Introduction

Thanks to the progress in shale gas geology and exploration and development technologies in China, industrially economic production of shale gas has been realized in recent years from the Silurian Longmaxi Formation shallower than 3500 m in the southern Sichuan Basin (southern Sichuan). The Longmaxi Formation has thick organic-rich shales, high quality reservoirs, intensive exploration and good results of production, and, at present, it is the major formation for shale gas exploration and development in China[1,2,3,4].

Up to February, 2020, the cumulative proved reserves were 10 610×108 m3 and the cumulative shale gas production exceeded 200×108 m3 in the shale gas demonstration blocks of Changning, Weiyuan, and Zhaotong (at the depth of 2000- 3500 m). Daily shale gas production now by China National Petroleum Corporation (CNPC) exceeds 3000×104 m3, and the shale gas production is expected to exceed 100×108 m3 by the end of 2020. CNPC has made sustained efforts to investigate the Longmaxi shale gas at the depth of 3500-4500 m in the southern Sichuan since 2018 and obtained a yield of 138×104 m3/d (equal to 202×104 m3/d in case of 1500 m long horizontal section) in gas production test for Well Lu203 with a depth of 3800 m in Luzhou, southern Sichuan. This is a new benchmark of individual-well yield in shale gas production tests. Some high-yielding wells were also drilled, marking a strategic breakthrough in deep shale gas production in China[5].

With economic production of shallow and middle shale gas at 2000-3500 m and a breakthrough in deep shale gas exploration at 3500-4500 m in China, CNPC has developed a series of theories and techniques for marine shale gas exploration and production. In the present study, we summarize the geological understandings of the Lower Silurian Longmaxi Formation shale gas exploration according to the latest results of geological evaluation, in the hope of promoting the effective production of shale gas in the marine shale gas of southern China.

1. Geology of Longmaxi shale gas reservoirs in the southern Sichuan

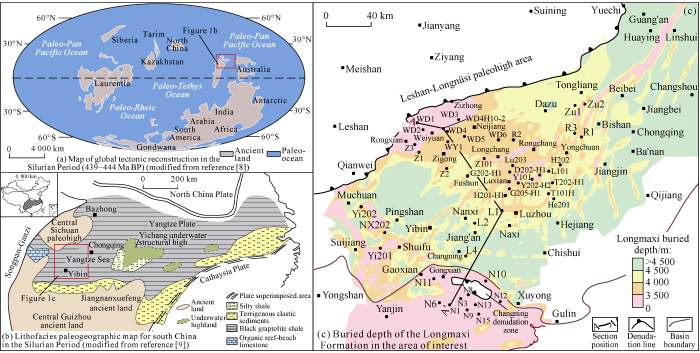

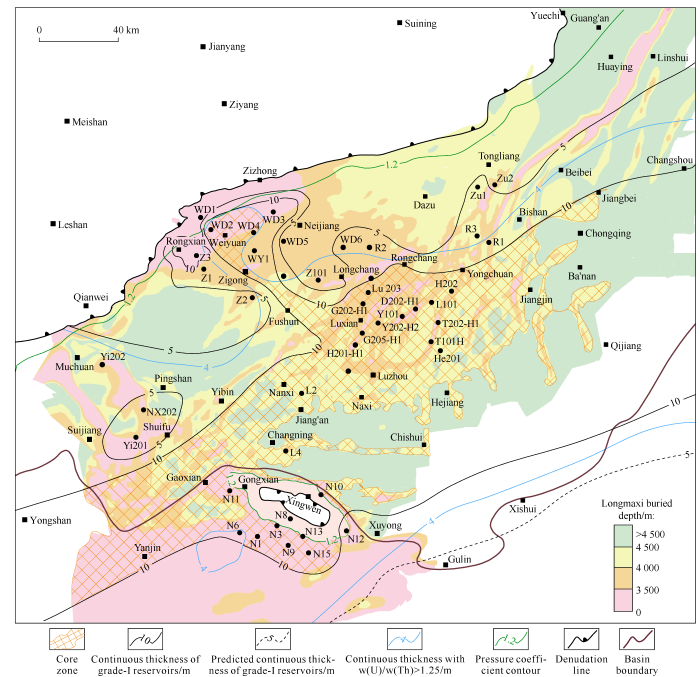

Covering an area of 4×104 km2, the southern Sichuan Basin is located in the southwest margin of the Upper Yangtze Platform in southern China, to the east of the Daliang Mountains, the south of the denudation line of the Longmaxi Formation in the Leshan-Longnüsi paleohigh, the west of the Huaying Mountain, and the north of the Northern Guizhou sag. This area is in the southern Sichuan gently dipping tectonic belt with small-scale fractures. It was tectonically uplifted in a late stage[6], and hence there is an extensive tectonically quiet region with small magnitude of uplift[7]. Now, the Longmaxi Formation is at a moderate depth of 2000-4500 m, and the area at 3500-4500 m is mainly distributed to the south of Weiyuan-Neijiang-(Leshan-Longnüsi) denudation line, the north of Naxi-Luzhou-Hejiang-Jiangjin, the east of Zigong-Fushun- Nanxi, and the west of Tongliang-Bishan-Jiangjin (Fig. 1).

Fig. 1.

Fig. 1.

Geologic setting in the area of interest.

1.1. Sedimentary formations

The Longmaxi Formation was deposited in the Early Silurian Rhuddanian-Aeronian Ages (439-444 Ma BP) after the end of Ordovician Ice Age. It was in a deep-water shelf environment surrounded by the Central Sichuan Uplift, Central Guizhou Uplift, Southern China Xuefeng Uplift, and local underwater structural highs[10], which changed into neritic shelf and tidal flat-shore environments toward the paleohigh and ancient land, respectively.

The Longmaxi Formation is in conformable contact with the underlying bio-shell limestone in the Guanyinqiao Member of the Upper Ordovician Wufeng Formation. The overlying formation is in unconformable contact with the overlying Lower Permian Liangshan Formation along Zigong-Weiyuan- Neijiang. Residual formation thickness ranges from 0 to 200 m and becomes large toward the south. The Longmaxi Formation is in conformable contact with the Lower Silurian Luoreping Formation along Mabian-Leibo and in conformable contact with the Lower Silurian Shiniulan Formation along Yibin-Changning-Luzhou. The thickness ranges from 500 m to 600 m.

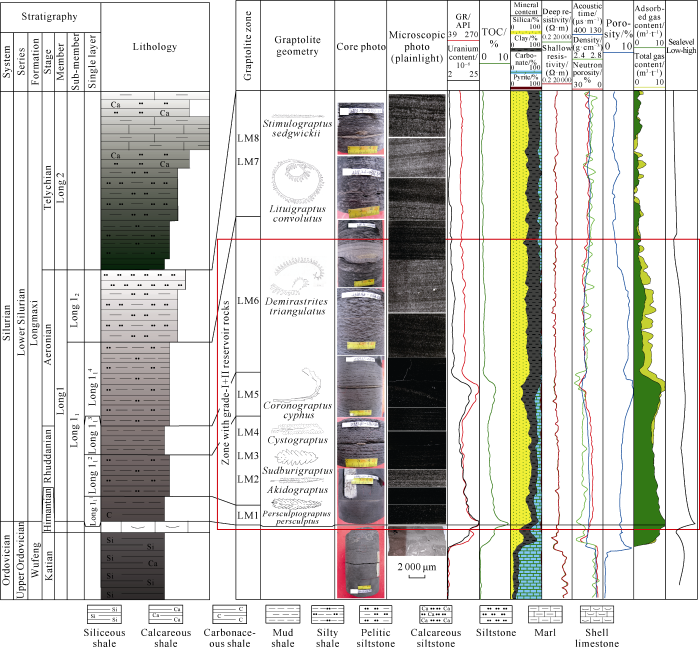

The Longmaxi Formation is divided into the Long1 and Long2 members from the bottom up. The Long1 Member is subdivided into Long11 and Long12, and Long11 is further subdivided into Long111, Long112, Long113, and Long114 (See reference [11] for stratigraphic subdivision and correlation). The Long111-Long113 beds have the best results of production at present.

The Long111-Long113 beds correspond to the Rhuddanian LM1-LM4 graptolite zones (or to the LM1-LM5 graptolite zones locally)[12,13]. The formations of 8-24 m thick are composed of black carbonaceous shale and siliceous shale with lighter color and larger particle size from the bottom up. The Long111-Long113 feature high TOC content (over 2.5%) and high silica content (over 65%). Siliceous sponge spicules and siliceous radiolarian can be observed microscopically. Sedimentary structures include horizontal bedding and massive bedding with pyrite nodules. Electrical properties feature high GR (over 150 API), high uranium content (over 10×10-6), high acoustic time difference (over 240 μs/m), high resistivity (over 15 Ω•m), low compensated neutron porosity (below 15%), and low density (below 2.60 g/cm3) (Fig. 2)[14,15].

Fig. 2.

Fig. 2.

Generalized geologic column for Well N3.

The Long114-Long12 beds with a thickness of 110-170 m correspond to the LM6-LM8 Aeronian graptolite zones. Lithology is thick greyish black to grey silty mudstone and pelitic siltstone rhythmic interbed. The TOC content is smaller than 2% and the silica content is 40%-65%, smaller than those at Long111-Long113. The formations are rich in neritic calcareous organisms. Sedimentary structures such as calcareous nodules and parallel bedding occur frequently, and pyrite nodules and laminae have seldom been observed. The GR and acoustic time difference are lower than those at the Rhuddanian stage, but the density is higher than that at the Rhuddanian Stage.

The Long2 Member with a thickness of 200-300 m corresponds to the Telychian LM9-N2 graptolite zones. The lithology is yellowish green to grey silty mudstone, pelitic siltstone, and siltstone with particle size larger than that of the Long1 Member.

Graptolites have seldom been observed, and most of them are small cracked demirastrites, rastrites, and monograptus. Neritic gastropods developed well. Compared with the Aeronian Stage, the Long2 Member contains less laminae and pyrite nodules. Massive bedding can often be observed, and augen and quasi-augen structures can often be observed in Changning. The GR is lower than that at the Aeronian Stage[16].

1.2. Reservoir rocks

1.2.1. Classification

There are no uniform classification criteria for shale gas reservoirs in China. According to "Regulation of Shale Gas Resources/Reserves Estimation", the evaluation parameters include net-pay thickness (determined using TOC≥1%, Ro≥ 0.7%, and brittle mineral content greater than or equal to 30%), gas content, TOC content, Ro value, and brittle mineral content[17]. The Longmaxi shale in the southern Sichuan is highly to over mature with Ro above 2.1 in general; so, we excluded Ro from our evaluation parameters in this paper. We included porosity, which is not included in "Regulation of Shale Gas Resources/Reserves Estimation", to indicate gas bearing in reservoirs because porosity has significant influence on free gas content in the total gas content. As a result, we used three static parameters, i.e. TOC content, porosity, and brittle mineral content, to classify shale reservoir rocks into grade-I, grade-II, and grade-III reservoirs (Table 1).

Table 1 Classification and evaluation of shale gas reservoirs in the southern Sichuan.

| Reservoir | TOC/% | Porosity/% | Brittle mineral content/% | Applicability |

|---|---|---|---|---|

| Grade-I reservoir (high-quality shale reservoir) | ≥3 | ≥4 | ≥55 | Target point design |

| Grade-II reservoir (efficient shale reservoir) | 2-3 | 2-4 | 35-55 | Decision making basis for reserves estimation in development plan |

| Grade-III reservoir (prospective shale reservoir) | 1-2 | 1-2 | 20-35 | Prospective area selection and geologic resources/proved reserves estimation |

Note: The lower limits of grade-I, grade-II, and grade-III reservoirs in

1.2.2. Distribution

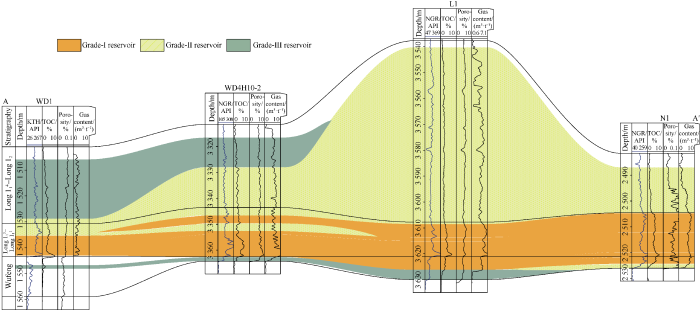

The vertical superposition of Longmaxi reservoirs is clear as per the evaluation of shale gas in the southern Sichuan. Grade-I reservoirs mainly occur in Long111-Long113. Grades-II+III reservoirs are concentrated in Long114, and there are more grade-II reservoirs in Long114 in Luzhou- Changning, and more grade-III reservoirs in Long114 in Weiyuan (Fig. 3).

Fig. 3.

Fig. 3.

Cross-well reservoir section across Wells WD1-WD4H10-2-L1-N1 in the southern Sichuan (section position shown in

Longmaxi grades-I+II reservoirs with a thickness of 20-80 m in the southern Sichuan extend continuously and stably in the horizontal direction. As per core data, the TOC content ranges 2.5%-4.5%; brittle mineral content ranges 51.6%- 80.0%; the porosity ranges 3.4%-7.9%[11].

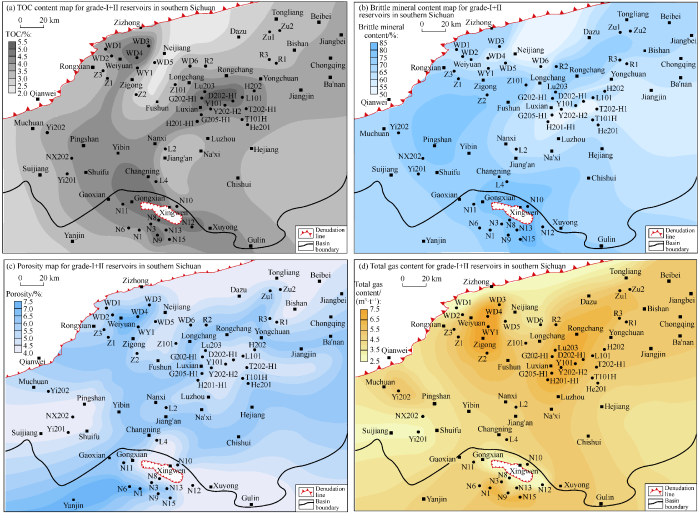

Grades-I+II reservoirs at 3500-4500 m are 32.1-70.9 m thick with the average of 58.0 m; the TOC content ranges 2.7%-3.7% with the average of 3.1%; brittle mineral content ranges 47.3%-68.4% with the average of 55.9% (Fig. 4). In general, the interval at 3500-4500 m exhibits smaller TOC content, smaller brittle mineral content, and smaller porosity than the interval shallower than 3500 m; but the Longmaxi reservoirs in the interval at 3500-4500 m features large reservoir thickness (Table 2).

Fig. 4.

Fig. 4.

Maps of reservoir properties and gas content for grade-I+II reservoirs in southern Sichuan.

Table 2 Longmaxi shale reservoir parameters at the interval of 3500-4500 m and typical wells in Changning and Weiyuan.

| Well name | Thickness of grades-I+II reservoirs/m | TOC/% | Porosity/% | Brittle mineral content/% |

|---|---|---|---|---|

| Well N1 | 26.1 | 4.1 | 7.4 | 71.0 |

| Well WD2 | 39.3 | 3.3 | 6.5 | 66.0 |

| Well WD4 | 42.7 | 3.6 | 7.9 | 56.0 |

| Average value for all wells at 3500-4500 m | 58.0 | 3.1 | 4.8 | 55.9 |

1.2.3. Factors controlling reservoir properties and thickness

1.2.3.1. Reservoir properties controlled by sedimentary water

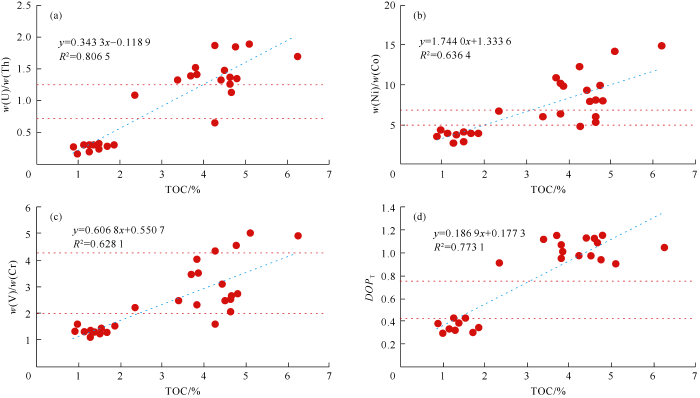

Inorganic geochemical tracing in sedimentary rock is an efficient approach to investigate sedimentary environment and its evolution. As per the evolution of oxidation reduction environment reconstructed using the oxidation reduction indexes (Table 3), the Longmaxi Formation was in a sedimentary environment evolving from anoxic strong reduction to weak reduction and weak oxidation and to oxic strong oxidation in the Rhuddanian-Aeronian-Telychian Ages[18,19]. With respect to the same tectonic and sedimentary frameworks, oxidation reduction conditions indicate the discrepancies in ancient microtopography and changes in sedimentary water. An anoxic environment indicates deep water, and water depth decreases while the oxygen content increases. We made the crossplots of TOC content of the Longmaxi Formation drilled in Well N6 with the 4 indexes which were used to indicate ancient oxidation reduction environment. We found that w(Ni)/w(Co) and w(V)/w(Cr) highly correlate with DOPT and w(U)/w(Th). It was easy to use the range of TOC content to distinguish oxidation reduction environments. Also, it was easy to calculate TOC content using log data (Fig. 5). Consequently, we used w(U)/w(Th) as a major parameter to investigate its relationship with reservoir rocks.

| Oxidation reduction environment | Oxidation reduction index | |||

|---|---|---|---|---|

| w(U)/w(Th) | w(Ni)/w(Co) | w(V)/w(Cr) | DOPT | |

| Strong reduction environment | >1.25 | >7.00 | >4.25 | >0.75 with H2S, 0.42-0.75 with no H2S |

| Weak reduction, weak oxidization environment | 0.75-1.25 | 5.00-7.00 | 2.00-4.25 | |

| Strong oxidization environment | <0.75 | <5.00 | <2.00 | <0.42 |

Note: w(U)/w(Th) is uranium-thorium mass ratio; w(Ni)/w(Co) is nickel-cobalt mass ratio; w(V)/w(Cr) is vanadium-chromium mass ratio; DOPT is the salinity of pyrite[

Fig. 5.

Fig. 5.

Crossplots between TOC content and w(U)/w(Th), w(Ni)/w(Co), w(V)/w(Cr), and DOPT at Well N6.

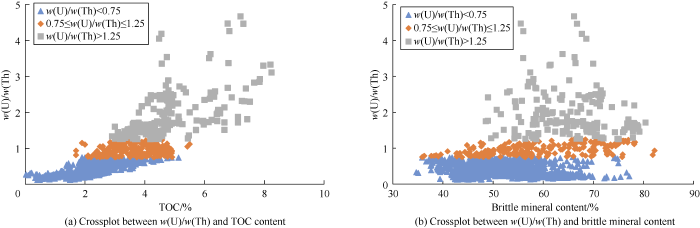

As per the correlation analysis of TOC content and w(U)/w(Th), which was made using gamma spectrometry logging at 6 wells in Changning, Weiyuan, and Luzhou (Fig. 6a), there is a positive correlation between these two parameters. For the shale with TOC>3%, w(U)/w(Th)>0.5. The TOC content, which is an indicator of reservoir properties, is high for all the shale deposited in shallow-water strong oxidization environment, semi-deep-water weak oxidization, weak reducing environment, or deep-water strong reduction environment. This means that TOC content is dependent on productivity of ancient organisms, diagenesis-burial evolution, and hydrocarbon generation and expulsion in addition to oxidation reduction conditions[25]. One thing is clear that in a relatively deep-water strong reduction environment with w(U)/w(Th)>1.25, the TOC content can be more than 3% regardless of other controlling factors. As per the correlation between w(U)/w(Th) obtained at above 6 wells and brittle mineral content which indicates fracturability (Fig. 6b), brittle mineral content mainly ranges 55%-80% for a relatively deep-water reduction condition with w(U)/w(Th)> 1.25, which indicates the plausible best performance of fracturing[26]. For a semi-deep-water weak oxidization, weak reduction condition with w(U)/w(Th) of 0.75-1.25, brittle mineral content mainly ranges 40%-75%. For a shallow-water strong oxidization condition with w(U)/ w(Th)<0.75, brittle mineral content mainly ranges 40%-70%.

Fig. 6.

Fig. 6.

Relationship between oxidation reduction environment and reservoir.

We used the relationships between w(U)/w(Th) and TOC content and brittle mineral content, which indicate reservoir properties, to investigate the mechanism of sedimentary environment controlling shale gas reservoirs in the southern Sichuan. We excluded gas content and porosity and concluded that shales in a relatively deep-water strong reduction environment with w(U)/w(Th)>1.25 are definitely grade-I reservoirs. Shales in a semi-deep water weak reduction, weak oxidization environment with w(U)/w(Th) of 0.75-1.25 are half grade-I and half grade-II reservoirs. Shales in a shallow-water strong oxidization environment with w(U)/w(Th)<0.75 are grades-II+III reservoirs, most of which are grade-III reservoirs.

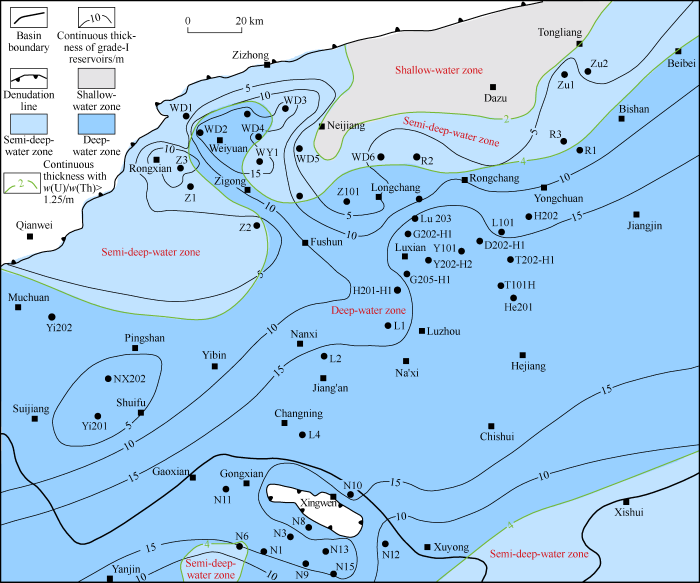

1.2.3.2. Continuous reservoir thickness controlled by sedimentary water

The Longmaxi shale was deposited in the sedimentary cycle with the transition from fast sea level rise to slow sea level drop. The Longmaxi sedimentary thickness was controlled by the discrepancies in ancient microtopography and changes in sedimentary water, which could be diagnosed using w(U)/w(Th). At the bottom of the Longmaxi Formation, w(U)/w(Th)>1.25 and continuous thickness above 4 m indicate deeper sedimentary water in the deep-water shelf. w(U)/w(Th)>1.25 and smaller continuous thickness indicate shallower sedimentary water. With respect to the same eustasy, there is a good correlation between the discrepancies in ancient microtopography and changes in sedimentary water and continuous thickness of grade-I reservoirs. Continuous thickness of grade-I reservoirs is less than 5 m in semi-deep water and relatively shallow- water zones and is relatively large in relatively deep-water zones. Continuous thickness of grade-I reservoirs is larger than 5 m, and usually larger than 10 m, along Yanjin-Junlian- Gongxian-Changning, Nanxi-Luzhou-Yongchuan-Jiangjin, and Weiyuan-Zigong and reaches a peak in Luzhou (Fig. 7).

Fig. 7.

Fig. 7.

Water depth in the deep-water shelf overlapped with continuous thickness of grade-I reservoirs.

1.3. Gas bearing characteristics of shale

There are abundant available static and dynamic data of shale gas exploration and production in the southern Sichuan. By the end of 2019, the southern Sichuan had been completely covered with 2D seismic survey grids and 3D seismic survey grids of 4856 km2 by CNPC. The Longmaxi Formation had been evaluated at 92 wells. Rapid mass production has been performed for the Longmaxi shale gas in the southern Sichuan with 1310 wells drilled, 584 wells fractured, and 624 wells in production. In 2019, the shale gas production exceeded 80× 108 m3 and the annual production capacity reached 90×108 m3.

Favorable shale gas areas at 3500-4500 m in the southern Sichuan are mainly concentrated in southern production area in Weiyuan, Luzhou, and western Chongqing-Dazu. The gas content at Long111-Long113 reaches 3.7-6.7 m3/t in Luzhou (Fig. 4d). The gas content reaches the peak near Y101-H202- H1-well Lu203 and drops in the surrounding area. According to the features of shale gas occurrence, we calculated the abundance of shale gas resources in Luzhou by free gas and adsorbed gas respectively and obtain the result of 8.13×108 m3/km2, which is the largest in the southern Sichuan. CNPC performed production tests for 3 new evaluation wells drilled in Luzhou, and the yield all exceeded 30×104 m3/d. Among these wells, Y1HA-B yield was 46.89×104 m3/d, Y1HB-H yield was 50.69×104 m3/d, and L4 yield was 14.40×104 m3/d (the horizontal section is 649 m long, and the test yield is equal to 33.28×104 m3/d in case of 1500 m long horizontal section). At present, the interval at 3500-4500 m is the major zone for shale gas exploration in the southern Sichuan.

2. Controlling law of high production of shale gas in the southern Sichuan

2.1. High production controlled by high-quality reservoirs

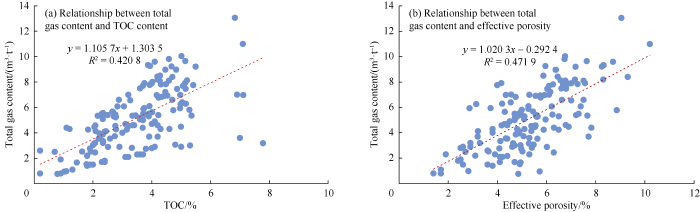

Compared with conventional gas production, shale gas reservoirs must be artificially hydraulically fractured, and thus, matrix permeability is not very useful in diagnosing reservoir rocks. Three key evaluation indexes of reservoirs are TOC content, brittle mineral content, and porosity. The brittle mineral content is closely related to the effect of engineering fracturing, and fracturing is secure when this parameter is greater than 35%. In reservoirs, the brittle mineral content is positively related to TOC. However, TOC is closely related to the quality of shale reservoirs. Under the condition of the same pressure coefficient, the total surface porosity and adsorbed gas content increase while the TOC content increases; the free gas content increases while the effective porosity increases. Thus, the total gas content is controlled by TOC content and porosity (Fig. 8).

Fig. 8.

Fig. 8.

Relationships between gas content and reservoir properties.

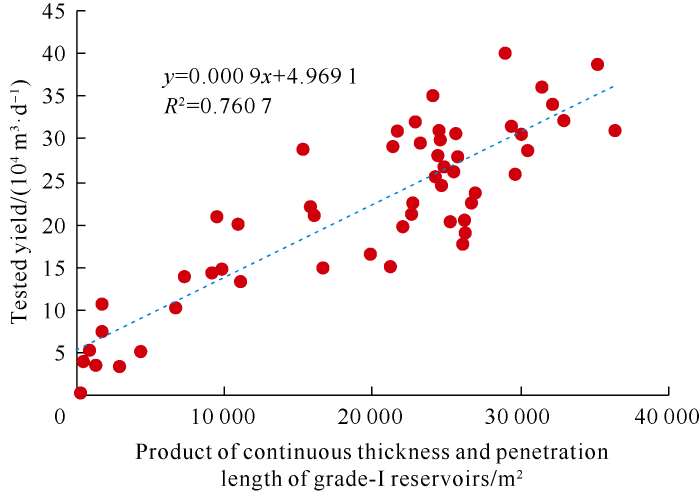

Two factors, i.e. a geologic factor of continuous grade-I reservoir thickness and an engineering factor of propped fracture height after fracturing, are crucial to high-quality reserves of shale gas. The nonradioactive ceramsite tracer logging shows that the height of propped fractures generally ranges 10-12 m. Reserves in the propped section are of high quality if continuous thickness of grade-I reservoirs exceeds 10 m, and high production can be easily obtained if continuous thickness of grade-I reservoirs is large enough. The shale gas production shows that under the same technological conditions, tested yield of individual wells correlates positively with continuous thickness of grade-I reservoirs together with penetration length of grade-I reservoirs (Fig. 9). We established a chart to describe the relationship between the product of continuous thickness and penetration length (volume of high-quality producing reserves) of grade-I reservoirs and tested yield. This chart can be used to semi-quantitatively predict the penetration length necessary for high production at different continuous reservoir thickness. As per its application in the southern Sichuan, the tested yield in Changning-Weiyuan production area could reach 20×104 m3/d in the case that the thickness of Longmaxi grade-I reservoir is 10 m and the horizontal length is 1500 m when high-quality reservoir is penetrated (Fig. 10).

Fig. 9.

Fig. 9.

Correlogram of tested yield and the product of continuous thickness and penetration length of grade-I reservoirs.

Fig. 10.

Fig. 10.

Chart for quantitative prediction of individual-well productivity in the southern Sichuan.

2.2. High production controlled by preservation conditions

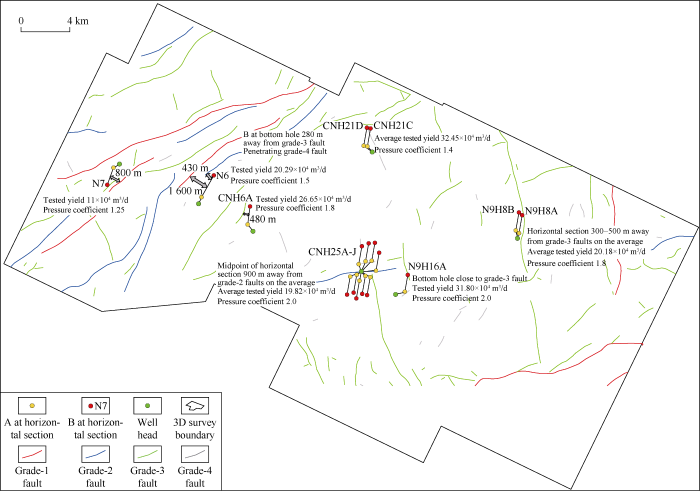

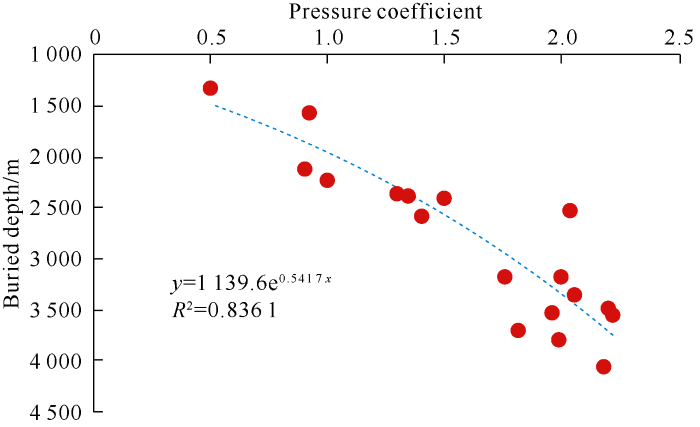

The Longmaxi Formation in the southern Sichuan has good cap, roof and floor conditions. The most important conditions characterizing gas preservation are faults development extent and the distance from the denudation line. As per shale gas production, grade-1 faults (with a fault throw above 300 m) have a great impact on Longmaxi shale gas production. Tested yield is low if the well, e.g. N7, is less than 1.5 km away from grade-1 faults. For the wells 800 m away from grade-1 faults, the pressure coefficient is 1.25 and tested yield is 11×104 m3/d. The impact of grade-2 and grade-3 faults is small. The tested yield of the horizontal wells close to these faults is higher than 20×104 m3/d on average (Fig. 11). The conditions of shale gas preservation may be damaged if the well is close to the denudation line. At Well N8 which is 2800 m away from the denudation line, the pressure coefficient is 0.50 and a tiny amount of gas was observed. At Well WD1 which is 6000 m away from the denudation line, the pressure coefficient is 0.92 and a tiny amount of gas was observed. The pressure coefficient tends to be low in the area close to grade-1 faults, Changning denudation zone, and Leshan-Longnüsi paleohigh denudation zone. Hence, pressure coefficient, which characterizes subsurface fluid energy and sealing performance for internal fluids, could be used to indicate the conditions of Longmaxi shale gas preservation in the southern Sichuan[27]. From the Changning denudation line and Leshan-Longnüsi paleohigh denudation line to Luzhou, the pressure coefficient at the Longmaxi Formation increases while the buried depth increases; in other words, there is a positive correlation between pressure coefficient and buried depth (Fig. 12).

Fig. 11.

Fig. 11.

Relationship between fault grade and tested yield in Changning.

Fig. 12.

Fig. 12.

Relationship between measured pressure coefficient and buried depth nowadays in the southern Sichuan.

High pressure coefficient zones with great gas energy and sealing performance feature larger porosity, better pore structure and gas content.

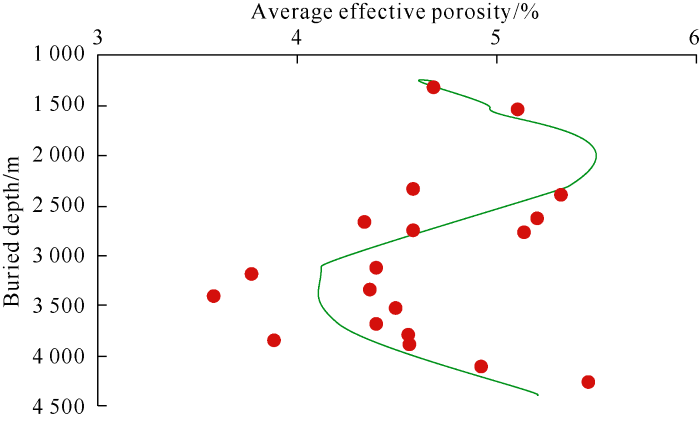

As per the correlation between buried depth and reservoir porosity of 27 wells drilled in southern Sichuan, the effective porosity of grade-I reservoirs first decreases and then increases while the depth gradually increases in the range of 2000-4500 m (Fig. 13). The porosity is large in the range of 2200-3000 m and of 3500-4500. Pores in Longmaxi grade-I reservoirs in the southern Sichuan are mainly plastic pores such as organic matter pores and clay mineral-hosted inorganic pores, which are lack of rigid mineral particles for supporting and are easily compacted under the effective stress of overburden formations. Overpressure fluid could protect pores[28,29,30,31] against formation compaction, and thus round or elliptic shale pores, as well as pore space, forming in the diagenetic process could be preserved. In accordance with the observation using argon ion polishing SEM, Longmaxi grade-I reservoirs show larger organic matter-hosted pore diameter at high pressure coefficient (Fig. 14).

Fig. 13.

Fig. 13.

Relationship between average effective porosity and buried depth of grade-I reservoirs.

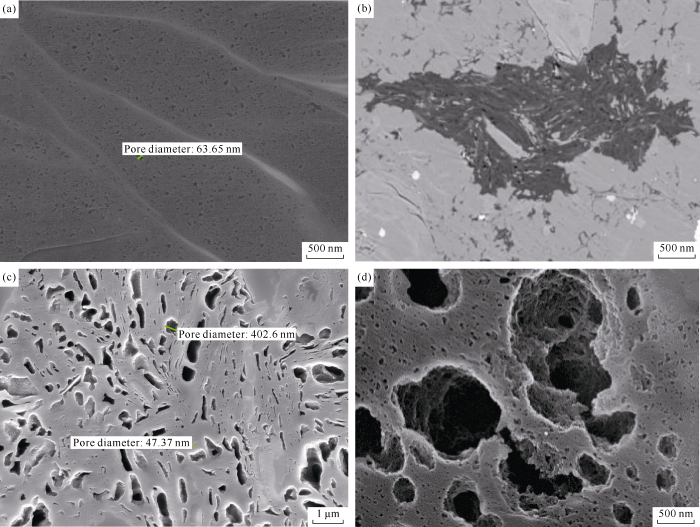

Fig. 14.

Fig. 14.

Difference between organic matter-hosted pore diameters in low pressure and high pressure areas at the bottom of the Longmaxi Formation. (a) Well Xi202, pressure coefficient 0.6, organic matter-hosted pore diameter 63 nm; (b) Well Bao201, pressure coefficient 1.1, organic matter-hosted pore diameter below 100 nm; (c) Well N6, pressure coefficient 1.8, organic matter-hosted pore diameter above 400 nm; (d) Well WD204, pressure coefficient 2.0, organic matter-hosted pore diameter above 500 nm.

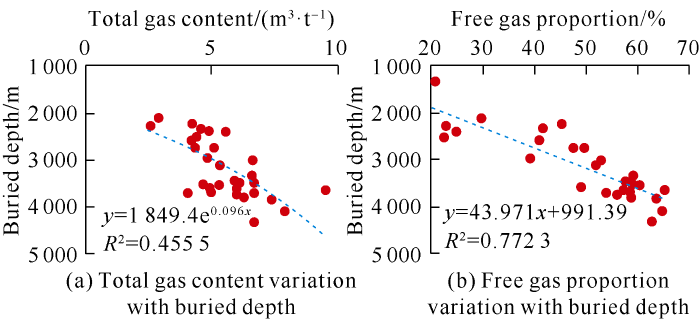

The theoretical simulative calculation of adsorbed gas and free gas at different depths and pressure coefficients[32] and the analysis of gas content of shale gas wells at different depths in the southern Sichuan (Fig. 15) shows that adsorbed gas content increases with the increase of formation temperature and pressure and then decreases at a specific temperature (at depth of 1500 m). After that, free gas proportion increases constantly from 30% to above 65%. This is favorable for the production with high economic benefit.

Fig. 15.

Fig. 15.

Relationship between buried depth and gas content of the Longmaxi Formation.

The production activities in the southern Sichuan show that high pressure coefficient is a prerequisite to high shale gas production. All the shale gas wells with economic production have been drilled in overpressure zones with pressure coefficient above 1.2. It is difficult to obtain high production from shale gas wells with pressure coefficient less than 1.2.

2.3. Sweet spotting criteria

In view of the fact that Longmaxi reservoir properties and thickness are related to oxidation and reduction conditions and high shale gas production is related to high-quality reservoirs and preservation conditions, CNPC reestablished evaluation parameters and criteria for shale gas sweet spotting in southern Sichuan (Table 4) and determined 4 major indicators and parameters. Core zones satisfy the conditions of w(U)/w(Th)> 1.25 with continuous thickness above 4 m, continuous thickness of grade-I reservoirs above 10 m, pressure coefficient above 1.2, and buried depth of 2000-4500 m.

Table 4 Major evaluation parameters for shale gas sweet spotting in the southern Sichuan.

| Type of prospect | Parameters | |||

|---|---|---|---|---|

| Deep water conditions | Deep reservoir conditions | |||

| Continuous thickness with w(U)/w(Th)>1.25/m | Continuous thickness of grade-I reservoirs/m | Pressure coefficient | Buried depth/m | |

| Core zone | >4 (Relatively deep-water zone) | ≥10 | ≥1.2 | 2 000-4 500 |

| Favorable zone | 2-4 (Semi-deep-water zone) | 10-5 | ||

| Prospective zone | <2 (Relatively shallow-water zone) | <5 | <1.2 | <2 000, >4 500 |

2.4. Deep shale gas high production-related techniques

Compared with shallow and middle zones at 2000-3500 m in southern Sichuan, deep shale reservoirs at 3500-4500 m feature more complicated geological structures with abundant faults and micro-relief structures. It is challenging to control well track accurately in such complicated geologic conditions and thus to ensure the penetration of reservoir rocks. Another issue lies in high operation pressure and challenge to produce a complicated fracture network in the context of natural fractures at high formation temperature, high earth stress, and large horizontal stress difference. To address these issues, CNPC has developed optimized fast drilling technology based on high-efficiency PDC bit + geo-steering + oil-base drilling fluid. Rotary steering was used for well track control and accurate landing at the angle-buildup section, and combined geo-steering of rotary steering and near-bit/far-end LWD was used at the horizontal section. Thanks to the “technologies + parameters + fluids + tools” four-in-one learning curves, the efficiency of well drilling has been improved gradually. CNPC has also tentatively established the large-SRV fracturing technology based on slick water, dense cutting + high-intensity sand injection, and large displacement injection. Integrated geologic-engineering techniques were utilized to mitigate the risks in well drilling and fracturing and realize successful well drilling and fracturing. Based on deepened geologic knowledge and technical progress, a model, which could be copied and generalized, was established for high-production wells (Table 5): (1) The targets in deep shale gas production areas were optimized to be Long111 high-brittleness shales thicker than 10 m, horizontal section of 1 500 m long, and 90% of grade-I reservoirs penetrated. (2) Major technologies were optimized to be dense cutting + high-intensity sand injection + large displacement + large fluid volume. These technologies boosted the discoveries of high-production wells with individual-well EUR (expected ultimate recovery) of more than 2×108 m3. Mass production with economic benefit could be realized with the investment controlled within RMB 100 million in the evaluation stage and RMB 80 million in the development stage.

Table 5 Technological indexes for high production of deep shale gas in the southern Sichuan.

| Geology | Engineering | |||||||

|---|---|---|---|---|---|---|---|---|

| Box position | Well track direction | Box height/m | Penetration rate/% | Wellbore integrity/% | Fracturing technology | Displacement/(m3•min-1) | Intensity of fluid injection/(m3•m-1) | Intensity of sand injection/(t•m-1) |

| Long111- Long113 with high brittleness | Perpendicular to major horizontal principal stress | 10 | ≥90 | ≥90 | Low-viscosity slick water, dense cutting + high-intensity sand injection, and temporary blocking and diverting | >14 | >30 | >2.0 |

2.5 Favorable exploration zones of deep shale gas in the southern Sichuan

According to the latest results of resources assessment by CNPC, the favorable workable area is 1.4×104 km2 for shale gas shallower than 4500 m in the Lower Silurian Longmaxi Formation in the southern Sichuan and the geologic resources of shale gas are 7.6×1012 m3. This means that potentially an annual shale gas deliverability of (750-1100)×108 m3 can be realized. Many areas at a depth of 3500-4500 m in the southern Sichuan are relatively deep water areas, which, based on the basic geological characteristics of the Longmaxi shale gas reservoirs in the southern Sichuan and the controlling law of high production of shale gas, overlap the areas with w(U)/ w(Th) greater than 1.25, cumulative thickness greater than 4 m, pressure coefficient greater than 1.2 and grade-I reservoir continuous thickness greater than 10 m. The core exploration zones are mainly located in Yanjin-Gongxian-Changning, Nanxi-Luzhou-Yongchuan-Jiangjin, and Weiyuan-Zigong (Fig. 16). The total area of the core zones with high production in the southern Sichuan excluding unworkable area is 8100 km2, 82% of which is at 3500-4500 m; 1.5×104 horizontal wells could be deployed and recoverable reserves were estimated to exceed 2×1012 m3. Potentially, an annual sustained shale gas deliverability of 500×108 m3 in 20 years or 1000×108 m3 in more than 10 years can be realized.

Fig. 16.

Fig. 16.

Distribution of favorable Wufeng-Longmaxi exploration zones in the southern Sichuan.

3. Conclusions

Unified classification and evaluation criteria are established for shale gas reservoirs. For grade-I reservoirs, the TOC value is greater than 3%, the porosity is greater than 4%, and the brittle mineral content is greater than 55%. For grade-II reservoirs, the TOC value is 2%-3%, the porosity is 2%-4%, and the brittle mineral content is 35%-55%. For grade-III reservoirs, the TOC value is 1%-2%, the porosity is 1%-2%, and the brittle mineral content is 20%-35%

It is proposed to characterize the relative depth of sedimentary water with oxidation and reduction parameter w(U)/ w(Th). According to the study, the w(U)/w(Th) greater than 1.25 indicates an anoxic reduction environment and relatively deep water; the w(U)/w(Th) ranging from 0.75 to 1.25 indicates a weak reduction and weak oxidization environment and semi-deep water; the w (U)/w(Th) less than 0.75 indicates a strong oxidization environment and relatively shallow water.

The height of propped fractures generated in fracturing treatment of shale reservoirs is generally 10-12 m. When the continuous thickness of grade-I reservoirs is greater than 10 m, the longer the continuous thickness of penetrated grade-I reservoirs is, the higher the shale gas production will be.

Deep shale gas at 3500-4500 m in the southern Sichuan features high formation pressure, large pressure coefficient, good preservation of pores, good pore structure, and large free gas proportion. Pressure coefficient above 1.2 is a prerequisite to high shale gas production. The high-production well model in the deep shale gas production area is Long111-Long113 sublayer thickness more than 10 m, 1500 m long horizontal section, more than 90% of grade-I reservoirs penetrated, and major technology of dense cutting + high-intensity sand injection + large displacement + large fluid volume.

Yanjin-Gongxian-Changning, Nanxi-Luzhou-Yongchuan- Jiangjin, and Weiyuan-Zigong are the most favorable shale gas exploration and development zones in the southern Sichuan. Based on theoretical and technological progress, the annual shale gas production in the southern Sichuan is expected to fulfill the goal of 450×108 m3.

Reference

Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin

Shale gas in China: Characteristics, challenges and prospects(I)

Geological factors controlling shale gas enrichment and high production in Fuling shale gas field

A golden era for natural gas development in the Sichuan Basin

China first million square shale gas well was born

Cretaceous sedimentary basins in Sichuan, SW China: Restoration of tectonic and depositional environments

Unique geological features of burial and superimposition of the Lower Paleozoic shale gas across the Sichuan Basin and its periphery

Evolution of lithofacies and paleogeography and hydrocarbon distribution worldwide (I)

Facies patterns and geography of the Yangtze region, South China, through the Ordovician and Silurian transition

Reservoir-forming conditions and favorable exploration zones of shale gas in Lower Silurian Longmaxi Formation of Sichuan Basin

Micro-layers division and fine reservoirs contrast of Lower Silurian Longmaxi Formation shale, Sichuan Basin, SW China

Stage-progressive distribution pattern of the Lungmachi black graptolitic shales from Guizhou to Chongqing, Central China

DOI:10.1007/s11430-016-9031-9 URL [Cited within: 1]

Ordovician-Silurian brachiopod fauna turnover in South China

Enrichment laws and scale effective development of shale gas in the southern Sichuan Basin

Stratigraphic sequence and sedimentary characteristics of Lower Silurian Longmaxi Formation in the Sichuan Basin and its peripheral areas

Sedimentary facies of marine shale gas formations in Southern China: The Lower Silurian Longmaxi Formation in the southern Sichuan Basin

Land and Resources

Unconventional shale-gas systems: The Mississippian Barnett Shale of north- central Texas as one model for thermogenic shale-gas assessment

The discussion on anoxic environments and its geochemical identifying indices

A new paleoenvironmental index for anoxic events: Mo isotopes in black shales from Upper Yangtze marine sediments

Comparison of geochemical indices used for the interpretation of paleo-redox conditions in ancient mudstones

Interoceanic variation in the rare earth, major, and trace element depositional chemistry of chert: Perspectives gained from the DSDP and ODP record

Relationship between inferred redox potential of the depositional environment and geochemistry of the Upper Pennsylvanian(Missourian) Stark Shale Member of the Dennis Limestone, Wabaunsee County, Kansas, USA

Pyrite and organic matter in Phanerozoic normal marine shale

On the geobiological evaluation of hydrocarbon source rocks

The formation mechnism of over-pressure reservoir and target screening index of the marine shale in the South China

Ultra-low water saturation characteristics and the identification of over-pressured play fairways of marine shales in south China

Comprehensive prediction of shale gas sweet spots based on geophysical properties: A case study of the Lower Silurian Longmaxi Fm in Changning block, Sichuan Basin

Research status and exploration enlightenment on over-pressure and enrichment shale gas in North America

Mechanisms for abnormal pressure seal in pressure compartments: A review

Analyses of influences on shale reservoirs of Wufeng-Longmaxi Formation by overpressure in the South-eastern Part of Sichuan Basin

Main controlling factors and enrichment area evaluation of shale gas of the Lower Paleozoic marine strata in south China