Introduction

Conventional natural gas reservoirs usually have good physical properties, and can be economically developed using vertical wells and formation energy. As natural gas development process continues to deepen in China, reservoirs with poor physical properties have become targets. Such reservoirs have pore throats dropping from micrometers to nanometers, and permeability dropping from ~100×10-3 μm2 to ~0.0001×10-3 μm2. And their production capacities keep declining, even natural production is not available. This type of resource is usually called unconventional gas, including tight gas, shale gas, and coalbed methane (CBM).

With abundant reserves, unconventional natural gas resources have become the primary contributor to the growth of China’s natural gas production. For the devel-opment of unconventional gas, previous workers put forward a series of understandings, concepts and theories. In terms of the characteristics of unconventional gas, the concept of "continuous oil and gas accumulation" is proposed[1], and it is believed that unconventional gas is characterized by self-generation and self-storage, accumulates in place driven by overpressure and diffusion[2]. Unconventional gas reservoirs follow the law of "two factor enrichment". High-quality shales developed in deep-water shelf facies are the basis for "generation and storage" of shale gas. Good preservation conditions are key factors of "accumulation and production" of shale gas[3,4]. Unconventional gas enrichment is based on two models -- "structural sweet spots" and "continuous sweet spots"[5]. High shale gas production is controlled by high-quality reservoirs and preservation conditions[6,7]. As for the development technologies and effects, it is proposed that unconventional gas reservoirs should be "artificial" or "man-made". The development of gas reservoirs should take the "sweet spot" as a unit and form an "artificial high permeability" through manual intervention[8]. To achieve the effect of "volume development" of unconventional gas[2], the volumetric fracturing technology can be applied on horizontal well staged fracturing stimulation to maximize the volume of induced fractures[9]. In general, the current understanding mostly focuses on a certain aspect of unconventional gas geological characteristics, development technology and development effect, and it is necessary to systematically summarize the theory and understanding of unconventional gas development.

To develop unconventional gas effectively, our team have explored for more than 20 years, and gradually formed the "extreme utilization" development concept with "continuously breaking through the limits of development technology" as the core. We have clarified the connotation of the "extreme utilization" theory, and developed a series of technologies including micro/nano-scale reservoir evaluation, “sweet spot” prediction, unconventional percolation theory and production capacity evaluation, optimization of grid well pattern, optimal and fast drilling and volume fracturing, and working regulation optimization and “integrated” organizing system. These technologies have ensured the large-scale commercial development of unconventional gas in China. This paper systematically introduces the theory, key technologies and application of "extreme utilization", with the intent to provide a systematic guideline and technical system for promoting the effective and sustainable development of unconventional gas.

1. The connotation of the "extreme utilization" development theory

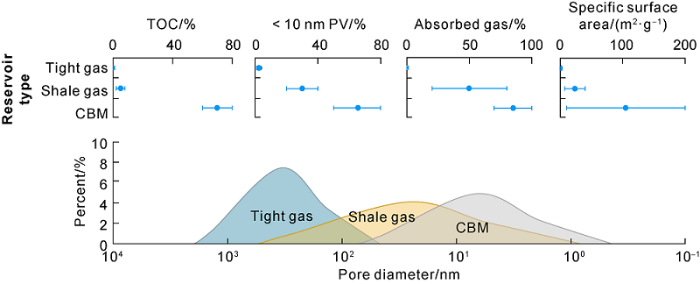

Compared with conventional gas reservoirs, the development and production of three types of unconventional gas -- tight gas, shale gas and CBM, are more difficult. From tight gas to shale gas and CBM reservoirs, the Total Organic Carbon (TOC) increases, the pore throats become smaller (from micrometers to nanometers), the specific surface area becomes larger, the gas occurrence changes from free gas to adsorbed gas, and the gas flowing mechanism transforms from percolation to diffusion[6, 10-11]. All these factors result in slow and short pressure propagation, low production, and extremely difficult development. Such reservoirs are collectively called "extreme gas reservoirs".

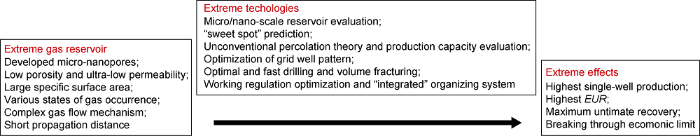

The connotation of the "extreme utilization" development theory is that, for the "extreme gas reservoirs" that cannot be developed economically and effectively by conventional development technologies, "extreme technologies" such as grid well pattern, long horizontal-section wells and volume fracturing are used to create subsurface connected bodies, expand the discharge area, enlarge the production range, and ultimately obtain maximum single-well production and extreme recovery, namely the “extreme production” of unconventional gas (Fig. 1).

Fig. 1.

Fig. 1.

The therotical framework of "extreme utilization".

1.1. Features of "extreme gas reservoirs"

From tight gas to shale gas to CBM, the changes are as follows. The TOC of the reservoirs gradually increases. The TOC of tight gas reservoir is nearly zero; the TOC of shale gas reservoir is 2%-10%; and the TOC of CBM reservoir is 60%-80%[12,13,14]. The specific surface area increases with the decrease of the pore radius and the increase of the TOC. The specific surface area of tight gas reservoir is 0.1-3.0 m2/g, that of shale gas reservoir is 7-40 m2/g, and that of CBM reservoir is 10-200 m2/g. Pores gradually become smaller, from micrometers to nanometers. The pore diameters of tight gas reservoirs are mainly distributed in the range of 0.04-2.00 μm, those in shale gas reservoirs are 4 to 500 nm, and those in CBM reservoirs are 1 to 100 nm. The proportion of adsorbed gas increases with the increase of TOC and the decrease of pore throat diameter. The gas occurrence state changes from free gas to adsorbed gas. Tight gas reservoirs hardly have adsorbed gas, the adsorbed gas in shale gas reservoirs accounts for 20% to 80%, and that in CBM reservoirs accounts for 70% to 100% (Fig. 2).

Fig. 2.

Fig. 2.

Characteristic models of "extreme gas reservoirs".

1.2. Percolation

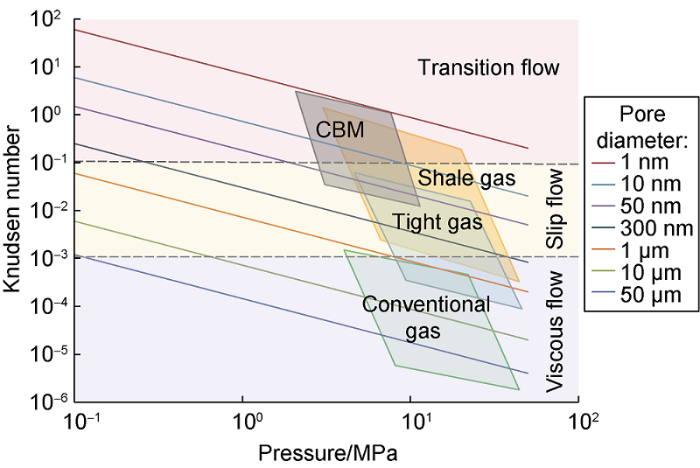

In "extreme gas reservoirs", the pores range from micrometers to nanometers, the specific surface area becomes larger and larger, the surface effect increases sharply, and the slippage effect, surface diffusion, and desorption cannot be ignored. The percolation theory of conventional gas reservoirs cannot effectively describe the process of unconventional gas percolation any longer[6, 15-16]. According to Knudsen's theory, the mean free path of gas molecules and the size of pores together determine the gas flow regime. Based on this, we plot gas flow regime charts (Fig. 3). From conventional gas to unconventional gas, the Knudsen number gradually increases, and the gas flow gradually changes from viscous Darcy flow to slip flow and transition flow, and it is harder and harder to produce gas. Tight gas is almost viscous flow. And as pressure decreases and pores become smaller, local slip flow occurs. Desorption, surface diffusion, Knudsen diffusion and other mechanisms coexist in the pores of shale gas reservoir, thus shale gas is slip flow and transition flow.

Fig. 3.

Fig. 3.

Flow regime charts of unconventional gas.

With small matrix pores and low reservoir pressure, CBM follows transition flow, and desorption and diffusion play an important role on CBM flow.

1.3. Production

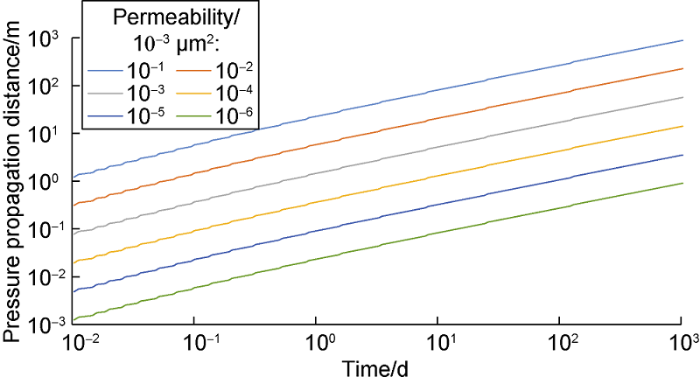

Unconventional gas is usually produced by depletion development, and pressure propagation velocity and distance are mainly controlled by reservoirs permeability[6, 16]. The permeability of "extreme gas reservoirs" is low. The permeability of tight gas reservoir is generally (0.001- 0.100)×10-3 μm2, the permeability of shale gas reservoir is generally (0.000 01-0.001 00)×10-3 μm2, and the permeability of CBM reservoir is generally in (0.000 001-0.010 000)×10-3 μm2, resulting in slow pressure propagation[17,18,19]. The pressure propagation distance in conventional gas reservoirs can reach the level of kilometer, while it is only tens of meters or lower in "extreme gas reservoirs". For the example shown in Fig. 4, the pressure propagation distance in the gas reservoir with permeability of 0.1×103 μm2 is more than 500 m after production of 1000 d, while it is only 14 m in the gas reservoir with permeability of 0.0001×103 μm2 after production 1000 d. For propagation of 10 m, it takes only 5 h in the gas reservoir with permeability of 0.1×103 μm2, while it takes more than 500 d in the gas reservoir with permeability of 0.0001×103 μm2. The pressure propagation distance and velocity in "extreme gas reservoirs" are several orders of magnitude lower than those in conventional gas reservoirs. To effectively develop "extreme gas reservoirs", it is necessary to break through the limits of slow and short pressure propagation.

Fig. 4.

Fig. 4.

Pressure propagation in an extreme gas reservoir.

1.4. Geomechanics

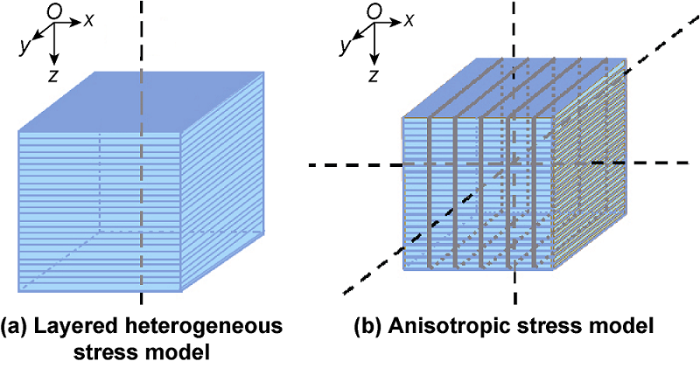

As they are very heterogeneous, the in-situ stress of unconventional natural gas reservoirs cannot be simplified as an isotropic model, but a model which is laterally homogeneous and vertically heterogeneous or even anisotropic (Fig. 5). In the model with layered heterogeneity, Ev≠Eh; usually Eh/Ev is between 1 and 2, and the stronger the heterogeneity, the larger the Eh/Ev. In the anisotropic model, Ex≠Ey≠Ez. Due to the change of reservoir medium, rock mechanics parameters, such as elastic modulus, Poisson's ratio, brittleness and toughness, on the vertical section change rapidly and are very different. Correspondingly, the minimum principal stress changes quickly and the interval difference is very large.

Fig. 5.

Fig. 5.

In-situ stress models of unconventional gas reservoirs.

Poisson's ratio, brittleness and toughness, on the vertical section change rapidly and are very different. Correspondingly, the minimum principal stress changes quickly and the interval difference is very large.

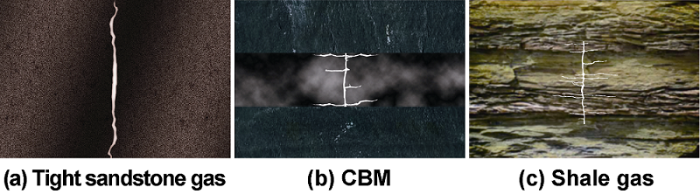

The complex in-situ stress and the influence of multi-layered structure lead to complicated hydraulic fracture shapes, which are generally superposed and interacted vertically and horizontally, and their vertical expansion is limited. Due to changes in geomechanical characteristics, the fracture shapes in tight sandstone gas, coalbed methane and shale gas reservoirs gradually change from simple to complex (Fig. 6).

Fig. 6.

Fig. 6.

Schematic diagrams of three types of hydraulic fractures in unconventional gas reservoirs.

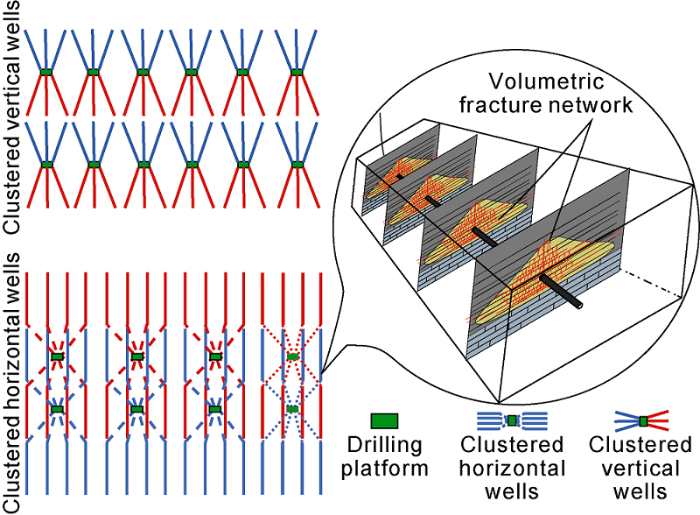

1.5. Subsurface connected bodies

To effectively develop “extreme gas reservoirs”, it is necessary to create “subsurface connected bodies” with dense volumetric fracture networks and effective flowing channels (Fig. 7). The scientificity and effectiveness of the connected bodies depend on the density of well pattern and the degree of reservoir stimulation. Changes in geomechanical characteristics bring great challenges to engineering technology, especially drilling and fracturing technology. It is necessary to continuously break through the technical limits and induce a volumetric fracture network which matches the features of "extreme gas reservoirs" through grid drilling and horizontal well volume fracturing stimulation. Optimal "subsurface connected bodies", pressure propagation distance, effective gas reservoirs and improved seepage capacity are controlling factors on effective development of unconventional gas.

Fig. 7.

Fig. 7.

Schematic "subsurface connected body" of extreme utilization of unconventional natural gas.

2. "Extreme utilization" development technology

The ultimate goal of developing unconventional natural gas is to increase single-well production and Estimated Ultimate Recovery (EUR). The key to achieving this goal is to create the best "subsurface connected bodies" based on the geological and engineering conditions of "extreme gas reservoirs". It is important to carry out multi-disciplinary reservoir characterization, determine favorable "sweet spot intervals", and establish seepage models. Optimal well patterns and spacing, effective reservoir stimulation, integration of geology and engineering, and reasonable drainage system are key factors for obtaining the highest EUR and profitable production. Geological and engineering integration on research, design and implementation are inevitable requirements for technical breakthroughs in the development of unconventional natural gas[15] (Fig. 8). Aiming at effective development of shale gas fields, we put forward a general idea of "good well location", "good drilling operation", "good fracturing stimulation" and "good well management", which is the accurate interpretation of the integration of geology and engineering[6]. The "extreme utilization" development technologies include micro/nano-scale reservoir evaluation, "sweet spot" prediction, unconventional percolation theory and production evaluation, optimization of grid well pattern, optimal and fast drilling and volume fracturing, optimal working system and integrated management.

Fig. 8.

Fig. 8.

Schematic extreme development models for different types of unconventional natural gas.

2.1. Micro/nano-scale reservoir evaluation

Micro/nano-scale pores are developed in unconventional natural gas reservoirs. With the development and improvement of micro/nano-scale reservoir characterization technology, the understanding to unconventional oil and gas reservoirs has continuously improved and evolves to up to molecular scale. Accurate characterizations of micro-pore structures are the basis for reservoir evaluation. With supports of experimental techniques such as high- pressure mercury intrusion, low-temperature N2/CO2 adsorption, FESEM and micro/nano CT, clear characterization of full-scale pores of unconventional natural gas reservoirs has been realized, and the different pore structures of tight sandstone, shale and coal has been revealed. Based on the accurate understanding of the micro-pore characteristics, and by combining and upgrading rock mechanics and other evaluation technologies, the micro/nano- scale reservoir evaluation technology has been developed. It is based on the understanding of micro/nano pore structure and more than 30 experimental technologies for analyzing gas-bearing, fluid, rock mechanical, geochemical, physical and petrophysical properties to evaluate the gas-bearing capacities, storage and stimulation of reservoir, and then determine the methods and standards of reservoir classification and evaluation based on development effect. The results lay the foundation for the "extreme utilization" of unconventional gas.

2.2. “Sweet spot” prediction

Since unconventional gas reservoirs are very heterogeneous, it is necessary to use various technical means such as experiments, well logging, seismic survey and field monitoring to construct "transparent gas reservoirs". To accurately determine the richest and vertically best "sweet spots"[8] is important to "extremely utilize" unconventional gas. And it is also inevitable for economic and effective development of unconventional gas.

Micro/nano-scale reservoir evaluation provides a reliable basis for logging calibration, and fine reservoir characterization. Logging evaluation centered on comprehensive evaluation of indicative parameters of sweet spots is useful to understand geological and engineering parameters of unconventional gas reservoir such as mineral composition, TOC, porosity, saturation, gas-bearing and rock mechanical properties, and clarify the horizontal and vertical heterogeneity of the reservoir[20], as well as the morphological characteristics of hydraulic fractures. On this basis, a comprehensive prediction technology of "sweet spots" is established after geological and engineering "sweet spots" are identified and effectively integrated[13]. In other words, it is a process starting from using well and seismic data to build a high-resolution 3D geological model, to accurately predicting the horizontal and vertical "sweet spots" of unconventional gas reservoirs. It is the basis for developing an optimal plan for developing unconventional gas.

2.3. Unconventional percolation theory and production capacity evaluation

Aiming at the extreme characteristics of the three types of unconventional gas, a series of physical simulation technologies have been established, gas flow and pressure propagation laws have been clarified, and universal seepage models have been built. These are theoretical basis for realizing the extreme utilization of unconventional gas.

2.3.1. Physical simulation of gas production law

The extreme characteristics of unconventional gas lead to its unique production characteristics of high initial production, fast decline, low and long stable production in the later stage[20,21]. It is difficult to characterize the flowing capacity and development effect of unconventional gas reservoirs using conventional technology and theories. To study the "extreme utilization" law of unconventional gas, a series of experimental technologies such as whole-life-cycle development simulation on coupled diffusion and seepage processes have been developed. Taking reservoir cores as the research object, using methane as the medium, and at reservoir temperature and pressure, the gas production law and production characteristics are studied under the condition of free pressure relief. The experimental findings provide key parameters for productivity evaluation and production prediction.

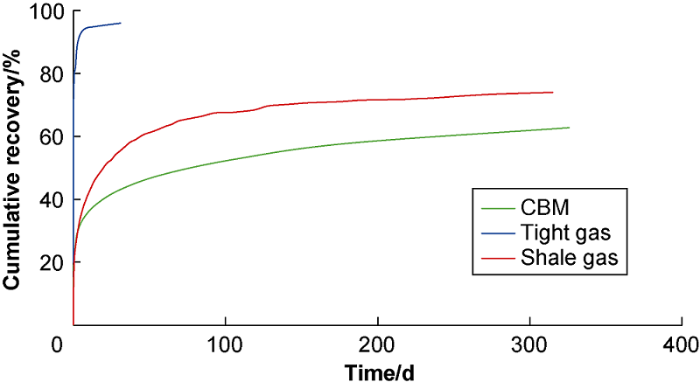

The full life cycle development simulation experiment was carried out to compare the gas production laws of tight gas, shale gas, and coalbed methane. The initial production rates of tight gas, shale gas and coalbed methane were all relatively high. Due to the short supply distance of the experimental cores (about 30 cm each) and large pressure difference, the production of tight gas rose rapidly to over 90% in a short period. In comparison, shale gas and CBM were produced 70% and 60%, respectively, after 300 days (Fig. 9). The primary cause was the coexistence of adsorbed and free gases in shale gas and CBM cores.

Fig. 9.

Fig. 9.

The relationship between production and time.

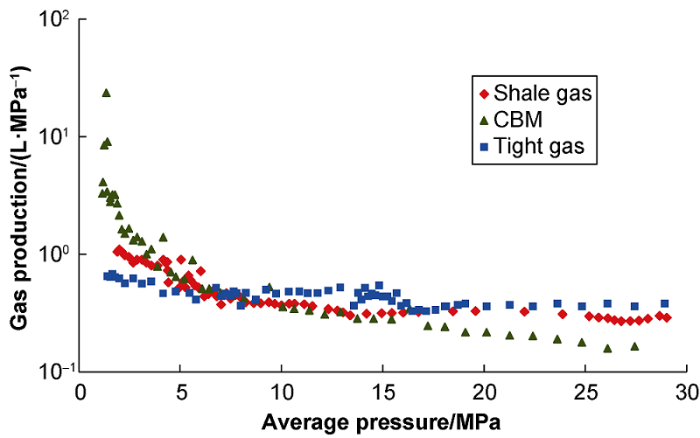

After the initial free gas was produced, the production depended on the slow desorption and supply of adsorbed gas, so the recovery was slowly increasing. The gas production per unit pressure drop (Fig. 10) shows that at high pressure, the production of tight gas, shale gas and CBM maintained at a relatively stable level. After pressure dropped to 12-15 MPa, the tight gas production remained basically unchanged, while the production of both shale gas and CBM increased significantly, indicating that the adsorbed gas began to desorb to free gas, and gradually produced. The studies have shown that the pressure propagation in shale and coal reservoirs is slow, and later desorption and diffusion are the forces to drive pressure propagation. This is the basis for long-term low and stable production of shale gas and CBM.

Fig. 10.

Fig. 10.

The relationship between gas production and average pressure.

2.3.2. Universal percolation model

Since the occurrence and migration of unconventional gas are complex, it is necessary to correct the porosity and permeability according to the physical properties and flow mechanism of the "extreme gas reservoir" to establish a universal percolation model.

Considering the tightness of unconventional gas reservoirs, the model assumes that the fractures induced by volume fracturing stimulation have an infinite conductivity, at the same time, the pressure drop caused by gas flow in the fractures is ignored, the one-dimensional flow supplied by the matrix to the fractures is considered, and the mass transfer from the matrix to the fractures is a transient flow.

Based on the law of conservation of mass, the general form of the continuity equation of gas production in unconventional gas reservoirs is established:

Because adsorbed gas occupies part of the pore volume in shale gas reservoirs, considering the influence of the volume occupied by the high-pressure adsorption phase on the porosity[22,23,24,25], the expression of the porosity correction coefficient is shown in equation (2). At the same time, the influences of Knudsen diffusion and stress sensitivity need to be considered in the mass transfer process, so the expression of the permeability correction coefficient is shown in equation (3).

For CBM reservoirs, it is also necessary to consider the influence of adsorbed gas volume on the porosity, so the matrix porosity correction coefficient is shown in equation (4). The single-phase gas transfer in CBM reservoirs obeys Fick's law of diffusion[26,27], so the expression of the permeability correction coefficient is shown in equation (5).

Different from CBM and shale gas, the porosity correction coefficient of tight sandstone reservoir needs to consider the influence of water saturation[28,29] (equation 6), and the permeability correction coefficient (equation 7) reflects a variety of non-Darcy effects, such as stress sensitivity, gas permeability and water permeability, starting pressure gradient, and low-pressure slippage.

2.3.3. Evaluation of production capacity

According to the reservoir, percolation and production characteristics, a whole-life-cycle evaluation system and evaluation technologies have been formed for unconventional gas reservoirs. From drilling to production, an unconventional gas well generally goes through four stages from drilling and fracturing, production test, rapid production decline to low production at low pressure. According to the characteristics of different stages, the corresponding productivity evaluation methods are established. For the drilling and fracturing stage, a multi-factor productivity model is established. It is based on the analysis of the control factors on the productivity of the wells that have been put into production, and used to predict the productivity of the well that has not been put into production by considering its reservoir physical properties and fracturing parameters. For the stage of production test, a production regression method is established. By establishing the empirical relationship between test production or open flow and EUR, test production or open flow is used to predict EUR. For the rapid decline stage, an analytical model is established. It is a non-linear flow model of multi-zone combination (primary fracture zone, secondary fracture and matrix zone) and multi-flow coupling. It matches the historic pressure and production of old wells, and reflects the reservoir and engineering parameters, and predicts the production capacity of new wells. For the low pressure and low production stage, a decline analysis method is established. The gas well in this stage generally has reached a boundary flow or pseudo-boundary flow, so the Arp's empirical decline model can be used to predict the productivity. Tight gas wells generally use an exponential decline model, and shale gas wells follow a hyperbolic decreasing model. The whole-life-cycle production prediction method can greatly improve the prediction accuracy of unconventional gas wells.

2.4. Optimization of grid well pattern

In unconventional "extreme gas reservoirs", the fluid in the pores is basically isolated into small blocks. If an "extreme" well pattern is not used to establish effective channels and "connected bodies", the reserves will not be effectively produced. The "grid well pattern" is the core of the development technology. It can improve the production of unconventional gas reserves and pursue an "extreme" recovery on the basis of "sweet spot" prediction. Well type, well spacing and well pattern are the controlling factors of the "grid well pattern".

Gas wells of "extreme gas reservoirs" have low production. The well type should aim to increase the contact between the wellbore and the reservoirs, which specifically depends on the spatial distribution of the "sweet spot interval/section". When the target zone is vertically thin and horizontally continuous, horizontal wells are the best, and laid out as a double-row, single-row, "spoon", or double-platform cross plot, and at the same time the formation dip and surface conditions should be considered. When the target zone is composed of layers which are vertically thin, but thick after superimposition, highly deviated wells or vertical wells (cluster wells) are often used, depending on the sedimentary facies belt, reservoir scale and distribution.

Pressure propagation is short in "extreme gas reservoirs", and the control range of a well is limited. In order to achieve the development limit, it is necessary to construct underground connected bodies, and reasonably design well pattern and well spacing. On a three-dimensional geological model, the well type, spacing and pattern are optimized through interference well test, reservoir numerical simulation, fracture propagation simulation, and microseismic monitoring data. If there are several target zones, a three-dimensional well pattern is recommended to increase vertical reserve utilization. If the gas reservoir has a large scale distribution, a relatively uniform well pattern is useful.

2.5. Optimal and fast drilling and volume fracturing

Maximizing development efficiency and capability is the only way to continuously expand the field of unconventional natural gas and achieve sustainable growth in output and profitable development. Taking the Marcellus shale gas field in North America as an example, the key engineering technology of shale gas has gone through four generations. The fourth generation technology with dense and intersected horizontal wells has realized the horizontal section increase from 1500 m to more than 3000 m, the proppant concentration in reservoir section increasing from 1.2 t/m to 4.5 t/m, and the single-well EUR increasing from 1.2×108 m3 to 4.0×108 m3[15].

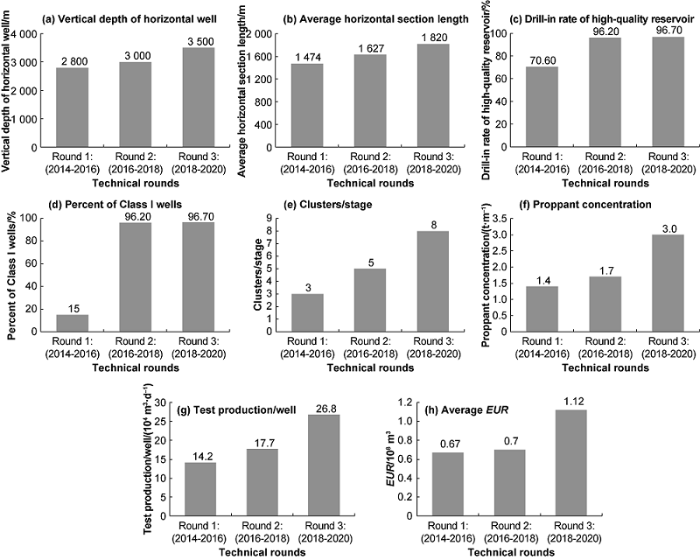

The technical indicators continue to break through, and the development effect increases substantially in China's unconventional natural gas. The optimal and fast drilling technology based on fine 3D geological models continuously breaks through engineering and efficiency indicators, and guarantees wellbore quality, reduces drilling risks, increases ROP, and reduces drilling costs of "extreme gas wells". And the latest rotary steering tools and anti-wear drill bits greatly improve the drilling production of horizontal wells. For example in the southern Sichuan Basin, after 3 rounds of technical optimization, the target of shale reservoir has been expanded from 2800 m to 3500 m, the average horizontal section increased from 1474 m to 1820 m, and the drilling-in rate increased from 70.6% to 96.7%[15] (Fig. 11). Especially the "one-trip" technology for drilling horizontal section, the one-trip footage has been over 2150 m, and the average rate of penetration (ROP) over 13 m/h.

Fig. 11.

Fig. 11.

Changes in technical indicators of the shale gas development project in southern Sichuan Basin.

The technology for stimulating unconventional gas reservoirs has been updating, and the degree of stimulation has been breaking through. Volume fracturing stimulation, as the representative of multi-stage fracturing technology, is used to effectively establish "man-made underground gas reservoirs"[2,8] and realize the beneficial development of unconventional natural gas. Volume fracturing technology matches well with the reservoir and seepage characteristics of "extreme gas reservoirs" and it is the first option to achieve optimal underground connectivity in such reservoirs. The technology is challenging its extremes in fracturing scale and parameters, well density and intersection, sand addition and fluid consumption. And equipped with low-viscosity slippery water and low-density proppants, it can create optimal underground connected bodies through extreme control. The volume fracturing technology has experienced the process of well density from low to high, well intersection from sparse to dense, proppant concentration from low to high, and fluid consumption continuously increasing. Using version 2.0 process focusing on "long section and multiple clusters, temporary plugging and uniform expansion, fluid control and proppant increase", the average horizontal section that can be fractured in a shale gas well has been increased from 71 m to 90 m, clusters per stage increased from 3 to 8, and proppant concentration increased from 1.4 t/m to 3.0 t/m. The reservoir has been fully stimulated, and the EUR has increased from initial 0.67×108 m3 to 1.12×108 m3 (Fig. 11).

2.6. Working regulation optimization and “integrated” organizing system

Unconventional gas reservoirs are characterized by poor permeability. After volume fracturing, a complex fracture networks can be induced, which is the "aorta" of gas flow. A typical unconventional gas well usually has high initial production, but it declines rapidly. The conductivity of artificial fractures determines the productivity of the gas well. The conductivity of the fractures is very sensitive to stress, especially the fractures not supported by proppants. A too fast formation pressure drop will cause the fractures to close. As a result, the conductivity of the fractures will decrease, the productivity of the gas well will be reduced, and the recovery will be affected. We propose a pressure-controlled production method for "extreme gas reservoirs". Numerical simulation and production practices show that, compared to production by free pressure drop, pressure and production control can effectively reduce the damage to reservoirs caused by pressure-sensitive effects. This method can maintain the permeability of near-fracture matrix and fracture network, and increase EUR.

Compared with conventional natural gas development, to get stable and continuous production, many wells are required during the stages of constructing production capacity and keeping stable production of unconventional gas. Efficient production organization and management should be implemented to achieve optimal engineering operating procedures, and "integrated" organization should be set up to reduce costs and improve development efficiency.

To break the management boundaries among departments and companies and to realize an "integrated" organization of all parties are the key to improving production capacity construction. Through years of practice, a platform chief responsibility system has been established in North America. It has implemented a day rate system in operating crews, innovated a Party A controlled management system, broke the boundary between the client and the service company, and promoted substantial increase in construction efficiency.

In the process of shale gas development in southern Sichuan Basin, PetroChina set up a work team whose members are from PetroChina leader group in charge of shale gas development, Sichuan-Chongqing shale gas development headquarters, oil companies and engineering service companies. The three-level management system and "integrated" organization provide a strong organizational guarantee for PetroChina's shale gas output to exceed 10 billion m3 during the 13th Five-Year Plan period. Multi-discipline cooperation ensures seamless "integration", and greatly improves the efficiency of equipment and materials utilization. "Integrated" factory-style operations, namely standard wellsite layout, rapid mobilization of drilling rigs, batch drilling with dual rigs, and reuse and sharing of liquids and pipelines, are effective ways to reduce development costs.

Under the "integrated" organizational structure, data sharing, professional analysis, comprehensive utilization, and decision-making assistance have been realized through reservoir-wellbore-ground digitization and informatization[30,31,32]. For example, using a digital development and management system, unattended shale gas well sites are working. This greatly reduces wellsite staff and management costs.

In response to the big data of unconventional natural gas development, an AI big data analysis method is used to dig more effective information, optimize development designs, and increase the efficiency of shale gas development.

3. Application of the “extreme utilization” theory

Since the discovery of the Sulige gas field in 2000, development ideas have advanced, engineering technology and management models are integrated to the largest extent. Tight gas development benefits are advancing to a large scale. In 2006, the development of the Qinshui CBM field was initiated. It made breakthroughs to low pressure, low permeability and under-saturated high-rank CBM reservoirs. And after repeated practice, it was believed that the development of coalbed methane must adopt extreme development technology and fine management model. In 2012, PetroChina started the development of shale gas in southern Sichuan Basin. Through maximizing the understanding of the shale reservoirs, the most advanced technology and optimal management and organization methods were adopted and promoted the proven reserves of shale gas to exceed 10 000 ×108 m3 and the output to exceed 100×108 m3 in 2020.

3.1. Tight gas: Sulige tight gas field

The Sulige tight gas field is located in the northwestern part of the Yishaan Slope of the Ordos Basin. The primary pay zones are the Permian He 8 and Shan 1 members. Since its discovery in 2000, the cumulative proven tight gas reserves are 5×1012 m3, and the cumulative production was 260×108 m3 in 2020. By now it is the largest natural gas field in China.

Compared with conventional natural gas reservoirs, the pressure coefficient of the Sulige tight sandstone reservoir is 0.8-1.1; the permeability is (0.001-1.000)×10-3 μm2, averaging 0.6×10-3 μm2; the porosity is 0.3%-18.0%, averaging 7%; and the reserve abundance is (1-2)×108 m3/km2. The reservoir is of low pressure, low permeability and low reserve abundance.

The large-scale and effective development of the Sulige tight gas field is benefited from several measures which are accurate prediction of the distribution of Class I high-quality reservoirs, low-cost and rapid drilling technology, a "5+1" cooperative model (5 contractors: Chuanqing Drilling Company, Western Drilling Company, Bohai Drilling Company, Great Wall Drilling Company and Huabei Oilfield Company; 1 oilfield company: Changqing Oilfield Company), and breakthrough in natural gas development. The specific measures are: (1) Carried out accurate reservoir prediction and found "sweet spot zones/sections". Experiments and tests, logging interpretation, and seismic identification were used; whole digital seismic acquisition broadened effective frequency from 8-85 Hz to 4-120 Hz; the distribution of He 8 and Shan 1 sandstone reservoirs were accurately predicted, and divided into three classes according to the physical properties. That provided a strong basis for the large-scale development of the tight gas. (2) Optimized the well pattern to make the recovery reach the maximum. In the initial stage, vertical well fracturing stimulation was performed. The well pattern was 800 m×1 200 m, and the recovery was only 15%. After densifying the well pattern in the gas-rich zone to 600 m×400 m, the recovery exceeded 60%, which was close to conventional gas. (3) Used fast and efficient drilling and volume fracturing technology to promote continuous breakthrough of single-well production to new highs. The drilling cycle of a horizontal well with a horizontal section of 1500 m was shortened to less than 45 d. The multi-interval fracturing technology realized to fracture 6 intervals at a time, and the output was more than twice that of commingled fracturing. The horizontal well staged fracturing technology realized to fracture 3 to 15 stages in a well. The average single-well production reached 6×104 m3/d, and the average single-well producing reserve reached 8000×104 m3. (4) Innovated management systems and mechanisms to effectively reduce development costs. In 2005, a market-oriented cooperation mechanism was introduced. It focused on innovation on "operating mechanism, conceptual understanding, and technological integration". A "5+1" cooperative development model was set up. As a result, the drilling cost per vertical well was reduced to less than RMB 5 million, and that of a horizontal well was reduced to less than RMB 19 million. Large-scale commercial development came true.

At the end of 2013, the annual output was 230×108 m3, making the Sulige gas field a gas field with the largest reserves and production capacity in China. By the end of 2020, it had stably produced for 7 consecutive years. During the "15th Five-Year Plan" and "16th Five-Year Plan" periods, in accordance with the development theory of "extreme utilization", the production is expected to be 300×108 m3 in 2030 through densifying the well pattern in gas rich zones, initiating lower-class reserves and discovering new fields.

3.2. CBM: Southern Qinshui field

The coalbed methane field in the southern Qinshui Basin is located in the southeastern part of Shanxi Province. The primary coal-bearing formations are the Permian Shanxi Formation and the Carboniferous Taiyuan Formation, and the pay zones are 3# and 15# coal seams. Since 2003, the cumulative proven geological CBM reserves are 2475×108 m3. The CBM output was 12×108 m3 in 2020. At present, it is the largest coal-bed methane field in China.

CBM reservoirs are more complex than conventional gas reservoirs. The coal reservoirs in southern Qinshui Basin are highly heterogeneous. With a pore-cleat-fracture system, the heterogeneity index, P10/P90 ratio may be 10-15, 3 to 5 times higher than conventional reservoirs. The coal seams are low in mechanical strength, and fragile and easy to collapse and block. The porosity is generally less than 5%, and the permeability is (0.03-1.50)×10-3 μm2. The reservoir pressure is relatively low, globally low and locally normal. The reservoir is characterized by "one strong and three low" features, namely strong heterogeneity, low strength, low permeability and low pressure. With complicated flowing channels, the process of gas flow follows pressure dropping, desorbing, diffusing to percolating. And the percolating mechanism is very complicated.

Measures taken to get scaled CBM production in the south of the Qinshui Basin include precise prediction of the distribution of coal reservoirs, transform of well types, optimization of well patterns, and low-damage drilling and fracturing, scientific, quantitative and intelligent drainage and production, breakthrough to the limit of CBM beneficial development. Specifically: (1) Used the CBM geophysical exploration and evaluation technology characterized by "locating favorable targets, finding fractures and measuring gas content" to accurately predict the distribution of coal reservoirs. Shallow mountain 2D and 3D seismic acquisition, processing and fine interpretation provided strong support for drilling horizontal wells. The drill-in rate of new horizontal wells has been significantly improved. (2) Transformed well types to realize profitable development. In the initial stage, vertical and directional wells were drilled. The average gas production per well was only 300-500 m3/d from the middle and deep layers, and the internal rate of return was only 3%. Then open-hole multi-sidetrack horizontal wells, tree-like horizontal wells, U-shaped wells, on-branch L-shaped horizontal wells, etc. were tested and compared. At last it was found that on-branch L-shaped horizontal wells have stable boreholes and low costs, and they are fracturable and recoverable. The stable production can reach 5000 to 8000 m3/d, and the internal rate of return can reach 12%. (3) Optimized well patterns to improve the recovery. In vertical wells, the pressure drop and desorption range is small. On the one hand, the density of the vertical well pattern was increased from 300 m×300 m to (200-250 m)×(200-250 m); on the other hand, combination of horizontal wells and vertical wells was adopted. At last the recovery increased from 34% of the vertical well pattern to 50%. (4) Optimal and fast well drilling, completion and fracturing with rapid flowback and low cost to promote a breakthrough in single-well production. The drilling cost was dropped. The drilling cycle was generally 20 days. The flowback rate reached 25%. The gas production of a vertical well increased by 500 m3/d on average, and the gas production of a horizontal well was 7000-10 000 m3/d, which is 8-10 times the average production of the vertical well nearby. (5) Scientific, quantitative and intelligent drainage technology to reduce costs and increase efficiency. Focused on flow pressure control and desorption pressure, and adhered to "continuous, gradual, stable, and long-term" pressure drop to ensure the most efficient water and gas production. The "double-loop and three-control" intelligent drainage technology and supporting equipment applied to field production capacity construction not only met the requirement of controlling bottom hole flow pressure, but also achieved cost reduction and efficiency increase. (6) Integrated management to realize economic development. Some blocks didn’t use the best technology and management, resulting in poor initial development effect. For example, the production capacity of the Zhengzhuang block, which was put into development in 2012, was only 25%. After 2016, using the best technology and management, the EUR of the vertical wells was increased from 230×104 m3 to 780×104 m3, and the EUR of horizontal wells was increased from 1351×104 m3 to 3900×104 m3, and the capacity construction reached 80%.

China's CBM production in 2020 was 60×108 m3, which is far below the expectation of the 13th Five-Year Plan. China's CBM resources are abundant. According to the development concept of "extreme utilization", China's CBM production is expected to reach more than 200×108 m3 by finding "sweet spots/sections" through accurately characterizing coal reservoirs and using extreme development technology and development management.

3.3. Shale gas: Weiyuan shale gas field

The Weiyuan shale gas field is located in the southern part of the Sichuan Basin. The primary pay zone is the Wufeng Formation to Long11 sub-member. Since the exploration and development in 2009, the cumulative proven shale gas reserves are 4277×108 m3. The annual shale gas production was 40×108 m3 in 2020. It is an important contributor to China’s shale gas development.

Shale reservoirs are ultra-tight and of low permeability. In the conventional oil and gas theory, shale is usually deemed as the caprock or source rock of hydrocarbon accumulation. The development of shale gas is beyond the limit of unconventional gas reservoirs. In the Weiyuan shale gas field, the reservoir permeability is (0.0001-0.010 0)×10-3 μm2, and 0.001×10-3 μm2 on average; the porosity is 5.2%-6.7%, and 5.9% on average; the TOC is 2.5%-3.6%, and 3.2% on average; the gas content is 3.3-8.5 m3/t, and 5.5 m3/t on average; the brittle mineral content is 60%-82%, and 74% on average; the favorable target is Long11, 1.0-7.5 m thick; the formation pressure coefficient is 1.2-2.0, and the stress difference is 7.7-18.7 MPa. The reservoir is characterized by low porosity, low permeability, strong heterogeneity, large horizontal principal stress difference, and variable thickness.

Measures taken to develop the shale gas reservoirs include accurately predicting the reservoir distribution, developing low-cost and fast drilling, completion and fracturing technologies, optimizing drainage and production systems, establishing high-yield well models, and breaking through the economic limit. Specifically: (1) Carried out accurate reservoir prediction and found "sweet spot intervals/sections". Experimental, biostratigraphic, logging and seismic data were used to accurately predict the distribution of the Wufeng Formation and Long11. The Long11 was selected to be the favorable target. (2) Used fast and efficient drilling and volume fracturing technology to push the single-well output to a new high. The drilling cycle of the horizontal well with a horizontal section of 1500 m was shortened to less than 49 days. Multi-stage fracturing with high proppant concentration and high displacement was implemented. The average stages were 23, the average stage spacing was 12 m, the average proppant concentration was 2.3. t/m, the displacement was 14-16 m3/min, and the average single-well EUR reached 1.16×108 m3. (3) Optimized the drainage and production system to improve the single-well EUR and recovery. In the early stage, the horizontal well spacing was 400 m. Later the spacing was shortened to 300 m, which greatly improved the reservoir producing degree and the overall recovery of the gas field. The production system was updated from free pressure drop to pressure control and kept stable production for 3 years. The EUR per well was increased. Drainage measures were taken according to different production stages. Tubing string was run downhole at pressure in the early stage. Intermittent production, boosting pressure, running down plungers, gas lift and draining in the horizontal section were done in the middle and late stages. Gas wells with abnormal liquid accumulation used gas lift and plug removing. General or platform pressurization, or general + platform pressurization was performed to realize whole field pressurization. The life cycle and production of the gas well has been greatly increased. (4) Established a high-yield well model. In the Long11 pilot production area with reservoir thickness more than 5 m, the drill-in length in the Class I reservoir was longer than 1500 m, the fracturing clusters were 7 to 8 per stage, and the proppant concentration was higher than 2.5 t/m. Through temporary plugging and steering, and optimizing fracturing parameters, the test production exceeded 50×104 m3/d. (5) Innovatively established an efficient organization chart to realize unified decision-making, unified command, unified coordination and unified performance assessment.

The production of shale gas in the southern Sichuan Basin has been increasing significantly. In 2020, the annual production was 116×108 m3, and the cumulative proven reserves were 1.06×1012 m3. Following the development theory of "extreme utilization", and by strengthening shallow layers and breaking through deep layers, the development of shale gas in China will go forward by a large step. PetroChina's shale gas production is estimated to be (240-300)×108 m3 in 2025, and the production capacity is estimated to be 500×108 m3 in 2030.

4. Conclusions

The development theory of "extreme utilization" of unconventional natural gas is the product after continuously studying and summarizing the long-term development of unconventional natural gas in China. It is the wisdom crystallization of Chinese scholars who have been breaking through the limits of oil and gas development. The so called "extreme" is not the end of the development of unconventional natural gas, but a process of constantly breaking through the understanding of unconventional gas reservoirs, and also a process of constantly pursuing the highest technical level and the most efficient management model, and breaking the barriers of profitable development of unconventional natural gas.

The development theory of "extreme utilization" means to use "extreme technologies" to establish subsurface connected bodies in "extreme gas reservoirs", increase the discharge and production range, and pursue the highest single-well production and extreme recovery. Focusing on the connotation of "extreme utilization", six "extreme utilization" supporting technologies have been developed, which are micro/nano-scale reservoir evaluation, “sweet spot” prediction, unconventional percolation theory and production capacity evaluation, optimization of grid well pattern, optimal and fast drilling and volume fracturing, and working regulation optimization and “integrated” organizing system.

The development theory of "extreme utilization" has been applied in the Sulige tight gas field, southern Sichuan shale gas field and Qinshui CBM field. By applying the development theory and supporting technologies of "extreme utilization", unconventional natural gas will become the primary contributor to natural gas growth, and boost the natural gas production to a new level in China.

Acknowledgements

Thanks go to the PetroChina Research Institute of Petroleum Exploration & Development, PetroChina Exploration and Production Company, PetroChina Southwest Oil & Gasfield Company, PetroChina Changqing Oilfield Company, PetroChina Zhejiang Oilfield Company and PetroChina Huabei Oilfield Company for their support in the research process, and thanks to Wang Hongyan, He Dongbo, Hu Zhiming, Zhao Qun, Weng Dingwei, Liu Honglin, Guo Wei, Sun Yuping, Duan Xianggang, Sun Shasha, Shi Zhensheng, Wang Meizhu, Zhou Shangwen, Zhang Leifu from the PetroChina Research Institute of Petroleum Exploration & Development for their help in the process of writing this paper.

Nomenclature

A, B—empirical parameters of apparent permeability from experiments;

b—slippage factor, Pa;

Bg—bulk gas coefficient, dimensionless;

Dm—coalbed methane diffusion coefficient, m2/s;

Eh, Ev—elastic modulus in horizontal and vertical directions, GPa;

Ex, Ey, Ez—elastic modulus in x, y, z directions, GPa;

EUR—estimated ultimate recovery, 108 m3;

K—matrix permeability, m2;

Kn—Knudsen number, dimensionless;

Krg—gas relative permeability;

P—pressure, Pa;

PL—Langmuir pressure, Pa;

P10, P90—the probability of 10% and 90% reliability of target value, %;

r—the distance from a point in matrix to axis, m;

R—gas constant, 8.314 J/(mol·K);

Sw—water saturation, %;

t—time, s;

T—temperature, K;

TOC—total organic carbon, %;

VL—Langmuir volume, m3/kg;

x, y, z—rectangular coordinate system, m;

αc—the porosity correction coefficient of CBM reservoir, dimensionless;

αi—porosity correction coefficient, dimensionless;

αs—the porosity correction coefficient of shale gas reservoir, dimensionless;

αss—the porosity correction coefficient of tight gas reservoir, dimensionless;

βc—the apparent permeability correction coefficient of coalbed methane reservoir, dimensionless;

βi—permeability correction coefficient, dimensionless;

βs—the apparent permeability correction coefficient of shale gas reservoir, dimensionless;

βss—the apparent permeability correction coefficient of tight gas reservoir, dimensionless;

γ—stress sensitivity coefficient, MPa-1;

ξ—gas high-pressure adsorption correction coefficient, dimensionless;

ρ—gas density, kg/m3;

ρd—shale density, kg/m3;

ρdc—coal density, kg/m3;

σ—effective stress, MPa;

λ—starting pressure gradient, related to permeability and water saturation, Pa/m;

μ—gas viscosity, Pa·s;

ϕ—matrix porosity, %.

Subscript:

i—gas reservoir type.

Reference

Theoretical insights, core technologies and practices concerning “volume development” of shale gas in China

Hydrocarbon generation and storage mechanisms of deep-water shelf shales of Ordovician Wufeng Formation-Silurian Longmaxi Formation in Sichuan Basin, China

Rules of two-factor enrichment for marine shale gas in Southern China: Understanding from the Longmaxi formation shale gas in Sichuan basin and its surrounding area

Shale gas in China: Characteristics, challenges and prospects (I)

Dominating factors on well productivity and development strategies optimization in Weiyuan shale gas play, Sichuan Basin, SW China

Tight sand gas development technologies and practices in China

Concept, technology and practice of “man-made reservoirs” development

Conductivity and performance of hydraulic fractures partially filled with compressible proppant packs

Exploration on enrichment law and scale effective development of shale gas in southern Sichuan Basin

The progress and prospects of shale gas exploration and exploitation in southern Sichuan Basin, NW China

High- pressure methane sorption isotherms of black shales from the Netherlands

Morphology, genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale

Experiences and lessons learned from China’s shale gas development: 2005-2019

Geological characteristics and high production control factors of shale gas in Silurian Longmaxi Formation, southern Sichuan Basin, SW China

Shale high pressure isothermal adsorption curve and production dynamic experiments of gas well

Effect of anaerobic metabolites of anthracite on its nano pores

A model for flows in channels, pipes, and ducts at micro and nano scales

Discussion on reservoir forming characteristics and exploration and development of natural gas, coalbed gas and shale gas

Scientific issues on effective development of marine shale gas in southern China

Progress and prospect of key experimental technologies for shale gas geological evaluation

Experimental investigation on water adsorption and desorption isotherms of the Longmaxi shale in the Sichuan Basin, China

URL PMID:32778746 [Cited within: 1]

Establishment of a new slip permeability model of gas flow in shale nanopores based on experimental and molecular dynamics simulations studies

Insights into interactions and microscopic behavior of shale gas in organicrich nanoslits by molecular simulation

Nanopores and apparent permeability of gas flow in mudrocks (shales and siltstone)

Action mechanism of water on the gas seepage capacity in tight gas reservoir

Characters of micro-structures and percolation in sandstone gas reservoir

Experimental study on mechanism of gas flow in coal bed

Coal-bed methane percolation equation and its numerical simulation

Practice and prospect of geology-engineering integration technology in the efficient development of shale gas in Weiyuan block

High-efficiency integrated shale gas development model of Zhaotong National Demonstration Zone and its practical enlightenment

Practice of geology-engineering integration in Changning State Shale Gas Demonstration Area