Introduction

Over 50% of the remaining oil and gas resources in onshore oil fields in China exist in low-permeability, extra-low-permeability, and ultra-low-permeability reservoirs. Waterflooding is one of the most important techniques used to exploit these reservoirs. These three types of reservoirs differ greatly in pore structure and have complex flow characteristics. Previous studies only focused on one type of them[1,2,3,4,5], and few in-depth studies on the characteristics of crude oil producing feature and remaining oil distribution during waterflooding exploitation of different types of reservoirs.

Based on the differences between the volume scale of remaining oil research objects, scholars in China and abroad have studied the distribution and influence of the remaining oil in reservoirs after waterflooding with micro-models, plunger core models, large models, and macro-models[6]. Micro-model waterflooding experiments are performed in core micro-models[1-3, 7-11] and photolithographic (simulation) micro-models[12,13,14,15], under a constant displacement differential pressure or constant injection rate to visually reveal the distribution of remaining oil on the plane and inside the pore space. Photolithographic microscopic models differ significantly from the pore structure and surface physical properties of actual reservoir rocks. Core microscopic model is made by placing reservoir core between high-quality glass after oil washing, slicing, and smoothing, which can truly reflect the microscopic pore structure of the reservoir. However, as the rock samples become more and more complex in pore structure, it becomes increasingly difficult to perform a quantitative analysis on water displacing oil images of core microscopic models. Small plunger core model can be used to perform water displacing oil experiments at a constant displacement differential pressure or injection rate. In recent years, to better understand the characteristics of crude oil occurrence and production in a three-dimensional space of core pores and the remaining oil distribution, computed tomography (CT) scanning[16,17,18] and nuclear magnetic resonance (NMR)[19,20,21,22,23,24,25,26] technologies have been applied in small plunger core waterflooding experiments. CT scanning technology has reached the nanometer resolution. But with a long test cycle, it takes over 1 h to complete one test point. In contrast, NMR technology not only realizes the test of fluid distribution in nanometer-level pores, but also reduces the time required to analyze each test point to less than 1 min; consequently, the imaging test can be completed in less than 2 min. Researches with large and macroscopic models are primarily realized by using mine measurements (e.g., pressure tests, tracer tests, etc.) or reservoir engineering theory[27,28,29].

The studies on oil-water flow patterns and remaining oil distribution characteristics under rock pore scale with micro-models and plunger core models have laid the foundation for revealing the mechanism of water displacing oil with large and macro-models[16]. Previously, researchers primarily used micro-model or plunger core model to study the reservoir waterflooding production characteristics and remaining oil distribution. In this study, taking low permeability, extra-low permeability, and ultra-low permeability reservoirs in the Ordos Basin as research objects, we carried out microscopic and visualized waterflooding experiments and NMR-based waterflooding experiments on plunger cores (referred to as NMR-based plunger core waterflooding experiments). The experimental results were obtained from constant-velocity mercury injection and cast thin-section experiments to analyze the characteristics of water displacing oil and remaining oil distribution at the pore scale in different types of reservoirs of Ordos Basin, in the hope to provide a basis for improving waterflooding effect of these reservoirs.

1. Waterflooding experiment

1.1. Experimental cores

Three pairs of cores were taken from the low-permeability reservoir of the Yan 9 Member of the Jurassic Yan'an Formation in the Zhenbei area and the extra-low permeability and ultra-low permeability reservoirs of the Chang 6 Member of the Triassic Yanchang Formation in Wuliwan area of Ordos Basin respectively[30]. Each pair of cores was drilled at adjacent locations in the same well to ensure that the samples have similar physical and lithological characteristics. The two samples in a core pair were used to core microscopic and visualized waterflooding experiment and NMR-based plunger core waterflooding experiment respectively (Table 1). The two low-permeability cores, taken from the medium-coarse grained quartz sandstone of Well Z55, have primarily intergranular pores with good connectivity (Fig. 1a), an average pore radius of more than 200 μm, mainly medium-coarse throats (coarse throats larger than 4 μm accounting for above 65%), smaller average pore-throat radius ratio (referred to as pore-throat ratio), and larger coefficient of variation, indicating the samples have good pore structure. The two extra-low permeability cores were taken from the medium-coarse grained feldspathic sandstone of Well L352. Primarily, they have intergranular pores, more smaller pores than the low permeability cores; necking throats (Fig. 1b), primarily medium-fine throats with a radius of less than 4 μm, developed coarse throats, and smaller variation coefficient, indicating they are poorer in pore structure. The two ultra-low permeability cores were taken from the fine-grained quartz sandstone of Well L49. They have mainly intergranular pores, and more small pores in number and volume proportion; necking throats (Fig. 1c), largely fine and micro-throats with radii of less than 2 μm, larger pore-throat ratio, and the lowest variation coefficient; indicating they are the poorest in pore structure among the three types of reservoirs. According to a previous study, the rocks of the low-permeability reservoir in the Yan 9 Member are weakly oil-wet to oil-wet[32]. The wettability indices of the extra-low permeability core L352-5 and the ultra-low permeability core L49-3 were experimentally measured herein according to the industry standard SY/T 5153-2007 (Test Method of Reservoir Rock Wettability)[33]. The wettability indices of these two cores are -0.32 and -0.93, respectively, meaning they are oil-wet and strong oil-wet, respectively.

Fig. 1.

Fig. 1.

Pore structures of different types of reservoir cores.

Table 1 Basic physical properties, pore throat parameters, and experimental design of experimental cores.

| Sample | Porosity/ % | Permeability/ 10-3 μm2 | Average pore radius/μm | Average throat radius/μm | Average pore-throat radius ratio | Pore variation coefficient | Throat variation coefficient | Conversion coefficient/ (ms·μm-1) | Experiment type | Reservoir type |

|---|---|---|---|---|---|---|---|---|---|---|

| Z55-2 | 11.391 | 30.32 | 210.95 | 8.65 | 47.19 | 0.188 | 0.189 | 0.290 | NMR-based plunger core waterflooding experiment | Low permeability (Yan 9 Member) |

| Z55-3 | 10.935 | 11.91 | - | - | - | - | - | - | Microscopic visualized waterflooding experiment | |

| L352-5 | 13.270 | 3.65 | 163.28 | 2.92 | 116.05 | 0.166 | 0.127 | 0.610 | NMR-based plunger core waterflooding experiment | Extra-low perMeability (Chang 6 Member) |

| L352-7 | 12.640 | 7.40 | - | - | - | - | - | - | Microscopic visualized waterflooding experiment | |

| L49-3 | 11.738 | 0.85 | 141.15 | 1.45 | 210.10 | 0.129 | 0.105 | 0.699 | NMR-based plunger core waterflooding experiment | Ultra-low permeability (Chang 6 Member) |

| L49-2 | 12.670 | 0.87 | - | - | - | - | - | - | Microscopic visualized waterflooding experiment |

Note: The pore throat parameters were calculated based on the experimental data of constant-velocity mercury injection. The coefficient of variation is equal to the ratio of the standard deviation to the mean value[

1.2. Microscopic visualized waterflooding experiment

Three core models of microscopic visualized water displacing oil experiment with length, width and height of 3, 2, 0.062 cm were made, and the waterflooding experiments on the micro-models were performed under room temperature and atmospheric pressure conditions using the core microscopic visualized waterflooding experimental apparatus of Southwest Petroleum University[7]. The experimental fluids used were simulated formation water with the salinity same as the formation water and simulated oil, in which the simulated oil was a mixture of kerosene and white oil, with a viscosity of 1.5 mPa·s, approximately equal to that of crude oil under formation conditions. To distinguish and characterize the oil-water distribution during the experiment, methyl blue was added to the simulated formation water, and solvent red was added to the simulated oil.

The experimental steps were as follows: (1) The samples were vacuumed, and then saturated with simulated formation water. (2) The simulation oil was injected into the fully simulated formation water saturated microscopic models to displace water until reaching the point of irreducible water saturation. (3) The simulated formation water was injected into the microscopic models at a rate of 1 μL/min to displace oil until oil didn’t produce at the outlet anymore. The typical oil-water distribution images during the waterflooding process were collected and analyzed to find out the characteristics of crude oil occurrence and production in the core samples.

1.3. NMR-based plunger core waterflooding experiment

1.3.1. Basic theory of nuclear magnetic resonance

NMR can directly detect the relaxation signals of hydrogen-containing fluids in rock pores to analyze the fluid content in the pore space[34]. The relaxation time (T2) in rock consists of three components: surface relaxation time (T2S), bulk relaxation time (T2B), and diffusion relaxation time (T2D). These components are related as follows:

Usually, in a uniform magnetic field (with small magnetic field gradient), the T2B of the fluid is approximately 2-3 s, which is much longer than T2. As the value of TE is small, T2B and T2D in Eq. (1) can be neglected, and T2 is primarily determined by T2S:

where $C\text{=}\frac{1}{{{\rho }_{2}}{{F}_{r}}}$

As the conversion coefficient of a core is constant, long relaxation time corresponds to large pore, and short relaxation time corresponds to small pore. By determining the conversion coefficient, we can obtain the pore size and fluid information of the rock, and the NMR technique can quantitatively characterize the fluid flowing characteristics at the pore scale in water displacing oil experiment.

1.3.2. Experimental cores and experimental fluids

The experimental cores were plug samples with a diameter of 2.54 cm and a length of 4 cm; their basic physical parameters are listed in Table 1. The water used in the experiment was aqueous solution of MnCl2 with a salinity of 55 000 mg/L to block the signals of water phase in the core. The experimental oil was the same as the simulated oil used in the microscopic visualized waterflooding experiment.

1.3.3. Experimental setup and procedure

The NMR core waterflooding experimental apparatus mainly consists of a core holder, intermediate containers, an NMR instrument, and a high-precision displacement pump[21]. Based on the production pressure and well spacing of the blocks from which the cores were taken, the displacement differential pressures of the core waterflooding experiments were set at 400, 600, and 800 kPa, respectively.

The test procedure was established based on the national standard GB/T 28912-2012 (Test Methods for two-phase relative permeability in rocks)[37]. The NMR- based plunger core waterflooding experiment was performed at room temperature, and the main steps were as follows. (1) The Carre-Purcelle-Meiboome-Gill (CPMG) sequence was chosen for NMR after adjusting and setting parameters of NMR apparatus, and the waiting time, echo spacing time, echo number, and scanning number, were set at 5000 ms, 0.5 ms, 18 000, and 32, respectively. (2) The sample was vacuumed until reaching 133 Pa, and then saturated with experimental water (MnCl2 solution) at 20 MPa for more than 48 h. The weight of the fully water-saturated sample was measured and the porosity of the sample was calculated (the relative error of the calculated porosity from the helium porosity was less than 2%). (3) The fully water-saturated sample was displaced by injecting the simulated oil until reaching the point of irreducible water saturation; then, the sample was immersed in the experimental oil and aged at the formation temperature for 15 d. After aging, the NMR T2 spectrum of the sample was tested. (4) The samples was placed in the core holder and displaced with water at a constant differential pressure of 400 kPa. The cumulative water production and cumulative oil production, displacing pressure and time during waterflooding were recorded. When the volume of the injection water was 30 PV, the displacement was stopped, and the mass and T2 spectrum of the core were measured. Step (4) was then repeated at the displacement differential pressures of 600 kPa and 800 kPa respectively. To ensure the accuracy of the test results, the NMR device was calibrated before each measurement of the NMR T2 spectral curve.

2. Results

2.1. Microscopic visualized waterflooding experiment

The images recorded during the microscopic visualized waterflooding experiments are shown in Figs. 2-4. For the low permeability reservoir core Z55-3 with good pore structure, the injected water first entered the large pores with low resistance (Fig. 2a), and then gradually expanded in range on the plane (Fig. 2b). The core, with no obvious high-permeability channels, exhibited uniform displacement feature and high oil recovery factor. After the waterflooding, dispersed angular remaining oil and membrane-like remaining oil were observed at the blind end of the pore space and the grain surface of the core, respectively (Fig. 2c). As the experimental core was oil-wet, the adhesion force of the oil on the rock wall surface was stronger than the shear force during waterflooding, and consequently, the oil was more likely to adsorb on the rock wall surface in membrane form.

Fig. 2.

Fig. 2.

Oil and water distribution at different waterflooding stages of the low permeability reservoir core Z55-3.

For the extra-low permeability reservoir core L352-7 with poorer pore structure, multiple injection water lines appeared and alternated with each other after the injection water entered the model. Consequently, the water flowing path advanced toward the outlet end in a network pattern (Fig. 3a), appearing as a network displacement. After waterflooding, in addition to the dispersed angular remaining oil and membrane-like remaining oil, the core had more contiguous remaining oil blocks formed by bypass flow (Fig. 3b).

For the ultra-low permeability reservoir core L49-2 with the worst pore structure, the injected water advanced along one or several channels and reached the outlet first (Fig. 4a), exhibiting a one-direction fingering phenomenon, and the area of the injected water was dispersed. After the waterflooding, some continuous patchy remaining oil remained in the core, besides the dispersed angular remaining oil, membrane-like remaining oil, and contiguous remaining oil formed by bypass flow (Fig. 4b).

Fig. 3.

Fig. 3.

Microscopic waterflooding pattern and remaining oil distribution in the extra-low permeability reservoir core L352-7.

Fig. 4.

Fig. 4.

Microscopic waterflooding pattern and remaining oil distribution in the ultra-low permeability reservoir core L49-2.

Therefore, as the cores turn lower in permeability and poorer in pore structure, the waterflooding turned from uniform displacement to network displacement, and finger displacement, and the remaining oil gradually expanded from angular and membrane-like of dispersed phase to contiguous phase and even to continuous patchy phase.

2.2. Results of NMR-based plunger core waterflooding experiment

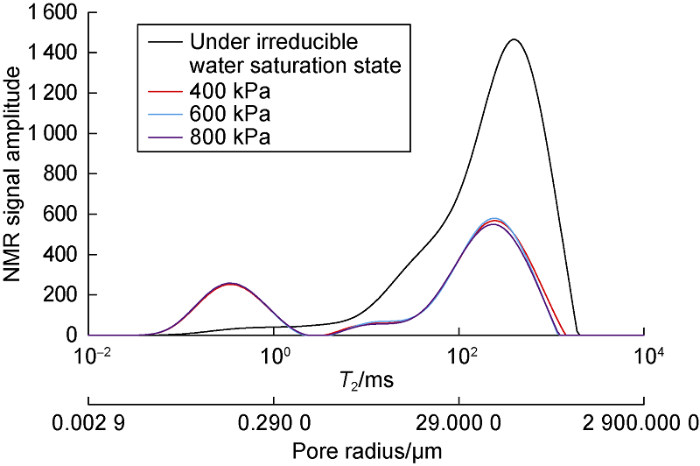

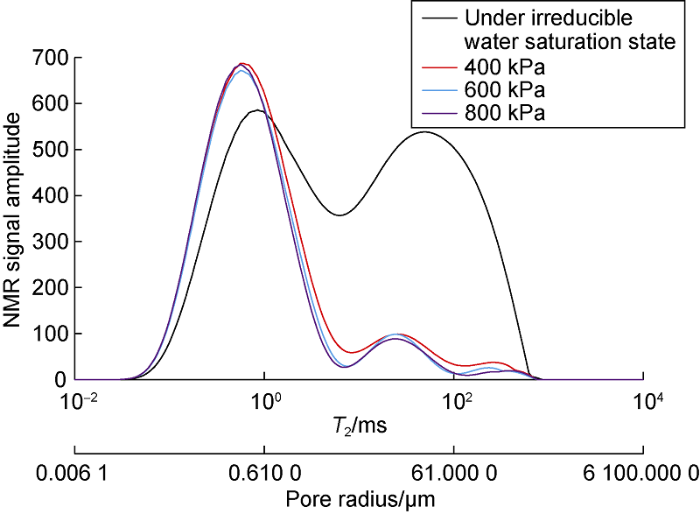

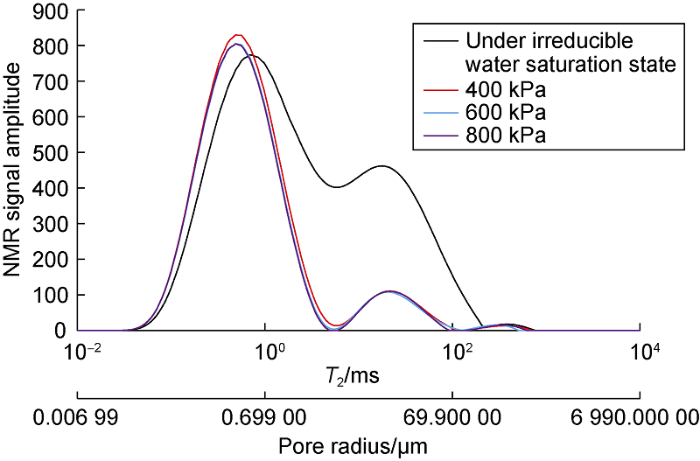

The changes in the T2 spectral curves obtained from the core waterflooding experiments only reflect the changes in the oil phase in the core. The T2 spectrum curve of the low permeability reservoir core in the irreducible water saturation state had a single peak and inclined toward the end of long relaxation time (10-1431 ms). The T2 value corresponding to the peak was 580 ms (Fig. 5). These features indicate that the oil was primarily stored in the uniformly distributed larger pores in the core. After displacement at 400 kPa, the signals of the pores with a T2 of more than 10 ms decreased significantly, whereas the signals in the pores with a T2 of less than 1 ms increased to some extent. The NMR T2 spectral curve did not change significantly when the displacement pressure was increased to 600 kPa and 800 kPa. The NMR T2 spectral curves of both the extra-low permeability reservoir core and the ultra-low permeability reservoir core in the irreducible water saturation state had two peaks (Figs. 6 and 7), of which the curve of the extra-low permeability reservoir core had almost the same signal amplitude in the short relaxation time (0.01-6.36 ms) and the long relaxation time ends (6.36-880.00 ms), whereas the curve of the ultra-low permeability reservoir core had signal amplitude of the peak of the short relaxation time (0.01-5.94 ms) larger than that of the long relaxation time (5.94-219.00 ms). This indicates that the crude oil distribution in these two types of reservoir cores had strong non-uniformity, and the crude oil in the ultra-low permeability reservoir cores was primarily stored in smaller pores compared with the extra-low permeability reservoir core. In the displacement at the differential pressure of 400 kPa of both the extra-low permeability and ultra-low permeability reservoir cores, mainly the signals of the T2 spectrum curve in the pores with a T2 of more than 6 ms decreased significantly. Furthermore, in the extra-low permeability core, the NMR signals of the pores with T2 values of more than 100 ms decreased more. The signals of pores with a short T2 (less than 1 ms) of the two cores increased. The T2 spectral curves of the both types of reservoir cores did not change significantly when the displacement differential pressure was increased to 600 kPa and 800 kPa, respectively.

Fig. 5.

Fig. 5.

T2 spectra of the low permeability core Z55-2 under different displacement differential pressures.

Fig. 6.

Fig. 6.

T2 spectra of the extra-low permeability core L352-5 under different displacement differential pressures.

Fig. 7.

Fig. 7.

T2 spectra of the ultra-low permeability core L49-3 under different displacement differential pressures.

Based on the above analysis, the low permeability, extra-low permeability, and ultra-low permeability cores show the following characteristics in the waterflooding process: under the irreducible water saturation state, the NMR signal amplitude of the pores with longer relaxation time gradually decreased with the decrease of the core permeability. This is consistent with the results of microstructure analysis that the proportion of smaller pores gradually increases and the proportion of the larger pores gradually decreases in the three types of cores. After waterflooding, the T2 spectrum curves of the three types of cores had differences in shape, clearly indicating that they had differences in remaining oil distribution in the pore space. In addition, the T2 spectrum curves of the three types of reservoir cores increased in the signal amplitude of the pores with short relaxation time (less than 1 ms), indicating that the oil in these pores increased after waterflooding.

3. Oil occurrence state and displacement efficiency

When the water-saturated core was displaced by the experimental oil to the irreducible water saturation state, the measured volumes of water Vw displaced from cores Z55-2, L352-5, and L49-3 were 1.40, 1.24, and 1.16 mL, respectively (the volume of displaced water was numerically equal to the oil volume in the core Voi, i.e. Voi = Vw). The corresponding total NMR semaphore of the T2 spectral curve Toi of the cores calculated using Eq. (4), were 58 228.24, 52 416.38, and 48 726.95, respectively (Figs. 5-7). After waterflooding at 400 kPa, the oil production Vo of the cores Z55-2, L352-5, and L49-3 was 0.75, 0.50, and 0.35 mL, respectively. The corresponding total NMR semaphore of the T2 spectral curve Tor of the cores calculated using Eq. (5) were 27 001.88, 29 245.05, and 30 720.06, respectively. Based on the definition of oil recovery factor, the oil recovery factors Ec and ENMR were calculated using Eqs. (6) and (7) from the oil production data and NMR test data, respectively.

The ENMR values of Z55-2, L352-5, and L49-3 were 53.61%, 44.19%, and 36.95%, respectively, and the corresponding Ec values of them were 50.00%, 40.34%, and 29.31%, respectively. Therefore, the differences between the oil recovery factors calculated through two methods are not significant. This indicates that the parameters of the NMR core waterflooding test system were reasonably set, and the data acquisition method was reliable. In addition, the difference between ENMR and Ec gradually increases with the decrease in core permeability and oil production, which can be attributed to the fact that the smaller the oil production leads to higher error of the metering tube readings. Furthermore, as the displacement differential pressure increased, the oil production increased so slightly that the corresponding increase could not be read by the metering tube. Therefore, the NMR data was used to study the characteristics of produced oil and remaining oil distribution in the pore space during the waterflooding process.

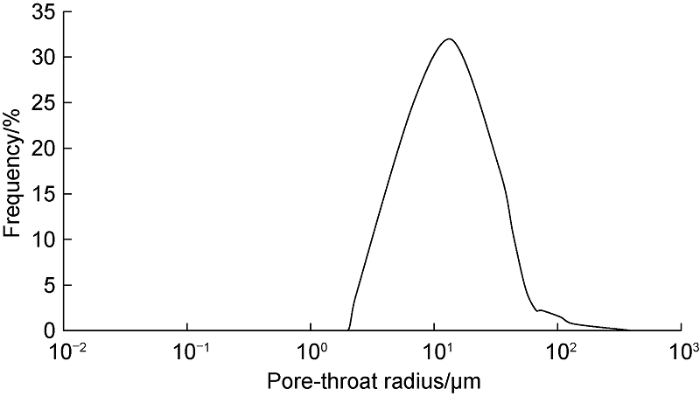

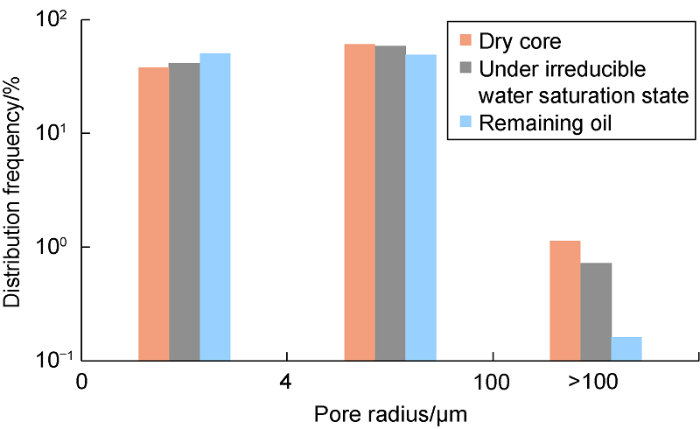

3.1. Microscopic oil distribution

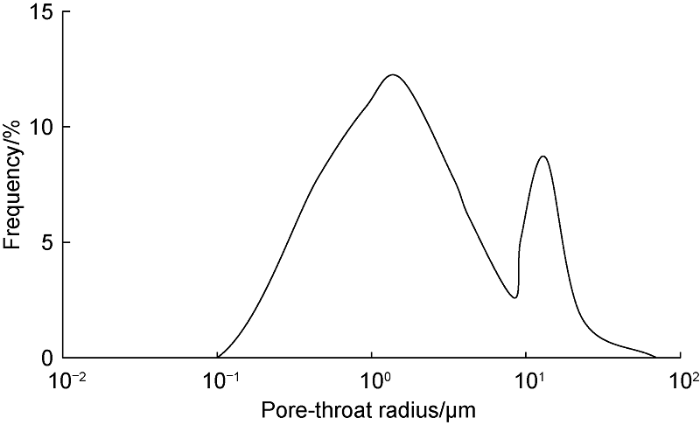

The key to obtaining the characteristics of oil occurrence and production in the plunger cores during NMR waterflooding experiments is to determine the conversion coefficient defined by Eq. (3). Combining the calculation approach of "converting the capillary pressure curve and NMR T2 spectrum to the same axis for scale comparison to obtain the conversion coefficient"[20-21, 38] and the data of the constant velocity mercury injection test, the following calculation steps were proposed: (1) The NMR T2 spectral curve under the irreducible water saturation state and the pore distribution curve obtained by constant velocity mercury injection were plotted in the same coordinate system (Fig. 8). (2) The largest value of the relaxation time in T2 spectral curve was made to correspond with the largest pore radius in pore distribution curve. (3) The conversion coefficient was determined using Eq. (3) (Table 1). Based on the above method, the T2 spectral curves of the three types of reservoir cores with different pore spaces during the waterflooding experiments were obtained (Figs. 5-7). Based on the criterion for the pore size classification of reservoir rocks[20,21,22,23,24,25,26], the pores in the experimental cores were classified into three types: micropores, mesopores, and macropores with pore sizes of 0-4 μm, 4-100 μm, and larger than 100 μm, respectively.

The images of the microscopic model captured at the irreducible water saturation state were processed by noise removal and contrast enhancement between the oil, water, and skeleton with the PhotoShop software. Subsequently, the corresponding water phase, oil phase, and skeleton contour maps were extracted from Figs. 2-4 by using the ImageJ software based on the differences in the color values (i.e. RGB values) between the oil, water, and skeleton. Finally, the frequency distribution curves of oil (droplets) in different pores were obtained (Figs. 9-11). Comparing the NMR T2 spectral curves of different pore spaces shows that the crude oil distribution curves obtained from the microscopic visualized waterflooding experiment and the NMR-based plunger core waterflooding experiment are basically the same in shape, indicating that the oil in two kinds of models have similar occurrence characteristics. It is found from further analysis of two kinds of models that the crude oil in the low-permeability reservoir core is primarily distributed in the mesopores (accounting for 53.72%) and macropores (accounting for 39.96%), and a very small proportion of oil is in the micropores (accounting for 6.32%). In contrast, in extra-low permeability and ultra-low permeability reservoir cores, the crude oil is primarily distributed in the micropores and mesopores. In the extra-low permeability reservoir core, the oil in the micropores and mesopores account for 48.8% and 41.65%, respectively, whereas in the ultra-low permeability reservoir core, the oil in the micropores (accounting for 61.57%) is larger than that in the mesopores (accounting for 36.16%), and the oil in the macropores was only 2.27%. Comparison of the three types of reservoir cores shows that the amount of oil in the micropores gradually increases, and the oil in the mesopores and macropores gradually decrease with the decrease in permeability under the irreducible water saturation state.

Fig. 8.

Fig. 8.

Scale comparison of NMR T2 spectrum and pore distribution from constant velocity mercury injection.

Fig. 9.

Fig. 9.

Oil phase distribution in the microscopic model of the low-permeability reservoir core under irreducible water saturation state.

Fig. 10.

Fig. 10.

Oil phase distribution in the microscopic model of the extra-low permeability reservoir core under irreducible water saturation state.

Fig. 11.

Fig. 11.

Oil phase distribution in the microscopic model of the ultra-low permeability reservoir core under irreducible water saturation state.

3.2. Producing characteristics of oil in the pore space during waterflooding

Based on T2 spectral curves (Figs. 5-7) of different pores before and after the waterflooding and Eq. (8), the recovery degrees of oil in three types of reservoir cores under different displacement differential pressures can be calculated.

During waterflooding, as the displacement differential pressure increased successively, the crude oil in the mesopores-macropores of three types of reservoir cores was preferentially produced. In the low permeability core Z55-2, the recovery degrees of oil in the mesopores and macropores were more than 56% and 75%, respectively. In the extra-low permeability core L352-5 and the ultra-low permeability core L49-3, the recovery degrees of crude oil in the mesopores and macropores were more than 83%, which are consistent with the results obtained by Gao

In the low permeability core Z55-2 after waterflooding, 50% of the remaining oil was distributed in the mesopores, and 29% and 21% of the remaining oil were distributed in the micropores and macropores, respectively. In the extra-low permeability core L352-5 and the ultra-low permeability core L49-3, the remaining oil was primarily distributed in the micropores (more than 85%), and a small amount was present in the mesopores (less than 10%) and macropores (less than 2%). In addition, the signal amplitude of the T2 spectral curves of the three reservoir cores exhibited increase of some extents in the pores with T2 of less than 1 ms or pore radii of less than 1 μm after waterflooding (Figs. 5-7), especially in the low permeability reservoir core. Similar results were observed by Wei

To further observe the oil-water distribution characteristics in the pores, waterflooding experiment was carried out on an ultra-low permeability reservoir core L60-1 with a porosity of 10.732% and a permeability of 0.101× 10-3 μm2 taken from the Chang 6 Member of the Wuliwan area by using the Micro-CT scanner at the State Key Laboratory in Southwest Petroleum University. The oil-water distribution in the three-dimensional space during the waterflooding experiment was obtained. The experimental fluids were the same as those used in the NMR-based core waterflooding experiment, but 10% n-iodobutane was added to shield the oil signal. The main steps of the experiment were as follows: (1) 3D CT images of the dry cores were obtained. (2) The irreducible water saturation state of the core was established and the core was aged for 15 d; subsequently, 3D CT image scanning was performed to obtain the oil-water distribution in the core under irreducible water saturation state. (3) The waterflooding experiment was performed at a constant pressure of 0.5 MPa. The experiment was stopped when the water cut reached 99%, and 3D CT image scanning was performed to obtain the remaining oil distribution in the core.

Taking the CT scan data of the dry core and the core under irreducible water saturation state as the reference, the oil-water distribution in the core before and after the waterflooding (Fig. 12) and frequency distribution of the oil phase in the pore space at different states (Fig. 13) were obtained with the Avizo software. After waterflooding, the continuous oil phase in the mesopores- macropores of the core L60-1 became oil droplets remaining at the blind end of the pore space or oil film adsorbed on the particle surface, showing discontinuous oil phase characteristics, this is consistent with the distribution pattern of crude oil in the ultra-low permeability reservoir core observed in two dimensions (Fig. 4b). The NMR response of the discontinuous phase of oil film and oil droplet corresponds to short relaxation time, which in turn results in the illusion of increased NMR signals and more remaining oil in the micropores. This is why the oil content in micropores on T2 spectral curve seems to increase without any actual increase in the crude oil in the micropores. Further investigations are required to objectively distinguish this "false appearance" signal from the NMR curves.

Fig. 12.

Fig. 12.

Oil-water distributions in different parts of the same slice of core L60-1 before and after waterflooding.

Fig. 13.

Fig. 13.

Distribution frequency of oil phase in core L60-1 under different states.

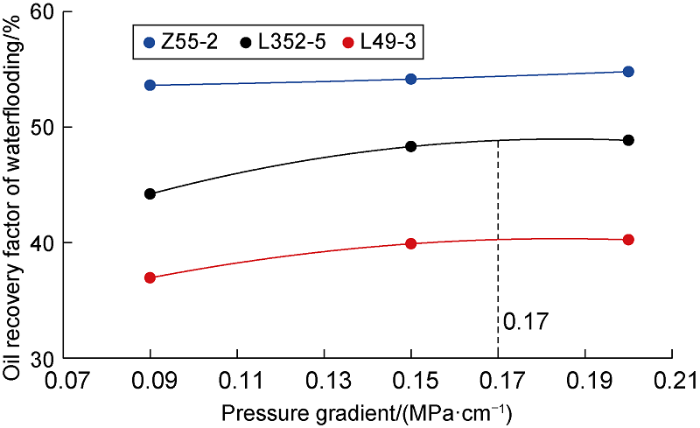

3.3. Effect of displacement pressure and microstructure on the oil recovery factor

Based on the oil occurrence characteristics under the irreducible water saturation state and after displacements at different pressures, the oil recovery factors at different displacement pressures were calculated (Fig. 14). Owing to the better pore connectivity of the low permeability reservoir core Z55-2, the waterflooding in this core had smaller flow resistance to the injected water, larger sweeping area and thus higher oil recovery factor (on average 54.2%). In comparison, the average oil recovery factors of the extra-low permeability core L352-5 and ultra- low permeability core L49-3 were 47.13% and 39.03%, respectively. Compared with the low permeability core, the extra-low permeability core has poorer pore structure, so multiple injection water lines alternating with each other appeared during waterflooding, some of the poorly connected micropore clusters were bypassed by the injection water, leaving contiguous remaining oil blocks. The ultra-low permeability core has the worst pore structure and strongest heterogeneity, so the oil phase snapped off easily during waterflooding[21], disrupting the continuous flow of the oil phase, increasing the flow resistance of the injected water, and leading to fast advancement of the injected water along channels with lower flow resistance and smaller sweeping area of the injected water.

Fig. 14.

Fig. 14.

Variations of oil recovery factor with pressure gradient during waterflooding.

Comparison also shows that the low permeability reservoir core Z55-2 had a quite high oil recovery factor at an initial pressure of 400 kPa (pressure gradient of approximately 0.09 MPa/cm), and the oil recovery factor hardly changed with the increase in pressure gradient (Fig. 14). In contrast, for the extra-low permeability core L352-5 and ultra-low permeability core L49-3, the oil recovery factor gradually increased with the increase of pressure gradient. As the pressure gradient increased from 0.09 MPa/cm to 0.17 MPa/cm, the oil recovery factor increased significantly by more than 3%. The oil recovery factor hardly changed with further increase of the displacement pressure gradient. This phenomenon indicates that during the initial stage of the waterflooding experiment (at pressure gradient below 0.17 MPa/cm) of these cores, the sweeping area of the injection water gradually increased with the increase of the displacement pressure gradient, and the oil recovery factor enhanced. In contrast, during the later stage of the waterflooding experiment (at pressure gradient higher than 0.17 MPa/cm), only the flow velocity of the injected water in the flow channel increased with the increase of the displacement pressure gradient.

According to the definition of capillary pressure, when the displacement pressure (or pressure gradient) is higher than the capillary pressure of the corresponding pore, crude oil can be produced from smaller pores. In the low permeability core, the crude oil was primarily distributed in the mesopores-macropores with good sorting, and the micropores contained only 6% of the crude oil. Although more oil can be produced from the micropores by increasing the displacement pressure gradient, its contribution to the total oil recovery factor is insignificant. Thus, the oil recovery factor of the low permeability core does not change significantly with the increase of the displacement pressure gradient. In contrast, in the extra-low permeability and ultra-low permeability cores, the crude oil in micropores accounted for 48% and 61%, respectively, and the crude oil in macropores accounted for 9% and 2%, respectively. This implies that more crude oil can be displaced by increasing the displacement pressure gradient. However, as the extra-low permeability and ultra-low permeability reservoir cores are poor in pore structure, the oil recovery factor did not increase significantly. Moreover, it is found through this study that the step-by-step increase of displacement pressure can’t eliminate the formation of dominant flow channels formed by the injected water at the initial pressure. Therefore, further investigations are needed to better understand the effect of displacement pressure on crude oil production degree under the same other conditions (e.g., similar permeability and saturation).

4. Conclusions

Under the irreducible water saturation state, the crude oil in the low permeability reservoir core was primarily uniformly distributed in the mesopores-macropores, whereas the crude oil in the extra-low permeability and ultra-low permeability reservoir cores was primarily non-uniformly distributed in micropores and mesopores. During waterflooding of the three types of oil-wet reservoir cores, the injected water preferentially produced crude oil in the mesopores-macropores, and the recovery degrees of crude oil in mesopores-macropores of the extra-low permeability and ultra-low permeability reservoir cores were higher. The permeability and pore structure of the cores have a significant effect on the type of waterflooding and remaining oil morphology. As the cores became lower in permeability and poorer in pore structure, the displacing type turned from uniform displacement to network displacement, then to finger displacement; and the remaining oil gradually changed from angular and membrane-like dispersed phase to contiguous phase and even to a continuous patchy phase. After waterflooding, the oil film and oil droplets of the discontinuous phase in the macropores corresponded to short relaxation time in the NMR response. This resulted in an increase of the NMR signal in the micropores and a false outcome that the amount of remaining oil in the micropores increased. The displacement differential pressure did not have a significant effect on the oil recovery factor of waterflooding of low permeability reservoir core, whereas for the extra-low permeability and ultra-low permeability reservoir cores, the oil recovery factor increased with the increase of displacement differential pressure.

Nomenclature

C—conversion coefficient, ms/μm;

D—diffusion coefficient of the fluid, cm2/ms;

Ec—oil recovery factor calculated by the production data, %;

ENMR—oil recovery factor calculated by the NMR data, %;

Er—recovery degree, %;

Fr—pore shape factor, dimensionless;

G—gradient of the magnetic field, G/μm;

m(ri)oi—NMR signal amplitude of crude oil before displacement in the i-th pore interval;

m(ri)ori—NMR signal amplitude of crude oil after displacement in the i-th pore interval;

m(T2)oi—NMR signal amplitudes corresponding to different relaxation times under irreducible water saturation state;

m(T2)or—NMR signal amplitudes corresponding to different relaxation times after water flooding;

r—pore radius, μm;

ri,min—the minimum pore radius corresponding to a certain pore interval, μm;

ri,max—the maximum pore radius corresponding to a certain pore interval, μm;

S—pore internal surface area, μm2;

TE—echo spacing time, μs;

Toi—total NMR semaphore under the irreducible water saturation state, dimensionless;

Tor—total NMR semaphore after waterflooding, dimensionless;

T2—transverse relaxation time, ms;

T2B—bulk relaxation time, ms;

T2D—diffusion relaxation time, ms;

T2S—surface relaxation time, ms;

T2,max—the maxium transverse relaxation time, ms;

V—rock pore volume, μm3;

Vo—oil production from the rock, mL;

Voi—oil content in the core, mL;

Vw—water production, mL;

γ—the gyromagnetic ratio of hydrogen nucleus, MHz/T;

ρ2—the surface relaxation ability, μm/ms.

Reference

Fluid seepage characteristics of permeability reservoirs based on real sandstone microscopic water flooding experiments: Taking Chang 6 reservoir of Wangpanshan in Ji-yuan Oilfield as an example

Experimental study on micro-flow channel and displacement characteristic of ultra-low permeability sandstone reservoir: Taking Yanchang Formation, Ordos Basin as example

A study of characteristics of low permeability formation with water flooding using micromodel experiment

Analysis on the water-drive mechanism and development results of Ansai supertight oil field after water-occurrence

Effect of heterogeneity on water producing of ultra-low permeability oil reservoir: An experimental study

Discussion on the research of remaining oil

Tests and numerical simulation for microscopic waterflooding in sandstone reservoirs

Main controls for oil displacement efficiency by the micro-model water flooding experiment in ultra-low permeability sandstone reservoir

Microscopic water flooding characteristics and influencing factor in extra-ultra low permeability reservoirs: A case study of Chang 6 and Chang 8 reservoirs in Heshui area of the Ordos Basin

Two-phase displacement experiment of sandstone micro-porosity model

A visual study on the mechanism of surfactant/polymer flooding a micro-layered sandstone

Experimental study on gas-water two phase flow and confined gas formation mechanism

Visual experimental study on oil-water two-phase flow and residual oil distribution

Study on microscopic mechanism of changing displacement direction in low-permeability reservoirs

Study on microemulsion flooding mechanism for the residual oil in low-permeability reservoirs

Effects of the microscopic pore structure heterogeneity on the distribution and morphology of remaining oil

Quantitative research on tight oil microscopic state of Chang 7 member of the Triassic Yanchang Formation in the Ordos Basin, NW China

Effect of pore structure on displacement efficiency and oil-cluster morphology by using micro computed tomography (μCT) technique

DOI:10.1016/j.fuel.2018.05.058 URL [Cited within: 1]

Tight oil occurrence space of Triassic Chang 7 Member in Northern Shaanxi Area, Ordos Basin, NW China

Determination of residual oil distribution during waterflooding in tight oil formations with NMR relaxometry measurements

DOI:10.1021/ef400631h URL [Cited within: 3]

Effect of displacement rates on fluid distributions and dynamics during water flooding in tight oil sandstone cores from nuclear magnetic resonance (NMR)

DOI:10.1016/j.petrol.2019.106588 URL [Cited within: 6]

Characterization of pore structure of low permeability reservoirs using a nuclear magnetic resonance method

Experiment of microscopic water displacement mechanism based on NMR displacement technology in ultra-low permeability sandstone

Experimental study of active pore distribution during water driving by using NMR.

Pore-scale analysis of gas huff-n-puff enhanced oil recovery and waterflooding process

DOI:10.1016/j.fuel.2017.11.033 URL [Cited within: 2]

A new method for predicting oilfield production change: Residual recoverable reserves oil production velocity method

Reservoir simulation of remaining oil distribution based on time-variant reservoir model

Study on the development law for different types of reservoirs in Changqing Oil Field

Reservoir characteristics changes in waterflooding development

Methods for calculating pore radius distribution in rock from NMR T2 spectrum

Analysis on the influencing factors of imbibition and the effect evaluation of imbibition in tight reservoirs

DOI:10.1016/S1876-3804(19)60231-4 URL [Cited within: 1]

Water- drive mechanism with nuclear magnetic resonance technology