Introduction

Well pads play an important role in the oil industry, making the development of oil and gas fields with complicated surface conditions feasible[1,2,3,4]. When designing a multi-well pad for oil and gas development, the following issues should be addressed: (i) the overall number of wells and well pads; (ii) which wells belong to which pads; (iii) well spacing and well interference; (iv) simultaneous operations and collision control; (v) well pad layout and the grouping (clustering) of wells on the pad; (vi) issues related to the daily operation of well pads.

Gakhar et al. took a well pad as a single system and its development strategy was optimized by changing the vertical conductivity and reservoir conditions while considering arrangement of two kinds of wells[8]. Schofield et al. investigated pad completion techniques to minimize the time to first oil and simulation of low permeability reservoirs[9,12-13]. Tolman et al. introduced an industrial experience of drilling multiple wells from a single pad, technology to stimulate multiple pay zones in each well, and technology for the simultaneous stimulation of multiple wells on the same well pad while drilling additional wells[14]. These technologies can save time, enhance production rate and reduce environmental impact. Ogoke et al. studied proper management of simultaneous (done within a cluster of wells) and concurrent (done within different clusters of wells) operations, tested simultaneous drilling-drilling, completion-completion and drilling-completion. These operations have proved to be efficient in accelerating construction of multi-well pads consisting of 26 wells in clusters of six to eight. Awad et al. presented a regional application of simultaneous operations on a 6-well pad[15]. Stagg and Reiley introduced a wellhead monitoring system to prevent sub-surface well collisions, which was used to ensure safe drilling in proximity to the already producing wells of a pad[4]. Demong et al. looked into the evolution of pad design over a period of field development to meet the needs during construction, drilling and completion[2], and they transformed an initial 6-well pad design to a 20-well pad with careful consideration of all practical aspects. Krome et al. presented implementation of an intelligent well pad program, which increased the level of automation and introduced remote surveillance[16].

When dealing with well pad configurations and the clustering of wells on the surface, oil and gas field operators follow national standards and regulations[17]. Such regulations set limits on the distances between wells and groups of wells, and limit the overall number of wells in pads. But sufficient freedom is left for an engineer to decide on the numbers of wells in groups and how many groups are there in a particular pad.

Although many aspects of well pad design have been extensively studied, there is no report of design optimization attempts utilizing unequal numbers of wells in groups. Well pad designs with constant number of wells in groups are common, but the groupings with varying numbers of wells have better economy than that with constant number of wells[18]. We further improve our technical-economic model to include more than 30 operational parameters. By combining these parameters differently, millions of possible clustering options for a well pad can be worked out. A model for well pad drilling projects has also been developed and optimized. By using the model, some practical drilling scenarios (case studies) have been simulated to confirm the economic efficacy of groupings with varying numbers of wells. The simulation results demonstrated that the proper clustering of wells could be economically beneficial and could play a key role in “go/no go” investment decisions.

1. Background

On a pad, wells are often grouped together in clusters (these clusters or groups may contain only one well). After the drilling of wells in a cluster is finished, the drilling rig is moved to the next cluster. For safety reasons, the distance between the clusters is larger than the distance between wells within the clusters. Hence a larger number of clusters will result in increase of well pad area and consequently pad cost. But having fewer wells within each cluster means earlier and fast-paced production. The economic results by changing these two competing factors need to be examined in depth, especially for groupings with unequal numbers of wells.

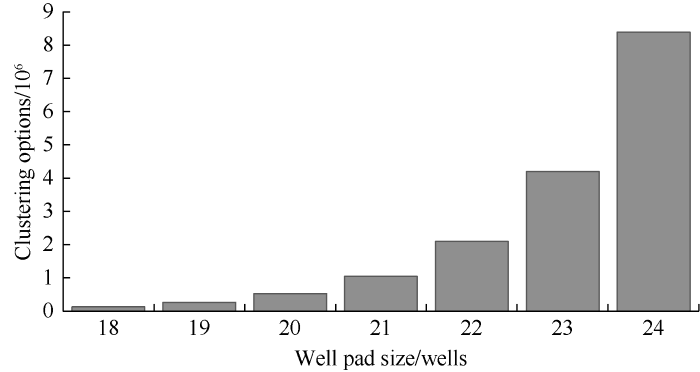

The complexity of the problem of grouping wells and searching for an optimal configuration is best illustrated by an example. Let us consider a 4-well pad. The possible groupings of such a pad would be {4}, {3,1}, {1,3}, {2,2}, {2,1,1}, {1,2,1}, {1,1,2}, and {1,1,1,1} (configurations are shown in curly brackets with the number of wells in each group being separated by commas). Here the first configuration consists of one cluster containing four wells and the last configuration consists of four clusters each containing one well. Real well pads are larger and include around 20 or more wells[2,3]. The overall number of possible groupings of such pads is given by 2N-1, with N being the total number of wells (Fig. 1). Previous studies have been limited to groupings with constant number of wells in clusters, overwhelming unequal grouping possibilities have been ignored. Obviously, for larger well pads, this subset of the configurations is also large and often is not considered in its entirety. As every configuration has a layout, production profile and drilling sequence specific to it, skipping some configurations may result in overlooking the optimum for the particular conditions of a drilling project.

Fig. 1.

Fig. 1.

Number of well clustering options as a function of number of wells in a pad.

There are three stages of a generalized well pad drilling project which may overlap in time: (i) landfill construction, (ii) drilling and completion of wells and (iii) production period. As some wells start producing before the drilling of a pad is finished, the second and the third stages normally overlap in time.

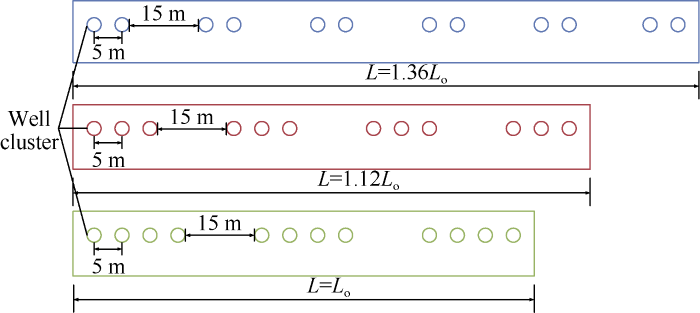

Landfill construction is modeled as an independent project implemented before the drilling of the first well. All the costs associated with this construction are expressed in terms of money of the first day of drilling. There is a fixed cost of construction, which is assumed to be covered on the day of construction start. There are everyday costs for keeping a constant construction speed. A provision is also made for some time after the completion of construction and the beginning of drilling, time that might be necessary for the mobilization of the drilling rig. The landfill design is different for every grouping of wells as the distance between the wells and distance between the groups of wells defines the length of the landfill (Fig. 2).

Fig. 2.

Fig. 2.

Some possible layouts of a 12-well pad.

After the landfill is prepared and the rig is ready (mobilized), drilling of the first well starts. The remaining wells are drilled in sequence. When the drilling of a well is done, the drilling rig is shifted to the next position. This shift could be short (from a well of one group to the next well of the same group) or long (from the last well of one group to the first well of the next group). When all the wells of a group have been drilled, completion of the first well of this group begins and the rig is shifted to the next group. Completion and tie-in operations are then done sequentially for the remaining wells of the group. After the last well of the pad has been drilled, the rig is demobilized and the wells of the last group are completed.

Once the wells are drilled and completed, they are put into production. The production characteristics of each well can be defined by a set of parameters, including the initial oil flow rate, production decline rate, initial water cut, production time, and costs of drilling and completion. In our model, we could shut-in any well on the basis of the current water cut or we could convert a producer into an injector after some time. In this work, we use a threshold water cut of 90 % to decide if a well should be shut in. We also assume that liquid production slightly grows year by year.

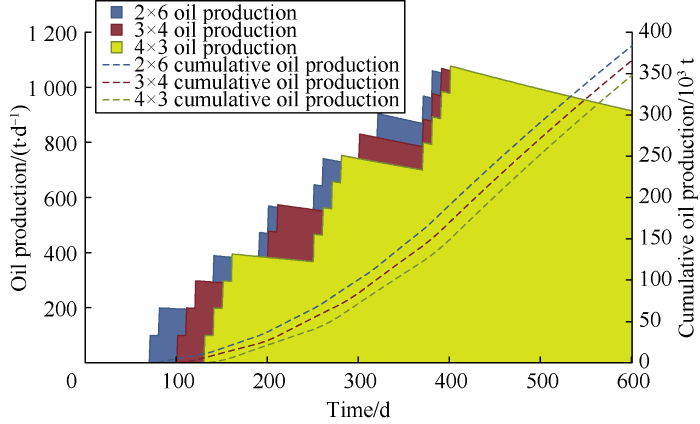

Possible oil production profiles of the pads with the layouts shown in Fig. 2 are exemplified in Fig. 3. From these figures, it can be seen that longer and more expensive pads start to produce earlier and have higher cumulative oil production. The economy and cost of a drilling project also depends on the price of oil and operational expenditures per cubic meter of produced liquid. Termination of each project could be for one of two reasons: the water cut of all wells is above given threshold or the modeling period exceeds 20 years.

Fig. 3.

Fig. 3.

Oil production and cumulative oil production of three pad layouts (2×6—two wells in six groups; 3×4—three wells in four groups; 4×3—four wells in three groups).

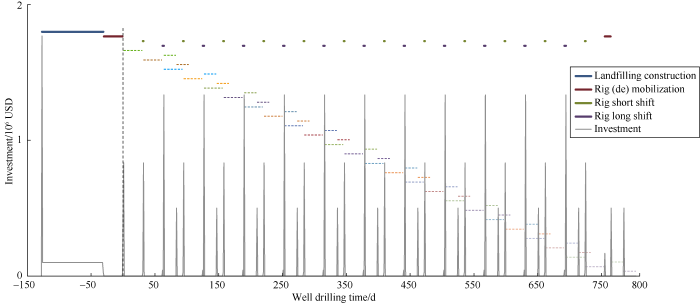

2. Simulation of drilling projects and computational details

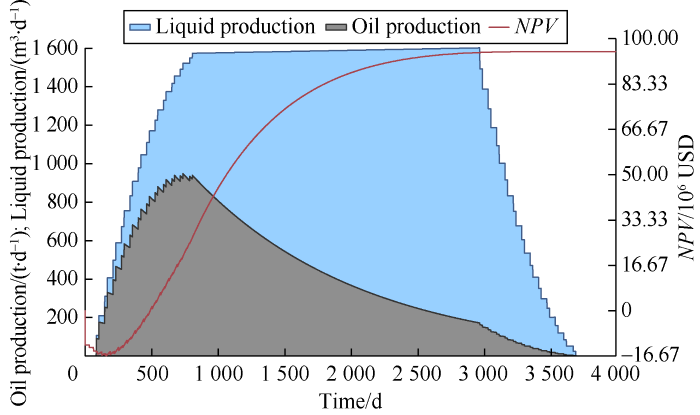

To simulate the drilling of well pads we constructed a model based on the premises given in the Background section. A typical drilling project of a 24-well pad (2×12 twelve groups of two wells) was simulated using this model and characterized by the parameters given in Table 1. Fig. 4 shows the time and total investments of an example design 2x12, including necessary rig shifts and mobilization/demobilization. The liquid and oil production, as well as NPV, of this example project are shown in Fig. 5. The initial flow rates of oil for all 24 wells linearly change from 90 t/d for the first well to 20 t/d for the last well. The discount rate was set at 20%/year and the oil production decline rate 25%/year.

Table 1 Technical and economic parameters of the model.

| Classifi- cation | Technical and economic parameter | Value |

|---|---|---|

| Landfill design and construction parameters | Distance between wells | 5 m |

| Distance between groups of wells | 15 m | |

| Distance from the first and the last wells of a pad to the landfill border | 80 m | |

| Landfill width | 75 m | |

| Landfill height | 2 m | |

| Landfill construction speed | 600 m3/d | |

| Drilling rig mobilization time | 30 d | |

| Landfill specific cost | 167 USD/m3 | |

| Fixed cost of pad construction | 1.7×106 USD | |

| Drilling and completion parameters | *Well drilling time | 30 d |

| *Well completion time | 20 d | |

| *Well drilling cost | 0.83×106 USD | |

| *Well completion cost | 0.5×106 USD | |

| Drilling rig short shift duration | 1 d | |

| Drilling rig long shift duration | 2 d | |

| Drilling rig demobilization time | 10 d | |

| Drilling rig short shift cost | 28333 USD | |

| Drilling rig long shift cost | 43333 USD | |

| Drilling rig demobilization cost | 166667 USD | |

| Technological parameters of wells | *Initial oil flow rate | 20, 50, 90 t/d |

| *Oil production decline rate | 25%, 40%, 45%, 50%, 60%, 70% | |

| *Initial water cut | 1% | |

| *Liquid production increment | 0.3% | |

| * Water cut at well shut-in | 90% | |

| *Oil density | 850 kg/m3 | |

| *Water density | 1010 kg/m3 | |

| Economic parameters | Price of oil | 200 USD/t |

| Specific operational expenditures (liquid based) | 16.7 USD/m3 | |

| Discount rate | 10%, 15%, 20% | |

| Time step | 1 d | |

| Modeling period | 20 a |

Note: * Parameters set for every well individually

Fig. 4.

Fig. 4.

Jobs and investment schedule for the example drilling project 2x12 (dashed horizontal lines - well drilling and completion).

Fig. 5.

Fig. 5.

Liquid and oil production, NPV of the example drilling project.

To analyze possible well clustering options in the manner demonstrated in Fig. 4 and Fig. 5, a Python program to enumerate groupings of all the wells of a 24-well pad (the number of wells may be arbitrary) was developed, and for the set of parameters given in Table 1, the NPV of each grouping was calculated. The enumeration of the clustering options can be formalized in the following way. There are N variables representing the number of wells in each group: ni, i =1, 2, ..., N. The sum of all the variables exactly equals N. In every set of variables, zero values are ignored. All the sets of N variables constructed in this way are essentially eligible well grouping options. Practical implementations of the formalism may be different from its straightforward interpretation, but its description in this way expresses the gist of the enumeration scheme in the simplest form (as an example of practical realization, we found a scheme where a fixed number of wells is recursively distributed among groups to be efficient and concise in terms of required coding). Every clustering option defines the scale of landfill, timing of construction, drilling sequence and production profile. Because of the large number of clustering possibilities and thus required significant computational effort, crucial parts of our code were written in Cython (Cython is a superset of the Python). The program has a regularly formatted input file for scientific computing, which can be generated by a top level utility or some GUI wrapper (Graphical User Interface wrappers run atop command line programs to simplify user interactions with software).

3. Results of computations for drilling project scenarios and discussion

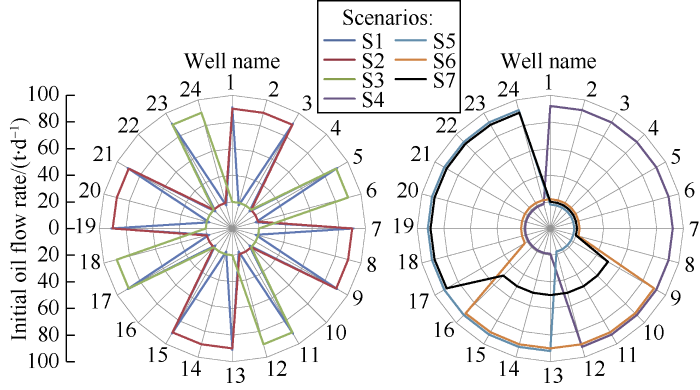

To demonstrate the benefits of groupings with unequal numbers of wells, realistic situations where the wells of a pad start producing at different rates were used. The economic parameters of seven scenarios with the initial flow rate of wells of 20, 50 or 90 t/day were evaluated. Fig. 6 shows these scenarios in the form of radial diagrams. In the S1 scenario, all the odd wells have initial oil flow rates of 90 t/d and all the even wells have starting oil flow rates of 20 t/d. In the S2 scenario, the first three wells have an initial oil flow rate of 90 t/d, the next three wells have initial oil flow rate of 20 t/d and so on. All the remaining scenarios may be interpreted in an analogous fashion.

Fig. 6.

Fig. 6.

Initial oil flow rate (t/d) of every well of the pad for seven scenarios.

For every scenario, through a primary selection, the grouping option with a constant number of wells in the groups that can reach the highest NPV was picked as the reference design. These groupings are labeled as “number of wells by number of groups”. The second optimization used a variable number of wells in each group. The number of wells in each group was labeled in curly brackets (Table 2). To find the absolutely optimal groupings in terms of NPV, all 8 388 608 possibilities were tested. Optimal groupings of wells for each scenario and for three discount rates are listed in Table 2. Here the oil production decline rate was set at 25%/year.

Table 2 Optimal groupings for three discount rates and seven scenarios.

| Sce- nario | Optimal groupings | |||||

|---|---|---|---|---|---|---|

| Discount rate 10%/a | Discount rate 15%/a | Discount rate 20%/a | ||||

| Groupings with equal numbers of wells | Groupings with un- equal numbers of wells | Groupings with equal numbers of wells | Groupings with unequal numbers of wells | Groupings with equal numbers of wells | Groupings with unequal numbers of wells | |

| S1 | 3×8 | {3,2,2,2,2,2,2,2,2,2,3} | 3×8 | {1,2,2,2,2,2,2,2,2,2,2,3} | 2×2 | {1,2,2,2,2,2,2,2,2,2,2,3} |

| S2 | 3×8 | {2,2,3,2,4,2,4,2,3} | 2×12 | {2,2,3,2,3,2,2,3,2,3} | 2×12 | {2,2,3,2,3,2,2,3,2,3} |

| S3 | 3×8 | {4,2,4,2,4,2,4,2} | 3×8 | {4,2,4,2,4,2,4,2} | 3×8 | {4,2,4,2,4,2,4,2} |

| S4 | 3×8 | {2,2,2,2,2,2,4,4,4} | 2×12 | {2,2,2,2,2,2,4,4,4} | 2×12 | {2,2,2,2,2,2,4,4,4} |

| S5 | 3×8 | {4,4,4,2,2,2,2,2,2} | 2×12 | {4,4,4,2,2,2,2,2,2} | 2×12 | {4,4,4,2,2,2,2,2,2} |

| S6 | 3×8 | {4,4,2,2,2,2,4,4} | 3×8 | {4,4,2,2,2,2,4,4} | 3×8 | {4,4,2,2,2,2,4,4} |

| S7 | 3×8 | {4,4,2,3,3,2,2,2,2} | 3×8 | {4,4,2,3,3,2,2,2,2} | 2×12 | {4,4,2,2,2,2,2,2,2,2} |

Note: Optimal groupings with equal numbers of wells are given as “number of wells” × “number of groups”. Optimal configurations with unequal numbers of wells are given in curly brackets, here the numbers of wells in every group are separated by commas.

It is interesting to note that sometimes very small changes to well pad design can maximize NPV. For the S1 scenario, only the first and the last groups require alteration for each discount rate to maximize NPV. Only two groups require modifications in S7 scenario at a discount rate of 20%/year.

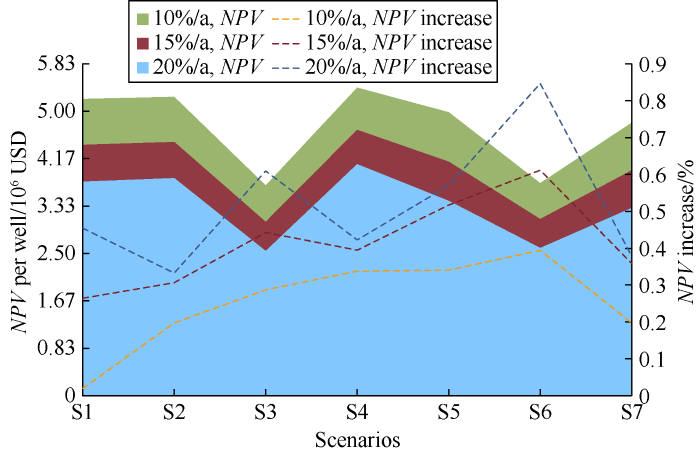

For each scenario, the NPVs of groupings with constant numbers of wells in clusters for discount rates of 10%, 15% and 20%/year are shown in Fig. 7. The NPV could be increased by using groupings with variable numbers of wells, it can be seen from the figure, the larger the discount rate the stronger the effect of proper groupings on NPV increment. In the best case situation, S6 scenario with a discount rate of 20%/year, the NPV increase may reach almost 1%. It should be noted here that these are secondary optimizations, optimizations with respect to previously found optimal groupings with constant numbers of wells in the clusters. It thus maybe safe to say that the demonstrated increases only set a lower limit to possible in practice.

Fig. 7.

Fig. 7.

NPV of optimal groupings with constant numbers of wells in clusters and NPV increase of groupings with variable numbers of wells in clusters at three discount rates.

Another intriguing feature of optimal groupings with variable numbers of wells is that larger NPV increases could be expected for projects with low absolute values of NPV. This is apparent for scenarios S3 and S6 (Fig. 7). This aspect could be decisive for marginal and near negative profit projects, including the development of shale and low permeability reservoirs. Contrariwise, for scenarios S2, S4 and S7, which have the largest absolute value of NPV, the NPV increments are the smallest. This feature clearly reveals itself for higher discount rates.

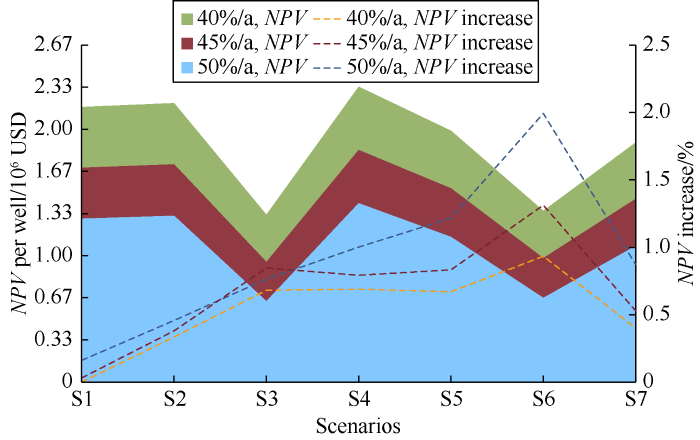

To specifically illustrate the advantages of groupings with unequal numbers of wells for the development of shale formations, the discount rate was set at 15%/year and the oil production decline rates were set at 40%, 45% and 50 % per year, which were about two times the value previously used in this study. Optimal clustering options with equal and unequal numbers of wells for all seven scenarios and at the oil production decline rates were found (Table 3). From Fig. 8, the closer the NPV to zero, the stronger the positive effect of groupings with unequal numbers of wells is. The general trend is that NPV increment gets higher with the increase of the oil production decline rate for all scenarios. There are only a couple of deviations from this behavior. For the S1 scenario and a 40%/year oil production decline rate, the optimal grouping with an unequal number of wells has the same NPV as the optimal grouping with equal number of wells. For S3 scenario, the efficiency of the optimal clustering with an unequal number of wells for an oil production decline rate of 50%/year is slightly less than that for 45%/year. These few exceptions from the general trend merely show that in particular conditions groupings with a constant number of wells in clusters could be close in economic efficiency to groupings with a variable number of wells. Yet, the former groupings are inferior to the latter ones. It can be seen from Fig. 8 the groupings with variable number of wells in clusters have the highest NPV increment of around 2%.

Table 3 Optimal groupings for three oil production decline rates and seven scenarios.

| Sce- nario | Optimal groupings | |||||

|---|---|---|---|---|---|---|

| Oil production decline rate 40%/a | Oil production decline rate 45%/a | Oil production decline rate 50%/a | ||||

| Groupings with equal numbers of wells | Groupings with unequal numbers of wells | Groupings with equal numbers of wells | Groupings with unequal numbers of wells | Groupings with equal numbers of wells | Groupings with unequal numbers of wells | |

| S1 | 3×8 | {3,3,3,3,3,3,3,3} | 3×8 | {3,3,3,4,4,4,3} | 3×8 | {3,3,3,4,4,4,3} |

| S2 | 3×8 | {3,4,2,4,2,4,2,3} | 3×8 | {3,4,2,4,2,4,2,3} | 3×8 | {3,4,2,4,2,5,4} |

| S3 | 3×8 | {4,2,4,2,4,2,4,2} | 3×8 | {4,2,4,2,4,2,4,2} | 4×6 | {4,2,4,2,5,4,3} |

| S4 | 3×8 | {2,2,2,2,2,2,6,6} | 3×8 | {2,2,2,2,2,2,6,6} | 3×8 | {3,3,3,3,6,6} |

| S5 | 3×8 | {6,6,2,2,2,2,2,2} | 3×8 | {6,6,2,2,3,3,2} | 4×6 | {6,6,3,3,3,3} |

| S6 | 3×8 | {4,4,2,2,2,2,8} | 4×6 | {7,3,2,2,2,8} | 4×6 | {7,3,3,3,8} |

| S7 | 3×8 | {6,4,3,3,2,2,2,2} | 3×8 | {6,4,4,3,2,3,2} | 4×6 | {7,4,4,3,3,3} |

Fig. 8.

Fig. 8.

NPV increment of optimal groupings with constant numbers of wells in clusters and of optimal groupings with variable numbers of wells in clusters for three oil production decline rates.

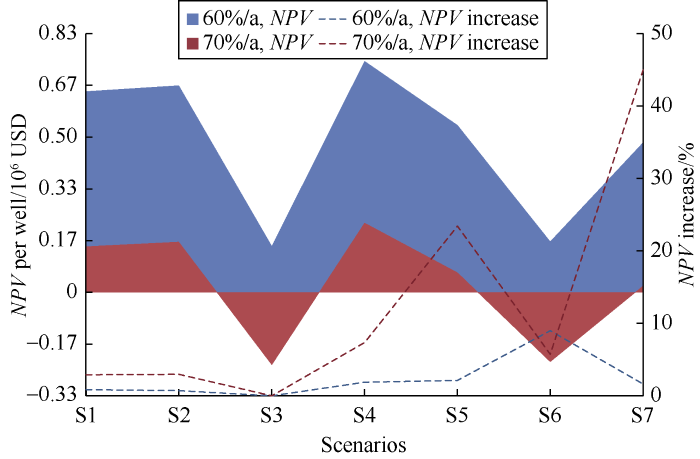

Performance of well pad configurations with unequal number of wells in extreme cases of very low, near-negative or negative NPV is depicted in Fig. 9, and the optimal well groupings are listed in Table 4. The scenario S7 has the highest NPV increment of 45% at the oil production decline rate of 70%/year. In some cases, like scenario S1 and S4 in Table 4, optimal groupings getting the highest NPV increment are the same for different oil production decline rates. This feature can make it easier to design well pad when conditions are uncertain.

Fig. 9.

Fig. 9.

NPV increment of optimal groupings with constant numbers of wells in clusters and NPV increment of groupings with variable numbers of wells in clusters for two very high oil production decline rates.

Table 4 Optimal groupings for two very high oil production decline rates and seven scenarios.

| Scenario | Optimal groupings | |||

|---|---|---|---|---|

| Oil production decline rate 60%/a | Oil production decline rate 70%/a | |||

| Groupings with equal numbers of wells | Groupings with unequal numbers of wells | Groupings with equal numbers of wells | Groupings with unequal numbers of wells | |

| S1 | 4×6 | {3,4,4,4,4,5} | 4×6 | {3,4,4,4,4,5} |

| S2 | 4×6 | {3,5,4,3,5,4} | 4×6 | {3,6,6,5,4} |

| S3 | 6×4 | {6,6,6,6} | 6×4 | {6,6,6,6} |

| S4 | 4×6 | {3,3,3,3,12} | 4×6 | {3,3,3,3,12} |

| S5 | 4×6 | {12,3,3,3,3} | 4×6 | {12,4,4,4} |

| S6 | 4×6 | {8,2,3,3,8} | 6×4 | {8,4,4,8} |

| S7 | 4×6 | {7,4,4,3,3,3} | 6×4 | {9,5,4,3,3} |

4. Conclusions

A rigorous enumeration of well grouping possibilities combined with an evaluation of the economic characteristics is an efficient method to locate the global maximum of economic performance for a well pad drilling project. The demonstrated approach paves a way to the routine study and optimization of configurations and designs of well pads with virtually any number of wells seen in practice. These optimizations take into account all known characteristics of drilling projects and technological parameters of individual wells. At the moment the number of such characteristics exceeds 30 and more than 10 of them are specified individually for every well.

In this work we studied seven drilling scenarios for a 24-well pad with different starting oil flow rates for the wells. Optimal well groupings in terms of NPV for three discount rates and five oil production decline rates have been found. The results demonstrate that: (i) NPV maximizing well pad designs with varying numbers of wells may require only the slight alteration of existing designs (changing the configurations of a couple of well clusters); (ii) Relative NPV increase is inversely proportional to the absolute value of NPV; (iii) The observed increases in NPV for groupings with varying numbers of wells reach up to 1% for conventional projects and could reach 2% and more for shale formation development projects, and up to 45% for marginal projects. In addition to these findings it must be mentioned that the development of a pad according to an optimized design with an unequal number of wells virtually does not demand financial or engineering effort; all that is needed is already present in regular layouts.

Reference

Asteroid mining, technologies roadmap, and applications

DOI:10.1111/j.1749-6632.2009.05415.x URL [Cited within: 1]

The evolution of high density pad design and work flow in shale hydrocarbon developments

Simultaneous operations in multi-well pad: A cost effective way of drilling multi wells pad and deliver 8 fracs a day

Watchdog: An anti-collision wellhead monitoring system

Analytical model to estimate the fraction of fracture hits in a multi-well pad

Completion and well-spacing optimization for horizontal wells in pad development

Completion and well spacing optimization for horizontal wells in pad development in the Vaca Muerta shale

Engineered approach for multi-well pad development in Eagle Ford shale

Optimization of well pad & completion design for hydraulic fracture stimulation in unconventional reservoirs

Is that interference? A work flow for identifying and analyzing communication through hydraulic fractures in a multiwell pad

DOI:10.2118/178509-PA URL

Time dependent fracture interference effects in pad wells

Hydraulic fracturing design and optimization: A modification to zipper frac

Optimizing fracture spacing and sequencing in horizontal-well fracturing

Method and apparatus for simultaneous stimulation of multi-well pads

Develop new “SIMOPS” procedures to safe workover operations on “PAD”

Revealing the benefits of the intelligent well pad program for onshore shale assets

The norms of process design of facilities for gathering, transport and treatment of oil, gas and water of oil fields: VNTP 3-85

Boosting economic efficiency of pads drilling projects: A comprehensive study of wells groupings and localization of the global maximum

DOI:10.1016/j.petrol.2018.02.012 URL [Cited within: 1]