Introduction

Tight oil has gradually become a major kind of strategic replacement resource in China’s oil and gas exploration and development[1,2]. According to the statistics of Energy Information Administration (EIA), tight oil took 54% of the U.S. crude oil production in 2017[3]. Hu Wenrui et al.[4] pointed out that tight oil reservoirs in China were generally characterized by low permeability, low porosity, tiny pore throat, and low mobile fluid saturation. Wu[5] and Yang et al.[6] found through study that, in the Ordos, Songliao and Junggar basins, tight oil had a very low fluidity of less than 0.2×10-3 μm2/(mPa·s) on average under reservoir conditions, basically equivalent to the fluidity of super-heavy oil, so tight oil only accounts for less than 1% of the total oil production in these basins. To efficiently recover the tight oil, proper development technology must be adopted to improve the fluidity of the fluid. "Long horizontal well + volume fracturing" is the main development technique for tight oil and has been applied extensively. Although this technique can enhance the effective permeability of tight oil reservoirs to some extent, but the ultimate recovery factors of tight oil reservoirs are less than 10% in general[7,8,9,10,11]. In recent years, researchers have worked actively on energy replenishing and EOR techniques (e.g. water injection, and surfactant huff and puff) to improve stimulation performance of tight oil reservoirs[12,13,14,15,16,17,18]. However, the existing volume fracturing fluid systems have some defects. He[19] and Liao et al.[20] found that the fluid systems such as linear plant gum and slick water used for volume fracturing all had micron-scale hydrodynamic radii, which were much larger than the average pore throat radius of tight reservoirs, so the fluid systems couldn’t efficiently enter the matrix pores, leading to poor connectivity between fractures and the matrix and huge difficulty in continuous replenishing of formation energy. Liang et al.[21] and Feng et al.[22] suggested that existing fluid systems were mainly water-phase systems and replenished energy mainly through imbibition caused by capillary force, while tight oil reservoirs were complicated in wettability and oil-wetting or more oil-wetting in most areas, to which injected water-phase system couldn’t access, so the capillary force turned into capillary resistance, making the capillary imbibition unable to work. Yu et al.[23] and Liang et al.[24] revealed that some surfactants could make wettability reverse, but the wettability reversal for fractured tight oil reservoir with a large surface area needed a large quantity of chemical agents, took long time to take effect, and was costly and difficult for field implementation. They also found that poor fluidity of crude oil in tight reservoir was a key factor influencing the efficient development of tight oil[4,5,6]. All existing fluid systems couldn’t improve the tight oil fluidity, and some surfactants might have emulsification or inverse emulsification reactions with crude oil, giving rise to "oil-in-water" or "water-in-oil" particles, hence the crude oil particles increased in size or apparent viscosity, making the migration of crude oil in tight reservoir more difficult.

To solve the technical problem that "water cannot be injected and oil cannot be produced" in tight oil development, a nanofluid permeation flooding system has been developed to enhance oil recovery through research. The system has the characteristics of small size liquid droplets, small size oil droplets, high surface activity, dual-phase wetting, and demulsification & viscosity reduction. Experiments were conducted to evaluate the characteristics and EOR mechanisms of the system.

1. Technical route

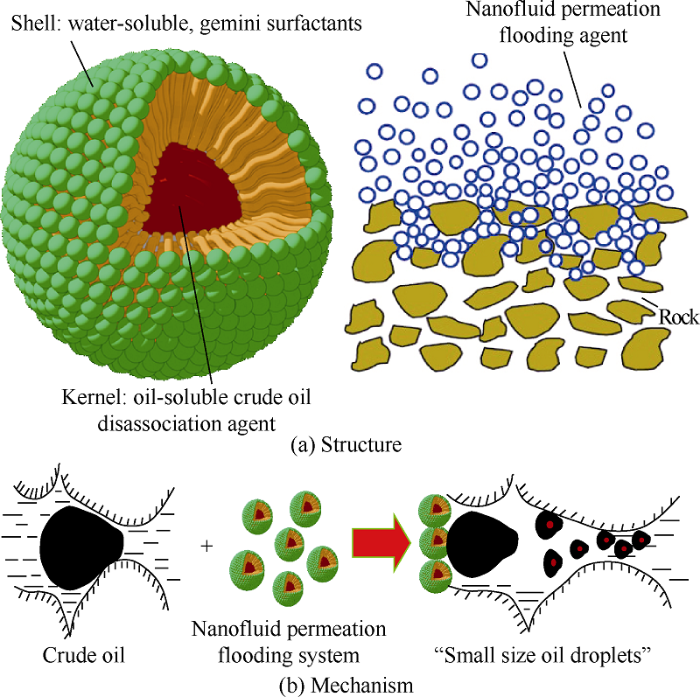

The nanofluid permeation flooding system is prepared with the diphenyl ethers water-soluble gemini surfactant as the shell and C10-C14 straight-chain hydrocarbon oil-soluble crude oil disassociation agent as the kernel (Fig. 1a). It has 5 characteristics and EOR mechanisms below.

Fig. 1.

Fig. 1.

Structure of the nanofluids permeation flooding system and the mechanism of enhancing oil permeation capacity by breaking oil into small droplets.

(1) “Small size liquid” and the mechanism of expanding the swept volume of matrix with micro-nano pore throats. With water-soluble gemini surfactants as the shell and oil-soluble crude oil disassociation agent as the kernel, the system appears as “oil-in-water” microemulsion, with small particle size of less than 30 nm on average, and is stable under reservoir conditions. The nano-scale microemulsion can permeate, diffuse and migrate in matrix with micro-nano pore throats, and can significantly weaken association of water hydrogen bond, reduce the starting pressure gradient of injected media and expand the swept volume in the matrix.

(2) “Small size oil droplets” and the mechanism of enhancing permeation of crude oil in the matrix with micro-nano pore throats. As shown in Fig. 1b, the nanofluid permeation flooding system in “oil-in-water” nano-scale micron-emulsion form would break the water-phase shell and release the kernel of oil-soluble crude oil disassociation agent immediately once in contact with oil under the simulated reservoir conditions. Following the principle that “the likes dissolve each other”, the disassociation agent attracts crude oil components strongly, weakening or even eliminating the molecular association of the oil components. Consequently, the crude oil is broken into "small-size oil droplets" under flow condition, to enhance migration and percolation capacity of oil in reservoir conditions, so crude oil can be recovered from the matrix, enhancing the oil displacement efficiency further on the basis of water flooding.

(3) High surface activity and the mechanism of enhancing oil displacement efficiency. Super-low interfacial tension between the system and crude oil can facilitate the displacement of crude oil from the reservoir matrix and enhance oil washing efficiency especially in tiny pores.

(4) Dual-phase wetting and the mechanism of full use of capillarity. The system can efficiently wet both water-wet and oil-wet interfaces, and enter the matrix with micro-nano pore throats under different wetting conditions, so that the capillarity can be made use effectively and made more adaptable to complex wetting conditions.

(5) Demulsification & viscosity reduction and the mechanism of improving crude oil fluidity. The system can demulsify and dehydrate, so it can destroy the inversely emulsified “water in oil” state of crude oil, thereby greatly improving the efficiency of demulsification & viscosity reduction of inversely emulsified state crude oil and increasing the oil fluidity.

With synergy of the five characteristics above, the nanofluids permeation flooding system can increase the swept volume in the matrix with micro-nano pore throats in tight oil reservoirs, improve the permeation capacity of crude oil under reservoir conditions, and finally achieve the goal of greatly improving production degree, development effect and recovery factor of tight oil reservoir.

2. Experiments

2.1. Materials

The 4,4°-benzenedicarbonyl chloride diphenyl ether was obtained through the acyl chloride reaction of 4,4°-dicarboxylic acid diphenyl ether. It was then esterified with octylphenol polyoxyethylene ether (OP-10) to prepare the (octylphenol polyoxyethylene ether disubstituted) dicarboxylic acid diphenyl ether[25,26]. Thus, the diphenyl ethers gemini surfactant was obtained to serve as the shell of nanofluids permeation flooding system.

The diphenyl ethers gemini surfactants, C10-C14 straight- chain hydrocarbon compounds and remaining water were mixed at an optimal proportion and stirred under the low energy conditions (30-400 r/min, 20-50 °C) until the mixture was completely dissolved to become a homogeneous solution. The homogeneous solution was diluted to low concentration (0.05%-0.50%) with deionized water or inorganic salt water, that was the nanofluids permeation flooding system with a shell-kernel structure[27,28,29].

The chemical agents used in the comparison experiments are all available on the market, and they were mainly heavy alkylbenzene sulfonate and betaine provided by a domestic oil field.

A simulated formation water or deuterium oxide system was prepared according to the formation water salinity condition of a tight oil reservoir in Xinjiang Oilfield. With a salinity of 10,900 mg/L, it comprises 277.1 mg/L Na2SO4, 6,087.4 mg/L NaCl, 219.8 mg/L KCl, 86.9 mg/L CaCl2, 49.9 MgCl2·6H2O and 4179 mg/L NaHCO3.

The oil used in the experiment was a tight oil sample taken from Xinjiang Oilfield, with a saturated hydrocarbon content of 49.57%), light aromatics content of 2.28%, medium aromatics content of 2.46%, heavy aromatics content of 7.47%, colloid content of 13.82%, an asphaltene content of 4.12%, and an apparent viscosity of 33.4 mPa·s under reservoir conditions.

The capillary was made of quartz and water-wet. Its inner wall was applied with chemical compounds like octadecyl trimethyl ammonium bromide to form a hydrophobic coating, thereby creating a hydrophobic capillary.

In the contact angle test, the hydrophilic surface was glass substrate, and the oil-wet surface was the glass substrate with hydrophobic coating made of octadecyl trimethyl ammonium chloride or other similar compounds.

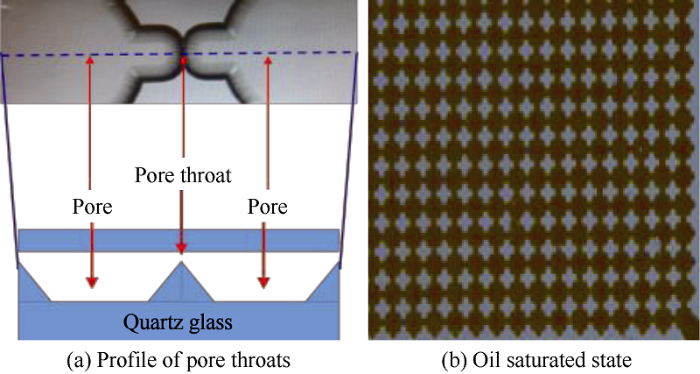

The 2.5-dimensional microscopic glass model (Fig. 2), more similar to the three-dimensional pore throat structure of the reservoir, has been widely used in the studies on oil and gas percolation in recent years[30,31]. In this study, the model was 1.5 cm×1.5 cm, with pore depth of 15 μm, throat depth of 2 μm and pore volume of 10 mm3.

Fig. 2.

Fig. 2.

2.5-dimentional matrix pore throat model.

The man-made tight core was mainly made of quartz sand and 2.5 cm×5.0 cm in size. It had a gas permeability of 1×10-3 μm2, water permeability of 0.02×10-3 μm2 and porosity of 10.13%.

2.2. Equipments

The equipment used in our experiment included JNM- ECA600 nuclear magnetic resonance spectrometer (600 HZ) (JEOL Ltd.), capillarity analysis system, microfluidic system, low-field NMR core displacement device, BI-200SM wide- angle dynamic/static laser scatterer, TX 500C spinning drop ultra-low interface tensiometer, Dataphysics contact angle meter, and HAAKE RS600 rheometer. The capillarity analysis system is developed by our own and composed of an injection system, a capillary bundle model, microscopic observation system, micro-flow measurement system and data processing system[32]. It can evaluates the changes of starting pressure gradient when different types of chemical agents are injected into hydrophilic or hydrophobic capillary, by assuming that the percolation of injected media in the reservoir is equivalent to the percolation in the capillary bundle. The microfluidic system consists of a Leica M165FC microscope, a Leica CCD camera (100 frames, 2,560 pixels ×1,920 pixels) and a neMESYS injection pump, etc. The low-field NMR core displacement device includes MESomR23-060H-HTHP low-field nuclear magnetic analyzer (Shanghai Niumai Electronic Technology Co., Ltd.) and MR-dd high-temperature and high-pressure displacement device (Nantong Huaxing Petroleum Instrument Co., Ltd.).

2.3. Evaluation procedures

The characteristics of the nanofluids permeation flooding system were evaluated through experiments at the temperature (85 °C) of a Xinjiang tight oil reservoir.

2.3.1. “Small molecular size liquid”

(1) Particle sizes and its distribution: Dynamic light scattering (DLS) technique was used to measure the hydrodynamic radius and distribution of the nanofluids permeation flooding system at different concentrations under the conditions of 532 nm wavelength and 90° scattering angle.

(2) Evaluation of oxygen spectrum with nuclear magnetic resonance (17O-NMR): Water in nature does not exist in individual molecules, but in the form of molecule network generated by hydrogen bond association. The width of 17O-NMR spectral line can directly reflect the relative size of water molecular network structure, i.e. the strength of hydrogen bond association. The larger the half-peak width of the spectral line, the larger the network structure, and the stronger the hydrogen bond association will be; conversely, the smaller the half-peak width of the spectral line, the smaller the network structure, and the weaker the hydrogen bond association will be[32,33]. The half-peak widths of 17O-NMR spectral lines of pure water, mineralized water, and betaine and nanofluids permeation flooding systems at 0.1% concentration prepared with mineralized water were measured at room temperature to evaluate the capability of the nanofluids permeation flooding system in weakening the hydrogen bond association of water.

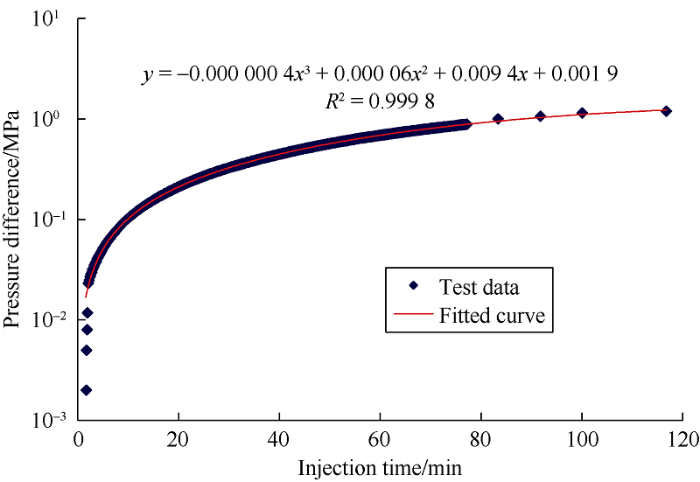

(3) Evaluation of starting pressure gradient: Currently, numerical simulation or core injection physical modeling experiment is used for evaluating the starting pressure gradient of the injected media. However, because of poor core reproducibility, the core injection experiment cannot repeat and may produce large error. Furthermore, there are no reports about evaluating starting pressure gradient by use of capillary injection method. We used the capillarity analysis system[32] to evaluate the starting pressure gradient by injecting different media at 0.1 mL/min into the hydrophilic and hydrophobic capillaries with the inner diameter of 1 μm or 300 nm and length of 60 cm. Fig. 3 shows the pressure differences measured in real time when different media were injected into the capillary. When the injection pressure difference approaches the balance range, the pressure difference vs. injection time curve was plotted. The calculation formula was obtained through data fitting and then the critical starting pressure of the injected media was worked out by extrapolation to the zero point of the abscissa. Finally, the critical starting pressure was divided by the capillary length (60 cm) to get the critical starting pressure gradient. By injecting different media into the capillary, the variations of starting pressure gradient of injected media under simulated pore throat conditions can be accurately evaluated; on this basis, the capacity of injected medium entering equivalent pore throat can be estimated. The lower the starting pressure gradient, the lower the capillary resistance to the injected medium.

Fig. 3.

Fig. 3.

Pressure difference vs. injection time curve tested by capillarity analysis system.

2.3.2. Evaluation of “small size oil droplets”

(1) Evaluation by micro etching model displacement experiment: A 2.5-dimensional glass pore throat model was used as the matrix unit to analyze the fluidity of crude oil under simulated reservoir conditions by using the micro-fluidic simulation technology. The experiment was completed in three steps: (a) Crude oil was injected into the model until the model was completely saturated with oil (Fig. 2b); (b) different media were injected into the model at a constant rate of 100 mL/min until crude oil in the model was no longer displaced out; and (c) the video images acquired for the matrix area were processed by Image J software, and oil saturation and displacement efficiency of the matrix area before and after displacement were calculated[23].

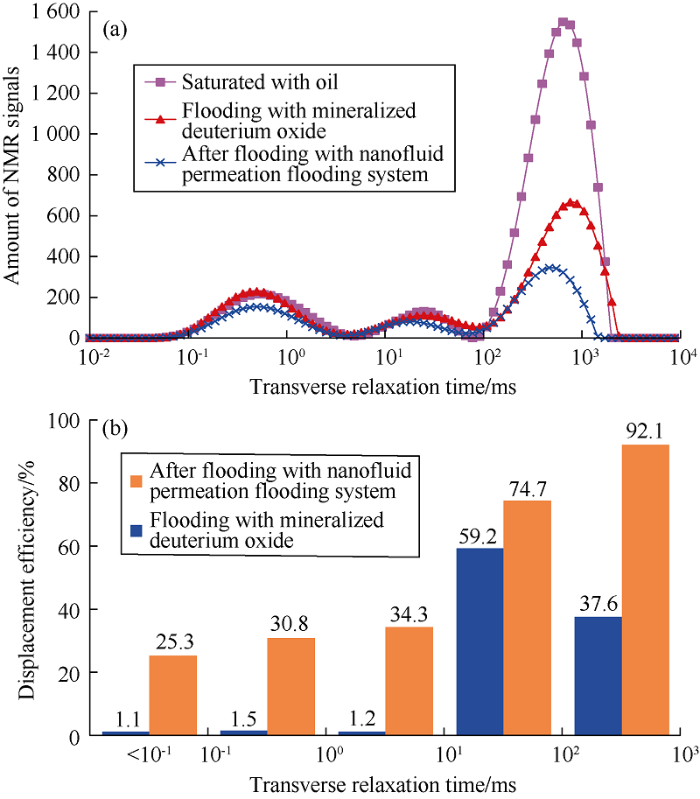

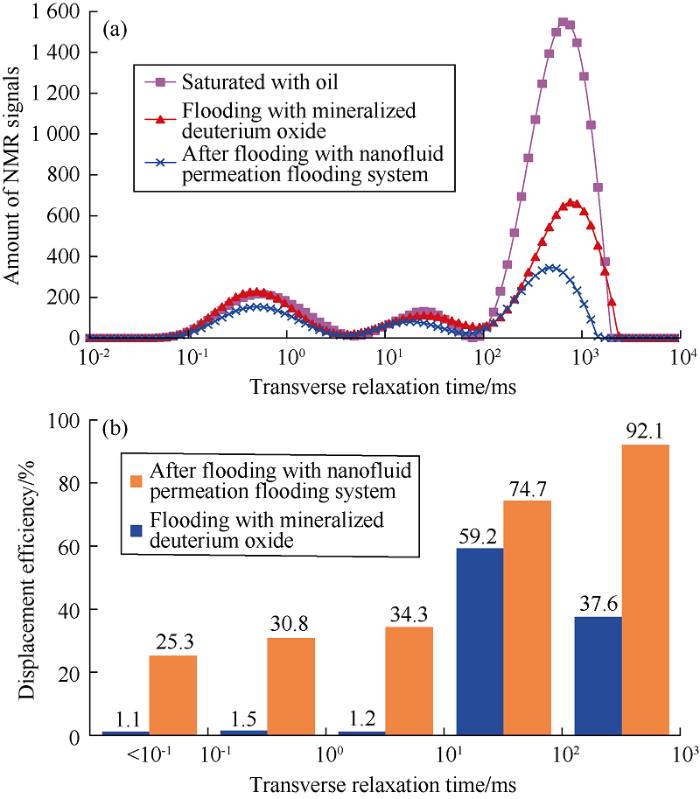

(2) Evaluation with low-field NMR core displacement: Based on the protons spin relaxation principle, the low-field NMR technology can measure the T2 (transverse relaxation time) spectrum of the fluid containing hydrogen protons. A larger T2 corresponds to the area of large pores, while a smaller T2 corresponds to the area with small pores in the core sample[34]. In this study, low-field NMR and core displacement were combined to measure the T2 spectra of saturated oil and the oil displaced by mineralized water prepared with deuterium oxide and by nanofluids permeation flooding system of 0.1% concentration prepared with mineralized deuterium oxide, to evaluate the oil displacement efficiency of nanofluids permeation flooding system. The experiments were conducted at the echo spacing of 0.3 ms, wait time of 3000 ms and the echo number of 8000. Finally, the artificial tight core was saturated with oil, and displaced successively by mineralized deuterium oxide and nanofluids permeation flooding system at the rate of 0.01-0.02 mL/min.

2.3.3. Evaluation of high surface activity

This was evaluated at a rotation speed of 6000 r/min according to the Method for Measurement of Surface Tension & Interfacial Tension (SY/T 5370-1999).

2.3.4. Evaluation of dual-phase wetting

This was evaluated by measuring the contact angles between the nanofluids permeation flooding system and the hydrophilic SiO2 and oil-wet SiO2 interfaces according to the Measurement of Reservoir Rock Wettability (SY/T 5153- 1999).

2.3.5. Evaluation of demulsification & viscosity reduction

Demulsification was evaluated according to the Bottle Test Method for Demulsification Performance of Crude Oil Demulsifiers (SY/T 5281-2000). Viscosity reduction was evaluated according to the Specifications of Heavy Oil Viscosity Reducers Used to Assist in Forming Oil-in-Water State (Q/SY 118-2013).

3. Results and discussion

3.1. "Small molecule size liquid" and the mechanism of increasing the swept volume of matrix with micro-nano pore throats

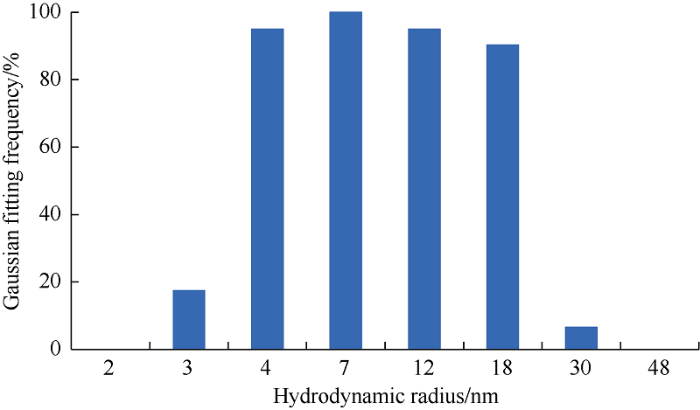

As shown in Fig. 4, when the nanofluids permeation flooding system is 0.1% in concentration, its hydrodynamic radius is less than 30 nm, only about 10 nm on average, and distributed in a narrow range, indicating that the system is in the state of "oil-in-water" nano-scale microemulsion on the whole.

Fig. 4.

Fig. 4.

Initial hydrodynamic radius distribution of the 0.1% concentration nanofluids permeation flooding system at the test temperature of 85 °C.

Fig. 5 shows that the initial average particle sizes of the nanofluids permeation flooding systems with the concentrations of 0.1%, 0.3% and 0.5% are respectively 8.0, 11.5 and 15.0 nm. This is because with the increase of the system concentration, the Brownian motion of the droplets in the “oil-in-water” nano-scale microemulsion intensifies, leading to a higher collision probability and slight increase of the initial particle size. Nevertheless, the overall particle size of the system remains less than 20 nm, indicating that the water phase shell formed by diphenyl ethers surfactants is stable and can effectively maintain the “small liquid droplet size” state of “oil-in-water” microemulsion. Over time, the microemulsion with 0.1% concentration remains stable, with the average particle size basically keeping at 10 nm. When the concentration of the system is increased to 0.3% and 0.5%, the particle size increases with time and reaches an equilibrium, and finally stabilizes at about 30 nm.

Fig. 5.

Fig. 5.

Stability of the nanofluids permeation flooding system of different concentrations at the test temperature of 85 °C.

The half-peak widths of 17O-NMR spectral line of purified water, mineralized water, betaine and nanofluids permeation flooding system are 125.56, 96.42, 80.02 and 65.71 Hz, respectively. It can be seen that the mineralized water and two chemical agents can reduce the half-peak width of 17O-NMR spectral line of the purified water to some extent. Specifically, the nanofluids permeation flooding system of 0.1% concentration reduces the half-peak width of 17O-NMR spectral line of the purified water by about 50% from 125.56 Hz to 65.71 Hz. This means that the nanofluids permeation flooding system can effectively weaken the hydrogen bond association between water molecules, thereby breaking the water molecule network structure into “small size liquid droplets” which can enter tight oil reservoir.

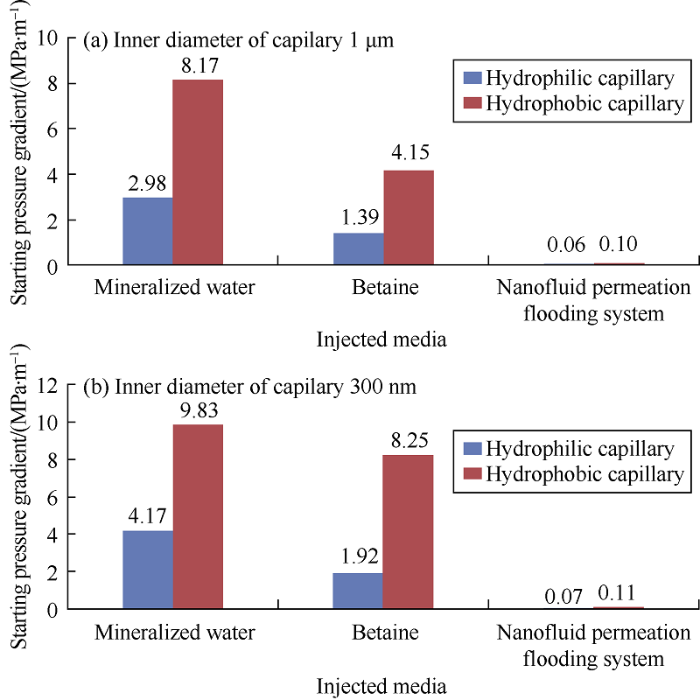

Fig. 6 shows that, for hydrophilic and hydrophobic capillaries 1 μm and 300 nm in inner diameter, compared with the case when mineralized water is injected, the starting pressure gradient drops greatly when the nanofluids permeation flooding system is injected, but drops slightly when betaine is injected. This is because the nanofluids permeation flooding system appears as “oil-in-water” nano-scale microemulsion with good stability, and its “small size liquid droplets” enables the system effectively migrate under the hydrophilic and hydrophobic micro-nano capillary conditions, thus greatly reducing the capillary resistance of micro-nano pores and effectively expanding the swept volume in the matrix. In contrast, betaine is limited in reducing the capillary resistance of micro-nano pores and expanding the swept volume in matrix with micro-nano pores, because its molecules may wind and aggregate when it is injected into the micro-nano capillary.

Fig. 6.

Fig. 6.

Starting pressure gradients when different media of 0.1% concentration are injected into hydrophilic and hydrophobic capillaries.

The experimental results of particle size, 17O-NMR and starting pressure gradient show that the nanofluids permeation flooding system has the characteristic of “small size liquid droplets”, which can greatly reduce the starting pressure gradient of micro-nano pore throats, improve the accessibility to micro-nano pore throats, and effectively expand the swept volume in matrix.

3.2. “Small size oil droplets” and the mechanism of enhancing permeation of crude oil in the matrix with micro-nano pore throats

Fig. 7 shows that the crude oil turns immediately into a disperse state of “small size oil droplets” when the nanofluids permeation flooding system of 0.1% concentration is injected into the 2.5-dimensional pore throat etching model saturated with oils of 33.4 mPa·s and 5.3 mPa·s in apparent oil viscosity. This is because when the system in “oil-in-water” nano microemulsion meets crude oil, the crude oil molecules are attracted by the molecules of the system-crude oil disassociation agent, breaking the “oil-in-water” microemulsion state, and the crude oil disassociation agent is released into the crude oil. According to the rule of “the likes dissolve each other”, disassociation agent attracts crude oil components strongly, thus weakening greatly even eliminating molecular association of the oil components (e.g. oil-saturated hydrocarbons, cycloalkanes, and aromatics). Subsequently, the crude oil is broken into "small size oil droplets" and enhance greatly in permeation capacity and displacement efficiency in pores and pore throats, making the crude oil easy to be displaced from the matrix. Based on the calculation results of oil saturation in the matrix area, the swept volume ratio of the matrix area and oil displacement efficiency both exceed 95% after injecting 1 PV (pore volume, the multiplier of injected fluid) of nanofluids permeation flooding system, which proves that the system can greatly improve the permeation capacity of crude oil under simulated reservoir conditions.

Fig. 7.

Fig. 7.

Experiment to evaluate the characteristics of “small size oil droplets” with the 2.5-dimensional pore throat model.

Fig. 8a shows the low-field NMR T2 spectra of saturated oil in artificial tight core and remaining oil in artificial tight core after flooding with mineralized deuterium oxide and nanofluids permeation flooding system. The integral area of each curve represents the total volume of remaining oil. From calculation, the oil displacement efficiency of mineralized deuterium oxide is 49.1%, and mainly the crude oil in larger pores (corresponding to larger T2) is displaced. The nanofluid permeation oil flooding system can increase the overall oil displacement efficiency by 19.7 percentage points on the basis of mineralized deuterium oxide flooding, and the remaining oil displacement efficiency in the smaller pore areas (T2 of 0.1-10.0 ms) is significantly enhanced compared with mineralized deuterium oxide flooding. Clearly, the system enters the micro-nano pore throats of the tight core more easily and improves the fluidity of the crude oil in the matrix. The oil displacement efficiency of matrix with micro-nano pore throats can be improved by making use of the characteristic of “small size oil droplets”.

Fig. 8.

Fig. 8.

T2 spectra (a) of remaining oil after flooding with mineralized deuterium oxide and nanofluids permeation flooding system and displacement efficiency in different T2 intervals (b).

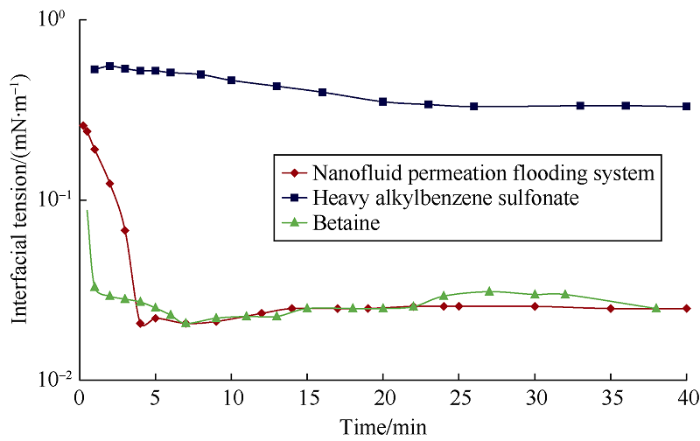

3.3. High surface activity and the mechanism of enhancing oil displacement efficiency

Fig. 9 shows that the interfacial tension equilibrium value between the nanofluids permeation flooding system and Xinjiang tight oil is basically same as that between betaine and Xinjiang tight oil at the same concentration of 0.1%, reaching the level of 1×10-2 mN/m, which is much lower than the interfacial tension equilibrium value between heavy alkylbenzene sulfonate and Xinjiang tight oil. This suggests that high interfacial activity exists between the shell of nanofluids permeation flooding system - diphenyl ethers surfactants and the crude oil, which can greatly reduce the interfacial tension between the crude oil and aqueous surfactant solution. From Table 1, it can be seen that the nanofluids permeation system takes the shortest time to reach the ultra-low interfacial tension and about 4 minutes to make the interfacial tension reach the equilibrium value. This is because the crude oil disassociation agent released when the nanofluids permeation flooding system meets the crude oil can greatly weaken the association of the oil components, and the surfactant molecules of the shell can reach the oil-water contact more easily to form regular arrangement to reduce the oil-water interfacial tension quickly and enhance the oil displacement efficiency of tiny pores in the matrix.

Fig. 9.

Fig. 9.

Variations of interfacial tension between different chemical agents of 0.1% concentration and Xinjiang tight oil at the test temperature of 85 °C.

Table 1 Interfacial activity between different chemical agents of 0.1% concentration and Xinjiang tight oil at the test temperature of 85 °C.

| Chemical agent | Interfacial tension equilibrium value/(mN·m-1) | Time for reaching the equilibrium/min |

|---|---|---|

| Heavy alkylbenzene sulfonate | 0.330 | 26 |

| Betaine | 0.025 | 7 |

| Nanofluids permeation flooding system | 0.025 | 4 |

3.4. Dual-phase wetting and the mechanism of full use of capillarity

According to Equation (1), the contact angle (wettability) is the key factor affecting the imbibition of the capillary force when the capillary radius and the interfacial tension are constant. When the contact angle of the injected medium with the interface is less than 90°, the capillary force plays the role of capillary imbibition and the chemical agent can enter tiny pores through spontaneous imbibition. When the contact angle of the injected medium with the interface is greater than 90°, the capillary force becomes capillary resistance and the chemical agent cannot spontaneously enter the oil-wet reservoir, and then the water-locking effect may occur. Hydrophilic and oil-wet mixed wetting conditions are ubiquitous in the tight oil reservoir[35], so both contact angles of the injected medium with water-wet and oil-wet interfaces are required to be less than 90°, thereby, the capillary imbibition can be given full play under the reservoir conditions.

where, ${{p}_{c}}$ is the capillary force, Pa; γ is the interfacial tension, N/m; θ is the contact angle, (°); r is the capillary radius, m.

Fig. 10 shows that the contact angles of the mineralized water with the water-wet and oil-wet SiO2 interfaces are (9±1)° and (107±1)° respectively. Therefore, the mineralized water can only spontaneously enter the water-wet pores, but not the oil-wet pores. The contact angles of the nanofluids permeation flooding system of 0.1% concentration with the water-wet and oil-wet interfaces are (46±1)° and (68±1)° respectively. This means on one hand the nanofluids permeation flooding system has good wettability to both water-wet and oil-wet interfaces, and can spontaneously enter the water-wet and oil-wet matrix with micro-nano pore throats. On the other hand, the system is capable of changing rock wettability. It can turn the reservoir from oil-wet to weak water-wet, effectively reduce the oil-water two-phase capillary end effect, give full play of the capillary imbibition of injected media, and improve the capillarity adaptability under complex reservoir conditions.

Fig. 10.

Fig. 10.

Contact angles between the mineralized water and nanofluids permeation flooding system of 0.1% concentration and water-wet and oil-wet SiO2 interfaces at the test temperature of 85 °C.

3.5. Demulsification & viscosity reduction and the mechanism of improving crude oil fluidity

Under the reservoir conditions, the Xinjiang tight oil can easily inversely emulsify with formation water. The produced liquid has an average water content of 30% and generally appears in inversely emulsified state of “water-in-oil”. Thus, the apparent viscosity of the crude oil rises greatly, lowering the fuidity of the crude oil in the reservoir. In Table 2, the nanofluids permeation flooding system has good demulsification and dehydration effects on the inversely emulsified crude oil under the conditions of 85 °C and 5 h. When the dosage is 300 mg/L, the demulsification and dehydration rate is more than 80%, which is better than the market-available water-soluble demulsifiers.

Table 2 Demulsification and dehydration effects of inversely emulsified crude oil with a water content of 30% by different systems under the condition of 85 °C and 5 h.

| Name | Dosage/ (mg·L-1) | Dehydration rate/% | Sample appearance after demulsification |

|---|---|---|---|

| Nanofluids permeation flooding system | 150 | 51.00 | Limpid at the bottom; clear oil-water contact |

| 300 | 84.44 | ||

| 500 | 88.89 | ||

| 700 | 93.33 | ||

| Market- available water-soluble demulsifiers | 150 | 20.00 | Limpid at the bottom; clear oil-water contact |

| 300 | 35.00 | ||

| 500 | 51.00 | ||

| 700 | 84.00 |

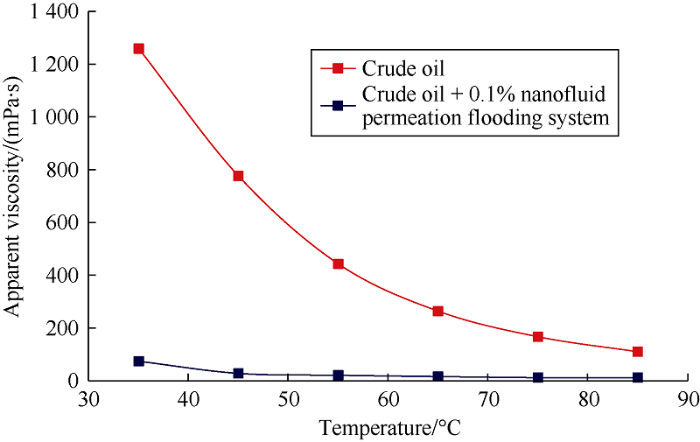

Fig. 11 shows that addition of the nanofluids permeation flooding system can greatly reduce the apparent viscosity of inversely emulsified crude oil. At the reservoir temperature of 85 °C, the apparent viscosity of the inversely emulsified crude oil decreases by 89% from 110 mPa·s to about 12 mPa·s. This verifies that the nanofluids permeation flooding system can assist demulsification & viscosity reduction and improve the fluidity of crude oil.

Fig. 11.

Fig. 11.

Viscosity-temperature curves of inversely emulsified Xinjiang tight oil with/without addition of the nanofluids permeation flooding system.

4. Conclusions

The nanofluids permeation flooding system with the diphenyl ethers water-soluble, gemini surfactants as the shell and the C10-C14 straight-chain hydrocarbon oil-soluble crude oil disassociation agent as the kernel has five characteristics: (1) “small size liquid droplets”, which can increase the swept volume of matrix with micro-nano pore throats; (2) “small size oil droplets”, which can greatly improve the permeation capacity and displacement efficiency of the crude oil in the matrix with micro-nano pore throats; (3) dual-phase wetting, which can give capillarity full play under the complex wetting conditions of the reservoir; (4) high surface activity, which can effectively improve the oil displacement efficiency in matrix with micro-nano pore throats; and (5) demulsification & viscosity reduction, which can improve the fluidity of crude oil in the reservoir and wellbore. With the five characteristics and EOR mechanisms, the system can be used to replenish formation energy, improve development effect and enhance oil recovery of tight oil reservoirs.

Reference

Breakthrough and significance of unconventional oil and gas to classical petroleum geological theory

Geological conditions for continental tight oil formation and the main controlling factors for the enrichment: A case of Chang 7 Member, Triassic Yanchang Formation, Ordos Basin, NW China

Unconventional energy resources: 2017 review

Development of the theory and technology for low permeability reservoirs in China

Classification and development characteristics of low-flow reservoirs

Profitable exploration and development of continental tight oil in China

A numerical simulation model for multi-scale flow in tight oil reservoirs

Advances in hydraulic fracturing techniques to maximize oil recovery from tight rocks

Assessment of global unconventional oil and gas resources

Benchmarking EUR estimates for hydraulically fractured wells with and without fracture hits using various DCA methods

What type of surfactants should be used to enhance spontaneous imbibition in shale and tight reservoirs

Application of nanotechnology in petroleum exploration and development

Experimental investigation of CO2, huff-n-puff process for enhancing oil recovery in tight reservoirs

Flow physics of how surfactants can reduce water blocking caused by hydraulic fracturing in low permeability reservoirs

Scaling of low-interfacial-tension imbibition in oil-wet carbonates

Experimental investigation of imbibitions in oil-wet carbonates under low IFT conditions

Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges

Microstructure and rheological properties of Carboxymethyl Guar gum solution with high degree of substitution

Study on drag reduction mechanism of water-in-water emulsion drag reduction agent

Evaluation of liquid nanofluid as fracturing fluid additive on enhanced oil recovery from low-permeability reservoirs

Nuclear magnetic resonance features of low-permeability reservoirs with complex wettability

Features and imbibitions mechanisms of Winsor Ⅰ type surfactant solution in oil-wet porous media

Evaluation of wettability alteration and IFT reduction on mitigating water blocking for low-permeability oil-wet rocks after hydraulic fracturing

DOI:10.1016/j.fuel.2017.08.029 URL [Cited within: 1]

Nonionic gemini surfactant of (Octylphenol polyoxyethylene ether disubstituted) dicarboxylic acid diphenyl ether and its synthesis: 201910001670.8

N,N,N°,N°- tetradodecyl-substituted diphenyl ether sulfonate anionic Gemini surfactant and synthesis thereof: 201910001658.7

A core-shell structured non-ionic nanoemulsion system and the preparation and use thereof: 201910001655.3

A core-shell structured anionic nano microemulsion system, and preparation and application thereof: 201910001672.7

A tight oil reservoir permeability increasing and oil displacement system, and preparation and application thereof: 201911139683.8

Egalitarianism among bubbles in porous media: An Ostwald ripening derived anticoarsening phenomenon

DOI:10.1103/PhysRevLett.119.264502

URL

PMID:29328713

[Cited within: 1]

We show that smaller gas bubbles grow at the expense of larger bubbles and all bubbles approach the same surface curvature after long times in porous media. This anticoarsening effect is contrary to typical Ostwald ripening and leads to uniformly sized bubbles in a homogeneous medium. Evolution dynamics of bubble populations were measured, and mathematical models were developed that fit the experimental data well. Ostwald ripening is shown to be the driving mechanism in this anticoarsening phenomenon; however, the relationship between surface curvature and bubble size determined by the pore-throat geometric confinement reverses the ripening direction.

Spontaneous and flow-driven interfacial phase change: Dynamics of microemulsion formation at the pore scale

DOI:10.1021/acs.langmuir.7b02856

URL

PMID:29052996

[Cited within: 1]

The dynamic behavior of microemulsion-forming water-oil-amphiphiles mixtures is investigated in a 2.5D micromodel. The equilibrium phase behavior of such mixtures is well-understood in terms of macroscopic phase transitions. However, what is less understood and where experimental data are lacking is the coupling between the phase change and the bulk flow. Herein, we study the flow of an aqueous surfactant solution-oil mixture in porous media and analyze the dependence of phase formation and spatial phase configurations on the bulk flow rate. We find that a microemulsion forms instantaneously as a boundary layer at the initial surface of contact between the surfactant solution and oil. The boundary layer is temporally continuous because of the imposed convection. In addition to the imposed flow, we observe spontaneous pulsed Marangoni flows that drag the microemulsion and surfactant solution into the oil stream, forming large (macro)emulsion droplets. The formation of the microemulsion phase at the interface distinguishes the situation from that of the more common Marangoni flow with only two phases present. Additionally, an emulsion forms via liquid-liquid nucleation or the Ouzo effect (i.e., spontaneous emulsification) at low flow rates and via mechanical mixing at high flow rates. With regard to multiphase flow, contrary to the common belief that the microemulsion is the wetting liquid, we observe that the minor oil phase wets the solid surface. We show that a layered flow pattern is formed because of the out-of-equilibrium phase behavior at high volumetric flow rates (order of 2 m/day) where advection is much faster than the diffusive interfacial mass transfer and transverse mixing, which promote equilibrium behavior. At lower flow rates (order of 30 cm/day), however, the dynamic and equilibrium phase behaviors are well-correlated. These results clearly show that the phase change influences the macroscale flow behavior.

Mechanism of nano-sized oil-displacement agent expanding swept volume

Study on liquid water cluster with 17O NMR

Visual evaluation method for fluids in cores based on low field nuclear magnetic resonance technology

Concept, technology and practice of “man-made reservoirs” development