Introduction

Polymer flooding is an effective method for improving the waterflooding effect. Industrial polymer flooding has been used in the Daqing oilfield, NE China, since 1996. Polymer flooding in the Daqing oilfield had an oil production of over 1000×104 t in 2003, and enhanced oil recovery (EOR) rate of around 13%-14%, showing good technical and economic effect[1,2,3]. Field tests and application of polymer flooding or combination flooding were carried out in oilfields such as Shengli, Henan, Xinjiang, Dagang, Liaohe, and Bohai in China successsively, and also had significant effects in increasing oil production[4,5,6]. As the industrial application scale and the types of oil reservoirs increased, unfavorable factors limiting the increase of recovery of polymer flooding have also gradually emerged and stood out. The oil increase per ton of polymer reduced from approximately 100-300 t during the well group test and pilot test to 45-50 t at present, showing worse technical and economic effects gradually. Analysis shows that besides poorer reservoir conditions (heterogeneity, average permeability, solvent salinity, etc.) and insufficient production management, practices such as using viscosity as the basis for evaluating the oil displacement agent performance and taking mobility ratio improvement as the displacement mechanism and theoretical basis of polymer flooding also are some causes of the worsening effects. Guided by this theory, researchers and manufacturers mainly developed salt resistant polymer products with "sheet-net" structure increasing viscosity by changing the structure of polymer molecular aggregates, such as hydrophobically associating polymers and comb-shaped polymers. Although with higher viscosity, this kind of salt-resistant polymer has poor reservoir adaptability[7,8,9]. Meanwhile, they increase the reversal speed of the injection profile of the injection well, leading to poorer oil production increase and water production decrease effect.

In order to improve the technical and economic effects of polymer flooding, taking the reservoir rocks and fluids of the Daqing, Dagang, Changqing, and Bohai oilfields as simulation objects, the mechanisms and technical approaches of polymer flooding in heterogeneous reservoirs were investigated in this work. The relationship between viscosity of the polymer displacement agent and displacement performance was analyzed by comparing the displacement performances of solutions of ordinary polymer, glycerol, salt-resistant polymer with "sheet-net" structure and heterogeneous weak gel equal in viscosity or concentration, exploring the methods to improve swept volume of polymer displacement agent.

1. EOR mechanisms and technical approaches of waterflooding

1.1. EOR mechanisms of waterflooding

Heterogeneity is an inherent characteristic of oil reservoirs, which is especially severe in continental sedimentary reservoirs[10,11]. Studies have shown that the high permeability reservoirs have lower seepage resistance. At the same injection pressure, high-permeability layers and high-permeability zones (hereinafter referred to as the high-permeability layers) have greater liquid absorption than medium-low permeability layers and medium-low permeability zones (hereinafter referred to as the low-medium permeability layers). In addition, this phenomenon will gradually aggravate with the extension of the waterflooding time, until eventually, the injected water will circulate inefficiently or even ineffectively in the high-permeability layers.

The waterflooding recovery depends on the swept volume and oil displacement efficiency. Only when the swept volume reaches a certain extent, can the improvement of the oil displacement efficiency significantly increase the oil recovery[12,13,14]. Only increasing the water absorption of the medium- and low-permeability layers or medium- and small-scale pores in the reservoir can expand the swept volume and increase the oil recovery considerably.

1.2. Technical approaches of EOR for waterflooding

reservoirs

Assuming that the seepage flow in a reservoir is a single phase flow, the injection volume of the injector in the center of the circular oil layer can be expressed as follows:

Equation (1) shows that the liquid injection volume can be increased by increasing the injection pressure of the water injector and the liquid injectivity index. And the most effective way to increase the liquid injectivity index is to decrease the seepage resistance.

The two technical approaches to increase the injection pressure are increasing the injection rate and decreasing the reservoir permeability. However, in actual operation of oilfields, increasing the injection rate is limited by the injection equipment capability etc., it is difficult to increase the injection rate substantially. In addition, as high-permeability layers have lower seepage resistance, most of the injected liquid by increasing injection rate would enter the high-permeability layers. This would make the erosive and destructive effects of the injected water on the high-permeability layers aggravate, the liquid injectivity of the high-permeability layers increase further, and the heterogeneity of the reservoir worsen. Reducing the permeability of the high-permeability layer is the main way used to increase the injection pressure in oilfields. Polymer has a retention effect in porous media and can achieve the goal of increasing seepage resistance of high-permeability layers.

The seepage resistance of middle- and low-permeability layers needs to be reduced. During waterflooding development of heterogeneous reservoirs, medium- and low-permeability layers have higher seepage resistance and smaller liquid absorption. By reducing the seepage resistance, the liquid absorption of the medium- and low-permeability layers can increase, to reach the goal of adjusting liquid injection profile. Fracturing and acidizing etc. can reduce the seepage resistance of medium- and low-permeability layers. Of them, fracturing, with strong penetration capacity, simple operation and low cost, has been widely used in recent years[15].

2. Oil displacement mechanisms of polymers

The key to enhancing recovery by chemical flooding is expanding the swept volume. This can be achieved by increasing the absorption pressure difference of the medium- and low-permeability layers or the small and medium pores. Polymers can selectively block high-permeability layers, and after injection, they can reduce the seepage capacity of the high-permeability area, thus increasing the injection pressure and the liquid absorption of medium- and low-permeability areas.

The oil displacement mechanism of polymer flooding is mainly expanding the swept volume[12, 16-17]. Based on the existing polymer flooding theory, polymers enhance oil recovery by reducing the mobility ratio between the displacing phase and the displaced phase. According to the definition of mobility ratio, there are two ways to reduce mobility ratio: (1) increasing the viscosity of the displacement agent and (2) decreasing the relative permeability of displacement agent. Increasing the viscosity is currently most commonly used in laboratories and oilfields.

The viscosity is an index used to evaluate the internal friction force of a fluid and is usually measured with a Brookfield viscometer. However, the Brookfield viscometer measures the torque value produced by the liquid in a sleeve to a rotor. The measured viscosity reflects the internal friction force of the fluid at the macroscopic spatial scale. At the macro-scale, the viscosity of a polymer is related to the relative molecular weight, concentration, molecular aggregate shape of the polymer, and solvent salinity etc. In micro-scale porous media, the viscosity of the polymer is obviously different from that on the macro- scale. Previous researches show that under the same shear rate, the polymer viscosity decreases with the feature pore size, especially at the micro-scale and low shear rate[18,19]. The ability of polymer to increase viscosity would reduce significantly in micro-porous media. In this case, the viscosity does not play a leading role, while the additional seepage resistance caused by the retention of polymer becomes the main oil displacement mechanism of polymer flooding.

When a polymer (such as partially hydrolyzed polyacrylamide) is injected into the porous media of a reservoir, it preferentially enters the high-permeability layers. Because of chemical adsorption and mechanical trapping, it retains in the high-permeability layers and produces additional seepage resistance. When the injection rate remains constant, the injection pressure of the whole well will increase, thus reaching the goal of increasing the adsorption pressure difference and liquid absorption volume of medium- and low-permeability layers. This process is called injection profile adjustment. Similarly, after diverting into the low- and medium-permeability layers, the polymer also stays in them, resulting in additional seepage resistance, and the increase in seepage resistance is much greater than that in high-permeability layers under the same liquid absorption. As the polymer adsorbed by the reservoir continuously increases, the injection pressure will continue to increase[20]. In order to avoid reduction of the swept volume caused by sudden breakthrough of the oil displacing agent when the reservoir fractures, the injection pressure in an oilfield is generally below the reservoir fracturing pressure. With the continuous injection of polymer, the adsorption pressure differences of different layers at the injection end gradually decrease, especially between the medium- and low-permeability layers. Finally, low- and medium-permeability layers gradually decrease in adsorption volume or even stop absorbing liquid.

The main mechanisms of polymer flooding can be summarized as follows. When polymer is injected into a reservoir, it stays in high-permeability layers, thus improving the injection pressure, and in turn the injection pressure difference and liquid absorption of the medium- and low-permeability layers increase, to reach the goal of expanding swept volume. At present, in the theoretical exploration and field testing of polymer flooding, increasing viscosity of the oil displacement agent is pursued excessively sometimes to enhance oil recovery. Physical experimental results have confirmed that there is no positive correlation between the polymer flooding effect and polymer viscosity.

3. Oil displacement effects of different flooding agents and injection modes

3.1. Flooding effects of polymer and glycerol solutions with equal viscosity

Displacement solutions: polymer and glycerol flooding solutions were prepared by the tap water from the Daqing Oilfield. The concentrations of the agents were adjusted to make the two solutions have a viscosity of approximately 50 mPa•s.

Laboratory cores: two artificial cores of 30 cm×4.5 cm× 4.5 cm each composed of high-, medium-, and low-permeability layers were prepared. Each layer had a thickness of 1.5 cm. The gas permeabilities of the high-, medium-, and low-permeability layers of the two cores were approximately 2400×10-3, 800×10-3, and 300×10-3 μm2, respectively.

Experimental oil: mixture of white oil and degassed and dehydrated crude oil from the Daqing Oilfield with a viscosity of 9.8 mPa•s at 45 °C.

The experimental process included the following steps: (1) The core was vacuumed and saturated with formation water from the Daqing Oilfield and then the pore volume was calculated. (2) The oil was injected into the core to displace the water until the water cut was approximately zero, and then, the volume of oil saturating the core was calculated. (3) Water was injected to displace oil till the water cut of 98%, and then a 0.3 pore volume (PV) glycerol solution was injected, followed by waterflooding to the water cut of 98%. Next, a 0.3 PV polymer solution was injected, water was injected to displace till the water cut of 98%. (4) The inlet and outlet pressures, and the oil and water production during the whole displacement process were recorded. (5) Steps (1) and (2) were repeated with the other core. (6) The polymer and glycerol injection sequence were reversed, and steps (3) and (4) were repeated.

The experimental results show: (1) The waterflooding recovery was 36.5%, on this basis, glycerol flooding increased the recovery by 13.9%, polymer flooding by another 13.9%, reaching the final recovery of 64.3%. (2) When the sequence was reversed, the waterflooding recovery was 36.2%, the polymer flooding increased the recovery by 26.9%, and the glycerol flooding increased by 4.9%, reaching the final recovery of 68.0%. Apparently, polymer flooding after waterflooding had a better development effect, with a final recovery of 3.7% higher than that of glycerol flooding after waterflooding. This is mainly because the polymer is linear macromolecule material, with larger molecular aggregate size, which makes it easier to retain in porous media, resulting in higher additional seepage resistance and higher injection pressure rise than glycerol flooding. Consequently, the medium- and low-permeability layers had more significant increase in adsorption pressure difference and liquid adsorption, and had larger increase in the swept volume. At the same time, although the glycerol and polymer had similar viscosity, the displacement processes were the same, the flooding effects were different with different displacing sequences.

3.2. Flooding effects of different types of polymer solutions

Displacement solutions: different flooding solutions were prepared using injection water from Block Gangxi3 in the Dagang Oilfield (with a total salinity of 6726 mg/L, and total concentration of Ca2+ and Mg2+ of 53 mg/L), including a common ultrahigh molecular weight polymer solution (HTPW, with a molecule weight of 2500×104), hydrophobically associating polymer solution (APP4, the introduction of a small amount of hydrophobic groups into common polymer molecules results in the aggregation of molecular chains under the hydrophobic effect, and the macromolecular chains form a "sheet-net" structure by their intramolecular or intermolecular association[21]), and comb-shape polymer solution (CAB20, the main chain of the polymer has a short side chain containing strong polar groups and hydrocarbon groups, and the side chain has volume and electrical repulsion, making the main chain unlike to shrink, the polymer has higher viscosity and its molecular aggregates are large in hydrodynamic size[22]). The three types of polymers used are all the polyacrylamide series.

The experimental cores: (1) Four similar artificial heterogeneous cores of 30 cm×4.5 cm×4.5 cm were prepared. Each core was composed of three layers with high, medium, and low permeability. Each layer had a thickness of 1.5 cm. The gas permeabilities of the high-, medium- and low-permeability layers of the four cores were approximately 4400×10-3, 800×10-3, and 200×10-3 μm2, respectively. (2) Three similar artificial homogeneous cores of 30 cm×4.5 cm×4.5 cm were prepared. Each had a gas permeability of approximately 1800×10-3 μm2, along with a pressure tap in the middle.

The experimental oil was a mixture of white oil and degassed and dehydrated crude oil from Block Gangxi 3 of the Dagang Oilfield with a viscosity of 40.0 mPa•s at 53°C.

Four experimental schemes for the heterogeneous cores were designed and listed in Table 1. Schemes 1-1 to 1-3 were used to investigate the flooding effects of the different types of polymers at the same concentration, while Schemes 1-4 and 1-1 were used to investigate the flooding effects of solutions at different concentrations but the same viscosity.

Table 1 Experimental schemes and development index data for flooding with different types of polymer solutions.

| Scheme No. | Polymer type | Polymer concentration/(mg•L-1) | Viscosity/ (mPa•s) | Oil saturation/% | Oil recovery/% | ||

|---|---|---|---|---|---|---|---|

| Water flooding | Final recovery | Recovery increase of polymer flooding | |||||

| 1-1 | APP4 | 1750 | 351.3 | 73.0 | 26.9 | 41.2 | 14.3 |

| 1-2 | CAB20 | 1750 | 289.5 | 72.8 | 26.7 | 42.6 | 15.9 |

| 1-3 | HTPW | 1750 | 78.0 | 72.7 | 26.8 | 45.6 | 18.8 |

| 1-4 | 3400 | 352.1 | 73.1 | 26.8 | 49.5 | 22.7 | |

Three experimental schemes were designed for the homogeneous cores to investigate the transport capacities of the different types of polymers at the same concentration (Table 2).

Table 2 Experimental schemes and flooding pressure data for different types of polymer solutions.

| Scheme No. | Polymer type | Polymer concentration/(mg•L-1) | Viscosity/ (mPa•s) | Pressure difference of polymer flooding/MPa | Pressure difference of waterflooding/MPa | ||

|---|---|---|---|---|---|---|---|

| First half of core | Second half of Core | First half of core | Second half of core | ||||

| 2-1 | APP4 | 1750 | 351.3 | 0.194 | 0.007 | 0.043 | 0.002 |

| 2-2 | CAB20 | 1750 | 289.5 | 0.147 | 0.012 | 0.026 | 0.004 |

| 2-3 | HTPW | 1750 | 78.0 | 0.074 | 0.018 | 0.017 | 0.007 |

The experimental process for the heterogeneous cores is as follows: (1) The core was vacuumed and saturated with formation water from Block Gangxi3 in the Dagang Oilfield, and then the pore volume was calculated. (2) Oil was injected into the core to displace the water until the water cut was approximately zero, and then the oil volume in the core was calculated. (3) Water was injected into the core to displace oil to the water cut of 98%, 0.3 PV APP4 solution was injected (Scheme 1-1), and then water was again injected to displace oil to the water cut of 98%. (4) The inlet and outlet pressure, the oil and water production throughout the displacement process were recorded. (5) Steps (1) and (2) were repeated with another core. (6) The polymer solution was changed to CAB20 solution (Scheme 1-2) or different concentration HTPW solutions (Scheme 1-3 and Scheme 1-4), and steps (3) and (4) were repeated.

The experimental process for the homogeneous cores is as follows: (1) The core was vacuumed and then saturated with formation water from Block Gangxi3 in the Dagang Oilfield. (2) 1 PV APP4 solution (Scheme 2-1) was injected, followed by 1 PV water. (3) The pressures at the inlet and middle of the core were recorded during the whole displacement process. (4) Step (1) was repeated with another core. (5) The polymer solution was changed to the CAB20 solution (Scheme 2-2) or HTPW solution (Scheme 2-3), and steps (2) and (3) were repeated.

It can be seen from the data in Table 1 that at the same concentration, although the APP4 and CAB20 solutions had much higher viscosities than the HTPW solution, the HTPW solution had much higher oil recovery increase than APP4 and CAB20 solutions[21,22,23,24]. In addition, at similar viscosity (Scheme 1-1 and Scheme 1-4, different in concentration), the HTPW flooding had much higher oil recovery increase than APP4 flooding.

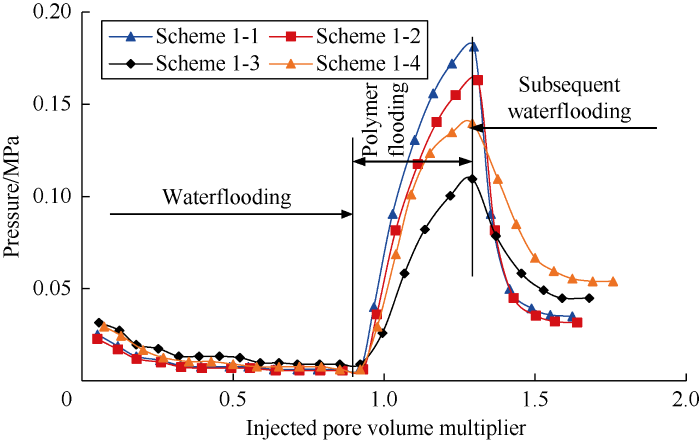

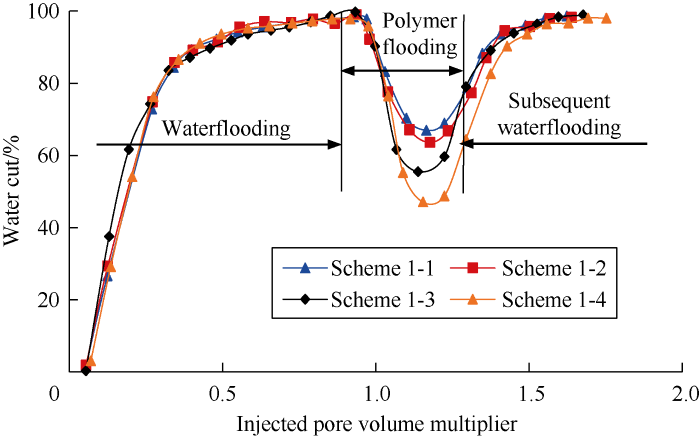

It can be seen from the injection pressure curves shown in Fig. 1 that although the injection pressures of the APP4 and CAB20 solutions were higher, the pressure losses were mainly at the injection inlet, as shown by the transport capacities of the homogeneous cores in Table 2, which indicates poor transport capacities of APP4 and CAB20. It can be seen from the water cut curves in Fig. 2 that the maximum water cut drops after the APP4 solution and CAB20 solution flooding were lower than that after the HTPW solution flooding, which shows that the APP4 and CAB20 solutions have lower retention capacities and result in lower seepage resistances, so only a small amount of fluid would divert into the medium- and low-permeability layers, thereby resulting into poor flooding effects.

Fig. 1.

Fig. 1.

Injection pressure curves of three types of polymer solutions.

Fig. 2.

Fig. 2.

Water cut curves of three types of polymer solutions.

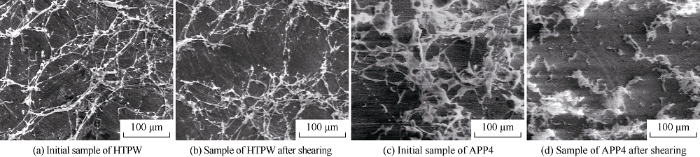

Viscosity is an evaluation index for the internal friction force of a fluid. The internal friction force of a polymer solution is closely related to its relative molecular weight, concentration, solvent salinity, and molecular structure, and the viscosity of a polymer solution can be increased by increasing the polymer concentration and changing the molecular structure. Fig. 1 shows the injection pressures of waterflooding after the APP4 or CAB20 solutions flooding were lower. This is mainly because as the molecular aggregate morphology of the polymer changes from a linear structure to "sheet-net" structure (Fig. 3), the polymer molecular hydrodynamic aggregates increase in size significantly, and thus have poorer compatibility with rock pore size, making the polymer solution difficult to be injected into the formation. Meanwhile, the molecular aggregates are likely to be sheared by pores and damaged to some extent, lowering retention capacity along the core, so the polymer solutions could become weaker in plugging ability to high-permeability layers.

Fig. 3.

Fig. 3.

Structural morphology of polymer molecular aggregates.

3.3. Influence of injection mode on oil displacement effect

The flooding solutions: polymer solution (with a molecule weight of 100×104 and concentration of 50 mg/L) and heterogeneous weak gel solution (with a molecule weight of 100×104, concentration of 50 mg/L, Cr3+ crosslinking agent, mass ratio of the polymer and crosslinking agent of 270:1, polymer as the continuous phase, and gel particles as the dispersed phase) were prepared using injection water for Block Chang 4+5 in the Changqing Oilfield (with a water salinity of 68 030 mg/L, and total concentration of Ca2+ and Mg2+ of 5197 mg/L).

Experimental cores: three similar artificial heterogeneous experimental cores were prepared. Each was 30 cm×4.5 cm×4.5 cm in size and composed of three layers with high, medium, and low permeabilities. Each layer was 1.5 cm thick. The gas permeabilities of the high-, medium-, and low-permeability layers of the three cores were approximately 25×10-3, 5×10-3, and 1×10-3 μm2, respectively.

The experimental oil was a mixture of white oil and degassed and dehydrated crude oil from Block Chang 4+5 in the Changqing Oilfield with a viscosity of 9.0 mPa•s at 60 °C.

Three experimental schemes were designed (Table 3), to investigate the effects of the polymer flooding, heterogeneous weak gel flooding, and alternative injection of heterogeneous weak gel and water.

Table 3 Experimental schemes and development index data of different injection modes.

| Scheme No. | Injection mode | Viscosity/ (mPa•s) | Oil saturation/% | Oil recovery/% | ||

|---|---|---|---|---|---|---|

| Waterflooding | Final recovery | Increase | ||||

| 3-1 | Whole slug of polymer solution | 5.9 | 64.07 | 32.79 | 39.07 | 6.28 |

| 3-2 | Whole slug of gel solution | 5.5 | 64.48 | 32.72 | 41.06 | 8.34 |

| 3-3 | Alternative slugs of gel solution and water | 5.5 | 65.53 | 32.93 | 44.58 | 11.65 |

The experimental process is as follows: (1) The core was vacuumed and saturated with formation water, and then the pore volume was calculated. (2) Oil was injected into the core to displace water until the water cut was approximately zero, and then the volume of oil saturated the core was calculated. (3) Water was injected into the core to displace oil to the water cut of 98%, and then a 0.18 PV polymer solution was injected, then water was injected to the water cut of 98% again. (4) The inlet and outlet pressures and oil and water production throughout the displacement process were recorded. (5) Steps (1) and (2) were repeated with another core. (6) The polymer solution was changed to a heterogeneous weak gel solution, and steps (3) and (4) were repeated. (7) Step (5) was repeated, the polymer solution in step (3) was changed to five slugs of 0.05, 0.04, 0.03, 0.03, and 0.03 PV heterogeneous weak gel solutions each combining with 0.02 PV water.

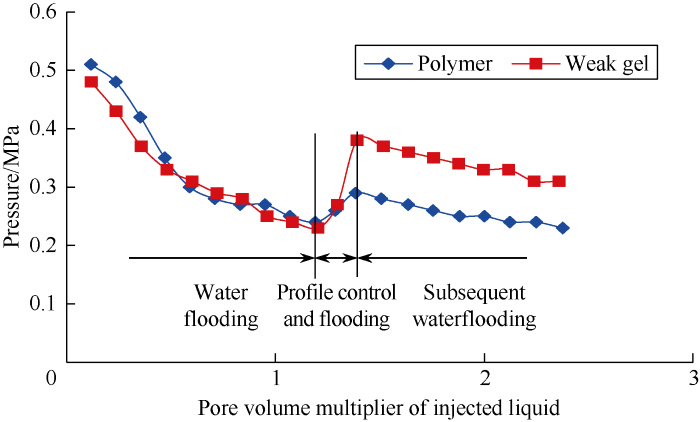

The experimental results in Table 3 show the whole slug flooding of heterogeneous weak gel after waterflooding had an oil recovery increase of 8.34%, while the polymer flooding after waterflooding had an oil recovery increase of 6.28%. It can be seen from Fig. 4 although the the heterogeneous weak gel and the polymer solution were almost the same in viscosity, as the heterogeneous gel had stronger retention in the core, its injection pressure was apparently higher, and the pressure differences and injected liquid volumes of the medium- and low-permeability layers were larger than those in the polymer flooding with good fluid diverting effect, and thus the oil recovery increase was higher.

Fig. 4.

Fig. 4.

Injection pressures of polymer and weak gel flooding.

It can be seen the experimental results that the alternate injection of weak gel and water had an oil recovery 3.31% higher than the whole slug weak gel flooding (Table 3). Both the whole slug weak gel flooding and alternate injection of weak gel and water had better effects than the whole slug polymer flooding. The weak gel consisted of gel molecular aggregates (dispersed phase, formed by crosslinking reaction between the carboxyl groups of some branched chains on some polymer chains), and a polymer solution (continuous phase). The weak gel solution was almost the same with the polymer solution of the same concentration in viscosity, gel molecular aggregate size and reservoir adaptability[25,26,27], but they differ in oil displacement effects considerably.

The mechanism analysis shows the following results. First, there are some crosslinking agents that haven’t participate in the crosslinking reaction, but enter the diffused double layer of weak gel molecules in a free state: (1) This neutralizes negative charge on some molecular chains of the weak gel, reducing the negative electronegativity of the chains on one hand, this also shields the electrostatic repulsion between the anions of the carboxyl groups on the weak gel chain on the other hand[28,29]. (2) When weak gel contacts with water, the water dilution effect desorbs the crosslinking agents from the surface of weak gel chains, so the negative electricity of the molecular chains increases, and the amount of crosslinking agents in the diffusion layer decreases, leading to weakening of the electrostatic repulsion shielding effect of the crosslinking agents on the carboxyl anion of the weak gel molecular chain, increase in the Zeta potential, thickness of the diffused double layer, and the extension degree of the weak gel molecule chains. Second, unlike the polymer molecular chains, the weak gel molecule aggregates have local three-dimensional structure inside, which is difficult to be destroyed by water dilution effect, and the water molecules are attracted by the hydrophilic groups on the molecular chains of the weak gel, and thereby entered the molecular chains continuously, causing hydration expansion. The water dilution effect leads to the stretching and hydration expansion of the molecular chains, which enhances the retention of the weak gel and improves its capacity to expand swept volume[28,29]. The alternate injection mode can achieve a better development effect.

It can be seen that there is no positive correlation between the viscosity of the polymer solution and oil displacement effect, and the main mechanism of enhancing oil recovery is expanding swept volume of waterflooding. Vital factors affecting the swept volume of waterflooding include the compatibility of the molecular aggregate size of the polymer flooding agent with the pore throat size of the reservoir rock and the retention and transport capacity of the polymer molecules in the reservoir. The oil displacement effect of the polymer agent flooding can be further improved by alternate injection of high-retention agents (such as polymer type agents) and low-retention or no-retention agents (such as a surfactant agent or water).

4. Practice of improving polymer flooding effect

4.1. Mechanisms and countermeasures of injection profile reversal

During the waterflooding process, more water injected enters high-permeability layers with lower seepage resistance. With the increase of waterflooding producing degree, water scouring would cause increasing damage to the reservoir rock. In the early stage of flooding with polymer or other profile control agent, the high-permeability layer has a lower seepage resistance, and the flooding agent enters into the high-permeability layer first and remains there. Consequently, the pore flow cross section gets smaller, and the seepage resistance increases. If the injection rate remains constant, the injection pressure of the whole well will increase, the flooding agent will flow into the medium- and low-permeability layers, resulting in expansion of swept volume. Similarly, when the oil displacement agent enters the medium- and low-permeability layers (zones), these layers will also increase in seepage resistance due to the retention of the oil displacement agent, and have much higher increase of seepage resistance than high-permeability layers at the same amount of liquid absorption. With the continuous injection of the oil displacement agent, the area where the oil displacement agent is retained increases, and the injection pressure of the whole well will continue to rise until close to the fracture pressure of the reservoir rock. Throughout the entire process, the medium- and low-permeability layers have first increase and then decrease in liquid absorption, injection profile reversal, and oil displacement effect getting poorer. When designing the type, concentration, slug size, and combination mode of oil displacement agents (profile control and displacement agent) for a heterogeneous reservoir, both the demand characteristics of the high-permeability layer and low-permeability layer must be considered. The former needs to be "plugged", and the latter "flooded" primarily, so the retention of the polymer oil displacement agent in the low- and medium-permeability layers should be minimized to slow the inversion speed of the liquid injection profile. The alternate injection of "high-retention" and "low-retention or no-retention" flooding agents can effectively improve the oil displacement effect.

4.2. Field test of alternate injection of heterogeneous weak gel and water

4.2.1. Profile control and flooding with heterogeneous weak gel

The LD10-1 oilfield is located in the middle of the Liaoxi low uplift in the Liaodong Bay area. The reservoir is subdivided into six oil-bearing groups, among which the second oil-bearing group is the major one, with a wide distribution range and good stability. The oil layers in groupⅡ have an average thickness of more than 30 m, and maximum thickness of 67 m, a porosity range of 29%-35%, and permeability range of (1000-5500)×10-3 μm2. The viscosity of the formation crude oil is 13.9-19.4 mPa•s. The oilfield was put into production in January of 2005, and started water injection in September of 2005. In March of 2006, the heterogeneous weak gel flooding test was carried out in group II of Well A23. The high molecular weight polymer produced by the PetroChina Daqing Refining and Chemical Company was used as oil displacement agent with a concentration of 1200-1500 mg/L, and the polymer and crosslinking agent ratio from 180:1 to 270:1. In 2012, the test was extended to 8 wells, and the designed profile control and flooding scheme was completed by the end of 2016, after that the wells were converted to subsequent waterflooding.

The blocks developed by heterogeneous weak gel flooding in this oilfield had achieved good results. By the end of 2016, 0.354 PV weak gel was injected, and the oil production increment was 115.85×104 m3, with output/input ratio of 3.179. Compared with the waterflooding blocks, the weak gel flooding blocks increased by 7% in producing degree, and had water cut rate 10% lower at the same producing degree.

4.2.2. Profile control and test of alternate heterogeneous weak gel and waterflooding

The NB35-2 oilfield is located in the Central Bohai Sea. There are 3 horizontal injection wells (B17, B06, B20m) and 24 oil wells in its southern part. Because of the poor effect of waterflooding development, rounds of heterogeneous weak gel flooding were carried out in well groups B17, B06, and B20m starting from 2008. The polymer solutions used had polymer concentrations of 2800-4000 mg/L and ratios of polymer to crosslinking agent from 120:1 to 180:1. The polymer flooding was conducted in 11 wells (Table 4, the last round was alternate weak gel and waterflooding in each well group).

Table 4 Basic information of profile control and flooding test wells.

| Well group | Injection round | Beginning time/ (Year-month) | Ending time/ (Year-month) | Weak gel injection volume/m3 | Injected pore volume | Cumulative oil increment//m3 |

|---|---|---|---|---|---|---|

| B17 | 1 | 2008-06 | 2009-11 | 59 956 | 0.013 0 | 15 829 |

| 2 | 2011-05 | 2013-05 | 58 964 | 0.012 8 | 20 506 | |

| 3 | 2013-07 | 2014-10 | 51 783 | 0.011 3 | 10 531 | |

| 4 | 2014-12 | 2016-04 | 53 749 | 0.011 7 | 6 582 | |

| 5 | 2016-10 | 2017-11 | 32 896 | 0.007 2 | 12 617 | |

| B06 | 1 | 2013-07 | 2014-12 | 41 911 | 0.032 2 | 2 964 |

| 2 | 2015-01 | 2016-02 | 32 388 | 0.024 9 | 3 889 | |

| 3 | 2016-10 | 2017-11 | 14 277 | 0.011 0 | 9 667 | |

| B20m | 1 | 2013-07 | 2014-10 | 50 950 | 0.063 7 | 4 317 |

| 2 | 2015-01 | 2016-02 | 44 792 | 0.056 0 | 7 755 | |

| 3 | 2016-10 | 2017-11 | 18 911 | 0.023 6 | 2 411 |

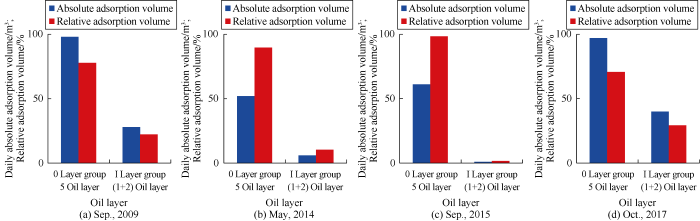

It can be seen from Table 4, the last injection round of alternate weak gel and waterflooding in well groups B17 and B06 had better effect. The fifth round of flooding in well group B17 had obviously better effect than the third and fourth rounds. Similarly, the third round in well group B06 had clearly better effect than the first and second rounds. Although the last round used a weak gel slug much smaller in size than the whole weak gel slug in the other rounds, it had better oil increasing effect than the other rounds with whole weak gel slug injection, which was mainly because the alternate flooding effectively improved the injection profile of the injection well (Fig. 5). In the B17 well, the first four rounds of flooding used whole slugs, and the long time injection of weak gel resulted in obvious flooding profile reversal in each round of flooding. To the fourth round (September 2015), the low-permeability layers (1+2 in oil layer I) hardly absorbed water. The injection liquid mainly entered high-permeability layer 5 in oil layer 0, and the oil production increment also decreased from 10 531 m3 in the third round to 6582 m3. In the fifth round of alternate weak gel and waterflooding, the weak gel slug size decreased from 0.011 7 PV in the fourth round to 0.007 2 PV. The injection profile (October 2017) showed that the liquid injection in layer (1+2) in oil layer I increased significantly. The injection profile significantly improved, and the oil production of well group increased from 6582 m3 to 12 617 m3, by 6035 m3, proving good effects. However, the third round of alternate flooding in well group B20m had poorer effect than the previous two rounds. The analysis shows that the main reason is that well group B20m is located at the edge of the reservoir, with less effective oil wells, and the oil increasing effect was limited in the third round with only a small amount of weak gel injected.

Fig. 5.

Fig. 5.

Comparison of injection profiles of B17 at different stages.

5. Conclusions

The main EOR mechanism of polymer flooding is that the retention polymer in porous media expands the swept volume of injected water. There is no positive correlation between the viscosity of the polymer and the polymer flooding effect. Although the salt-resistant polymers with "sheet-net" structure have strong ability to increase viscosity, they have poor compatibility with the pore throat structure of the reservoir rock, low injectivity and shear resistance, thus poorer selective plugging ability for high-permeability reservoirs.

The heterogeneous weak gel system has stronger adsorption and mechanical trapping in porous media. It is easily retained in the reservoir rock pores to bring about effective seepage resistance in the high-permeability layer. Compared with the polymer solution with equal viscosity or equal concentration, the heterogeneous weak gel solution has greater ability to expand the swept volume.

Injecting polymer flooding agent for a long period would inevitably lead to injection profile reversal, and worsening of the development effect of polymer flooding consequently. Alternate injection of high-retention and low- or non-retention displacement agents can further improve the displacement effect of polymer flooding.

Nomenclature

J—liquid injectivity index, m3/(d•MPa);

Q—absorption volume, m3/d;

pin—injection pressure, MPa;

pe—formation pressure, MPa.

Reference

New progress and prospect of oilfields development technologies in China

Technologies of enhancing oil recovery by chemical flooding in Daqing Oilfield, NE China

Chemical flooding development status and prospect

Research on sewage based polymer flooding for high temperature and high salinity oil reservoir in south Dagang Oilfield

Experimental study on polymer flooding in the east of Block Jin 16 in Liaohe Oilfield

Application of pilot test for well pattern adjusting heterogeneous combination flooding after polymer flooding: A case of Zhongyiqu Ng3 block, Gudao Oilfield

Synthesis and property evaluation of a salt and alkali-resistant star-polymer

DOI:10.1016/S1876-3804(10)60049-3

URL

[Cited within: 1]

Abstract

A salt-and alkali-resistant star-polymer was made using graft β-CD functional monomer and acrylamide monomer employing copolymerization and post-hydrolysis methods. The optimum parameters: azobisisobutyronitrile with a concentration of 50 mg/L, a mass fraction of acrylamide 25%, a graft β-CD functional monomer mass fraction of 1.5%, initiating temperature 5°C, hydrolysis temperature 90°C and hydrolysis time of 3 hours. The atomic force microscope and infrared spectroscopy morphology characterization results show that: the star-polymer S07313 contains the star-nucleu of the graft β-CD functional monomer. The molecular weight of the star-polymer S07313 is 24.5 million, while other basic physical and chemical properties can meet the technical requirements of the application of such a polymer in oil fields. With the addition of NaOH as a mass fraction of 1.0% in the Daqing simulated brine, the apparent viscosities of the star-polymer S07313, HPAM3000 and MO4000 are 42.40 mPa·s, 29.20 mPa·s and 18.00 mPa·s. The star-polymer S07313 and surface active agents Alkylbenzene Sulfonate have an excellent compatibility.

摘 要

采用接枝β-CD抗盐碱功能单体与丙烯酰胺共聚后水解的方法制备超高相对分子质量抗盐碱星形聚合物。其最佳工艺参数为:偶氮二异丁腈质量浓度为50 mg/L、丙烯酰胺质量分数为25%、接枝β-CD抗盐碱功能单体质量分数为1.5%、引发温度为5 ℃、水解温度为90 ℃、水解时间为3.0 h。原子力显微镜形貌观察和红外光谱表征结果表明:抗盐碱星形聚合物S07313含有星核接枝β-CD功能单体。抗盐碱星形聚合物S07313的相对分子质量为2 450×104,其他基本理化性能都能达到油田应用指标的技术要求。当大庆模拟盐水中加入NaOH质量分数为1.0%的碱水时,抗盐碱星形聚合物S07313、HPAM3000和MO4000的表观黏度分别为42.40 mPa·s、29.20 mPa·s和18.00 mPa·s。抗盐碱星形聚合物与表面活性剂重烷基苯磺酸盐的配伍性优良。图10表3参20

Salt resisitance of surfactants and anionic polyacrylamide combined system

Reservoir adaptability and mechanism of salt-resistant polymer

Modeling and application of the lithofacies controlled primary pore reservoir of proximal sandstone

Three major rich areas of “large scale” unswept remaining oil in water flooded bedded sandstone reservoirs

Influence factors of oil displacement efficiency and sweep efficiency in chemical flooding

Quantitative description of the effects of sweep efficiency and displacement efficiency during chemical flooding on a heterogeneous reservoir

Effects of pore structure on surfactant/polymer flooding-based enhanced oil recovery in conglomerate reservoirs

Analysis of dynamic imbibition effect of surfactant in micro cracks in reservoir with high temperature and low permeability

Current development and application of chemical combination flooding technique

Experimental research on sweep efficiency and oil-displacement efficiency of polymer flooding

Micro-scale shear viscosity testing approach and viscosity model of polymer melts

Theoretical and experimental approach of the viscosity of polymer melt under micro-scale effect

Oil displacing mechanism of soft micro particle dispersion in porous media

The determination of weight-average molecular weight of hydrophobically associated water-soluble polymers

DOI:10.3724/SP.J.1105.2014.13250

URL

[Cited within: 2]

Intrinsic viscosity and strength of hydrophobic association of hydrophobically associated water-soluble polymers (HAWSP) were investigated in different solvents containing formamide and salt, through the capillary tube method and fluorescence probe technique. Weight-average molecular weight of HAWSP was measured by static light scattering method under suitable solvent conditions that could eliminate the hydrophobic association and polyelectrolyte effect. The experimental results showed that NaCl had the capability of eliminating the polyelectrolyte effect, but NaCl can not destroy hydrophobic association. And NaCl promoted hydrophobic interaction because of increasing the polarity of HAWSP solutions. Macromolecular aggregation would be greater at higher levels of hydrophobe, which explains the observed rise in molecular weight. As a result, the weight-average molecular weight of HAWSP measured in NaCl solvent was not the real molecular weight. However, hydrophobic association can be completely destroyed by formamide. Moleculars of HAWSP dispersed in the formamide solvent, and real molecular weight of HAWSP can be measured. The results showed that weight-average molecular weight of HAWSP can be measured accurately in 50% formamide solvent with 0.2 mol/L NaCl. When hydrophobic association was eliminated completely, the values of weight-average molecular weight were identical with increasing formamide concentration; when the polyelectrolyte effect was removed, altering the salt concentration would not change the results of weight-average molecular weight.

Compatibility between polymer molecular size and pore throat in reservoirs

Property and application of comb_shape polyacrylamide

Study on rheology of polyacrylamide copolymer used in enhanced oil recovery

Effect of profile-control oil-displacement agent on increasing oil recovery and its mechanism

DOI:10.1016/j.fuel.2018.10.089 URL [Cited within: 1]

Matching between the diameter of the aggregates of hydrophobically associating polymers and reservoir pore-throat size during polymer flooding in an offshore oilfield

Analysis of reservoir applicability of hydrophobically associating polymer

DOI:10.2118/174553-PA URL [Cited within: 1]

Differences in molecular configuration and seepage properties among polymer, active polymer and Cr3+ polymer gel

Mechanism and gelling effects of linked polymer solution in the core