing about risks of well control. (6) In the event of a stuck drill accident, there are few tools and means to deal due to the limited size of the wellbore, so the quality of drilling tools must be good.

Fig. 1.

Fig. 1.

Structure schematic of sidetracking horizontal well.

Fig. 2.

Fig. 2.

Fracturing string for sidetracking horizontal well.

4.2.2. Difficult evaluation and selection of remaining gas enrichment area

With the development going on, the block has seen problems such as unbalanced utilization of reserves in the developed area and complicated distribution of remaining gas. To recover remaining gas between wells with sidetracking horizontal wells, the favorable zones and target layers must be selected on the basis of the detailed description of the reservoirs between the wells and clear understanding on remaining gas enrichment rules. The reservoirs in the Sulige area are highly heterogeneous, small in scale and variable in gas content, which adds difficulty to evaluate and select remaining gas enrichment areas between local wells.

4.2.3. Well deployment restricted by the basic well pattern

In Block Su10, sidetracking horizontal wells in the already infilled 600 m×600 m vertical cluster well pattern is likely to cause well interference. Moreover, as the adjacent wells are developed in the same layer, the risk of fracturing fluid channeling into the adjacent well is high. Therefore, sidetracking horizontal wells are mostly deployed in areas where productivity is a certain and well pattern is not fully infilled while tapping the remaining gas in infilled areas is relatively difficult. In Block Su53 developed by horizontal wells, on the whole, the sidetracking wells are selected from the evaluation wells or a small number of vertical wells drilled at the beginning of the development and are mostly deployed in the areas with unsaturated wells or at the edges of the block.

5. Key technologies for sidetracking horizontal wells from old wells

After several years of trial and development, the old well-sidetracking technology has made significant progress in the drilling process and geological design and deployment, parameter optimization, and adaptability research forming a set of technology.

5.1. Drilling technology

Overcoming the "collapse, leakage, sticking" complexes in the initial stage, a drilling template of Φ139.7 mm casing sidetracking horizontal well has been set up, including some key drilling technologies for small borehole sidetracking problems:

(1) Slimhole integrated window opening technology. The window opening point conforms to the well profile design and is beneficial to the trajectory control of the open-hole section, with regular window point caliper and good cementing quality, avoiding the unstable complex formation and the casing coupling or centralizer positions. By using the self-developed Φ118.0 mm integrated high-efficiency window-opening tool, the window opening can be completed in one trip[12].

(2) Slimhole drilling speeding up technology. PDC bits were tailor designed, with a higher density of teeth and optimized crown shape to enhance drilling efficiency. The size of the drill coupling is reduced to lower the annular circulation pressure loss, the small-size screw has been carefully selected to improve its matching with the drill bit and extend the usage time. The drilling tool combination and drilling parameters of each well section are optimized, and the double stabilizer is used to drill the horizontal section to improve the angle holding effect and increase the composite drilling. The displacement, pump pressure, and cutting carrying capacity are kept balanced during drilling to ensure cutting carrying efficiency and prevent blockage in annulus[13].

(3) Well trajectory control technology. The drilling tool combination is adjusted carefully according to the formation variation and different well inclination stages, and the deviation of the actual drilling trajectory from the design is analyzed constantly, to predict the build-up rate of the next step and adjust the well trajectory in time. Reasonable reaming and short lifting scheme are made to ensure regularity of well wall.

(4) Drilling fluid technology. Polyamine inhibitor+potassium chloride system with the density of 1.14-1.16 g/cm3 is selected to deal with mudstone collapse, circulation lost and back pressure by making use of its low density, good inhibition and lubricity.

5.2. Optimization of sidetracking horizontal well deployment

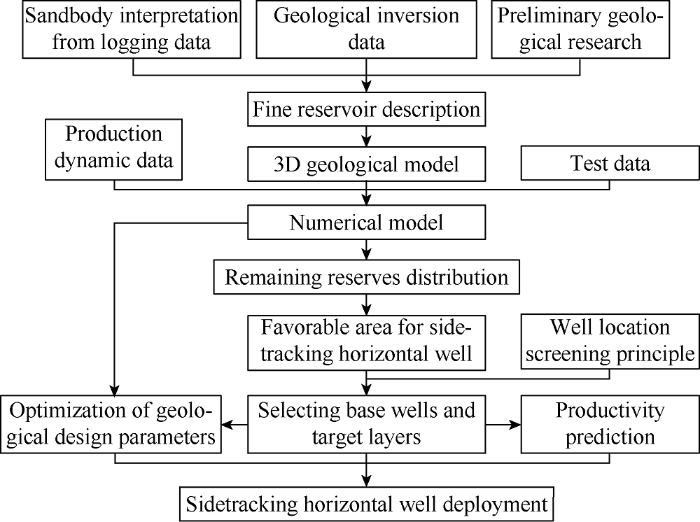

By making full use of the logging interpretation of sand body and seismic inversion data, the reservoirs are described in detail, a three-dimensional geological model is established, and numerical simulation technology is used to find out remaining gas between wells, so the favorable area for sidetracking drilling and appropriate base wells and target layers can be sorted out. According to the geological conditions of target area and base wells and distribution of remaining gas, the deployment of sidetracking horizontal well is optimized and the horizontal section parameters are designed. The technical route for optimizing the deployment of sidetracking horizontal wells is shown in Fig. 3.

Fig. 3.

Fig. 3.

Technical route for optimizing sidetracking horizontal well deployment.

5.2.1. Study on remaining reserves distribution

For the first time, the geological modeling and numerical simulation were combined to quantitatively evaluate remaining gas, which has successfully overcome the problem of difficult prediction of reservoir parameters in strong heterogeneous gas reservoirs. The main methods are: (1) Seismic waveform indication inversion technology[14], spectrum attenuation gas detection technology and reservoir logging evaluation technology were used to predict inter-well gas content and track sand body, to establish a more elaborate three-dimensional prediction model. (2) On the basis of integrating geologic, seismic and logging data, the stochastic simulation technique was adopted to fit the variation function of the variables and establish a three-dimensional reservoir parameter model[15]. The calculated reserves of the 9 main layers from the simulation were less than 2% in error. The simulated production data like gas well pressure and production rate etc. had conformity of 95%, indicating strong reliability of the simulation, which improved the success rate of well deployment. (3) Through analyzing the production characteristics, production capacity and pressure drop and well test of adjacent wells, the reservoir productivity, gas well control radius, and remaining reserves range were figured out to define horizontal displacement and pre-target distance of the wells. The designed pre-target distance for most wells is about 300 m. Through analysis of static and dynamic data and numerical simulation, it is found that the distribution of remaining gas is closely related to sedimentary micro-facies, micro-structure and well pattern. Generally, the lateral margins of the distributary channel are relatively poor in physical properties, and often become the remaining gas enrichment area; the main channel sand belt has a large absolute remaining gas reserve due to the large number of original geological reserves, although it has been developed[6].

5.2.2. Selection of sidetracking horizontal wells

Based on the detailed description of the reservoir and in-depth study of remaining gas distribution, the selection of favorable areas and base wells for sidetracking drilling in Sulige Gas Field adheres to the following principles: (1) The reservoirs with good connectivity, high gas saturation, thin interlayer and effective thickness of more than 8 m are preferred vertically. (2) On the plane, the layers with rich remaining gas, good gas-bearing response on seismic data, confirmed structure, stable reservoir distribution and the thickness of the sand body tracked in horizontal section of greater than 3 m are selected to ensure a high drilling rate and a good wellbore trajectory and reduce drilling failure[13]. (3) The base wells should have a certain reserve basis. Combined with the recovery ratio and input-output analysis, the predicted control reserves should be greater than 5 000×104 m3, and the distance from the adjacent well should meet the requirement of the well pattern to avoid interference between wells. (4) The base wells should have low recovery degree of reserves and are in a state of low production or stoppage.

5.2.3. Optimization of sidetracking horizontal well parameters

According to the geological conditions of the base wells, combined with the development effect of the target area, the numerical simulation technology is used to optimize the parameters of sidetracking horizontal wells, to determine the parameters such as the azimuth, length and longitudinal position of the horizontal section.

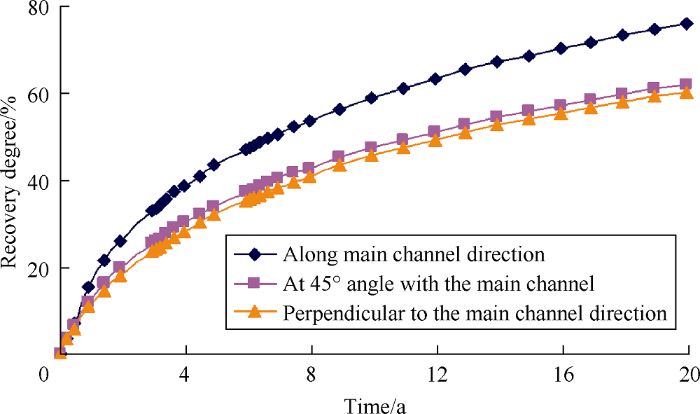

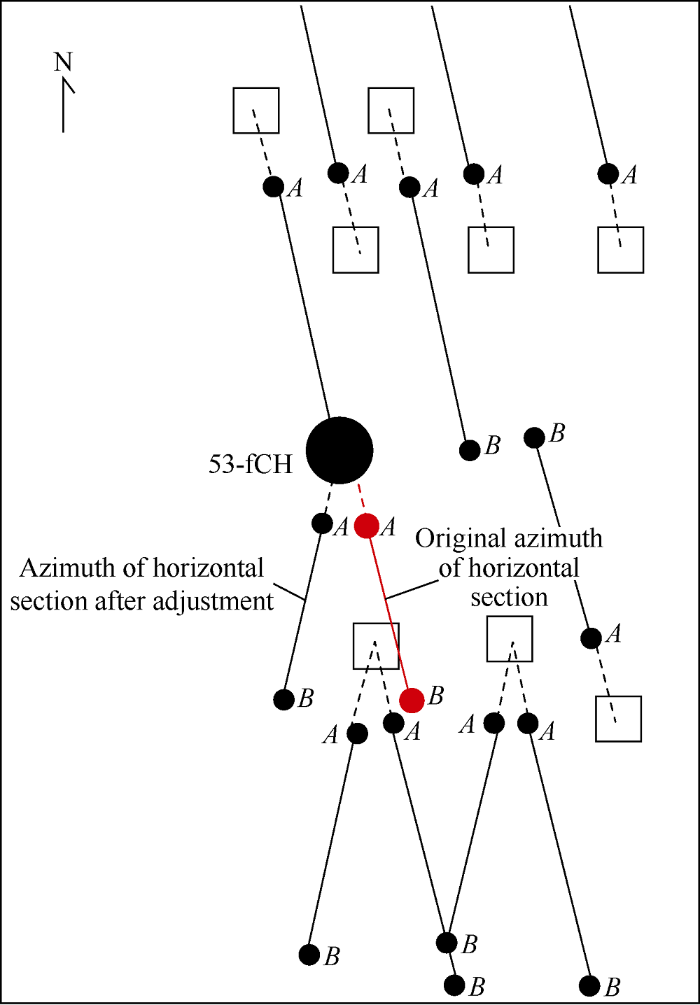

(1) Horizontal section azimuth. The main stress direction of the block is 60°-80° north by east. When the designed horizontal section is about 20° north by west, the fractures in the horizontal section are orthogonal to the well axis by about 90°, and the fracturing effect is the best. Numerical simulation results show that the development effect is the best when the horizontal section is along the main channel[16] (Fig. 4).

Fig. 4.

Fig. 4.

Variation curve of recovery degree with different horizontal section directions.

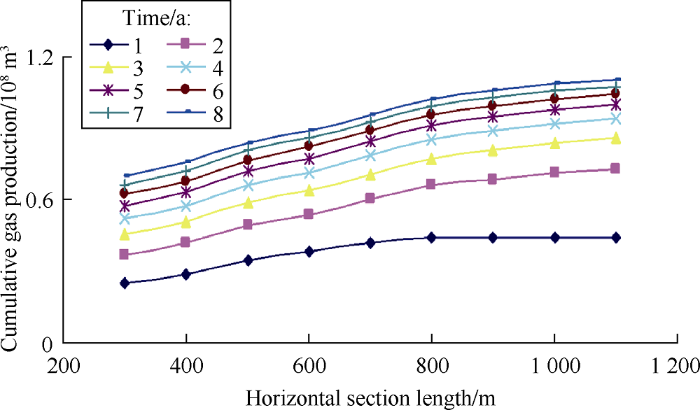

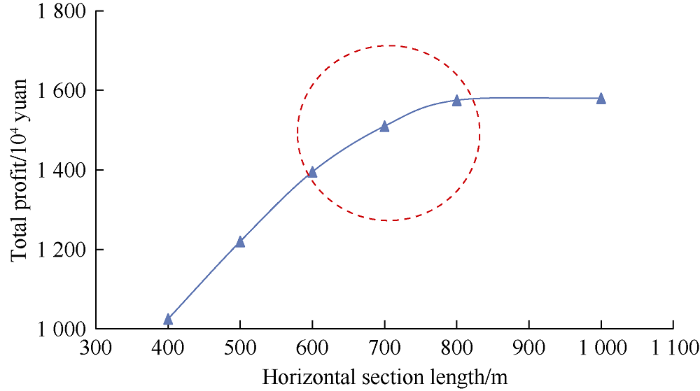

(2) Horizontal section length. The numerical simulation results show that the construction risk is small when the horizontal section is controlled at 600-800 m long, and the conversion between gas production increment and operation cost is beneficial (Figs. 5 and 6). However, the actual design should also consider the deployment space of wells and construction difficulties, etc.

Fig. 5.

Fig. 5.

Relationship between the length of horizontal section and cumulative gas production.

Fig. 6.

Fig. 6.

The relationship between horizontal section length and development profit.

(3) Longitudinal position. The horizontal section should be located in the middle of the target layer with good quality[17], so the reserves in the reservoirs above and below the horizontal section can be produced to the maximum extent after fracturing.

5.3 Geosteering technology for sidetracking horizontal well

As the sidetracking horizontal wellbore trajectory is more difficult to control than conventional wells, there is a risk of facies change that the reservoir may become mudstone in the lateral direction, and with development of micro-structures, the horizontal section may be drilled out from the top or bottom of the reservoir, so strengthening geosteering study for sidetracking horizontal wells is the key to improve the drilling rate of reservoir. Guided by geological research, the reservoirs were predicted by various means such as seismic processing and modeling, and micro-structural models were established to analyze the attitude of target layers, to anticipate trajectory better. The guiding function of the base wells were made full use to select the mark layers and divide the sublayers accurately. The stratigraphic correlation with adjacent wells was strengthened according to the logging curve while drilling so that the trajectory of the well could be adjusted in time to ensure accurate target landing. Under the influence of the blind zone of the measuring instrument, the drilling time, torque, sedimentary cycles, cuttings grain grading characteristics, and formation deflecting ability, etc. were used to predict the bottom lithology and improve the drilling rate of effective reservoir[18]. Through the application of geosteering technology, the average drilling rate of the effective reservoir has gone up from 46.5% to 69.3%.

6. Development effect of sidetracking horizontal wells in Sulige Gas Field

From 2011 to 2017, 12 sidetracking horizontal wells were drilled in Block Su10 and Su53, and the drilling cycle shortened from the initial 90 d to approximately 40 d, averaging at 49 d. The horizontal section increased from 500 m to about 800 m long, with an average of 689 m, the sand drilling ratio went up from 50% to over 90%, with an average of 84.2%; the drilling ratio of effective reservoir increased from 40% to over 70%, with an average more than 61.5%, the produced thickness of effective gas layer was 6.0 to 12.3 m, with an average of 9.6 m, the gas saturation was 40.6% to 75.9%, with an average of 56.5%; the controlled reserves were (3 180-11 943)×104 m3, with an average of 6 438×104 m3 (Table 1). Before sidetracking, the average daily gas production per well was less than 0.1×104 m3 and the cumulative gas production was 568×104 m3. The sidetracking horizontal wells had an average initial wellhead pressure of 16.2 MPa and the average initial gas production of 4.7×104 m3 after putting into production. By the end of 2017, they had an average gas production increment per well of more than 1 000×104 m3, showing substantial production increase (Table 2).

Table 1 Statistics on the drilling rate of sidetracking horizontal wells.

| Serial number | Well | Sidetracking year | Drilling cycle/d | Horizontal section length/m | Sandstone drilling ratio/% | Effective reservoir drilling ratio/% | Produced effective gas layer thickness/m | Gas saturation/% | Controlled reserves/ 104 m3 | Target layer |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Su10-aCH | 2011 | 61 | 528 | 89.2 | 53.6 | 6.4 | 48.5 | 3 180 | P2h86 |

| 2 | Su10-bCH | 2012 | 92 | 700 | 53.7 | 39.4 | 6.0 | 58.9 | 3 652 | P2h86 |

| 3 | Su10-cCH | 2015 | 37 | 654 | 100.0 | 38.4 | 11.9 | 48.6 | 5 070 | P2h85 |

| 4 | Su10-dCH | 2015 | 47 | 600 | 100.0 | 82.8 | 8.7 | 50.1 | 4 765 | P2h85 |

| 5 | Su53-aCH | 2016 | 36 | 800 | 16.5 | 16.5 | 11.2 | 49.5 | 4 578 | P1S17 |

| 6 | Su53-bCH | 2016 | 21 | 800 | 100.0 | 72.6 | 8.3 | 75.9 | 9 169 | P2h86 |

| 7 | Su53-cCH | 2016 | 33 | 800 | 98.3 | 90.6 | 8.7 | 40.6 | 5 129 | P2h86 |

| 8 | Su53-dCH | 2016 | 52 | 769 | 86.2 | 23.4 | 8.7 | 53.1 | 3 397 | P1S17 |

| 9 | Su53-eCH | 2016 | 62 | 558 | 72.0 | 65.1 | 10.9 | 64.8 | 6 404 | P2h85 |

| 10 | Su53-fCH | 2017 | 34 | 668 | 97.8 | 92.1 | 11.5 | 71.3 | 11 943 | P2h85 |

| 11 | Su53-gCH | 2017 | 60 | 593 | 97.8 | 76.1 | 12.3 | 57.8 | 9 254 | P1S17 |

| 12 | Su53-hCH | 2017 | 49 | 800 | 98.8 | 87.4 | 10.4 | 58.3 | 10 716 | P2h86 |

| Average | 49 | 689 | 84.2 | 61.5 | 9.6 | 56.5 | 6 438 |

Table 2 Production statistics of sidetracking horizontal wells.

| Serial number | Well | Date of production | Before sidetracking | After sidetracking | December 31, 2017 | |||

|---|---|---|---|---|---|---|---|---|

| Daily gas pro- duction/104 m3 | Cumulative gas production/104 m3 | Initial wellhead pressure/MPa | Initial daily gas production/104 m3 | Daily gas production/104 m3 | Production increment/104 m3 | |||

| 1 | Su10-aCH | 2011-07-20 | 0 | 235 | 13.5 | 1.8 | 0 | 545 |

| 2 | Su10-bCH | 2012-08-28 | 0.10 | 862 | 16.0 | 2.8 | 0.82 | 2 161 |

| 3 | Su10-cCH | 2015-05-27 | 0 | 252 | 21.0 | 4.5 | 1.16 | 2 017 |

| 4 | Su10-dCH | 2015-12-06 | 0 | 195 | 19.5 | 3.5 | 1.39 | 1 067 |

| 5 | Su53-aCH | 2016-12-03 | 0 | 280 | 17.2 | 3.5 | 1.42 | 634 |

| 6 | Su53-bCH | 2017-03-14 | 0.10 | 975 | 21.0 | 9.0 | 5.32 | 2 053 |

| 7 | Su53-cCH | 2017-03-19 | 0.10 | 401 | 19.5 | 5.0 | 3.95 | 1 008 |

| 8 | Su53-dCH | 2017-04-04 | 0.15 | 703 | 5.9 | 6.0 | 2.85 | 905 |

| 9 | Su53-eCH | 2017-04-24 | 0.05 | 312 | 14.2 | 3.0 | 3.30 | 1 048 |

| 10 | Su53-fCH | 2017-10-18 | 0.10 | 1 521 | 20.0 | 11.0 | 11.65 | 680 |

| 11 | Su53-gCH | 2017-11-07 | 0.03 | 552 | 14.0 | 3.0 | 3.17 | 192 |

| 12 | Su53-hCH | 2017-11-21 | 0.07 | 535 | 13.0 | 3.5 | 3.88 | 133 |

| Average | 0.06 | 568 | 16.2 | 4.7 | 3.24 | 1 037 | ||

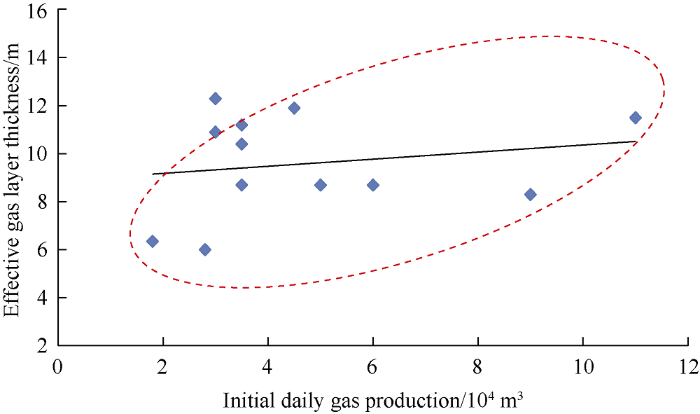

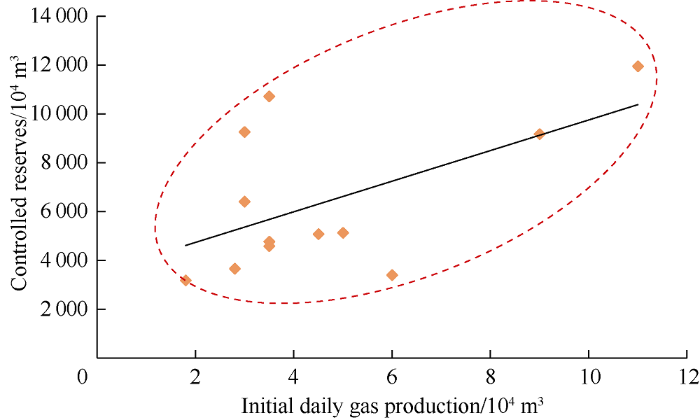

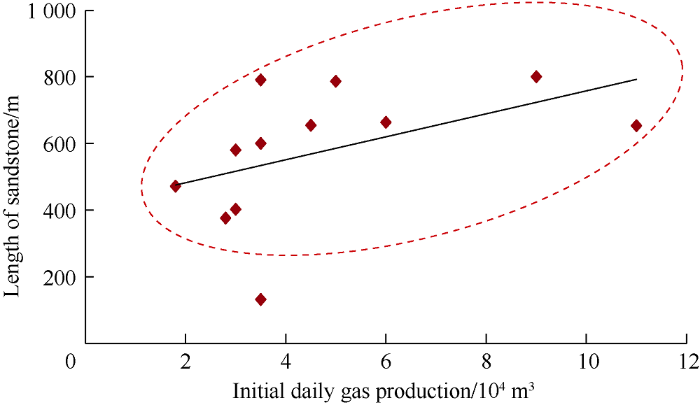

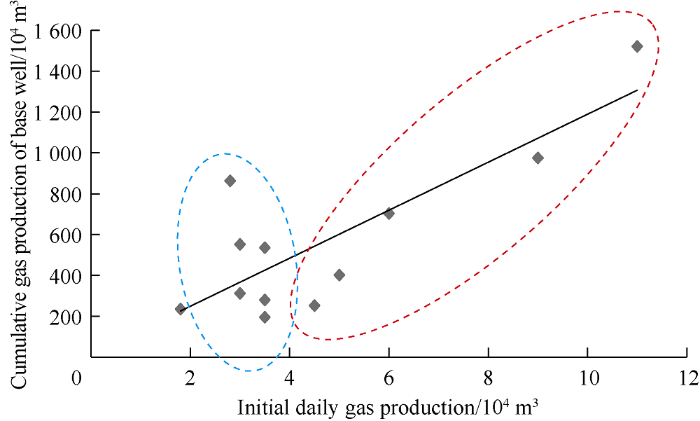

The production performance of sidetracking horizontal wells is affected by the length of the horizontal section, length of sandstone segment, the position of the horizontal section in the reservoir, produced effective gas layer thickness, gas saturation, controlled reserves, and fracturing, etc. Correlation analysis shows that there is an apparently positive correlation between the initial daily gas production and the produced effective gas layer thickness, length of sandstone segment and controlled reserves (Figs. 7, 8 and 9). From the cross-plot of the cumulative gas production of base wells and the initial daily gas production after the sidetracking (Fig. 10), it is found that when the initial daily gas production is less than 4×104 m3, it has no clear correlation with the cumulative gas production of old wells. When the initial daily gas production is greater than 4×104 m3, it has an obviously positive correlation with the cumulative gas production of old wells, and the maximum cumulative gas production of old wells did not exceed 1 600×104 m3.

Fig. 7.

Fig. 7.

Cross plot of effective gas layer thickness and initial daily gas production.

Fig. 8.

Fig. 8.

Cross plot of controlled reserves and initial daily gas production.

Fig. 9.

Fig. 9.

cross plot of length of sandstone and initial daily gas production.

Fig. 10.

Fig. 10.

Cross plot of cumulative gas production of base well and daily gas production of sidetracking horizontal well.

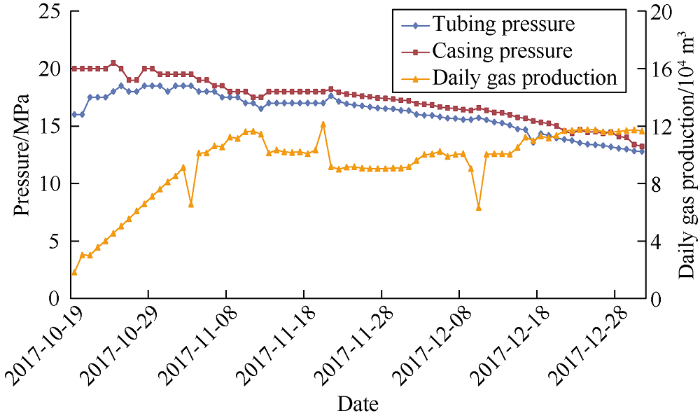

The base well of Su53-fCH, Su53-f, is located at the edge of Block Su53, the effective reservoir thickness of He-8-5 the layer where the base well and adjacent well located is large. Through the fine stratigraphic comparison, it is found that the planar distribution of this layer is stable, seismic inversion, seismic frequency spectrum attenuation, and prediction model result all show good gas content, the formation attitude is stable, and the cumulative gas production of the adjacent wells exceeded 1×108 m3, indicating certain production capacity. Therefore, a sidetracking horizontal well was deployed based on Su53-f (Fig. 11), the reservoirs in the horizontal section A and B were both confirmed, the length of the horizontal section was designed at 700 m. Considering the regional well spacing, in order to avoid well interference, the azimuth of the horizontal section was adjusted from south by east 20° to south by west 20°. Su53-fCH was drilled in 2017, with a drilling cycle of 34 d, sand drilling ratio of 97.8%, and drilling ratio of effective reservoir of 92.1%. The horizontal section, traversing the middle of the reservoir, has an produced effective producing thickness of 11.5 m, and controlled reserves of 11 943×104 m3. After put into production, the well had an initial pressure of 20 MPa and a daily gas production of 11×104 m3, showing remarkable production increase (Fig. 12).

Fig. 11.

Fig. 11.

Location of Well Su 53-fCH.

Fig. 12.

Fig. 12.

Production curve of Well Su 53-fCH in the initial stage of production.

7. Development direction of sidetracking horizontal drilling of old wells in Sulige Gas Field

Sidetracking horizontal well has become an effective means to tap remaining gas between wells, increase production of old wells and keep block production stable in Sulige Gas Field, and is still innovating and developing, its development directions are as follows.

7.1. Well pattern planning innovation

Sidetracking horizontal wells have the advantages of low cost and selective development, but currently limited by the basic well pattern, this measure can only be taken in the limited area. When the block is expanded or deployed step-out, sidetracking horizontal well pattern can be planned in advance to make use of its advantages, instead of a well pattern of 600 m×600 m vertical or horizontal wells. If the effect of vertical well drilling is good in the step-out area, with high production layer confirmed, sidetracking horizontal well infilling can be used to enhance reserves exploitation or the horizontal well can be deployed directly in the adjacent area at the later stage. If the reservoir is found thin by drilling a vertical well, making it difficult to drill sidetracking horizontal wells, infilled vertical wells can be taken later on. Therefore, according to the distribution characteristics of different reservoirs, the mixed pattern of a vertical well, horizontal well and sidetracking horizontal well can be selected[19].

7.2. Optimization of sidetracking horizontal well construction and parameter

The research of drilling and completion technology should be strengthened, and bit, drilling tool and drilling fluid system should be improved constantly to lower the difficulty of sidetracking horizontal well construction, shorten the drilling cycle, and reduce the costs. On the basis of reducing drilling risk and cost, sidetracking horizontal drilling with the long horizontal section, stepped horizontal wells and large displacement tests can be carried out for further improving development benefits.

7.3. Expansion of sidetracking horizontal well application

In the overall development area of horizontal wells, according to the utilization of reservoirs, the gas bearing condition, interlayer condition and utilization of adjacent wells of remaining unproduced reservoirs should be examined. If there is the possibility of separate layer development, a double- branch sidetracking horizontal well can be tested to explore the sidetracking stimulation technology based on horizontal well. In the infilled vertical well area, if the unproduced reservoirs meet the requirements of separate layer development, the sidetracking horizontal well may also be tried.

8. Conclusions

The development of sidetracking horizontal drilling in old wells in Sulige Gas Field has experienced four stages: test, development, breakthrough and large-scale application. It has become an effective measure to increase the production of old wells.

Sidetracking horizontal wells can greatly reduce development costs and produce remaining reserves between wells, with the output of 3 to 5 times that of adjacent vertical wells. They have more certain reservoir geological conditions. But this technology also faces difficulties such as tricky issues in drilling and completion, high technical level requirements, evaluation of remaining gas enrichment areas, and deployment limited by the basic well pattern.

After several years of development, the sidetracking horizontal well technology in Sulige Gas Field has formed a set of key technologies on drilling and completion, remaining reserves distribution research, favorable area selection, parameter optimization, and geosteering, which have effectively solved the difficulties in sidetracking drilling, enabling its large-scale application.

In Block Su10 and Su53, 12 sidetracking horizontal wells were drilled with a remarkable yield increase. The production of sidetracking horizontal wells is positive-correlated with produced effective gas reservoir thickness, length of sandstone segment and controlled reserves. The old well recovery degree is not the main factor affecting the production effect of the sidetracking horizontal well.

Sidetracking horizontal well can develop in the directions of innovative well pattern planning, optimizing well pattern layout and design parameters, testing long horizontal section and large displacement and expanding application area. This technology will have broad application prospects.

Reference

Horizontal well development technology for tight sandstone gas reservoirs in the Sulige Gas Field, Ordos Basin

Practice and recognition of horizontal well development in tight sandstone gas reservoirs: A case study from Block Su53

Controlling factors of underpressure reservoirs in the Sulige gas field, Ordos Basin

Well spacing optimization for Sulige tight sand gas field, NW China

Horizontal well drilling technology by slim hole casing window sidetracking in Daqing Oilfield.

Application prospect of sidetracking horizontal technology in old wells in Sulige gasfield

Method for taking the potential of residual oil in mid-high permeability and high water-cut reservoirs by using sidetracking horizontal wells

Water and gas distribution and its controlling factors of large scale tight sand gas: A case study of western Sulige gas field, Ordos Basin, NW China

Application of multi-stage fracture completion techniques of horizontal well with slim hole oriented window and sidetracking in gas field

Brief talk on sidetrack horizontal well technology in Sulige Gas Field old wells

Study and application of case overshot for sidetrack drilling horizontal well technology

Application method of slim hole slanting device in Sulige gas field

Practice of horizontal well drilling technology in deep small hole side drilling

Analysis and countermeasurement of seismic prediction in the Sulige Gas Field

3D geological modeling for tight sand gas reservoir of braided river facies

Parameter optimization and application of sidetracking horizontal wells in low-permeability tight gas reservoir: A case study of Su-S Block in Sulige Gas Field

Optimization of horizontal well development technology in the Sulige Gas Field

Application of geosteering technology in the development of Sulige gas field: Case studies of the Su10 and Su53 blocks

Well type and pattern optimization technology for large scale tight sand gas, Sulige gas field