Introduction

The horizontal well pattern has been widely used in the reservoir development. Compared with vertical wells, horizontal wells can greatly increase the contact area between the well and the reservoir, thereby expanding the drainage area and improving production and recovery. In the case of the same reservoir with the same physical properties and production, the production pressure difference of horizontal wells is significantly lower than that of vertical wells[1,2]. For reservoirs with sufficient formation energy due to active edge and bottom water, horizontal well development can effectively delay edge and bottom water coning[3]. Horizontal wells have high injection capacity and can be used to achieve a high injection rate at low injection pressure, thus improving oil displacement efficiency. When the horizontal well pattern is used for water injection development, the linear or staggered well pattern is usually adopted[4]. Some carbonate reservoirs in the Middle East have been developed by waterflooding in the way of bottom-injection and top-production with overall horizontal well patterns, which have achieved good results[5,6]. However, with the continuous development of water injection, dominant flow channels are easily generated between injection wells and production wells with this kind of well pattern, resulting in an ineffective circulation of injected water. There is still a large amount of remaining oil which has not been effectively swept in the reservoir[7,8,9,10,11]. How to retard water breakthrough and produce effectively the remaining oil between horizontal wells has become a major challenge to the long-term stable production of medium-thin layer and low permeability carbonate reservoirs in the Middle East. For vertical well pattern, the water injection development effect can be improved through perforation, water blocking and profile control. However, once the water breakthrough occurred in horizontal well pattern, the adjustment method is very limited.

At present, linear waterflooding horizontal well pattern with small well spacing, small row spacing, long horizontal section, parallel correlation, heel-toe reverse, and bottom-injection and top-production has been developed in some medium-thin layer and low-permeability carbonate reservoirs in the Middle East, due to undeveloped interlayers, such as Daleel Oilfield in Oman and Ahadeb Oilfield in Iraq. In the early stage of development in linear horizontal well pattern, the energy replenishment is fast, the production decline is slow, and the injecting-production streamline is mainly perpendicular to the horizontal section. However, when the reservoir heterogeneity is serious, such as the carbonate reservoir in the Middle East, the dominant flow channel between the injection well and production well in the middle and late stage of water injection development leads to the phenomenon of a rapid increase in water cut and ineffective circulation of injected water in the production well after water breakthrough. Meanwhile, the length of horizontal wells in carbonate reservoirs in the Middle East is more than 800 m, and the long horizontal section causes toe-end effect. That is, poor water absorption at the toe-end of the injection well and poor fluid production at the toe-end of the production well, resulting in strip flooding in the horizontal section of the production well, and a large amount of remaining oil at the toe-end of the horizontal well.

Currently, the researches on water injection development of horizontal wells mainly focus on the theoretical analysis of horizontal well production mechanism, productivity prediction, and injection-production parameter optimization[12,13,14]. In addition, the deployment of the well pattern at the early stage of development and water injection development technology of combined well pattern with horizontal wells and vertical wells has also been studied widely[15]. For the mature oil fields that have been exploited by horizontal wells for many years, measures and adjustment of injection and production parameters have limited effect on the improvement of water injection development effect, while further infill well pattern requires a large amount of economic cost. How to make full use of the original linear horizontal well pattern to improve oil recovery is a technical problem to be solved urgently. In this study, a method is proposed to change the linear waterflooding horizontal well pattern into cyclic alternating water injection well pattern by adjusting the water injection strategy, so as to change the injection-production streamlines, improve the waterflooding volumetric sweep efficiency, and thus realize oil stabilization, control water cut, and enhanced oil recovery factor. This technique has been applied to carbonate reservoirs in the Middle East and good pilot results have been achieved.

1. Cyclic alternating water injection technology for horizontal well pattern

After long-term water injection development of linear horizontal well pattern, the streamlines are perpendicular to the horizontal section of horizontal wells between most injection wells and production wells. The single direction of injection-production streamline leads to high water cut in production wells and low reservoir recovery. In order to solve the above problems, the original linear horizontal well pattern is changed into a cyclic alternating water injection well pattern by adjusting the water injection strategy. According to different injection-production strategies and well pattern transition, the following three alternating modes can be selected: apparent inverted seven-spot well pattern, apparent five-spot well pattern, and cyclic differential alternating water injection. In addition, the numerical simulation method is used to determine the optimal alternating injection-production parameters according to the characteristics of each reservoir. According to the characteristics of carbonate reservoirs and well spacing in the Middle East, the alternating cycle of alternating water injection is generally set to 60-180 d, in which each cycle is divided into the first and second half cycle.

1.1. Alternate waterflooding with apparent inverted seven-spot well pattern

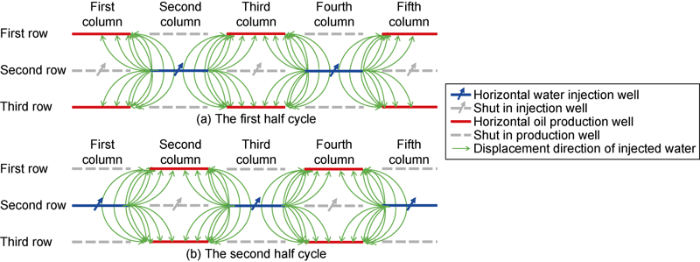

In the first half cycle of alternating water injection by the apparent inverted seven-spot well pattern method, the injection wells in odd columns are closed and the water injection rate of the even sequence water injection wells is increased to ensure that the water injection rate of the whole well group during the alternating water injection is consistent with that before. The liquid production rate of even-numbered production wells is reduced, and the liquid production rate of odd-numbered production wells is increased, so as to ensure that the liquid production rate of the whole well group during the alternating water injection is consistent with that before. As a result of the adjustment, most of the injected water flowed to the odd-numbered production wells in the first half cycle, so the direction of some of the original streamline is changed (Fig. 1a). In Fig. 1 it can be seen that for the injection-production wells group with 5 columns and 4 rows, the injection wells in columns 1, 3, and 5 are closed, and the injection rate of the injection wells in columns 2 and 4 is increased. All production wells should be kept open and production should be performed according to the adjusted production parameters. Under such a water injection network, the injected water will displace oil to the surrounding six production wells through the water injection wells in row 2, columns 2 and 4, forming an apparent inverted seven- spot well pattern. The injection-production streamlines between the injection wells and the two directly opposite production wells remain perpendicular to the injection well's horizontal section, while new streamlines with a certain angle with the horizontal section of the injection wells are generated between the injection well and the production wells on both sides of the injection wells, which change the direction of the injection-production streamline, with better sweep efficiency on the remaining oil that cannot be displaced at the heel-end or toe-end of the horizontal wells in the original injection-production well pattern.

Fig. 1.

Fig. 1.

Schematic diagram of streamline of alternating water injection with apparent inverted seven-spot well pattern.

In the second half cycle, the even-numbered injection wells are closed and the water injection of the odd-numbered injection wells are increased; meanwhile the liquid production rate of the odd-numbered production wells are reduced, and the liquid production rate of the even-numbered production wells are increased to ensure the injection rate during alternating water injection period is the same as that before the alternating. As shown in Fig. 1b, for the injection-production well group with 4 rows and 5 columns, the injection wells in columns 2 and 4 are closed, and the injection wells in columns 1, 3, and 5 that have been stopped before are reopened, and the injection rate of the injection wells and the liquid production rate of the production wells are adjusted. In the second half cycle, apparent inverted seven-spot well pattern is still formed by the injection wells in row 2, column 3 and the surrounding 6 production wells. The streamlines between the open water injection well and the directly opposite two production wells are still perpendicular to the direction of the horizontal well, but the streamline direction between the water injection wells and the production wells on both sides changes significantly compared with that of the first half cycle. For example, between row 1 and row 2, the injected water flows from right to left in the first half cycle, while in the second half cycle, the water flow direction is from left to right, so that the same area is displaced by two different directions of injection streamline in the same alternating injecting-production cycle. This water injection strategy ensures that the remaining oil can be fully and continuously displaced, while avoiding the long-term flushing of injected water along the same channel to form a dominant channel, and the ineffective circulation of injected water in the formation, so as to further improve the waterflooding efficiency.

In accordance with the above steps, the parameters are adjusted for periodic circulation, and the effect of well pattern alternating water injection is tracked and evaluated at the same time. If the development effect for three consecutive cycles is worse than the development prediction effect of the original linear well pattern injection-production, the alternating water injection will be stopped and water injection of the previous linear well pattern mode will be reused. In a particular development, the first and second half-cycles can be switched.

1.2. Alternating water injection with apparent five-spot well pattern

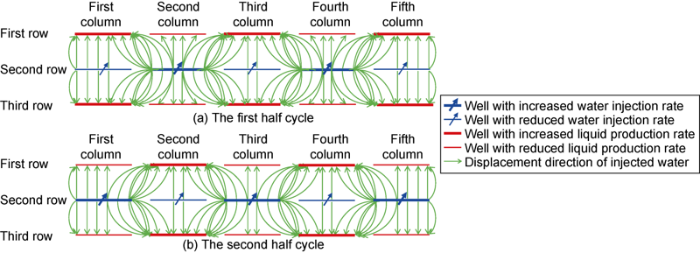

In the first half cycle of alternating water injection with apparent five-spot well pattern, the odd-sequence injection wells and even-sequence production wells are closed. In the second half cycle, the even sequence injection wells and the odd sequence production wells are closed, and the odd sequence injection wells and even sequence production wells are reopened to achieve the development effect of the five-spot injection-production well pattern (Fig. 2). During the whole cycle, the water injection rate and liquid production rate of individual well are increased, and the injection-production ratio of the entire well group remains consistent with that before the alternating water injection of the well pattern. Through adjustment, the direction of injection streamlines is changed. Since the production wells directly opposite to the injection wells are closed, the injection water will flow to the production wells on both sides. There are no injection-production streamlines perpendicular to the horizontal section of the injection wells between the injection and the production wells, but new oblique streamlines are generated. At this time, the flow direction of the fluid has a certain angle with horizontal wells. The remaining oil retention area between the injection and production wells in the original linear horizontal well pattern is also well displaced. Under this injection water well pattern, injected water from each injection well will flow to four surrounding production wells, forming an apparent five- spot well pattern. The injection-production well spacing of apparent five-spot well pattern is extended compared with the origin linear well pattern, delaying the water cut increase rate of a horizontal well, resulting in alternate displacement of the same area by two water injection streamlines in different directions in the same period.

Fig. 2.

Fig. 2.

The schematic diagram of alternating injection-production streamline of five-spot well pattern.

1.3. Cyclic differential alternating water injection

The cyclic differential alternating water injection is achieved by periodically adjusting the injection rate of injection wells and the liquid production rate of production wells. In the first half cycle, the water injection rate of the even-numbered injection wells is increased, and the water injection rate of the odd-numbered injection wells is decreased. Meanwhile, the production rate of the odd-numbered production wells is increased, and the production rate of the even-numbered production wells is decreased. In the second half cycle, the water injection rate of odd-numbered injection wells and the liquid production rate of even-numbered production wells is increased, the water injection rate of even-numbered injection wells and the liquid production of odd-numbered production wells is reduced. After parameter adjustments, the water injection rate and liquid production rate of the entire well group are still consistent with that before. The streamlines after cyclic differential alternating water injection have the superimposed effect of the apparent inverted seven-spot well pattern and the linear waterflooding pattern (Fig. 3). The same area in the same period is flooded by streamlines from two different directions which achieves the effect of changing the flow direction.

Fig. 3.

Fig. 3.

Schematic diagram of periodic differential alternating injection-production streamline of well pattern.

2. Different well pattern alternation

2.1. Davantages/disadvantages of different well patterns

By periodic and differential adjustment of well status and development parameters, the alternating water injection changes the direction of injection-production streamlines fixed by the original linear well pattern. The adaptability, advantages, and disadvantages of three different types of alternating injection-production well patterns are discussed as follows.

The production wells are shut down during the implementation of alternating water injection with apparent inverted seven-spot well pattern, and the total fluid production rate is maintained as that before the alternating, so the output after the alternating is guaranteed. However, due to the need to close half of the injection wells, while greatly injection rate increasement of other half of the injection wells, the injectivity of the injection wells is required to be higher. In addition, after greatly increasing the water injection rate of open water injection wells, if there is a dominant channel between the water injection wells and the directly opposite production wells, the possibility of rapid water breakthrough of production wells increases significantly, which limits the effect of alternate water injection to a certain extent.

Inclined streamlines are formed between injection and production wells by alternating water injection with apparent five-spot well pattern, which solves the problem of rapid water breakthrough caused by vertical streamline in apparent inverted seven-spot well pattern. Therefore, the water cut of the well group after alternating water injection with apparent five-spot pattern will generally decrease significantly. Theoretically, the water cut reduction is greater than that of alternating water injection with apparent seven-spot well pattern. At the same time, the adjustment range of injection-production parameters of the well pattern is less than that of apparent inverted seven-spot well pattern, which can be implemented in any reservoir. However, since half of the injection wells and production wells should be shut down during implement of alternating water injection, when the increasement of production caused by the reduction of water cut cannot compensate for the production loss caused by the shut-down, it will have a certain impact on the production of the whole well group in the short term, especially when the liquid production of the production wells cannot be increased as required.

The cyclic differential alternating water injection avoids the possibility of rapid water breakthrough of production wells with the apparent inverted seven-spot well pattern and the possibility of short-term production loss with the apparent five-spot well pattern. Moreover, this kind of well pattern has the lowest adjustment range for injection and production parameters and can be implemented in any reservoir. However, due to the periodically small adjustment of injection-production parameters, the streamline variation between injection and production wells is weaker than the other two well patterns.

2.2. Areal sweep efficiency of different well patterns

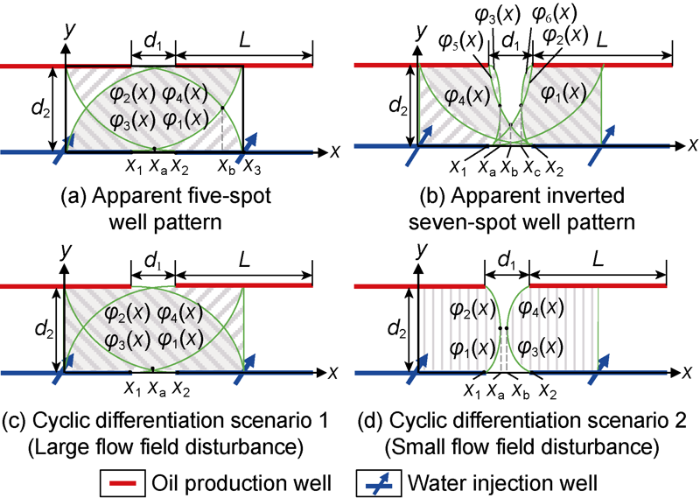

The areal sweep efficiency (EA) is an important index to measure the areal waterflooding effect of different injection-production well pattern. For a homogeneous single-layer reservoir, the areal sweep efficiency (EA) can be defined as the ratio of waterflooding area of well group to the controlled area of the well group. Taking 1/4 injection-production unit of different alternating well patterns as the research object, the plane rectangular coordinate system is established (Fig. 4). The shadow part in the first quadrant is the maximum swept area of the injection-production unit in the whole water injection cycle. According to the principle of the integral, the formulas for calculating the maximum swept area of 1/4 injection-production unit of alternating well pattern with apparent five-spot well pattern and apparent seven-spot well pattern method are as follows:

Fig. 4.

Fig. 4.

Schematic diagram of areal sweep in the full cycle of the 1/4 injection-production unit with different alternating well patterns.

There are two cases for cyclic differential alternating water injection well patterns. When the flow field disturbance caused by the periodic adjustment of injection-production is large, the oblique streamlines generated by the well pattern can spread to the adjacent production wells (Fig. 4c). However, when the flow field disturbance is small, the sweep range of the oblique streamlines generated by the well pattern is limited, and it is difficult to sweep the adjacent production wells (Fig. 4d). The formulas for calculating the maximum swept area of 1/4 injection-production unit of the periodic differential alternating well pattern in the two cases are:

The formula for calculating the areal sweep efficiency of each alternating well pattern is:

The above formulas are used to calculate the maximum theoretical EA of linear well pattern, apparent inverted seven-spot well pattern, apparent five-spot alternating well pattern, cyclic differential alternating well pattern with small flow field disturbance and large flow field disturbance, respectively, which are 85.31%, 90.25%, 90.38%, 86.03%, and 98.74%. Compared with the linear well pattern, the three types of alternating well pattern effectively expand the sweep efficiency, in which the apparent inverted seven-spot and apparent five-spot well pattern increase the area sweep efficiency by about 5%. The theoretical areal sweep efficiency of the cyclic differential alternating well pattern is related to the adjustment range of injection and production, which increases by 0.72%-13.4%. Notably, the calculated values obtained by the theoretical formula represent the areal sweep of homogeneous reservoirs and have certain universality, reflecting the general sweep situation and improvement effect of different alternating well pattern.

In summary, cyclic differential alternating water injection is the easiest to implement, and the adjustment range is the smallest. Alternating water injection with apparent inverted seven spot well pattern shuts down injection well periodically, which requires high injection capacity and moderate adjustment range. According to the apparent five-spot well pattern, the injection and production wells are switched periodically, therefore the adjustment range is large, and the expected reduction of water cut is the largest. However, due to the need to close half of the production wells, the production of the well group may decrease in the short term.

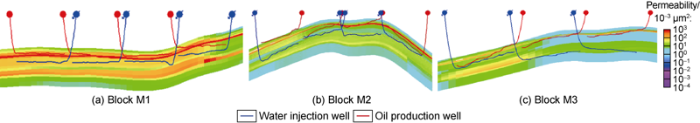

3. Comparison of simulations with different well patterns in typical blocks

The M Oilfield is located in Iraq in the Middle East, and the main reservoir is a medium-thin carbonate reservoir. The vertical heterogeneity is serious, and the high permability zone with thickness of about 1 m exists in the top. The reservoir is developed by the integral linear well pattern of horizontal wells. At present, part of the well pattern has entered a high water cut period. The high permeability zone at the top is the main reason for the rapid water breakthrough and high water cut of production wells. Three typical high water cut blocks in the oilfield are selected (Fig. 5) to conduct the numerical simulation of alternating water injection with apparent inverted seven-spot well pattern, apparent five-spot well pattern and cyclic differentiation for each well group, and the development effect are compared with that of the original linear well pattern.

Fig. 5.

Fig. 5.

Permeability and horizontal well trajectory profiles of geological model in three typical blocks.

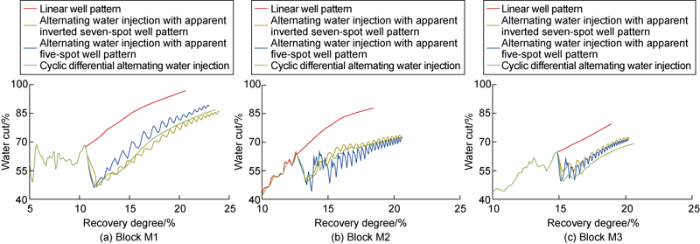

The reservoir numerical simulation models have been established for three typical blocks of M oilfield in the Middle East. The horizontal well length of each block is 800 m, the injection-production well spacing is 300 m, the horizontal grid step length of the model is 100 m and 40 m, and the vertical grid step length is 0.5-6.0 m. The basic geological parameters of each block are shown in Table 1. Among them, the reservoir property of M1 block is the best, the reservoir property of M2 block is medium and the heterogeneity is the strongest, and the reservoir property of M3 block is the worst. By comparing the numerical simulation results of each block, the water cut by the alternating water injection with three sets of different well patterns is obviously reduced compared to the original linear well pattern, and the oil recovery is increased which mean the water injection development effect is significantly improved. The prediction results of alternating water injection of apparent inverted seven- spot well pattern in Block M1 are better (Fig. 6a). The analysis shows that the block has best physical properties and the weakest heterogeneity. The geological conditions of the model can meet the requirements of alternating water injection of apparent inverted seven- spot well pattern for high injection rate of open injection wells,without affecting the total production rate after alternation. In addition, the injection rate of the injection wells with apparent inverted seven-spot well pattern has the largest variation range and the maximum strength at the injection side, therefore the disturbance effect is the largest due to the homogeneity of the reservoir, so the development effect is good. The prediction results of apparent five-spot well pattern in Block M2 are the best (Fig. 6b). The analysis shows that the heterogeneity of the block is serious, and the water cut shows a rapid upward trend before alternating water injection. Therefore, the water cut decreases the most after the implementation of apparent five-spot well pattern when shut down half of the production wells alternately. At the same time, due to the good physical properties of the block, the increase of production caused by the reduction of water cut can compensate for the production loss caused by well shutdown, and the development effect is the best at this time. The results of cyclic differential alternating water injection in M3 block are the best (Fig. 6c). The analysis shows that the physical properties of the block are poor and the heterogeneity is medium. The cyclic differential alternating water injection can better maintain the injection and production rate of the whole well group, so the adjustment effect is better. At the same time, due to the poor reservoir physical properties, the single-well water injection rate of apparent inverted seven-spot well pattern and the injection and production rate of apparent five-spot well pattern cannot be increased by a corresponding multiple according to the demand, resulting in the development effect not as good as the cyclic differential alternating water injection. In addition, compared with the simulation results of three blocks, it can be seen that the simulation results of cyclic differential alternating water injection are relatively good. In conclusion, alternating water injection with apparent inverted seven-spot well pattern has the best adaptability to reservoirs with good physical properties, serious water absorption capacity and weak heterogeneity. The alternating water injection with apparent five- spot well pattern has the best adaptability to the reservoir with serious heterogeneity, especially in the development stage of high to ultra-high water cut with moderate physical property preference. Cyclic differential alternating water injection has good adaptability to various reservoirs, especially low permeability reservoirs.

Table 1 Basic geological parameters of 3 typical blocks.

| Block | Reservoir thickness/m | Average permeability/10-3 μm2 | Permeability range |

|---|---|---|---|

| M1 | 18.19 | 149 | 102.41 |

| M2 | 18.95 | 84 | 208.28 |

| M3 | 17.53 | 10 | 168.54 |

Fig. 6.

Fig. 6.

Comparison of numerical simulation development effects with different alternating well patterns in three blocks.

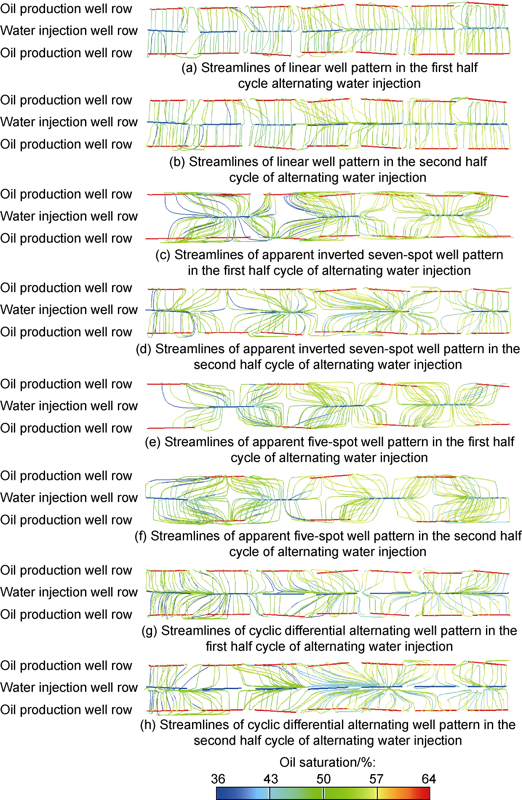

With the numerical simulation results of the M2 block as an example, it can be seen that the numerical simulation flow diagram is in good agreement with the conceptual diagram (Figs. 1-3) of well pattern streamlines (Fig. 7). The streamlines of the original linear well pattern are mainly in the direction perpendicular to the horizontal well section, while the alternating water injection of three different types of well patterns generates oblique streamlines with a certain angle to the horizontal section of the injection well, so that the remained oil between the injection and production wells of the original linear well pattern is well displaced, and the waterflooding sweep efficiency is significantly improved. The injection-production streamlines of alternating water injection in apparent inverted seven-spot well pattern have both vertical streamline and oblique streamline, which change in the first and second half cycle. The injection-production streamlines of the first and second half cycle of alternating water injection in apparent five-spot well pattern are all oblique streamlines. When compared with the other two types of well pattern, cyclic differential alternating water injection has a sparse distribution of streamlines and a relatively small range of variation, and some oblique injection-production streamlines play a role in converting the fluid flow direction. The numerical simulation results of streamline show that the direction of streamline all changes in the three types of well patterns of alternating water injection compared to the original linear well pattern. The same area is displaced by streamlines of two different directions in one alternating cycle, and there are differences in the changes of streamlines in different well patterns. The maximum volume sweep efficiency of each well pattern in the first and second half cycle is calculated by the tracer technology in streamline numerical simulation, which is 75.31% and 79.74% for linear well pattern, 84.39% and 87.25% for apparent inverse seven-spot pattern is, 86.88% and 89.18% for apparent five-spot pattern, and 84.94% and 87.85% for the cyclic differential alternating water injection. It can be seen that the sweep efficiency of three types of alternating well pattern is greater than that of the linear well pattern, and the sweep area also changes significantly. Among them, the sweep efficiency of alternating water injection with apparent five-spot well pattern is the highest, and the development effect is the best. In addition, the reservoir heterogeneity of the actual block model in M oilfield is serious and there are high permeability zones. The simulated volume sweep efficiency is different from the theoretical calculation of the plane sweep efficiency. The reasons include: (1) The volume sweep efficiency is equal to the product of the plane sweep efficiency and the vertical sweep efficiency, and the difference is partly caused by the vertical sweep efficiency. (2) In the actual streamline simulation, effective sweep is identified when the water saturation or over-water multiple reach a certain value, that is, the statistical results of numerical simulation are affected by the reference threshold. For example, the minimum adjustment of injection-production parameters in cyclic differential alternating water injection leads to a small change in the injection-production streamlines. Some streamlines do not reach the limitation of the reference threshold for effective sweep, so the simulated calculation value of the sweep efficiency of the well pattern is small.

Fig. 7.

Fig. 7.

Streamline simulation results of different alternating water injection patterns in block M2 (The streamline shown in the figure is the plane top view of three-dimensional streamline of different layers).

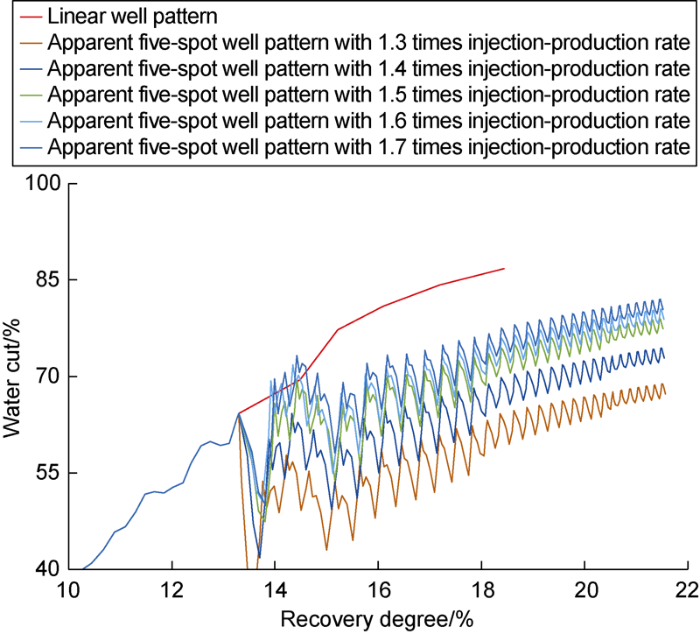

The injection-production parameters of the optimal well pattern are optimized based on the three-block models. Taking alternating water injection with apparent five-spot well pattern of in M2 block as an example, the water injection rate of the injection well and the liquid production rate of the production well during well opening are respectively increased to 1.3-1.7 times that before the alternating water injection. The numerical simulation and prediction results are shown in Fig. 8. It can be seen that with the increase of the injection and production rate, the reduction of the water cut decreases. When injection-production rate increases to greater than 1.5 times, the increase of injection and production will have slight influence on the simulation results. At the same time, taking account of the limitation of injection capacity of an injection well in the actual reservoir and the limitation of the reasonable working range of the pump, it is suggested that the reasonable multiple of injection and production adjustment should be less than 1.5 for the M2 block according to apparent five-spot well pattern of alternating water injection well pattern. Similarly, the optimal injection and production parameters during alternating water injection of other blocks can be obtained (Table 2).

Fig. 8.

Fig. 8.

Development effect of the five-spot well pattern in M2 block under different injection-production parameters.

Table 2 Adjustment and optimization of injection-production parameters of different alternating well patterns.

| Block | Alternating well patterns | Injection- production well | Daily injection and production rate in the first half cycle (30 days) | Daily injection and production rate in the second half cycle (30 days) | ||

|---|---|---|---|---|---|---|

| Odd-numbered columns | Even-numbered columns | Odd-numbered columns | Even-numbered columns | |||

| Block M1 | Inverted seven-spot alternating water injection | Production well | Increase to 1.2-1.4 times liquid production rate | Decrease to 0.6-0.8 times liquid production rate | Decrease to 0.6-0.8 times liquid production rate | Increase to 1.2-1.4 times liquid production rate |

| Injection well | Shut down | Increase to 2 times water injection rate | Increase to 2 times water injection rate | Shut down | ||

| Block M2 | Five-spot alternating water injection | Production well | Increase to 1.0-1.5 times liquid production rate | Shut down | Shut down | Increase to 1.0-1.5 times liquid production rate |

| Injection well | Shut down | Increase to 1.0-1.5 times water injection rate | Increase to 1.0-1.5 times water injection rate | Shut down | ||

| Block M3 | Periodic differential alternating water injection | Production well | Increase to 1.2 times liquid production rate | Decrease to 0.8 times liquid production rate | Decrease to 0.8 times liquid production rate | Increase to 1.2 times liquid production rate |

| Injection well | Decrease to 0.5 times water injection rate | Increase to 1.5 times water injection rate | Increase to 1.5 times water injection rate | Decrease to 0.5 times water injection rate | ||

4. Case study

Since 2018, well group pilots have been carried out on three types of well pattern of cyclic alternating water injection in M oilfield of Middle East, and the effect of well groups that implemented alternative water injection tests was also analyzed.

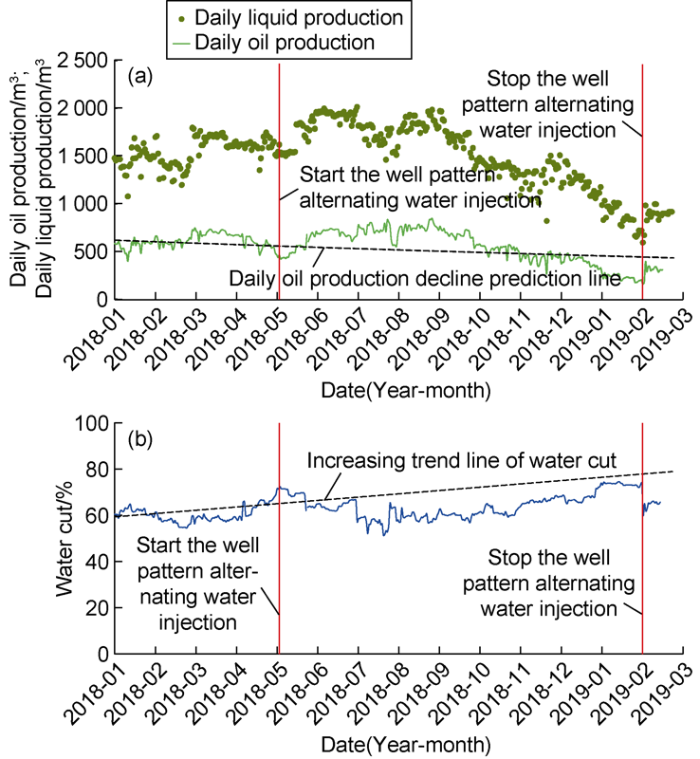

4.1. Alternating water injection test of well groups

The pilot well group of alternating water injection with apparent inverted seven-spot well pattern consists of 8 production wells in 2 rows and 4 injection wells in 1 row, and the water cut of each production well is above 60%. The alternating period of alternating water injection is 60 d. Due to the intermittent opening of injection wells, the injection allocation of an individual well is about twice the original one. The well group began to implement alternating water injection in May 2018. After implementation, the daily oil production firstly increased and then decreased, with a maximum increase of about 30%. The comprehensive water cut decreased significantly in the initial stage, and the maximum reduction was more than 15%. The effect of production stabilization and water cut control was obvious (Fig. 9). Half a year after the implementation, the formation pressure decreased due to the failure to meet the requirements of injection allocation in injection wells, and the production rate of well groups began to decline. The pilot was stopped in February 2019, the liquid production rate was significantly recovered and the water cut was significantly reduced even after the original linear well pattern was reused. It can be seen that when well pattern was changed to linear well pattern after alternating water injection, the flow direction are changed again due to the change of streamlines, thus playing the role of development effect improvement.

Fig. 9.

Fig. 9.

Oil production curve of alternating water injection testing well group with inverted seven-spot well pattern.

In addition, 3 rows of 15 production wells with high water cut and 2 rows of 10 injection wells were selected for cyclic differential alternating water injection and apparent five-spot alternating water injection pilots. Due to the widely development of high permeability zones near the production layer of the well group, the early injected water rapidly flew into the production well along the high permeability channel, resulting in only 15.3% recovery and 73.6% water cut of the well group, which had great adjustment potential. The alternating cycle period of cyclic differential alternating water injection stage was 60 days. In the first and second half-cycles, the injection rate of different injection wells was adjusted to about 1.5 times and 0.5 times of the original injection rate respectively, and the liquid production rate of different production wells was adjusted to about 1.2 times and 0.8 times of the original fluid production rate respectively. This well group started to implement two cycles of cyclic differential alternating water injection in January 2020. After alternating water injection, the average daily oil production rate of individual well increased by 15.89 m3, and the water cut decreased by up to 11%. The effect of water cut control and production stabilization was obvious (Fig. 10). In May 2020, the well group switched to alternating water injection with apparent five-spot well pattern, with a cycle period of 30-40 d. The injection rate of water injection wells during the first and second half cycle was adjusted to 1.5 times the original injection rate. The liquid rate is adjusted to 1.2 times the original liquid rate. By this well pattern, the average daily oil production of individual well increased by 23.84 m3, and the water cut decreased by 18%. It can be seen from the pilot results that with apparent five-spot well pattern, water cut has declined greatly, and daily oil production of individual well has increased. At the same time, compared with apparent inverted seven-spot well pattern, the requirement for water injection well allocation is lower, so as to ensure the stability of reservoir pressure and the best effect. This is also consistent with the understanding of the simulation results of typical blocks, that is, the alternating water injection with apparent five-spot well pattern has the best adaptability to reservoirs with serious heterogeneity, especially those with medium preference for physical properties in the development stage of high-extra high water cut.

Fig. 10.

Fig. 10.

Production curve of alternating water injection testing well group with periodic differentiation and five-spot well pattern.

4.2. Analysis and optimization of development effect

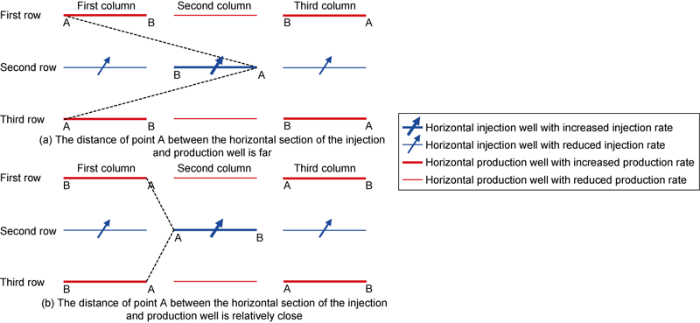

By comparing the development effect of all individual wells in the pilot well group before and after alternating water injection, it is found that the alternating water injection effect is greatly affected by the trajectory direction horizontal injection-production well, that is, the distance of point A between injection and production well. The point A is the location of horizontal well near the deviated section that is the heel-end, where the water injection intensity is relatively large. Point B is the location of the horizontal well away from the deviated section that is the toe-end, where the water injection intensity is relatively weak (Fig. 11). The direction from point A to point B of horizontal production wells in M oilfield are mainly from west to east, and that of horizontal injection wells is in the opposite, mainly from east to west; but there are also some wells with different trajectory. The difference in trajectory directions of production and injection wells will cause different distances of point A in the first and second half cycle of alternation water injection. Using two extreme cases as examples, when the distance is furthest, it exceeds the length of the horizontal section of two wells (Fig. 11a); while the shortest distance only exceeds the row spacing or well spacing (Fig. 11b).

Fig. 11.

Fig. 11.

A-point distance diagram of alternating injection-production wells under different oil-water well trajectories.

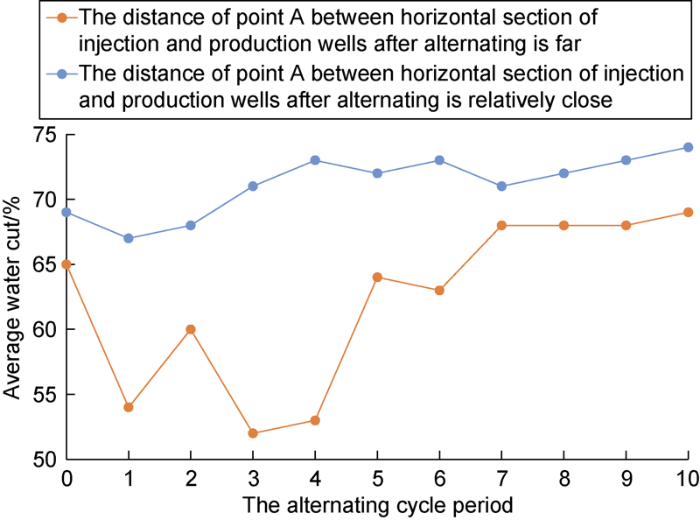

The variation of water cut in the pilot well group shows that the precipitation effect is more obvious when the distance of point A between the horizontal sections of the injection and production well after alternation is far (Fig. 12). The toe-end effect of horizontal wells makes it easier for the heel-end to absorb water and produce liquid. When the distance between point A of the injection and production wells after alternating is close, it is not conducive to the expansion of water drive swept volume. Therefore, by further optimizing the injection- production corresponding relationship of alternating well pattern, the point A distance between injection and production well after alternating can be as far as possible, so as to improve the effect of water cut control and production increase.

Fig. 12.

Fig. 12.

The water cut variation curve under different A-point distances between injection-production wells after alternation.

5. Conclusions

In the carbonate reservoir with serious heterogeneity in the Middle East, which is developed by linear horizontal well pattern without drilling any new wells, the origin linear horizontal well pattern can be alternated into three types of alternating water injection well patterns by adjusting the on-off state of the injection-pro-duction well and the injection-production parameters, i.e., apparent inverted seven-spot well pattern, apparent five- spot well pattern, and the cyclic differential alternating water injection, which can enhance the oil recovery. With these three types of alternating water injection well patterns, the direction of injection-production streamlines and fluid flow can be changed. The same area is flooded by streamlines with two different directions in the first and second half cycles of the alternating water injection, improving the sweep volume and displacing effectively the remaining oil between wells.

Cyclic differential alternating water injection is the easiest to implement, and is suitable for all types of reservoirs. Apparent inverted seven-spot well pattern water injection requires a high injection rate of water injection wells, which is suitable for reservoirs with good physical properties and weak heterogeneity. The alternating water injection adjustment range of apparent five-spot well pattern is large, and the expected water cut decline is the largest. Due to the shutdown of half of the production wells, the production of the well group may decrease in the short term, which is suitable for reservoirs with moderate physical properties and already in the development stage of high-extra high water cut and serious heterogeneity.

In M oilfield in the Middle East, good development results have been achieved through the pilots of alternating water injection with three different well patterns. The average daily oil production of an individual well in the pilot well group increases by 23.84 m3, and the water cut decreases by 18%, improving the effect of production stabilization and water cut control. Through the pilot, it is found that the development effect of the well group with far distance of point A between injection and production well is significantly better than that of the well with close distance.

Nomenclature

d1—production well spacing, m;

d2—row spacing of injection-production well, m;

E—areal sweep coefficient,%;

L—horizontal well length, m;

S—the swept area of injected water in 1/4 injection-production unit, m2;

xa, xb, xc—transverse coordinates of intersection points between different curves, m;

x1, x2, x3—cross coordinates of intersection points between different curves and x-axis, m;

ϕ1(x), ϕ2(x), …, ϕ6(x)—function corresponding to the maximum open streamline at different locations in the swept area, m.

Subscript:

5spot—apparent five-spot well pattern;

7spot—apparent inverted seven-spot well pattern;

cyclic, 1—cyclic differential alternating water injection with large flow field disturbance;

cyclic, 2—cyclic differential alternating water injection with small flow field disturbance variation.

Reference

Water extraction and cone control of horizontal well in exploitation of bottom water reservoir

Optimum development options and strategies for water injection development of carbonate reservoirs in the Middle East

Controlling factors of remaining oil distribution after water flooding and enhanced oil recovery methods for fracture-cavity carbonate reservoirs in Tahe Oilfield

DOI:10.1016/S1876-3804(19)60232-6 URL [Cited within: 1]

Inter-well interferences and their influencing factors during water flooding in fractured-vuggy carbonate reservoirs

DOI:10.1016/S1876-3804(20)60111-2 URL [Cited within: 1]

Practice and knowledge of volumetric development of deep fractured-vuggy carbonate reservoirs in Tarim Basin, NW China

Experiments on gas and water injection for enhanced oil recovery in porous carbonate reservoir