Introduction

With the rapid development of the national economy of China, the oil and gas consumption has also increased significantly. However, due to the poor quality of resources, it is difficult to increase the reserves and production of domestic oil and gas. In 2019, more than 70% of the oil and 40% of the natural gas were imported. Restricted by factors such as international political and economic environment, oil and gas geopolitics, and technical bottlenecks in domestic oil and gas exploration and development projects, the uncertain international oil and gas supply and fragile supply chain ecology contradict prominently with the ineffective utilization of domestic oil and gas reserves, which seriously affects the economic and social development and energy security of China[1,2,3,4,5,6,7,8,9,10,11]. It is necessary to strengthen the domestic oil and gas exploration and development, accelerate the technology progress of domestic oil and gas exploration and development, and to make effective development and utilization of the reserves and resources difficult to produce, so as to ensure national energy security. Based on the successful development practice of some domestic oil and gas reserves difficult to produce, this paper systematically summarizes the "four in one" petroleum engineering synergetic management model to promote the effective development of these reserves.

1. Background of petroleum engineering synergetic management model innovation

Difficult-to-produce reserves with poor quality account for a large proportion in total oil and gas resources of China. From the perspective of resource attributes, the difficult-to- produce reserve resources are owned by the state and the oil mining rights are assigned to enterprises. Within the enterprise, such explored resources have been transferred from the exploration department to development units. In some enterprises, such explored resources are managed by specialized departments of oil and gas field subsidiary companies, while in other enterprises, they are operated by oil production (gas) plants or management areas subordinate to each oil and gas field subsidiary company due to limited area or scale of resources. The ownership of resources causes the management bodies responsible for the difficult-to-produce reserves to be relatively scattered. In terms of resource types, it mainly includes low porosity and low permeability, super heavy oil or extra-super heavy oil, deep to ultra-deep oil and gas resources, as well as tight oil and gas, shale oil and gas and other unconventional oil and gas resources. The engineering technology requirements for the development of reserves difficult to produce are diversified and integrated, with poor quality, low efficiency and difficult to recover. Therefore, the existing technologies cannot fully meet the development needs and need vigorous synergetic technical innovation[2,3,4,5,6,7,8,9,10]. From the perspective of specialty and industrial chain, the dispersion of responsibility subjects, the complexity of resource types, the high integration of engineering technology required and the highly specialized management system and mechanism within the enterprise group require that the development of each block of difficult to produce reserves must go through the whole life cycle of exploration and development, which requires high degree of synergy among multi disciplines, such as geology, exploration, drilling, logging and well completion and ground gathering. It also requires the full synergy between oil and gas field subsidiary companies, oil production (gas) plants, management areas and petroleum engineering companies, third-party service providers, scientific research institutes and other responsible parties. However, for each responsible party who is independently operating and undertakes different specialized management functions and profit-earning responsibilities, the goal of pursuing the maximum benefit of itself is higher than the overall objective of the development of difficult-to-produce reserves. Currently, the four major domestic oil companies have a large number of undeveloped proven reserves difficult to produce[2,3,4,5]. Taking Sinopec (China Petrochemical Corporation) as an example, it has 16×108 t of crude oil reserves difficult to produce alone. Considering the above characteristics of difficult-to-produce reserves, there has been no effective management model or a series of supporting technologies suitable for all kinds of difficult-to-produce reserves.

There are three main reasons for the ineffective development of the difficult-to-produce reserves. The first reason is due to the poor quality of resources and the difficulty of effective development. As the development of the oil and gas resources of medium shallow layer and large thick layer with good permeability and low viscosity gradually move to the later stage, the quality of remaining resources becomes worse and worse. Low permeability, ultra-low permeability, special lithology (carbonate rock, etc.) and heavy oil reservoir account for 91% of the difficult-to-produce reserves, and its development difficulty is no less than the exploration and development of new oil and gas resources. The second reason is that it is difficult to develop on an effective scale due to engineering technology limitations. In recent years, great progress has been made in petroleum engineering technology, and breakthroughs have been made in single technology. However, there are still many bottlenecks in the integration of technologies for difficult-to-produce reserves, lacking of overall technical support, and the overall advantages of engineering technology have not been formed through integration, optimization and innovation. Thirdly, limited to the current system and mechanism, the motivation of effective development is not strong enough. At the national policy level, there is no special financial subsidy and tax preferential policy for the development of oil and gas reserves difficult to produce; in terms of enterprise mechanism, oil companies have no incentive mechanism for the effective development of difficult-to-produce reserves; the economic evaluation mechanism by all parties involved for the development of difficult-to-produce reserve projects need to be optimized; the project cooperation model of Party A and Party B needs synergic innovations in management so as to motivate the enthusiasm of all participating parties.

Viewing from the main participating parties in the development of difficult-to-produce reserves, there are two most direct reasons for the ineffective development of the difficult-to-produce reserves. One reason is the serious technology difficulty, thus both Party A and Party B lack effective means; the other is that the investment risk is high, which leads to lacking of enthusiasm for both Party A and Party B. The development of difficult-to-produce reserves is not only a technical problem, but also a problem of enterprise internal management. Completing the task of the development of the difficult-to-produce reserves goes beyond the level of a single enterprise or business entity independently. More partners such as Party A, Party B and the third parties should cooperate to complete the development. There are many levels that need to be coordinated among partners of different specialties and different interest orientations. The high risk of investment and the high uncertainty of benefit return aggravate the difficulty of cooperation.

The risk exploration of oil and gas resources is faced with unknown exploration objects. In the framework of national and enterprise policies, the fault tolerance rate of risk exploration is clear, and the responsibility subject is clear about its own risk boundary; however, compared with the risk exploration of oil and gas resources, the development of difficult-to-produce reserves faces the known but not completely clear development objects, and the fault tolerance rate is far lower than the standard of risk exploration. Under such situation, the risk is mainly taken care of by the responsible party, and the allowable trial and error space is far less than risk exploration. This fundamentally leads to very low enthusiasm of the responsible party of difficult-to-produce reserves development. Consequently, the difficult-to-produce reserves cannot be effectively developed.

To solve the problem of effective development of difficult-to-produce reserves, we are faced with the core difficulty of improving cooperation efficiency and dispersing cooperation risks.

2. Innovative construction of synergetic management model for petroleum engineering

As the core of the "new three theories" (dissipative structure theory, synergetics and catastrophe theory) of system theory, synergetics is the theoretical guide of management model innovation, which is known as "a science about cooperation". In 1971, the famous German physicist Harken put forward the concept of synergy. In 1976, he systematically discussed the theory of synergy and published “Introduction to Synergetics”, demonstrating that the evolution of various natural and social systems from disorder to order and from chaos to clarity is the result of the interaction and coordination of various elements of the system, which has a wide application foundation[12,13]. The essence of synergy is cooperation. To act towards the same overall direction, sharing almost the same objective, with the same overall interests is the driving force to promote cognition from disorder to order and management from chaos to clarity[12,13]. Through the change of management model, innovation vitality is released to promote the progress and improvement of engineering and process technology; the progress of engineering and process technology also promotes the dynamic development of management model[14,15,16,17,18,19,20,21,22].

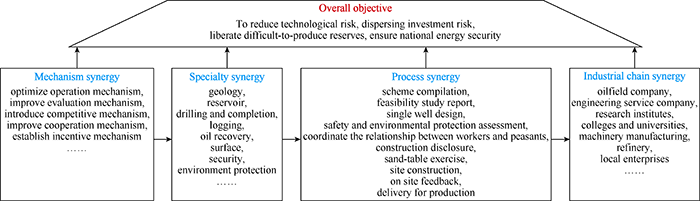

The problem of effective development of domestic difficult-to-produce oil and gas reserves emerges with China’s reform and opening up policy and the development of market economy, and it has become a problem faced by the oil and gas industry, needing to be solved urgently, especially with the establishment of economic-efficiency-centered responsibility mechanism of oil and gas resources enterprises, changes in the external environment such as the integration of domestic and international oil price, and the continuous increase of external dependence of domestic oil and gas resources. For a long time, I have been responsible for the development of oil and gas resources, engineering technology research and development, as well as engineering project management. I have accumulated experience in different periods and working units through either in charge of or organizing the development of difficult-to-produce reserves. Especially when I was in charge of the development of different types of difficult-to-produce reserves in Shengli Oilfield branch and Northwest Oilfield branch of Sinopec, I insisted in summarizing while practicing, and constantly improving in practice, and gradually developed and innovated the "four in one" synergetic management method of mechanism synergy, specialty synergy, process synergy and industry chain synergy for petroleum engineering. I have consequently innovated and constructed the petroleum engineering synergetic management model (Fig. 1). Under the guidance of system theory, cybernetics and synergism, the model focuses on reducing the technical risk and dispersing the economic efficiency risk in the development of difficult-to-produce reserves. By learning from the models and practices of risk exploration home and abroad, taking the reasonable sharing of risks and interests of project participants into full consideration, and adopting various cooperation methods according to local conditions, it effectively reduces the worries of the project participants and therefore stimulate the vitality and power of active coordination of project participants to jointly develop the difficult-to-produce reserves.

Fig. 1.

Fig. 1.

Illustration of petroleum engineering synergetic management model.

As shown in Fig. 1, from the horizontal perspective, the "four in one" synergy is gradually progressive, with mechanism synergy as the prerequisite to stimulate the vitality and motivation of project participants and disperse investment risks; specialty synergy is the means of innovation to promote the technological progress of supporting projects, optimize scheme design and reduce technological risks; process synergy is the implementation guarantee, which provides dynamic feedback in the whole life cycle to ensure the construction effect of the project, and to ensure that risks can be controlled by handling and adjusting system factors in time in case of emergency; industrial chain synergy is the extension of upstream and downstream, which helps to maximize the overall interests. Vertically, the "four in one" synergy is the basis and support for the realization of the overall objective. It is also the synergy of integration, complementation and mutual promotion.

2.1. Mechanism synergy

Mechanism synergy is the basis of petroleum engineering synergetic management model and the guarantee of dispersing the cooperative development risk of difficult-to-produce reserves.

Considering the scale and development risks of the common blocks of difficult-to-produce reserves, in contrast to the development of newly proved packaged oil and gas fields, it is inappropriate to integrate the partners by system integration in the current market environment. Due to the high cost and risk of system reform, we should rely more on mechanism innovation supplemented with system reform. Mechanism innovation mainly comprises of the following five aspects: (1) Optimize the operation mechanism and implement the integration of project management. Think out of the traditional oil company model, learn from the integrated development project management organization home and abroad, build an integrated operation organization structure, create a community of shared interests of Party A and Party B, implement the efficient and intensive production construction model of integrated efficiency and cost reduction, integrated production organization and integrated technology management, so as to maximize the overall objective benefits. (2) Improve the evaluation mechanism and realize the explicitness of recoverable reserves. By breaking the limitation of 12% and 8% internal rate of return after tax for investment projects in traditional economic evaluation, evaluate the projects according to the necessary conditions that Party A has marginal benefits and Party B has positive cash flow, any projects that meet the conditions can enter the sequence of recoverable reserves. (3) Introduce competition mechanism and highlight the marketization of engineering service. According to the principle of "urgent need for production, leading technology, overall optimization and total quantity control", the market of petroleum engineering technology service should be moderately open. The cooperative partners will gradually expand from the internal oil engineering companies of oil companies to other state-owned oil companies, social private enterprises (capital) and overseas oil companies (capital), so as to establish a diversified market-oriented service scheme. (4) We should improve the cooperation mechanism and form a diversified cooperation model. Based on the characteristics of geology and engineering technology of difficult-to-produce reserves reservoir, the risk cooperative development model and practice home and abroad should be taken for reference, and various cooperation models should be adopted according to local conditions. For example, for the difficult-to-produce blocks with high exploration degree, proven reserves and high project investment, such as Honghe Oilfield, the sharing mode of break-even production and efficiency increase should be adopted; in the production capacity construction blocks of new and old areas with low exploration degree, insufficient reserve implementation and high reservoir geological risk, such as Xujiahe Formation gas reservoir in Xinchang gas field, risk production and efficiency increase sharing model should be adopted; advanced technologies are needed to be introduced in the large-scale application blocks of single technology and engineering technology integration, such as tight oil in southern Hubei Province, the risk contracting mode of technical service should be adopted; in the production capacity construction blocks of new and old areas with low exploration degree and difficult-to-produce reserves, such as Zhunzhong Yongjin Oilfield, the joint venture risk lease development mode should adopted. (5) Establish incentive mechanism to reduce cost and improve efficiency. According to the principle of positive incentive and increasing efforts, the responsible parties should formulate reasonable incentive measures according to the current situation of construction and the objective of increasing the speed and efficiency, and formulate reasonable incentive methods at multiple levels, such as at the level of single well, project and block, as well as drilling cycle, efficiency, quality and production. Engineering companies are encouraged to shorten the construction period through management innovation, technology improvement, operation optimization and construction efficiency improvement, and rewards are given according to team ranking and days saved. If the project output is obviously improved in quality and efficiency compared with the scheme design (basic output), the reward shall be given accordingly.

Through a series of mechanism innovation, it can reduce the worries of the participants in the development project of difficult-to-produce reserves to the greatest extent, fully motivate the enthusiasm of the participants in the cooperation, promote the participants to optimize the scheme, optimize the construction, consciously reduce the technical risk of the project, and stimulate the participants' instinct of continuously pursuing higher output and reducing benefit risk. In the actual operation process, individualized incentive and restraint measures should be taken according to local conditions. For example, in the evaluation test area with high risk, Party A takes the initiative to bear the risk; when the output fails to reach the scheme design, Party B can obtain the minimum basic daily fee; when the output reaches the scheme design and exceeds 20%, Party B will be rewarded with 20% of the workload; when the output reaches the scheme design and exceeds 20% but less than 50%, Party A and Party B share the profits of the excess part; when the output reaches the scheme design and the amount exceeds 50%, part of the profit exceeding 50% shall be obtained by Party B. In the actual project operation process, according to the difficulty of the project and the negotiation between Party A and Party B, the specific reward and restraint measures are determined.

From the perspective of mechanism synergy, according to the characteristics of low pressure, low permeability and low production of difficult-to-produce reserves in Daniudi gas field, the synergetic management model of petroleum engineering was adopted to carry out cooperative development with many companies, and achieved positive results. The first step is to cooperate with Jiaoen energy company, which has unique experience in reservoir protection and transformation technology of low permeability and low pressure oil and gas fields, and promote the high-efficiency adjustment and development test of greatly increasing single well production, and achieving good results. First of all, a joint development project team is set up to formulate a production sharing contract, and the project team will be given corresponding rewards on the basis of increasing output to a certain range. Three wells were selected to carry out pilot test. The actual drilling of these three wells showed that the drilling encounter rate and average total hydrocarbon content of sandstone were lower than the average index of Daniudi gas field, and the average initial production was 2.4 times of the original plan. Secondly, in order to improve the recovery of Daniudi Gas Field, we cooperated with Halliburton company to test the concept, technology and process of secondary fracturing, and explored to enhance the stable production capacity of low permeability, low pressure and low production gas fields. On the basis of the establishment of joint research team, the corresponding incentive measures are formulated to allow a certain degree of fault tolerance. Four wells were operated by secondary fracturing, with an average increase of 92% in production. The above examples show that through mechanism innovation, the enthusiasm of the participants in the development project of difficult-to-produce reserves can be motivated, so as to disperse the investment risk, enhance the overall value of the project, and improve the utilization rate of difficult-to-produce reserves.

2.2. Specialty synergy

Specialty synergy is the core of collaborative management model innovation in petroleum engineering, and is a means to reduce the technical risk of difficult-to-produce reserves development. Specialty synergy mainly follows the law of technological innovation and carries out interdisciplinary collaborative innovation from three stages according to the technology life cycle. (1) Basic research synergy. Basic research is the source of the whole technology system, the foundation of technological innovation and a long-term accumulation process. Based on the differences in difficult-to-produce reserves between the eastern and western regions of China, we should take the strategy of combining the internal and external cross- border, changing from "individual innovation" to "group innovation", and seek breakthrough through long-term continuous innovation. On the one hand, we should strengthen the fine reservoir geological research, focusing on the whole chain research of "seismic-geology-reservoir -reservoir transformation", and find "sweet spots" in the difficult-to-produce reserves, and form a series of "sweet spots" evaluation and identification technology series for different types of reservoirs and different regions. On the other hand, we should strengthen the research on the basic theory and new methods of oil production engineering and surface engineering, focusing on the mechanism of viscosity reduction, lifting, gathering and transferring. (2) Synergetic engineering technology research. We should give prominence to strategic guidance, problem orientation and value drive, and focus on the development of "neck sticking" technologies such as quality improvement, speed-up, efficiency improvement and production improvement, and intelligent drilling and completion technology for tackling key problems, or technologies with strong guidance and good prospects for popularization and application. (3) Synergetic engineering technology integration. A series of integrated development technologies are integrated for different reservoir types to form a series of integrated solutions. In the Junggar Basin, we focus on wellbore instability mechanism, collapse and leakage control technology in complex formation; tight cutting and low damage fracturing technology for tight oil in southern Hubei; low-cost drilling and completion technologies such as small-size and micro hole in old Eastern oilfields; nitrogen drilling technology and underbalanced drilling technology in Xujiahe gas reservoir in Sichuan Basin; and low-cost drilling matching technology in shale gas research.

Synergetic basic research makes the understanding of difficult-to-produce reserves more clear, synergetic engineering technology breakthrough makes the development of difficult-to-produce reserves more efficient, and synergetic supporting engineering technology integration makes the development of difficult-to-produce reserves more targeted. Advanced supporting engineering technology series suitable for the development of different types of difficult-to-produce reserves can liberate the difficult-to-produce reserves and effectively reduce the development technology risk.

In order to alleviate the contradiction between insufficient production of difficult-to-produce reserves and high production pressure in Shengli Oilfield, the theory of HDCS enhanced oil recovery technology was put forward. A new development model of collaborative viscosity reduction, mixed mass transfer and energy and drainage increase among horizontal well (H), viscosity reducer (D), carbon dioxide (C) and steam drive (S) was established, and a set technology suitable for medium and deep ultra-heavy oil development was formed. The developed supporting technology realizes the synergetic innovation among multiple processes. The results have been applied to Shengli Oilfield, Huadong Oilfield, Jiangsu Oilfield and other old Eastern oilfields, with newly increased reserves of 2.2×108 t and production capacity of 230.5×104 t. The cumulative oil production increased by 435.4×104 tons and the profit was 3.15 billion yuan.

2.3. Process synergy

Process synergy is the executive guarantee for the development of difficult-to-produce reserves. In the traditional petroleum engineering project, the participants have obvious specialty interface and responsibility boundary, and the main participation process is "series connection". The efficiency of project implementation process is not high, the feedback optimization of scheme is insufficient, and there is no real-time dynamic adjustment. Process synergy mainly starts from building an integrated management platform, integrating project participants into a management interface, changing "series" to "parallel", and realizing real-time synergy. It mainly includes three aspects. (1) Synergetic scheme optimization. Focusing on the integrated design and integration of geological and engineering, breaking the barriers of departments and specialties, realizing the specialty union of exploration, geology, reservoir, economic evaluation, drilling, completion, logging, oil production, surface, safety, environmental protection, etc., with the economic benefit of the scheme as the center, timely guide, adjust and optimize the scheme. (2) Cooperate with on-site construction. Through remote video monitoring, first-line data acquisition and information centralized processing, real-time perception of field data can be realized, problems can be solved through joint research, and optimization implementation scheme can be adjusted dynamically. (3) Coordinate abnormal situation disposal. In case of emergency, the experts of various disciplines shall be concentrated for timely collaborative disposal and adjustment, so as to achieve controllable risk.

Synergetic scheme optimization is a scheme optimization with the participation of all professionals, which can improve the integrity and scientificity of the scheme at the source. The pre-drilling coordination work before the project construction can greatly improve the work efficiency of all parties. Through sand-table exercise, the problems that may occur in the drilling process can be predicted in advance and corresponding plans can be made. The whole professionally synergetic disposal of abnormal situation can reduce the risk to the minimum, and feed back to the front end to optimize the single well design. Process synergy can achieve obvious improvement in four aspects: one is to shorten the time in the early stage of the project; the second is to control various risks in the implementation process of the project; the third is to be able to handle and respond quickly in case of emergency; the fourth is to improve the quality of project deployment, engineering quality and operation, reduce engineering investment and management costs, and ensure that the difficult-to-produce reserves are converted into effective production.

Pai 609 block in the Junggar Basin is a shallow and thin structural lithologic reservoir with edge and bottom water. The reservoir is characterized by shallow buried depth, low reservoir thickness, high viscosity of crude oil and complex regional oil-water relationship which is typical difficult-to produce reserve. In February 2019, Xinchun Company signed a cooperative development contract with the development project department of difficult-to-produce reserves to optimize the well structure and shorten the drilling cycle; optimize the drilling parameters to improve the drilling speed; implement the "factory" operation model to improve the operation efficiency; improve the supporting technology to reduce the comprehensive cost. In Pai 609 block, 65 new drilling wells were designed. Before optimization, the design drilling investment was 110.838 million yuan, and after optimization, the design drilling investment was 70.04 million yuan, reducing the cost by 36.8%. The average completion period of drilling is shortened from 4.5 d to 1.5 d, which is 66.7% shorter. The average daily oil production in the initial stage of production is 10.8 t, realizing the benefit development under the oil price of $50/bbl.

2.4. Industrial chain synergy

The purpose of industrial chain synergy is to give full play to the comprehensive integration advantages of enterprise groups, break professional barriers, maximize the upstream and downstream extension of the industrial chain and the accumulation of advantageous resources, and help to realize the effective development of difficult-to-produce reserves and maximize the overall interests of enterprise groups. Industrial chain synergy is to establish the overall industrial ecosystem of oil and gas industry on the basis of mechanism synergy. Driven by the main body in the middle reaches, the overall benefits of the upstream, middle and lower reaches of the ecosystem are continuously increased. The whole industrial chain can achieve synchronous promotion, synchronous development and synchronous benefits, which can maximize the marginal cost of enterprise group development, enhance the sustainable development ability of the industry, and ensure the sustainable development of the industry. In addition, it can also protect the ecological environment, promote economic development, increase employment, and help the harmonious and stable development of society.

3. Operation process of synergetic management model for petroleum engineering

In the development of difficult-to-produce reserves, the emphasis of petroleum engineering synergy management model is different at different levels and stages. At the level of oil companies, it mainly considers mechanism synergy, formulates and issues guidance documents related to the development of difficult-to-produce reserves, puts forward the principles of cooperation mechanism and the relevant differential assessment opinions on the development of difficult-to- produce reserves of oilfield subsidiary companies without complicated and detailed restrictions, mainly "loosening the binding" of the development policies of difficult-to-produce reserves; at the same time, it also considers the coordination of upstream, middle and downstream industrial chains to optimize the allocation of resources, expand the industrial chain ecosystem, and maximize the overall interests. At the level of oilfield branch, under the principle coordination mechanism of oil companies and considering the actual situation of enterprises, the specific operation documents of differentiation coordination mechanism are formulated, the assessment objectives of differentiation are determined, and the vitality and power of integrated development project department are stimulated. At the level of integrated development project department of difficult-to-produce reserves, focusing on specialty synergy and process synergy, it optimizes the whole professional scheme, participates in the project implementation and abnormal situation disposal in the whole process, and finally converts the difficult-to-produce reserves into production.

4. Practice of synergetic management mechanism model for petroleum engineering

By the end of 2017, domestic proven undeveloped and difficult-to-produce oil reserves reached 54×108 t, accounting for about 14% of the total reserves[23]. In different work areas and different types of reservoirs, the application of synergetic management model for petroleum engineering in the development of difficult-to-produce reserves has achieved good results, rich application results, great significance, and with good driving and demonstration role.

4.1. Synergetic development and integrated innovation in auxiliary technics and application in development of ultra-deep wells and super-heavy oil reservoirs

The Tahe Oilfield has a super-heavy oil reservoir with the deepest burial depth (7000 m), the largest reserves (7.36×108 t) and the highest viscosity (1.0×107 mPa•s at 50 ℃) in the world. At the same time, it has a high salt content (2.2×105 mg/L) and high hydrogen sulfide content (more than 1.0×104 mg/m3). Its effective development is recognized as a world-class technical puzzle.

By implementing the synergetic management model for petroleum engineering, we organized scientific research institutes, colleges and universities, relying on the key scientific and technological projects such as national major scientific and technological projects, formed a technical team of multi-disciplinary experts to carry out joint research and development, and coordinated the development of adaptive chemical viscosity reduction technology, realizing the efficient recovery of ultra-deep wells and super-heavy oil. First, the synergetic research revealed the viscosity mechanism of super-heavy oil, which laid a theoretical foundation for the development of new viscosity reducer. The second is to organize chemical engineering experts and petroleum engineering technology experts to develop different types of high-efficiency composite viscosity reducer, and realize the chemical viscosity reduction and efficient recovery of ultra-deep wells and super-heavy oil. The third is the integration and innovation in green gathering and transportation processing technology for millions of tons of super-heavy oil, realizing zero emission and full recovery of hydrogen sulfide, and protecting the environment of populus euphratica ecological fragile area in Tarim River. Fourth, it promoted the upgrading of downstream refineries and promoted the synergetic development of industrial chain. The successful application of the project results has provided sufficient crude oil for Sinopec Tahe refining and Chemical Co., Ltd., PetroChina Urumqi Petrochemical Branch, Harbin Tianyuan Petrochemical Engineering Design Co., Ltd., Xinjiang Sanhe Construction Engineering Co., Ltd., and Xinjiang Meihuite Petrochemical Products Co., Ltd., which ensures the use of Western oil in the West and promotes the development of local enterprises. Grade A asphalt produced by heavy oil as raw material provides strong support for the traffic construction in Western China, forming a good industrial chain ecosystem as a whole.

This achievement sets a precedent for the application of chemical engineering technology in the field of ultra-deep well and super-heavy oil development. It has been applied to many super-heavy oil blocks such as Yuqi in Tahe Oilfield. The annual production of heavy oil reaches 350×104 t, which makes the annual crude oil production of Northwest Oilfield branch of Sinopec rapidly jump to 735×104 t. Being one of the top ten oil fields in China, it is of great significance to promote the strategic replacement of energy in Western China and ensure national energy security. From January 2011 to December 2013, the new output value was 6.003 billion yuan, the profit was 3.295 billion yuan, the tax was 660 million yuan, and the heavy oil reserves were 1.25 ×108 tons.

4.2. Synergetic research and application of nitrogen injection enhanced oil recovery technology in fractured-vuggy reservoir

The proven reserves of Tahe ultra-deep carbonate fractured-vuggy reservoir reach 13.2×108 t. in 2017, the newly increased reserves accounted for 34% of Sinopec's total newly increased proved reserves. However, due to strong heterogeneity, complex spatial distribution of fractures and cavities, and rapid natural decline, the recovery after water flooding is only 15%, which is lower than the 17%-51% of similar reservoirs and far lower than the average level of 26.8% of Sinopec. Due to the particularity of ultra-deep (over 6000 m), high temperature (120-190 ℃), high salinity (22×104 mg/L), high calcium and magnesium ion content (more than 1×104 mg/L) and high hydrogen sulfide content ((0.003-12.600)× 104 mg/m3), the adaptability of conventional chemical flooding is poor. The physical simulation experiment of nitrogen injection after water flooding is carried out in laboratory, and it is found that the recovery of nitrogen injection is increased by 30%, which has obvious adaptability. However, "no injection", "poor injection" and "too expensive injection" have become the three major problems of nitrogen injection in fractured-vuggy reservoir.

This achievement has made a breakthrough in filling up the blank in replacement technology in the later stage of water injection development of fractured-vuggy reservoir, helped to realize the strategic replacement and support of development technology of fractured-vuggy reservoir in Tarim Basin, and provided field practice reference for efficient development of similar reservoirs; localization and mature application of high-pressure gas injection equipment in China plays an important role in promoting national manufacturing industry; large-scale application of nitrogen injection can cultivate specialized talents. 12 teams and more than 1000 jobs were created, which was of great significance for improving people's livelihood and maintaining social stability in Xinjiang. By the end of 2018, 1332 wells had been implemented in Tahe fractured-vuggy reservoir, increasing oil by 261.1×104 t and increasing profit by 2.231 billion yuan. The results not only have a good application prospect for EOR of fractured-vuggy reservoirs in Tahe Oilfield, but are also significant industry demonstrations for the development of carbonate reservoirs in Tarim Basin, also home and abroad. It has been applied in fractured reservoirs in North China, Tarim and Algeria for more than 65 wells, increasing oil by 7.5×104 t.

4.3. Development of difficult-to-produce reserves in Shengli Oilfield

The Shengli Oilfield has a low permeability and heavy oil hard to produce of nearly 6×108t, accounting for more than 10% of the country. The effective development is faced with many challenges such as complex oil-water system, difficult process matching and low productivity[24].

The application of petroleum engineering synergetic management model was adopted to solve the above problems. As for the mechanism synergy, the first step was to improve the cooperation mechanism by general contracting the block construction and production, calculating the investment according to the balanced oil price of $50/bbl, and rewarding the overproducing part to the engineering company. In this way, it broke the previous development mode where oil companies bore all the risks and benefits, and effectively stimulated the engineering companies to do more work. The second step was to improve the internal distribution mechanism. The project department, on behalf of the engineering company, signed a general contract with the oilfield company, and signed a subcontract with the construction unit. In this way, the service income was connected with the project quality, block production and project contribution, based on which the total amount and reward amount was calculated. This method stimulated the internal power of the engineering company, and ensured the macro coordination of the project. The third step was to improve the market opening mechanism. On the one hand, it adopted market-oriented operation to give full play to the flexible advantages of some packages in the project department, increasing the independent procurement and reducing the cost of engineering materials. On the other hand, it introduced the external market mechanism, listed and classified scientific research projects, making public bidding for social scientific research institutions and universities, appointing qualified personnel. It also opened market platforms of drill bits, screws, and speedup tools, widely accepting social high-tech products to compete with each other. As a result, it stimulated the upgrading of technology and product. We have carried out collaborative research in the field of "finding sweet spots in difficult-to-produce reserves". In the aspect of process synergy, focusing on the integration of design source, technology optimization and stimulation scheme, reservoir geological research and design ran through the whole process of well location deployment, drilling, completion and production. According to the dynamic iterative optimization of engineering and process feedback, the whole process of "geology-engineering integration" was achieved, and the goal of fine reservoir transformation and large production capacity was also achieved. The purpose of producing reserves is to "manage, move and activate". In the past three years, the cumulative oil reserves produced reached 4860×104 t, the built production capacity was over 50×104 t, the drilling cycle was shortened by more than 60%, the single well production was increased by about 40%, and the balanced oil price was reduced from $75/bbl to less than $50/bbl. The practice of beneficial development of difficult-to-produce oil reserves in Shengli Oilfield effectively proves that the synergetic management model for petroleum engineering has a good application prospect in the old oil areas with high exploration degree, and opens a new direction for the sustainable development of old oilfields in eastern China[24].

5. Conclusions

The development of difficult-to-produce oil and gas reserves is restricted by engineering technology and cost, highly sensitive to oil price and greatly affected by the relationship between supply and demand. It is a progressive and dynamic puzzle, the main problems and solutions needing to be paid attention to under different conditions are also different. Based on the successful practice of the development of some difficult-to-produce oil and gas reserves in China, the new "four in one" synergetic management model for petroleum engineering proposed in this paper effectively overcomes the problems of decentralization of management responsibility main bodies, multiple management objectives, high risk of engineering technology innovation, and many uncertain factors of project construction, which stimulates the vitality and power of active collaboration of project participants, and effectively realizes the coordinated innovation in engineering technology, the cost reduction and efficiency increase of the whole chain and the reduction of the balanced oil price of the project, disperses the investment risk of the project, liberates a large number of difficult to use reserves, and finally realizes the effective development and utilization of the difficult-to-produce oil and gas resources. To some extent, it has become an important supplement to ensure the national energy security.

This paper focuses on how to develop the difficult-to-produce reserves economically and effectively under the market economy environment. It cannot be said to have made a deep thinking on the strategic attribute of oil and gas resources and the development without considering economic benefits under extreme conditions. From the perspective of ensuring national energy security, based on the continuous low international oil price shocks in recent years and the great pressure on enterprises operations, it is suggested that relevant ministries and commissions of the state may formulate and issue temporary financial subsidies and preferential tax policies for the development of difficult-to-produce oil and gas reserves, so as to further stimulate the enthusiasm of enterprises to accelerate the development of difficult-to-produce reserves.

Reference

Safety engineering introduction for development of gas field with high H2S content: Safety engineering practice in Puguang Gas Field

Overview of Sichuan-to-East gas transmission project engineering construction

A study on petrochemical engineering knowledge

The general trend of win-win cooperation is unstoppable

Development trends of oil industry and China’s countermeasures

Geology-engineering integration: A necessary way to realize profitable exploration and development of complex reservoirs

Innovative management and practice of oil production engineering continual integration

Philosophic view on exploration engineering of Daqing Oil Field at a new stage

Application of system decision making and integrated innovation theory to promote the development of tertiary oil recovery technology in Daqing Oilfield

Challenges and development tendency of engineering technology in oil and gas development in Sinopec

360° integrated “four improvements” engineering management model of Sinopec

Basic concepts of synergetics

DOI:10.1126/science.1.1.3 URL PMID:17835947 [Cited within: 2]

On engineering management methodology

Theory parsing and system construction for engineering management

On engineering management

New technology integration will bring management reform

Research on engineering methodology in Qinghai-Tibet Railway

Exploring in construction of integrative management system of environment-health-safety- transportation of the Qinghai-Tibet Railway

Proposal on further improving and promoting “collaborative innovation” (2011 plan)

Construction and practice of integrated management model for petrochemical engineering

Integrated investigation and industrial application of sour nature gas treatment technology

Innovating exploration and development mode to improve oil and gas exploration and development in China

Exploration on geology-engineering integration of hard-to-recover reserves in Shengli Oilfield