Introduction

As a highlight in global unconventional oil exploration and development, tight oil has become an important replacement resource for increasing production and reserves in major oil fields of China[1,2]. In 2013, the US Energy Information Administration (EIA) predicted that the global tight oil recoverable reserves were 473×108 t, and by 2035, tight oil production would account for 45%[3] of total oil production in the world. China's tight oil resources are abundant, and it is preliminarily predicted that the distribution area of tight oil in the main onshore basins in China is 50×104 km2, the amount of geological resources is about 200×108 t, and the amount of technological recoverable resources (20-50)×108 t[4]. At present, although the horizontal well and volumetric fracturing stimulation have realized the initial scale utilization of tight oil, the overall recovery of tight reservoirs is less than 10%, and it is urgent to develop new technologies to effectively develop tight reservoir resources[5,6,7,8]. In oilfields such as Changqing, Daqing and Jilin, water huff-and-puff has been tested in some tight oil blocks and achieved some progress. Meanwhile, some problems have been disclosed. The solution to these problems depends on deep understanding of the imbibition mechanism of tight reservoirs. Tight reservoirs have many micro-fractures, so their productivity can be increased by creating a more complicated network system of pores, micro-fractures and artificial fractures with large-scale volumetric fracturing. But as the fracture and matrix differ widely in permeability, the injected water is highly likely to channel along fractures, resulting in a large amount of residual oil left in the matrix and poor water flooding effect. How to effectively make use of the imbibition effect between the fracture and matrix to increase the producing degree of oil in the matrix has become key to enhance the development effect of tight oil reservoir[9,10,11,12,13].

Imbibition is the process of replacing the non-wetting phase by the wetting phase through capillary force. Many researchers at home and abroad have conducted related researches. In 1952, Brownscombe et al.[14] proposed that the imbibition effect could enhance oil production. Subsequently, a number of researchers[15,16,17,18,19,20] conducted systematic studies on the spontaneous imbibition process in porous media, analyzed the effects of various factors on spontaneous imbibition, and established corresponding imbibition models. But many of these studies were based on fractured reservoirs, and few were on tight reservoirs, and the imbibition effect and imbibition distance during the displacement process were seldom covered.

In this study, the high-pressure large-model physical simulation system and nuclear magnetic resonance technology[21] are adopted to establish a physical simulation experiment approach of core imbibition at different scales, to investigate the impact of permeability, fracture and wettability on the imbibition of tight core, study the magnitude of the displacement and imbibition, propagation distance of the imbibition effect, and reveal the mechanism of imbibition in tight reservoirs, and explore the theoretical basis for efficient development of tight reservoirs by imbibition.

1. Factors affecting reverse imbibition in tight reservoirs

Reverse imbibition refers to a phenomenon of imbibition in which the direction of inhalation and the direction of discharge are completely opposite. In the process of water- flooding huff and puff, reverse imbibition plays an important role in the transport of fluid between fractures and matrix. Imbibition physical modeling experiment were conducted on core samples shown in Table 1 to investigate the effects of permeability, fracture and wettability on reverse imbibition.

Table 1 Basic physical properties of the core samples.

| No. | Influence Factor | Length/ cm | Diameter/ cm | Permeability/ 10-3 μm2 | Poro- sity | Wett- ability |

|---|---|---|---|---|---|---|

| 1 | Permea- bility | 7.08 | 2.50 | 0.21 | 0.095 | Weakly water-wet |

| 2 | 7.23 | 2.50 | 1.52 | 0.138 | Weakly water-wet | |

| 3 | 7.16 | 2.50 | 8.16 | 0.168 | Weakly water-wet | |

| 4 | Frac- ture | 6.95 | 2.50 | 0.22 | 0.098 | Weakly water-wet |

| 5 | 6.95 | 2.50 | 0.22 | 0.010 | Weakly water-wet | |

| 6 | Wett- ability | 7.12 | 2.50 | 0.26 | 0.101 | Strongly water-wet |

| 7 | 7.12 | 2.50 | 0.26 | 0.102 | Weakly water-wet | |

| 8 | 7.12 | 2.50 | 0.26 | 0.099 | Neutral | |

| 9 | 7.12 | 2.50 | 0.26 | 0.101 | Strongly oil-wet |

1.1. Permeability

Three core samples with air permeability of 0.21×10-3 μm2, 1.52×10-3 μm2 and 8.16×10-3 μm2 were selected (No. 1, No. 2, No. 3 in Table 1) to carry out experiments. Experiment steps: (1) The core appearance and one end face was sealed with PTFE material, leaving only one end face of the core connected with the outside. (2) The core was vacuumed and then saturated with crude oil and then placed in the experimental system to ensure that the end face of the core connected to the outside contact with water, while no pressure gradient was generated inside the core. (3) The crude oil was displaced by capillary force and discharged from the inlet end, and the produced oil was introduced into the oil-water separator by the peristaltic pump, with the oil volume recorded.

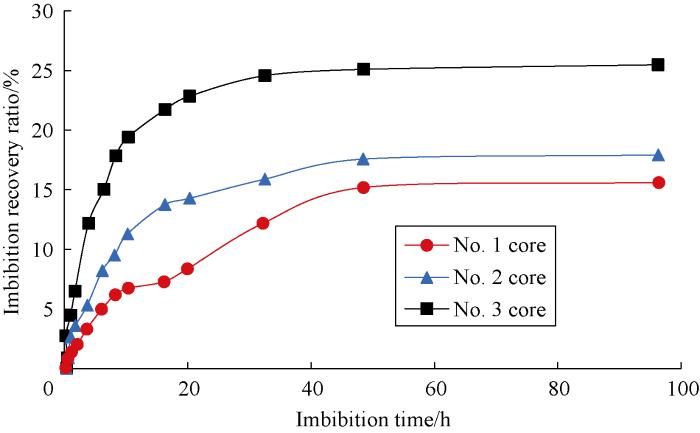

The experiment results are shown in Fig. 1, in which the degree of imbibition recovery is the percentage ratio of the oil produced by imbibition to the initial total oil to saturate the sample. It can be seen that during imbibition, the lower the permeability, the longer the imbibition balance time, the lower the recovery ratio will be, and the later the oil droplet will precipitate. As the permeability increases, both the rate and recovery degree of imbibition increase.

Fig. 1.

Fig. 1.

Comparison of imbibition effect of cores with different permeabilities.

Reverse imbibition is controlled by the physical properties of the reservoir and mechanical mechanism. Reverse imbibition includes two processes: (1) Water inhalation process, which depends mainly on the capillary force. In the case of constant wettability, the smaller the capillary radius is, the lower the permeability, the greater the capillary force, and the greater the water imbibing distance will be. (2) During the oil discharge process, the resistances to oil discharge are the starting pressure of single-phase oil and the resistance of oil-water two-phase flow. These forces are directly related to permeability, that is, the greater the permeability is, the smaller the resistance is, and the easier it is for the oil to discharge, so the greater the permeability, the higher the recovery ratio of reverse imbibition will be.

1.2. Fractures

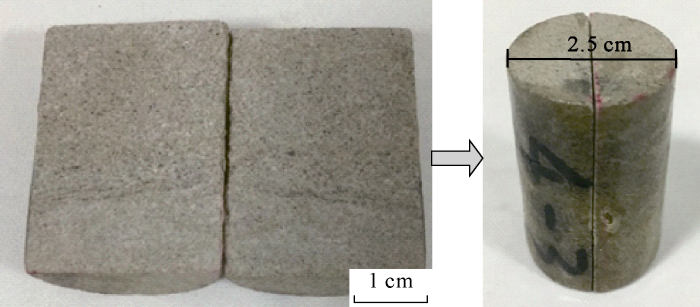

In order to analyze the effect of fractures on the imbibition effect, the No. 4 and No. 5 core samples in Table 1 were selected to do experiments (with matrix air permeability of 0.22×10-3 μm2), and one of them was cut into two parts along the axis, then the two parts were pieced together to construct an artificial fracture (Fig. 2), to represent fractured core. Imbibition experiments were done on the two samples to compare the results.

Fig. 2.

Fig. 2.

Schematic diagram of artificial fracture in the core.

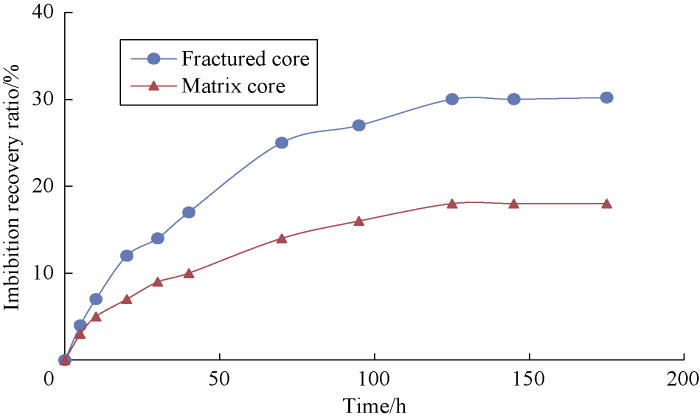

The experiment results are shown in Fig. 3. It can be seen that the existence of the fracture not only enlarges the imbibition area of the tight matrix in contact with water and the range of imbibition front, but also reduces the resistance of oil discharge and improves the imbibition rate and recovery ratio. Therefore, large-scale volumetric fracturing stimulation and water-flooding huff and puff of tight reservoirs can be carried out to enhance the rate of oil drainage and the degree of recovery and improve the development performance by making use of the mechanism of water inhalation and oil drainage of reverse imbibition.

Fig. 3.

Fig. 3.

Comparison of imbibition effects of fractured and matrix cores.

1.3. Wettability

Four matrix cores No. 6-9 with same air permeability of 0.26×10-3 μm2 and different wettability in Table 1 were selected to do reverse imbibition experiments (strongly water-wet, weakly water-wet, neutral and strongly oil-wet). The test results are shown in Table 2. It can be seen that the reverse oil imbibition and drainage efficiency of the strongly water-wet core is the highest, being 19.12%; the reverse oil imbibition and drainage efficiency of the strongly oil-wet core is the lowest, being 2.82%, with oil displacement efficiency 16.3% lower than that of the strongly water-wet core. Therefore, in the water flooding huff-and-puff of tight reservoir, the wettability of the reservoir can be changed to improve development effect.

Table 2 Imbibition performance of cores with different wettability.

| Wettability | Oil recovery by imbibition/% | Wettability | Oil recovery by imbibition/% |

|---|---|---|---|

| Strongly water-wet | 19.12 | Neutral | 11.57 |

| Weakly water-wet | 15.23 | Strongly oil-wet | 2.82 |

2. Quantitative evaluation method for imbibition during water flooding

In the process of water flooding in hydrophilic reservoirs, capillary force is the main driving force of imbibition. The microscopic image of water flooding[22] confirms that capillary force mainly drives crude oil near the wall of large pores and crude oil in the small pores, while the flooding pressure mainly drives the crude oil in the middle part of large pores. No papers about how to quantitatively evaluate the magnitude of imbibition have been published so far. Therefore, in this study, water flooding experiment and nuclear magnetic resonance spectroscopy were combined to work out a quantitative evaluation method for the imbibition magnitude during water flooding.

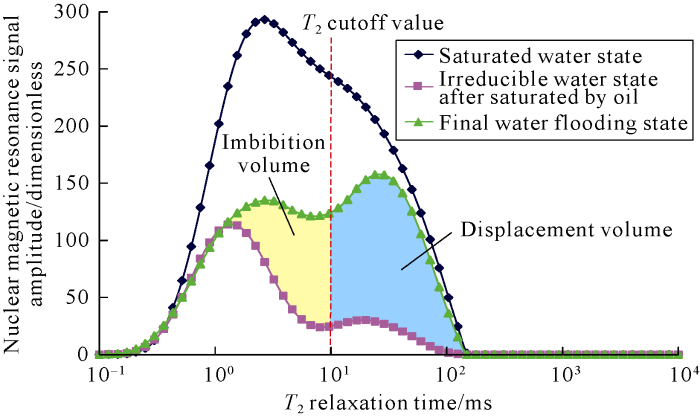

The relaxation time (T2) in the NMR spectrum is a parameter characterizing the amount of energy transferring by fluid. The T2 value of the fluid at the wall of the small and large channels are small, while the T2 value of the fluid in the middle of the large pore throats is large, and a T2 cutoff value can be used to separate the MRI spectrum[20], with the left part representing the fluid signal at the wall of large pores and small pores, and the right part representing the fluid signal in the middle of the large pore throats. Cores were selected to do oil displacement experiments to test the nuclear magnetic resonance signals in the state of saturated water, bound water, and at the end of water flooding, and the corresponding nuclear magnetic resonance spectra were obtained (Fig. 4) to calculate the recovery amount of imbibition and displacement, and evaluate the magnitude of imbibition and displacement quantitatively.

Fig. 4.

Fig. 4.

Schematic diagram of quantitative evaluation of imbibition during water flooding.

Experiment steps: (1) Vacuum the dried core and then saturate the core with water, complete the first nuclear magnetic resonance spectrum test, and obtain the fluid distribution of the whole core (saturated water state); (2) Displace the core saturated by water with dehydrogenation simulated oil (no signal in nuclear magnetic resonance), establish irreducible water saturation, complete the second time nuclear magnetic resonance spectrum (distribution of trapped water after saturated water flooding) test, the area surrounded by the two nuclear magnetic test curves of the first and second times was the distribution state of saturated oil; (3) Then the oil was displaced by water till no oil came out anymore to obtain the residual oil saturation field, and the third nuclear magnetic resonance spectrum (final conditions of water flooding) test was done. It can be seen from the experimental process that the difference between the third and second times nuclear magnetic resonance spectra is the produced oil (the sum of the areas of the yellow and blue parts in Fig. 4), and the right side of the T2 cutoff is the fluid produced in the middle of the large pore by displacement; the left side of the T2 cutoff value is the fluid produced from the wall of large pores and small pores by imbibition. It can be seen that the recovery ratio of displacement and imbibition can be quantitatively evaluated by the nuclear magnetic resonance spectrum.

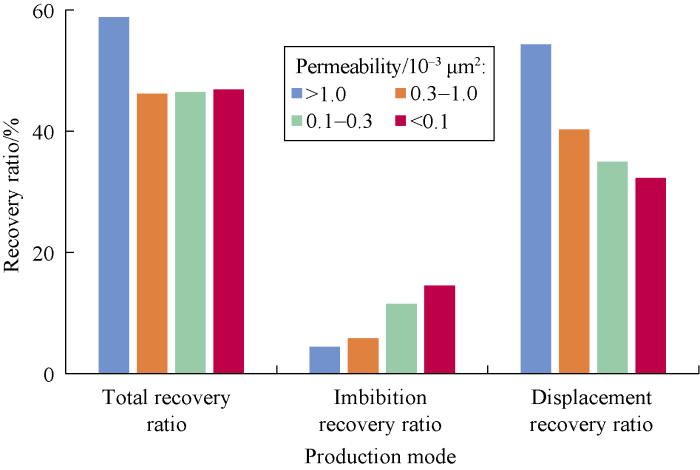

According to the method mentioned above, the water flooding NMR spectrum of 32 core samples in the Chang 7 tight reservoir of Changqing oil field were tested (Fig. 5), in which 2 core samples had a permeability greater than 1.0×10-3 μm2, 4 have permeability of (0.3-1.0)×10-3 μm2, 11 have permeability of (0.1-0.3)×10-3 μm2, and 15 have permeability of less than 0.1×10-3 μm2. It can be seen from the figure that the recovery ratio of displacement decreases with the decrease of permeability, while the recovery ratio of imbibition increases with the decrease of permeability, indicating that the lower the permeability is, the more obvious the imbibition effect will be.

Fig. 5.

Fig. 5.

Variation of the recovery ratio of imbibition and displacement of cores with different permeabilities.

It should be noted that the imbibition in the case of water displacing oil is a forward imbibition rather than a reverse imbibition under water flooding huff-and-puff. The effect of forward imbibition is mainly manifested by the percolation ability of water, that is, the smaller the permeability is, the smaller the capillary radius, the greater the capillary force, the stronger the imbibition effect, and the higher the recovery ratio of imbibition will be.

3. Propagation distance of imbibition

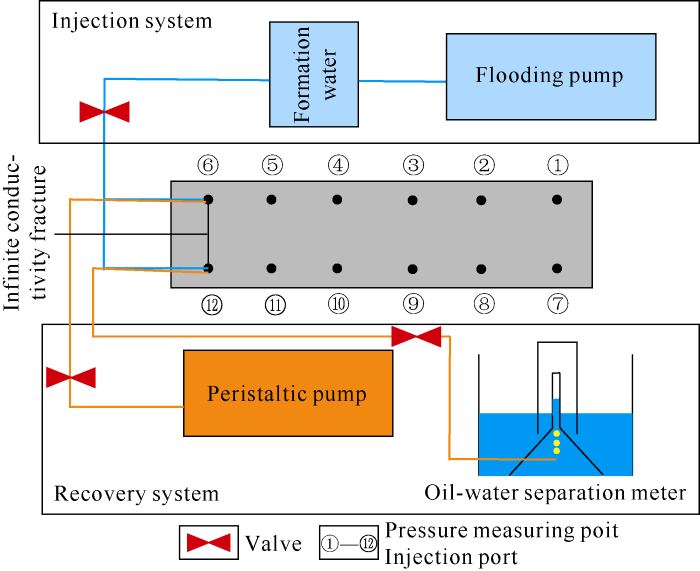

The propagation distance of imbibition is an important parameter reflecting the strength of imbibition. In this study, two high-pressure large-model experiments were designed using the self-developed high-pressure large-model experimental system[23]: (1) High-pressure large-scale model water-flooding huff-and-puff experiment, the experimental system consists of 4 parts, an injection system (Quizix displacement pump), a production system (speed regulatable peristaltic pump and oil-water separation and metering device), a monitoring system (pressure sensor) and a packaged outcrop rock sample (Fig. 6), and the experiment was carried out according to the “injection-stuffy-recovery” process. Firstly, the No. 6 and No. 12 valves at the fracture end were opened to simulate the process of groundwater injection to replenish formation energy with the injection pressure of 20 MPa, then the No. 6 and No. 12 valves were closed and placed under constant pressure for 15 h to simulate the process of fluid imbibition and replacement in underground closed wells, and finally the No. 6 and No. 12 valves were opened to simulate the process of underground oil production. (2) The reverse imbibition experiment was carried out using the experimental system shown in Fig. 6. The injection speed was designed to be 0.5 mL/min. Water was continuously injected from the No. 6 valve and continuously extracted from the No. 12 valve. The fracture connecting the No. 6 and No. 12 valves was a fracture with infinite conductivity, and there was no seepage resistance between the two valves, ensuring that only reverse imbibition would occur on the fracture surface in the reverse imbibition experiment.

Fig. 6.

Fig. 6.

Large model water-flooding huff-and-puff experiment system.

The principle of testing the imbibition distance is that by comparing the change pattern of the pressure field before and after the high pressure large model water huff-and-puff and reverse imbibition experiment, the sweeping distance of injected water and the distance of reverse imbibition were estimated.

Two outcrop rock samples (size 40 cm×10 cm×2.7 cm) with very similar air permeability (about 0.2×10-3 μm2) were selected for reverse imbibition and water huff-and-puff experiments. The outcrop rock samples have low permeability and large volume, and the conventional method of vacuuming and fluid saturation was difficult to meet the experimental requirements. In order to solve the problem, a large model multi-point vacuuming and fluid saturating method was developed according to the literature [19]: (1) The large model was vacuumed from 1-5 injection ports to ensure that the place was in vacuum state. (2) Brine was injected from the injection ports 6-12 (50 mg/mL standard brine, to avoid damage to the rock sample by fresh water injection). (3) When the overall vacuum degree of the outcrop rock restored to atmospheric pressure, the resistivity in all directions was tested to ensure that the model was completely saturated with water. (4) The outcrop rock sample saturated with water was put into the high pressure large model holder to be saturated with oil (vacuum pump oil and kerosene were mixed into simulated oil with a viscosity of 1.48 mPa•s), that was to first saturate the sample with the simulated oil by means of row injection and then re-saturate the sample at the cross injection-production ports. (5) The change of resistivity in all directions was tested to ensure that the model reached the original oil saturation state in the formation.

The experiment steps are as follows: (1) Simulated oil was injected to drive from the fracture-free end of the large model, and the pressure changes at the measuring points of the model at different times were recorded. (2) Water-flooding huff and puff (3 rounds, periodic injection volume of 5 mL) and reverse imbibition experiment were conducted respectively. (3) The rock sample was displaced again from the fracture-free end with simulated oil, and the pressure changes at each test point at different times were recorded.

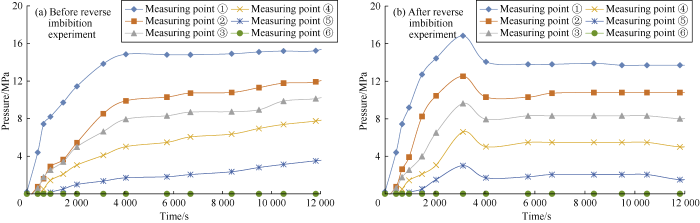

Fig. 7 shows the pressure variations at each measuring point before and after imbibition in the reverse imbibition experiment of the outcrop rock with permeability of 0.2×10-3 μm2. It can be seen that: (1) Before the reverse imbibition experiment, the pressure at each testing point gradually increased with displacement time. When the displacement time reached 4000 s, the pressure of each measuring point was basically stable, indicating that the internal resistance gradient of the model was stable, reflecting the single-phase percolation law of the model. (2) After the reverse imbibition experiment, when the sample was displaced by the simulated oil, the pressure of each measuring point increased first and then decreased with time, and then became parallel. This is because under the action of reverse imbibition, when the water enters into the matrix, a transition zone of oil-water two-phase is formed, while the region not affected by water still only has the oil phase, which results in different seepage resistances in the two regions. The pressure reached the maximum at each measuring point at 3 100 s. Comparing the pressure values before and after the experiment, it can be seen that the displacement pressure increased significantly after the reverse imbibition experiment. Except for the measuring point at the fracture end, the pressures after imbibition at the five measuring points were 0.7-2.0 MPa higher than the pressures before imbibition, indicating that there was a two-phase region after the reverse imbibition, and the seepage resistance increased.

Fig. 7.

Fig. 7.

Relationship between reverse displacement pressure and time before and after reverse imbibition of outcrop rock samples with permeability of 0.2×10-3 μm2.

The pressure curve at each measuring point before and after water-flooding huff and puff experiment is the same as that of the reverse imbibition experiment. The pressure after water-flooding huff and puff is greater than the displacement pressure before water injection.

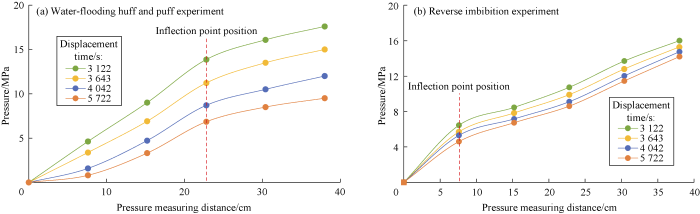

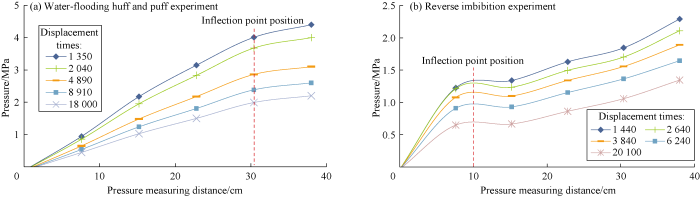

By comparing the change rules of seepage pressure with distance before and after water injection and reverse imbibition experiments, it is found when the inflection point of the pressure in the curve occurs, the distance corresponding to the point is the distance water reached in the process of water injection huff and puff and reverse imbibition (Fig. 8). It can be seen that the imbibition distance of water-flooding huff and puff was 22.8 cm, and the reverse imbibition distance was 7.6 cm. The imbibition distance of water-flooding huff and puff is greater than the reverse imbibition distance. The main reason is that during the process of water injection, a part of the water is squeezed into the matrix under the pressure (pressure difference) during the “huff” stage, and part of oil is produced through “drive” of the pressure difference between the matrix and the fracture during the “puff” stage, so the oil produced cannot be all regarded as the contribution of "imbibition", and the spread distance is not all the merit of "imbibition", but the collaborated influence of pressure difference and imbibition, and the water phase can enter the deeper matrix front.

Fig. 8.

Fig. 8.

Relationship between displacement pressure and distance in the experiment of water-flooding huff-and-puff and reverse imbibition on outcrop rock samples with a permeability of 0.2×10-3 μm2.

Referring to the approach mentioned above, during the huff and puff process, when the volume of the injected water was doubled, the measured imbibition distance was 40.0 cm, indicating that during the recovery process of the tight reservoir, the larger the injection volume, the longer the imbibition distance will be.

With the same experiment approach, an outcrop rock sample with a permeability of 2.0×10-3 μm2 was selected for testing. The measured imbibition distance of the water-flooding huff and puff was 30.4 cm, and the imbibitio Fig. 9). The results show that the greater the permeability of the low permeability reservoir, the longer the imbibition distance will be.

Fig. 9.

Fig. 9.

Relationship between displacement pressure and distance in the experiment of water-flooding huff-and-puff and reverse imbibition on outcrop rock samples with a permeability of 2.0×10-3 μm2.

4. Conclusions

In the process of reverse imbibition, the lower the permeability of the sample, the later the oil droplets will come out, the longer it takes to reach imbibition equilibrium, and the lower the recovery ratio will be. The fracture can enlarge the imbibition area where tight matrix contact with water and the range of imbibition front, reduce the resistance for oil to be expelled, and enhance the imbibition speed and recovery ratio. The more water-wetting the rock, the higher the imbibition speed and recovery ratio of imbibition will be.

In forward imbibition, the lower the permeability, the more obvious the imbibition effect will be; the recovery degree of displacement is positively correlated with the permeability, and the recovery degree of imbibition is negatively correlated with the permeability.

The imbibition distance of water-flooding huff and puff is greater than the reverse imbibition distance. The greater the permeability and the injection multiple, the longer the imbibition distance will be. The large-scale volumetric fracturing combining with wettability transformation and water-flooding huff and puff is beneficial to enhance the imbibition effect of tight reservoirs.

Reference

Geological concepts, characteristics, resource potential and key techniques of unconventional hydrocarbon: On unconventional petroleum geology

Assessment criteria, main types, basic features and resource prospects of the tight oil in China

U. S. Energy Information Administration. Status and outlook for shale gas and tight oil development in the U. S

Significance, geologic characteristics, resource potential and future challenges of tight oil and shale oil

Influence factors of single well’s productivity in the Bakken tight oil reservoir

Status quo of tight oil exploitation in the United States and its implication

Volume fracturing technology of unconventional reservoirs: Connotation, optimization design and implementation

Concept, technology and practice of “man-made reservoirs” development

Definition of tight oil in Ordos Basin

Spontaneous imbibition of water into oil-wet carbonates

Mechanism and influence factors of imbibition in fractured tight sandstone reservoir: An example from Chang 8 reservoir of Wuqi area in Ordos Basin

Evaluation of gas saturation during water imbibition experiments

Experimental and numerical investigation of high temperature imbibition into preferential oil-wet chalk

Water-imbibition displacement: A possibility for the spraberry

Experimental study of cocurrent and countercurrent flows in natural porous media

Experiments and modelling of water injection in water-wet fractured porous media

Advances in studies of spontanous imbibition in porous media

Role of fracture flow in matrix-fracture transfer

Water mixing during waterflood oil recovery: The effect of initial water saturation

Mechanism simulation of oil displacement by imbibition in fractured reservoirs

Physical and numerical simulation of porous flow pattern in multi-stage fractured horizontal wells in low permeability/tight oil reservoirs