Introduction

Hybrid sedimentary rocks (HSRs) are the product of mixed deposition of multi-source materials, including mechanical clast, chemical deposit, and volcanic materials[1]. Occurring often in sedimentary environments from delta fronts to lacustrine facies[2,3,4], HSRs feature fine grain size, diverse lithology, frequent thin layers, and strong heterogeneity[5]. HSR reservoir is an important reservoir type with abundant shale oil and a type of shale oil reservoir has been commercially developed in China[6], for example, the Permian Lucaogou Formation in the Junggar Basin[6,7]. HSR lithologic divisions, sedimentary models, and reservoir classifications have been studied extensively before[5, 8-9], but the impact of the mixing deposition process on HSR reservoir quality remains unclear. The Lucaogou HSRs are composed of organic matter, silt, mud-size grain, dolomitic matter (including dolomicrite and dolarenite), calcareous matter, and a small amount of tuffaceous matter. Each component affects the pore structure, and the mixing mode of multiple components also affects reservoir quality. Only by clearly understanding these effects, can we reveal the formation mechanism, evolution, and controlling factors of shale oil “sweet spots” in HSR strata. However, at present, only the microscopic structures of several main lithologic types in HSR (such as siltstone, dolomite, and mudstone) have been characterized and compared[10,11,12], and the impacts of the various components and their mixing process on reservoir quality haven’t been systematically examined.

In addition, the mixing of multi-components causes complex pore-throat structures, and superposition of different types of pores and throats in HSR may result in similar characteristic parameters (pore size, pore-throat size distribution, and pore-throat ratio), making these parameters unable to reveal microstructural differences of HSR. HSR pore-throat structures are related to the mixing process of multiple components and can also reveal the relationship between components.

A pore-throat system (PTS) is a network system with a certain scale of connectivity, composed of pores and the throats connecting with them in reservoir[13]. Comparing with other characteristic parameters such as pore types and size distribution, pore-throat systems tend to describe the types of pore-throat combinations and their contributions to the overall pore-throat network. For HSR reservoirs, multi-source components deposit in mixed pattern, leading to the superposition of various PTSs and the formation of a variety of mixed systems, hence, similar pore-throat size distribution may correspond to different pore-throat combinations and different fluid mobility. PTS identification should be the key to revealing pore-throat structure differences between HSR reservoirs and controlling factors of high-quality HSR reservoirs. The researches on the classification and identification of PTSs in HSR reservoirs are rare[4].

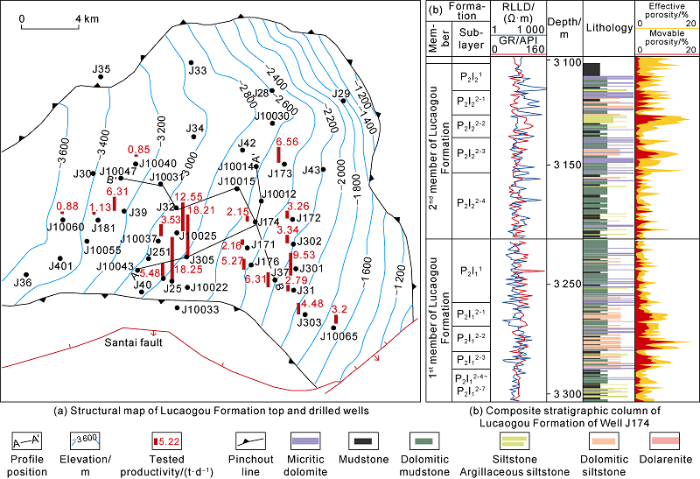

Fig. 1.

Fig. 1.

Structural location and stratigraphic column of Permian Lucaogou Formation in Jimusar sag. P2l21—1st sub-member in 2nd member of Lucaogou Formation; P2l22-1 to P2l22-4—sublayers 1 to 4 in 2nd sub-member of 2nd member of Lucaogou Formation; P2l11—1st sub-member in 1st member of Lucaogou Formation; P2l12-1 to P2l12-7—sublayer 1 to sublayer 7 in 2nd sub-member of 1st member of Lucaogou Formation.

This study examines samples from Lucaogou HSR in Jimusar sag, classifies the PTSs through thin section analysis, field emission scanning electron microscope (SEM), as well as mercury injection and nuclear magnetic resonance (NMR), sorts out features and controlling factors of PTS, impacts of the mixing process of each component on the PTSs, and the effects of the PTS on physical properties and fluid mobility of the HSR reservoir.

1. Basic features of the samples

The Jimusar sag located in the eastern margin of the Junggar Basin is a dustpan like fault depression higher in the east and lower in the west (Fig. 1). The Permian Lucaogou Formation is an important oil-bearing series in the sag[14,15]. This formation is a set of fine-grained hybrid sedimentary rocks including dark mudstone, siltstone, carbonate rocks, and transitional lithologies, with more than 20 lithologic types and frequent vertical interbeds (Fig. 1)[15,16]. The major lithologies include siltstone, mudstone, dolomite, and dolomitic siltstone (Table 1), and are further subdivided into 10 subcategories, including siltstone, argillaceous siltstone, dolomitic siltstone, and dolomicrite etc. (Table 1). Siltstone, argillaceous siltstone, and dolarenite (or silty dolomite) are the dominant reservoir rocks in the P2l22-1 to P2l22-3 sublayers of the 2nd member of the Lucaogou Formation ("Lu 2 Member" for short) corresponding to the upper sweet spot. Dolomitic siltstone is the dominant reservoir rock for P2l12-1 to P2l12-3 sublayers in the 1st member of the Lucaogou Formation (referred to as "Lu member 1") corresponding to lower sweet spot (Fig. 1). Multiple component mixing poses great challenges to lithology identification, shale oil reservoir evaluation, and sweet spot selection[4].

Table 1 Basic information of HSR samples from Permian Lucaogou Formation in Jimusar sag.

| HSR type | Sample No. | Lithology | Porosity/ % | Permea- bility/ 10-3 μm2 | PTS type | Reservoir type | Relaxativity/ (nm·ms-1) | Mineral content /% | Mean grain size/μm | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Feld- spar | Plagio- clase | Cal- cite | Dolo- mite | Clay | |||||||||

| Dolomite dominated | 11 | Argi. dolomite | 5.70 | 0.008 | E | IV | 70 | 19.1 | 2.6 | 13.7 | 0 | 56.1 | 7.2 | 28.5 |

| 16-h | Argi. dolomite | 4.01 | 0.008 | E | IV | 90 | 20.6 | 4.1 | 28.6 | 0.2 | 40.8 | 5.7 | 46.2 | |

| 25 | Silty dolomite | 6.20 | 0.009 | E | III | 30 | 16.1 | 3.8 | 13.4 | 0 | 60.2 | 6.5 | 24.5 | |

| 1 | Silty dolomite | 7.90 | 0.020 | D | II | 20 | 8.5 | 1.1 | 21.6 | 2.2 | 51.7 | 2.9 | 51.4 | |

| 39 | Silty dolomite | 14.90 | 0.047 | B | II | 80 | 6.4 | 0.5 | 4.8 | 0 | 88.3 | 3.0 | 61.8 | |

| 12-h | Dolarenite | 14.61 | 1.320 | A | I | 250 | 4.5 | 0.8 | 28.4 | 24.2 | 40.4 | 1.7 | 207.1 | |

| Siltstone dominated | 28 | Cal. siltstone | 0.80 | 0.005 | E | IV | 40 | 9.4 | 1.8 | 47.9 | 36.3 | 1.5 | 3.1 | 118.8 |

| 14 | Cal. siltstone | 3.30 | 0.036 | E | IV | 40 | 15.7 | 7.8 | 39.5 | 24.1 | 7.2 | 2.7 | 97.4 | |

| 13 | Cal. siltstone | 5.10 | 0.012 | D | III | 60 | 14.1 | 4.7 | 48.5 | 21.2 | 6.5 | 3.3 | 114.1 | |

| J43-26 | Cal. siltstone | 5.10 | 0.009 | D | IV | 60 | 17.1 | 5.9 | 42.5 | 24.8 | 4.2 | 3.1 | 57.0 | |

| J43-52 | Argi. siltstone | 4.20 | 0.004 | D | II | 120 | 22.1 | 8.0 | 50.0 | 13.9 | 1.2 | 4.0 | 101.0 | |

| 15-h | Argi. siltstone | 9.39 | 0.020 | B | II | 70 | 21.0 | 7.7 | 39.0 | 28.7 | 0 | 3.1 | 44.6 | |

| 23-h | Argi. siltstone | 11.71 | 0.049 | B | II | 170 | 19.7 | 11.5 | 46.7 | 9.3 | 1.8 | 9.6 | 65.3 | |

| 32 | Siltstone | 15.60 | 0.108 | A | I | 120 | 22.1 | 18.1 | 41.1 | 0 | 5.1 | 6.4 | 49.6 | |

| 2-h | Siltstone | 14.31 | 0.083 | A | I | 130 | 28.5 | 20.9 | 46.1 | 0 | 0 | 3.7 | 140.8 | |

| 9-h | Cal-b. siltstone | 14.03 | 0.289 | A | I | 180 | 12.0 | 5.5 | 68.7 | 9.8 | 2.4 | 1.6 | 120.4 | |

| 10-h | Cal-b. siltstone | 13.69 | 0.275 | A | I | 170 | 135.5 | |||||||

| Mudstone dominated | 3 | Dolo. mudstone | 4.30 | 0.003 | E | IV | 100 | 29.3 | 13.9 | 29.4 | 4.7 | 12.9 | 7.6 | 46.8 |

| 30 | Silty mudstone | 9.10 | 0.096 | D | III | 100 | 42.6 | 2.6 | 37.1 | 0 | 4.3 | 13.4 | 59.2 | |

| 10 | Siliceous shale | 11.90 | 0.577 | D | III | 170 | 40.2 | 18.7 | 17.0 | 0 | 11.1 | 13.0 | 65.4 | |

| 9 | Silty mudstone | 11.70 | 0.039 | C | III | 100 | 42.5 | 24.0 | 28.5 | 0 | 0 | 5.0 | 84.7 | |

| 33 | Siliceous shale | 10.20 | 0.026 | C | III | 180 | 18.3 | 18.2 | 26.7 | 27.6 | 3.7 | 2.7 | 54.2 | |

| 3-h | Silty mudstone | 14.68 | 0.062 | C | III | 150 | 37.5 | 16.5 | 31.5 | 3.8 | 2.6 | 5.2 | 51.6 | |

| Dolomitic siltstone | 5 | Dolo. siltstone | 2.60 | 0.008 | E | IV | 90 | 21.1 | 3.8 | 31.0 | 15.0 | 21.9 | 6.2 | 27.4 |

| 29-h | Dolo. siltstone | 10.20 | 0.027 | D | III | 140 | 13.7 | 8.0 | 42.2 | 0.5 | 32.1 | 3.5 | 50.0 | |

| 25-h | Dolo. siltstone | 12.39 | 0.037 | C | III | 200 | 21.2 | 4.8 | 50.6 | 0.6 | 18.1 | 3.5 | 49.8 | |

| 30-h | Dolo. siltstone | 16.22 | 0.056 | C | III | 150 | 14.3 | 7.2 | 45.2 | 0.5 | 27.9 | 4.2 | 57.2 | |

| 36 | Dolo. siltstone | 14.30 | 0.041 | A | I | 170 | 26.3 | 4.7 | 47.8 | 0 | 18.5 | 2.7 | 72.7 | |

Note: Samples are sorted according to lithology and PTS type; among PTSs, type A to E represent intergranular PTS, intergranular-dissolved-intercrystalline mixed PTS, dissolved PTS, dissolved-intercrystalline mixed PTS and intercrystalline PTS, respectively; reservoir classification is based on the HPMI curve shape; the mean grain size is 50% of the cumulative grain size of clastic grains or arenes counted by thin sections. Argi.: argillaceous; Cal.: calcite; Cal-b.: calcite-bearing; Dolo.: dolomite.

A total of 38 samples were collected from the sweet spot sections of the Lucaogou Formation, including 15 siltstone, 7 dolomitic siltstone, 7 dolomite, and 8 mudstone samples, with mean gas-measured porosities of 9.02%, 10.93%, 9.1%, and 8.7%, and the mean permeabilities of 0.077×10-3 μm2, 0.028×10-3 μm2, 0.18×10-3 μm2, and 0.1×10-3 μm2, respectively. These samples of different lithologies have a similar range of porosity, but widely different permeabilities (Table 1). They are composed of feldspar, quartz, and dolomite, and small amount of calcite and clay minerals. The siltstone, dolomitic siltstone, and mudstone samples have mean feldspar contents of 54.7%, 49.2%, and 41.3%, and mean quartz contents of 19%, 19.6%, and 34.7%, respectively. The mudstone samples show higher quartz and lower feldspar contents, which is related to the reduction of feldspar content far from provenance[17]. The grain sizes of terrigenous clastic grains or arenes of the samples were counted using thin section images. The mean grain sizes range from 24 to 207 μm, and over 65% of the samples have mean grain sizes lower than 62.5 μm. The terrigenous clastic grains larger than 30 μm are called sandy grains, while fine grains with less than 30 μm are called argillaceous grains (primarily composed of quartz and feldspar).

In order to characterize the PTS, SEM, NMR, and high-pressure mercury injection (HPMI) experiments were carried out. The T2 spectra of samples saturated with kerosene and samples after subjected to various centrifugal forces were measured using NMR to reveal the pore distribution and oil mobility. The NMR experiments were conducted at the echo interval of 0.2 ms, waiting time of 3 s, and centrifugal speeds of 2000, 4000, 6000, and 10000 r/min. Based on the HPMI experimental results (at the maximum pressure of 110 MPa), the pore- throat size distribution was obtained by using the Washburn equation[18], which was employed to calibrate T2 spectrum and then establish the cumulative comparison curves of pore-throats and pores for PTS identification.

2. Classification of HSR reservoirs

Tight reservoir quality is affected by micro pore structure[4,5]. The pore structure of HSR reservoir is complex, and the effectivity of the conventional classification method related to parameters such as mercury intrusion shapes or pore-throat size distribution becomes worse. It is necessary to deeply discuss the types and classification methods of PTS from the origin of pore structure, so as to fully reveal the difference of types and quality between HSR reservoirs. The classification of HSR reservoir related to mercury intrusion morphology and PTSs is described in detail below.

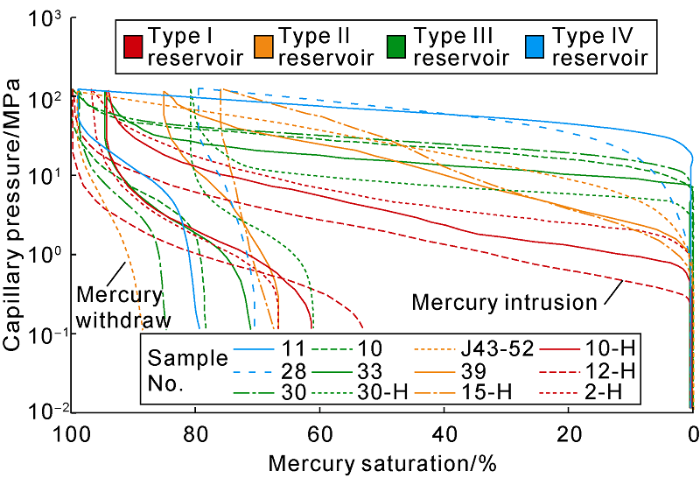

2.1. Conventional classification of HSR reservoirs related to mercury intrusion

HPMI is often employed in the classification of tight reservoirs, in which parameters such as mercury intrusion morphology and pore-throat size are common indicators. Based on mercury intrusion morphology, the Lucaogou HSR reservoirs are divided into four types (Fig. 2). Type I reservoir has lower displacement pressure, mercury injection curve of concave shape, and high mercury withdraw efficiency, indicating the reservoir has large pore-throats, good sorting, and more larger pores such as intergranular pores and intergranular dissolved pores. Type II reservoir has low displacement pressure, mercury injection curve in steep straight line shape, and low withdraw efficiency, indicating the reservoir has poor pore-throat sorting and wide size distribution of pore-throats, in other words, coexistence of many types of pore-throats. Type III has medium to high displacement pressure, mercury injection curve of gently straight line shape, and medium withdraw efficiency, suggesting the reservoir has good pore-throat sorting and simple pore-throat type, mainly dissolution pores or intercrystalline pores. Type IV has the highest displacement pressure, mercury injection curve of convex shape, and the lowest withdraw efficiency, meaning the reservoir has the smallest pore-throats, poor connectivity, and mainly intercrystalline pores. Overall, type I reservoir has the best physical properties (Table 1), type IV is the worst. Type II and type III reservoirs have similar physical properties distribution (Table 1), and their mercury intrusion curves intersect (Fig. 2), indicating no obvious differences in reservoir quality between these two types, which is related to the complex pore-throat structure and diverse pore-throat combinations of HSR reservoirs. It also reflects the conventional reservoir classification method related to single parameter such as mercury intrusion morphology is not suitable for HSR reservoir.

Fig. 2.

Fig. 2.

Mercury injection curves and classification of HSR reservoirs.

2.2. Classification of HSR reservoirs related to pore-throat system

2.2.1. Classification of pore-throat system

pore-throat systems are closely related to types and distribution of pores. When a certain pore type is dominant and has a certain continuous seepage length, these pores and adjacent throats (smaller part of the pores) constitute a complete pore-throat system. If a certain type of pore-throat system is obviously dominant in pore space and controls the seepage flow in a rock layer, it is considered the whole rock layer belongs to this kind of pore- throat system. In contrast, when multi types of pore-throats coexist and contribute equally to the seepage flow, the pore-throat system is mixed type. Combined with the previous classification scheme of pore types of tight reservoir[5,12], types and distribution of pores were identified using casting thin sections and SEM images, the proportion and distribution scale of different types of pores are counted, and the pore-throat system types of HSR reservoirs are determined. The pore-throat systems of the Lucaogou HSR reservoirs are divided into five types: intergranular PTS (type A), intergranular-dissolved-intercrystalline mixed PTS (type B), dissolved PTS (type C), dissolved- intercrystalline mixed PTS (type D), and intercrystalline PTS (type E). The specific features of them are as follows:

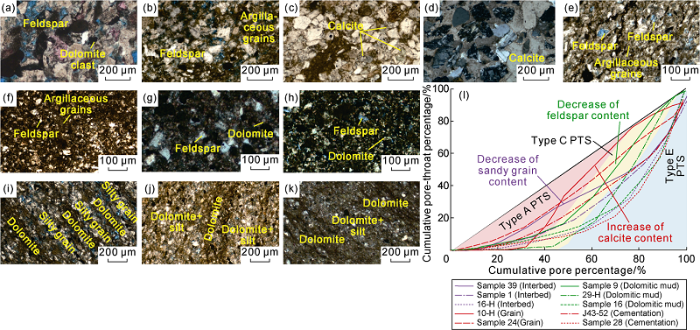

Intergranular PTS (type A) primarily consists of intergranular pores and intergranular dissolved pores (Fig. 3a), in which the pores are at the gaps between sandy grains (or arenes), and the throats are at the contacts of grains. This type of PTS has good connectivity and connected length (Fig. 3b), and is primarily distributed in type I reservoir of primarily siltstone or dolarenite (Table 1). Dissolved PTS (type C) is composed of mainly dissolved pores (Fig. 3c) and a few intergranular pores, and the dissolved pores are primarily honeycomb like and densely distributed (Fig. 3d), with wide parts functioning as pores and the narrow parts as throats. With larger pore-throat coordination numbers and good connectivity (Fig. 3d), monotonous pore type and well sorted pore throats, Type C PTS occurs primarily in type III reservoirs of dolomitic siltstone and mudstone (Table 1). Intercrystalline PTS (type E) is primarily connected by intercrystalline pores between quartz, dolomite, calcite and other minerals (Fig. 3e), and has some occasional dissolved pores and intergranular pores (Fig. 3f). Type E is characterized by small pore-throats and poor connectivity, and turns up primarily in type IV reservoir (Fig. 2) of argillaceous dolomite, calcareous siltstone, and dolomitic mudstone (Table 1).

Fig. 3.

Fig. 3.

Thin sections and SEM images of different PTSs. (a) Sample 12-H, cast thin section, dolarenite, with intergranular pores and Type A PTS; (b) Sample 12-H, SEM, with intergranular pores and intergranular dissolved pores; (c) Sample 33, cast thin section, siliceous shale, with feldspar and Type C PTS; (d) Sample 33, SEM, with intergranular and intragranular dissolved pores; (e) Sample 11, cast thin section, argillaceous dolomite, with no pores observed; (f) Sample 11, SEM, with dolomite intercrystalline pores and Type E PTS; (g) Sample 39, cast thin section, silty dolomite, with intergranular pores in the interbedded silt layer and intercrystalline pores in micritic dolomite; (h) Sample 39, SEM, with intergranular pores, intragranular dissolved pores, and Type B PTS; (i) Sample J43-52, cast thin section, calcareous siltstone, with intragranular dissolved pores and calcite blocking the intergranular pore-throats; (j) Sample J43-52, SEM, with calcite filling intergranular pores or metasomatizing intergranular dissolution pores and the Type D PTS; (k) Sample 30, cast thin section, silty mudstone, with mosaic feldspar grains and few pores; (l) Sample 30, SEM, showing dissolved pores connecting with intercrystalline pores and Type D PTS.

The mixed PTS includes intergranular-dissolved-intercrystalline mixed system (type B) and dissolved-intercrystalline mixed system (type D), which are related to the mixing of multi-source components. Type B commonly exists in interbedded lithologies composed of sandstone and dolomite (Fig. 3g), in which the silt bands have intergranular pore-throats developed, the mixed dolomite and silt layers have dissolved pore-throats developed, and the dolomicrite layers have intercrystalline pore-throats developed (Fig. 3h). In addition, when a small amount of calcite, argillaceous grains, and sandy grains are mixed (i.e., calciferous argillaceous siltstone), argillaceous grains and calcite fill between the sandy grains, and the intergranular pore-throat is partially destroyed, leading to the formation of this type of PTS (Table 1) in type II reservoirs. Type D is made up of dissolved and intercrystalline pore throats, including two subtypes. One is distributed in HSR composed of dolomite, argillaceous grains and a small amount of sandy grains (corresponding to mudstone or argillaceous dolomite) (Fig. 3k). The decrease in soluble minerals (such as feldspar) leads to poorer connectivity of dissolved pore-throats, so the intercrystalline pore-throats are important for maintaining the pore connection (Fig. 3l). The other subtype occurs in argillaceous siltstone with high calcite content, in which calcite not only fills intergranular pore-throats but also metasomatizes feldspar (Fig. 3i), and therefore destroys the connectivity of dissolved pore-throats (Fig. 3j), leading to the formation of type D PTS. These two subtypes are distributed in type III and type II reservoirs, respectively (Fig. 2).

Clearly, the types of HSR reservoirs (Fig. 2) don’t correspond with PTSs completely. Type I reservoirs has type A PTS, while type II reservoir with multiple types of pore-throats has both type B and type D PTSs, in which the type D has larger displacement pressure and intergranular pore-throats destroyed by cementation. Type III reservoir primarily develops type C PTSs, this type of reservoir with higher displacement pressure also may have type D PTS, due to the decrease of dissolved pores. Type IV reservoir primarily develop type E PTS.

Compared with conventional reservoir classification based on HPMI results, PTS classification can reveal the heterogeneity and genetic differences of pore-throat structure in HSRs more comprehensively. For type II reservoir, the samples with type B have more intergranular PTS (Fig. 3h), and their physical properties are significantly better than those with type D (Table 1 and Fig. 3j). For type III reservoir, the samples with type C develop more dissolution PTS (Fig. 3c), and their physical properties are significantly better than those with type D (Table 1 and Fig. 3l).

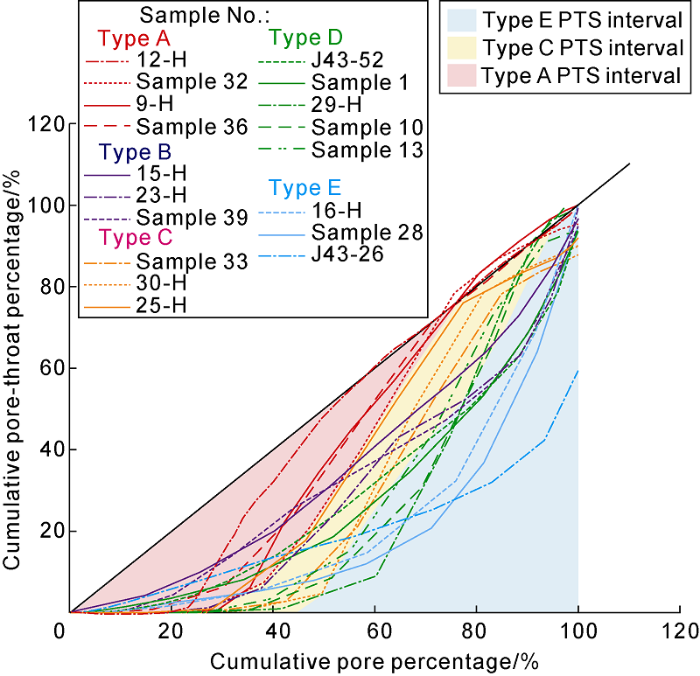

2.2.2. Quantitative identification of pore-throat system

The cumulative comparison method of pores and pore- throats is introduced to quantitatively identify PTSs. This method uses the relationship between cumulative pore and cumulative pore-throats to identify PTS. At the same cumulative pore proportion, different types of PTSs have different proportions of connected pore-throats, and the better the connectivity is, the higher the proportion of connected pore-throats is. The same type of PTS commonly corresponds to similar distribution curve. The steps of the pore-throat cumulative comparison method are as follows: the pore-throat distribution (PTD) curve is obtained from HPMI experiment, the T2 spectrum is calibrated by the PTD to calculate the surface relaxation rate (Table 1) and obtain the pore size distribution (PSD). Then, the cumulative proportions of pore-throats and pores at different pore sizes are counted from large to small pores, and the comparison chart of cumulative pores vs. pore-throats is plotted (Fig. 4).

Fig. 4.

Fig. 4.

Comparison chart of cumulative pores and pore- throats and the interval division of pore-throat systems.

In Fig. 4, the cumulative comparison curves are below the diagonal. The curves increase slowly first, then increase rapidly, and then hold steady near the diagonal. The larger the area enclosed by the cumulative curve and the diagonal, the lower the proportion of the connected pore-throats and the poorer the pore-throat connectivity is. The larger the slope of the rapidly increasing section is, the more monotonous the pore-throat type is. When multiple types of PTSs mix, the slope decreases significantly. Different types of PTSs are in different positions of the chart. Type A PTS is on the leftmost, has the smallest area enclosed by the diagonal and the greatest slope of rapidly increasing section, followed by type C, and type E is the rightmost. Based on the cumulative pore and pore throat curve distribution of multiple samples, the boundaries between these 3 types of PTSs can be defined (Fig. 4). The samples with mixed PTSs of type B and D have curves smaller in slope that usually cross several pore-throat size intervals. Based on the cumulative proportions of pore-throats in different size intervals, the contribution of different types of PTSs can be estimated. For example, intergranular PTS account for a higher proportion in the sample 39 than in the sample 1; and the samples 29-H and J43-52 both have type D PTS, but the sample 29-H contains more dissolved PTS. By using this method, PTSs, especially mixed PTSs, can be quantitatively identified.

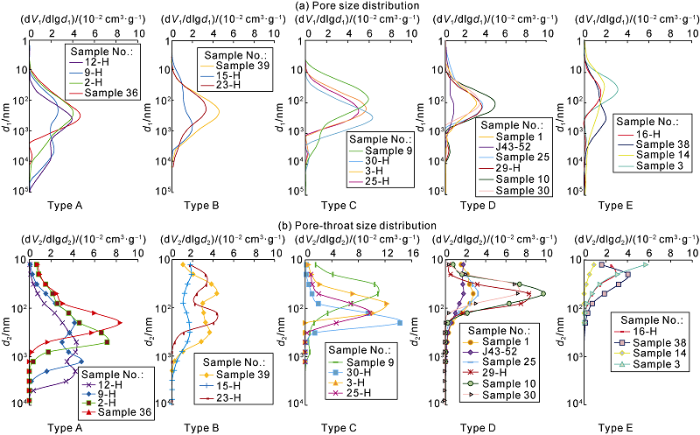

2.2.3. Comparison of microscopic features of different pore-throat systems

Fig. 5 shows the pore and pore-throat size distribution of the samples with the five types of PTSs, in which the PSD is converted from the T2 spectrum. The PSD of siltstone is bimodal and the PSDs of the other rock types are unimodal (Fig. 5). On the whole, the PTSs become worse with the decrease of pore size (Fig. 5). The samples with type A and type B PTS have the widest PSD range and the highest proportion of large pores more than 1 μm, indicating developed intergranular pores and intergranular dissolved pores. The samples with type C PTS have a unimodal PSD with the peak ranging from 100 to 400 nm, indicating the development of dissolved pores. The samples with type D and type E PTS have the narrowest PSD with peaks at 150 nm and 50 nm, respectively, indicating the development of intercrystalline pores.

Fig. 5.

Fig. 5.

Comparison of pore-throat and pore size distribution of samples with different pore-throat systems.

PTD is more closely related to PTS (Fig. 5). The PTD of samples with type A PTS is wedge-shaped. In these samples, large pore-throats, with the highest proportion, constitute the main seepage channels, while the other smaller pore-throats are connected into the seepage channels as nodes (falling on the diagonal of cumulative comparison chart). The PTD of samples with type C PTS has a symmetrical narrow peak, indicating monotonous and well sorted PTS, this is related to the dissolved pores in honeycomb shape and higher coordination numbers. The PTD of samples with type E PTS is the smallest in range and semi-unimodal, indicating that many pores in them are connected by smaller throats. The PTD of samples with type B PTS is symmetrical bimodal or wide unimodal and is wider than that of samples with type C PTS, which suggests the mixing of various PTS types and their similar contribution to seepage. The samples with type D PTS have two types of PTD: one is wide unimodal, which is equivalent to the left peak of type B PTS without the right peak, indicating intergranular pore-throats have been completely destroyed, primarily due to calcite cementation or metasomatism (such as sample J43-52); the other type is narrow single peak similar to that of PTD of the sample with type C PTS, but the pore-throats and pores decrease in size, indicating that intercrystalline pores take a higher proportion, which is related to the decrease of dissolved pore proportion (for example, sample 30).

However, some errors still exist in distinguishing PTSs with PTD. For example, samples 2-H and 30-H have similar PTD, but different PSD. Sample 2-H has bimodal PSD, and more developed intergranular pores, corresponding to type A PTS. In contrast, sample 30-H has a narrow unimodal PSD and belongs to type C PTS. Samples 29-H and 3-H are a similar case (Fig. 5). The pore-throat cumulative comparison method combined with pore and pore throat information can improve the accuracy of PTS identification.

3. Controlling factors of pore-throat system in HSR

3.1. Distribution of pore-throat system

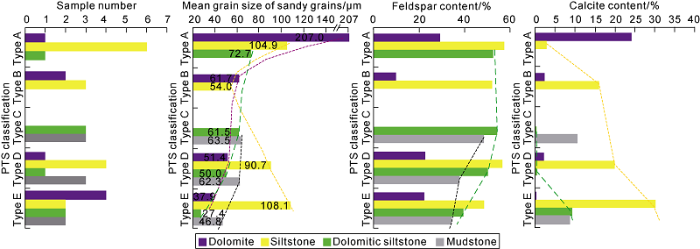

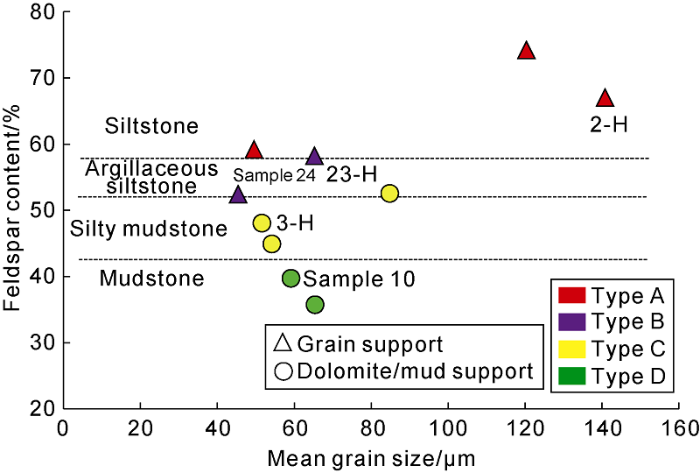

Type A PTS occurs largely in siltstone, dolarenite, and a small amount of dolomitic siltstone, and the samples with type A PTS have a mean grain size of greater than 72.7 μm, which is significantly higher than that of other types (Fig. 6 and Table 1). Type B PTS appears largely in dolomite and siltstone (Fig. 6 and Table 1). The dolomite is primarily interbedded silt and dolomite, and the siltstone is primarily argillaceous siltstone with small grain size (54 μm on average). Type C PTS only exists in dolomitic siltstone and mudstone (Fig. 6 and Table 1), in which sandy grains or arene are primarily nested in matrix of dolomite and mud dispersedly, making intergranular PTS difficult to come up. Type D PTS occurs in siltstone, mudstone, and a small amount of dolomite and dolomitic siltstone (Fig. 6). The siltstone is primarily calcareous siltstone (Table 1) with calcite content greater than 20%. Type E PTS turns up in all lithologies, slightly more in argillaceous dolomite (Fig. 6). Except for siltstone, the samples with type E PTS have grain size smaller than samples with other PTS types.

Fig. 6.

Fig. 6.

PTSs in different lithology and their relationships with median grain size, feldspar and calcite content.

3.2. Analysis of the pore-throat system controlling factors

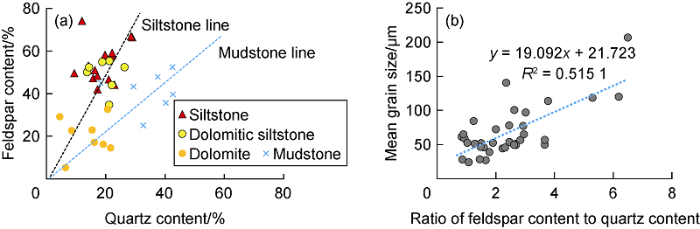

3.2.1. HSR Composition difference and arrangement

The Lucaogou hybrid sedimentary rocks are a mixture of fine-grained mechanical deposit, chemical deposit, and a small amount of volcanic material[19], in which the tuffaceous material, very low in content, is hard to count and thus not considered in this paper. Based on differences in grain size and mineral composition, the components of the HSR are divided into sandy grain (silt to fine sand with grain size larger than 30 μm), argillaceous grain (silt and mud with grain size less than 30 μm), dolomicrite, and arene. Sandy grains and arenes formed in high-energy environments are larger in grain size and high in resistance to overlying pressure, so they are conducive to the formation and preservation of intergranular pores. In addition, compared with argillaceous grains (the main component of mudstone), the sandy grains have higher ratio of feldspar to quartz (Fig. 7) and more feldspar, conducive to the formation of dissolved pores to further improve PTS. Meanwhile, compared with dolomicrite, arene is more conducive to intergranular dissolution. Sandy grains and arenes are the material basis for the formation of intergranular PTS, and with the increase of grain size, the resistance to pressure and dissolution increase (Fig. 7b). The type A PTS occurs in siltstone, dolarenite, and a small amount of dolomitic siltstone (Fig. 6 and Table 1). Dolomicrite and argillaceous grains are low-energy products with small grain size, which are not conducive to the preservation of intergranular pores. However, higher quartz content is conducive to the formation and preservation of intercrystalline pores, and feldspar grains could dissolve (Fig. 7). Type C, type D, and type E PTSs appear universally in mudstone, argillaceous dolomite, and dolomitic siltstone with small grain size. Obviously, the component difference, especially the coarse-grain content, such as sandy grains and arenes, dominates the distribution pattern of PTSs.

Fig. 7.

Fig. 7.

The relationship between the content of feldspar and quartz (a) and that between the ratio of feldspar to quartz and the mean grain size (b).

Fig. 8.

Fig. 8.

Thin section images and pore-throat system distribution of samples with different matrix support modes. (a) Sample 10-H, grain support mode, lime-bearing siltstone, with a calcite content of 9.8%; (b) Sample 24, grain support mode, argillaceous siltstone, with a calcite content of 10.1%; (c) Sample J43-52, partially cementation support mode, lime-bearing siltstone, with a calcite content of 13.9%; (d) Sample 28, cementation support mode, calcareous siltstone, with a calcite content of 36.3%; (e) Sample 9, mud grain support mode, silty mudstone, with a feldspar content of 52.5%; (f) Sample 16, mud grain support, dolomite-bearing mudstone, with a feldspar content of 25.1%; (g) Sample 29-H, dolomite support, dolomitic siltstone, with a feldspar content of 50.2%; (h) Sample 11, dolomite support, argillaceous dolomite, with a feldspar content of 16.3%; (i) Sample 39, interbed support mode, interbedding of silty dolomite, silt grains, and dolomicrite; (j) Sample 1, silty dolomite, interbedding of dolomicrite and dolomite-silt mixed layer; (k) Sample 16-H, silt-bearing dolomite, interbeds of dolomite and dolomite-silt; (l) Pore-throat system distribution characteristics of these samples.

The amount and arrangement of coarse-grain components will affect the support mode of HSR matrix and control the types and changes of the PTSs. Based on observation of thin sections, the matrix support of the HSR can be divided into 4 types: grain support, interbed support, dolomite/mud support, and cementation support. In the grain support mode, coarse-grained components, such as sandy grains or arenes in rock contact directly (Fig. 8a, 8b). This kind of support mostly appears in siltstone or dolarenite (Fig. 2a), and is conducive to the formation and preservation of type A PTS (Fig. 8a, 8b and 8l). Moreover, with the increase of grain size, the pore-throats increase in size too (Table 1). The change of this type of PTS in HSR is affected by the amount of argillaceous grains and calcite content. Argillaceous grains and calcite could fill intergranular pores (Fig. 8b to 8d), destructing intergranular pore-throats, and making the proportion of intercrystalline pores increase, and type A PTS transition to type B PTS (for example sample 24, Fig. 8b). When the calcite content exceeds 13% (Fig. 8c, 8d), calcite appears in contiguous pieces between the silt grains, and the grain support mode gradually transitions to the cementation support mode. In this case, calcite completely fills intergranular pores or metasomatizes feldspar (Fig. 8d), destroying the type A or type C PTS, and making them transform to type D (for example, J43-52 sample) and type E PTSs (for example, sample 28) (Fig. 8l).

In dolomitic/mud support mode, dolomicrite or argillaceous grains are support materials in the matrix, (Fig. 8e to 8h). This kind of support mode presents in argillaceous dolomite, mudstone, and dolomitic siltstone. In this kind of HSR, most sandy grains are less than 60 μm in size and don’t contact with each other, and intercrystalline pores between quartz and dolomite grains, and feldspar dissolved pores are abundant, forming type C, type D, and type E PTSs. The higher the feldspar content, the higher the proportion of dissolved PTS is; conversely, the lower the feldspar content, the higher the proportion of intercrystalline PTS is. Feldspar content controls the PTS change in this type of HSR (Fig. 8l). For example, when the feldspar content is greater than 50%, dolomitic siltstone has type C PTS developed, when the feldspar content is less than 40%, it has type E PTS developed, and when the feldspar content ranges from 40% to 50%, it has type D PTS developed (Fig. 6, Fig. 8, and Table 1). For mudstone, similar changes are also observed, the corresponding feldspar content limits are 45% and 35% (Fig. 6, Fig. 8 and Table 1), respectively. Argillaceous dolomite, with feldspar content of generally less than 35%, has primarily type E PTS (Table 1).

The interbed support mode refers to the interbedded distribution of coarse-grained components and fine- grained components (Fig. 8i to 8k). This support mode is common in silty dolomite, including interbeds of sandy grains and micritic dolomite (Fig. 8i), as well as interbeds of dolomite-silt and dolomite (less than 200 μm in thickness) (Fig. 8j, 8k). The coarse-grained layers have intergranular PTS, and dolomite layers have intercrystalline PTS, combining to type B PTS in this type of HSR (Fig. 8l). With decreasing size of the coarse-grained component (less than 55 μm), the PTS transforms to type D (Fig. 8l and Table 1). The PTS change is primarily controlled by grain size and silt content in this type of HSR. The larger the size and the higher the content of the sandy grain, the higher the intergranular PTS proportion is.

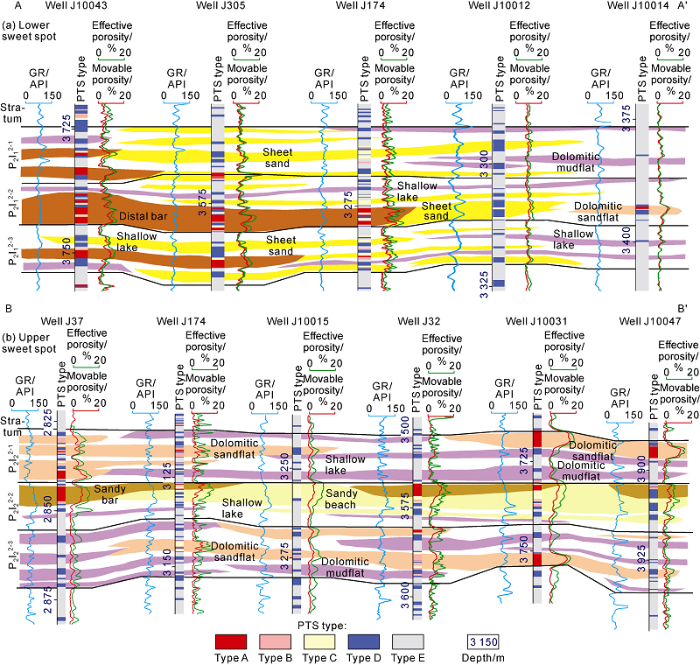

3.2.2. Provenance and sedimentary microfacies

The Lucaogou Formation is composed of deltaic and lacustrine deposits under the background of salinized lake basin, including delta front sheet sand, distal bar, shore sandy beach, sandy bar, dolomitic mudflat, dolomitic sandflat, and shallow lacustrine mud microfacies etc (Fig. 9)[15,16]. The provenance was primarily from south of the study area. The distance from provenance and the sedimentary microfacies affect the coarse-grained content and arrangement, and in turn the types of PTSs in the HSR.

(1) The farther away from the provenance, the smaller the grain size and proportion of silt in the HSR, and the poorer the PTS. The lower sweet spot cross-well section (Fig. 9a) shows from Well J10043 to Well J10014, as the distance from provenance increases, the lithology changes from thick siltstone, interbedded dolomitic siltstone and dolomitic mudstone to dolomitic mudstone intercalated with thin dolomitic siltstone, the siltstone within the HSR decreases in grain size, the dolomicrite and argillaceous grains increase, the matrix support mode changes from grain support near provenance to dolomitic/mud support far from provenance, and the dominant PTS changes from type A (Well J10043) to type D and type E PTS (Well J10012 and Well J10014).

(2) Based on hydrodynamic conditions and relative distance from provenance, the depositional environments of HSR can be divided into 3 types: near provenance and high energy, far from provenance and medium energy, as well as far from provenance and low energy. In the near provenance and high energy environment, strong wave modification and strong hydrodynamic conditions could transport coarse terrigenous grains or unconsolidated dolomite for deposition, so the HSR formed has higher content of coarse-grained components such as silt (or sandy grains) and grain support or interbed support mode, and better PTS types. For example, the littoral sand bar, distal sand bar, and dolomitic sandflat microfacies are all formed in the near provenance and high energy environment, and are thick siltstone, dolomitic siltstone, and dolarenite with type A or type B PTS (Fig. 9). In comparison, in the far from provenance and medium energy environment with weaker wave modification, the terrigenous grains in the HSR reduce in size, the argillaceous grains or dolomicrite increase in proportion, and the support mode changes to dolomitic/mud support or a small amount of interbed support, so the PTS becomes poorer. For example, the littoral sandy beach and sheet sand microfacies are formed in this kind of environment, and are composed of thick argillaceous siltstone or thin dolomitic siltstone and silty dolomite with type C and type D PTSs (Fig. 9). In the far from provenance and low energy environment (such as dolomitic mudflat and shallow lake mud microfacies), HSR is dominated by argillaceous dolomite and dolomitic mudstone; with low content of sandy grains and dolomite/mud support mode, this kind of HSR has mostly type E and a small amount of type D PTSs (Fig. 9).

Fig. 9.

Fig. 9.

Distribution of PTSs and sedimentary microfacies in the upper and lower sweet spot sections (see

3.2.3. Diagenesis

The Lucaogou Formation experienced three diagenetic processes, compaction, cementation, and dissolution[19], all of which affect the PTS. Compaction leads to reduction of intergranular pores, especially for dolomitic/mud support HSR, in which most intergranular pores are destroyed (Fig. 8e, 8f) and intergranular pore-throats are rare (Fig. 8l). In contrast, for grain support HSR with higher resistance to compaction, compaction has limited damage to the intergranular PTS (Fig. 8a, 8l). Calcite cementation can be divided into early stage and late stage. Calcite cementation of the early stage primarily appears as rim between silt or sandy grains (Fig. 8d). As the cementation support mode develops, the intergranular PTS gradually disappears (Fig. 8l). The calcite cementation of the late stage largely turns up in sporadic flakes metasomatizing feldspar grains (Fig. 3i, 3j), destroying the connectivity of dissolved pores and leading to the development of type D PTS (e.g. sample J43-52, Fig. 8l). Dissolution is key to the development of high-quality HSR reservoir, including dissolution of feldspar primarily (Fig. 8a, 8c, 8h) and dissolution of dolomite in local part. As the source and reservoir layers are close to each other in the Lucaogou Formation, the acidic fluid generated by organic matter would easily come into contact with feldspar, so the dissolution strength primarily depends on the feldspar content. Clearly, compaction and early calcite cementation destroy type A PTS, and later calcite cementation destroys type C PTS, while dissolution can effectively increase the proportion of dissolved PTS.

3.3. Variation of pore-throat system under multicomponent mixing deposition

Based on the composition of the Lucaogou HSR, the PTS change patterns in three mixing deposition situations, mixing deposition of sand and mud, dolomite and sand, and dolomite and mud were examined to guide the selection of high-quality HSR reservoirs.

Sand-mud mixing appears mainly in the shoreline beach bar subfacies near provenance with strong wave modification. Sandy-mud mixing is the mixing of sandy grains and argillaceous grains with low dolomite content. With the weakening of hydrodynamic force, the argillaceous grains in the mixing product increase, the lithology changes from siltstone and argillaceous siltstone to silty mudstone and silt-bearing mudstone, the grain size first decreases rapidly and then remains stable, and the mean feldspar content decreases rapidly from 66% to 37% (Fig. 10), indicating that the feldspar content can reflects the amount of sandy grains in HSR. With the decrease of feldspar content (Fig. 10), the support mode changes from grain support to dolomite/mud support, and the PTS changes from "A to B to C to D" successively (Fig. 10).

Fig. 10.

Fig. 10.

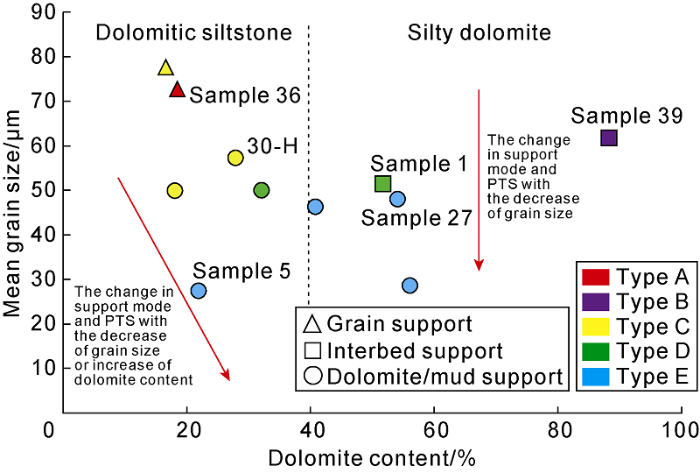

Variation of support modes and pore-throat systems in the sand- mud mixing deposits.

Dolomite-sand mixing mostly turns up in delta front subfacies and dolomitic sand flat, and is the mixing deposit of dolomicrite and sandy grains (or arene), including dolomitic siltstone and silty dolomite with low calcite content (Table 1). The dolomite is the product of penecontemporaneous dolomitization formed in lentic environment[19]. Therefore, with the increase of dolomite content (less than 40%) and the weakening of wave reformation, the sandy grains decrease in size rapidly, the support mode changes from grain mode (sample 36) to dolomite/mud mode (sample 30-h and sample 5), and the PTS changes from "A to C to D to E" (Fig. 11). This change process is controlled by grain size and dolomite content. When the dolomite content reaches more than 40% (dolomite), the sandy grains conversely increase in size to some extent, and grain size dominates the support mode and PTS changes, i.e., when grain size is greater than 50 μm, indicating hydrodynamics changed frequently, the deposit is interbeds of sandy grains and dolomicrite (for example, sample 39 and 1). With the decrease of grain size, the support mode changes to dolomite/mud mode (for example, sample 27), and the PTS transitions from "B to D to E" (Fig. 11).

Fig. 11.

Fig. 11.

Variation of support modes and pore-throat systems in the dolomite-sand mixing deposits.

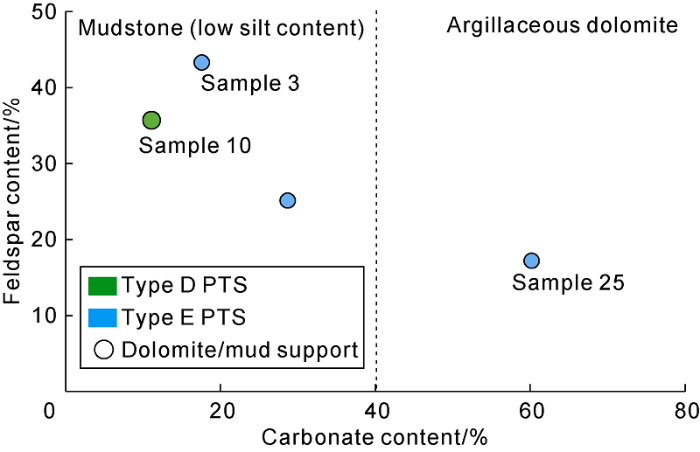

Dolomite-mud mixing appears in the dolomitic mudflat and shallow lake mud microfacies, and is the mixing deposit of dolomicrite and argillaceous grains, including dolomitic mudstone and argillaceous dolomite with a mean silt content of less than 10%. This kind of HSR, with dolomite/mud support mode and mainly intercrystalline pores and feldspar dissolved pores, has poorer PTSs than sandy-mud or dolomite-sand mixing deposits. With the increase of carbonate mineral content (dolomite and calcite), the feldspar content decreases rapidly, the dissolved pores become poorer in connectivity, and the PTS changes from type D to type E (Fig. 12). The PTS change is mainly dependent on the ratio of feldspar to carbonate minerals, i.e., with the decrease of the ratio of feldspar to carbonate minerals, type E PTS takes dominance gradually.

Fig. 12.

Fig. 12.

Variation of support modes and pore-throat systems in the dolomite-mud mixing deposit.

The PTS classification of HSR and the change patterns of PTS in the mixing sedimentation process can guide the selection of mixed shale oil reservoirs effectively. Favorable reservoirs developed during mixing deposition of sand-mud and dolomite-sand, especially in the high-energy sedimentary environment which can result in high content of coarse components such as sandy grains or arenes, and grain or interbed support mode conducive to the preservation of type A and type C PTS, and thus the formation of HSR sweet spots of shale oil.

4. Impacts of pore-throat system on physical properties and fluid mobility of HSR

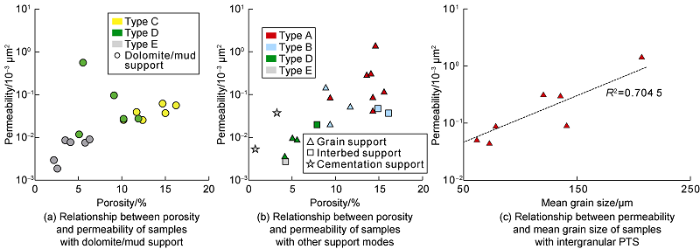

4.1. Impacts on reservoir physical properties

The impacts of PTS on physical properties were studied based on two categories, dolomite/mud support samples and non-dolomite/mud support samples. The PTS has significant control on the physical properties, i.e., the porosity and permeability increase from the samples with type E PTS to samples with type A PTS (Fig. 13). The samples with type E have the worst physical properties, with a porosity of less than 5% and permeability less than 0.01×10-3 μm2. Samples with type D PTS have the second worst physical properties, the samples with dolomite-mud support have a porosity of less than 10.2% and permeability less than 0.0277×10-3 μm2, while the samples with grain or interbed support mode have a porosity of less than 8% and a permeability less than 0.02×10-3 μm2. Type C and type B PTSs occur in deposits with dolomite/mud support and non-dolomitic/mud support, respectively, and samples with these two PTSs have similar physical properties but quite different PTD (Fig. 5). The samples with type A PTS have the best physical properties, with a porosity greater than 12% and permeability greater than 0.065×10-3 μm2. On the whole, samples with the same kind of PTS show a strong positive correlation between porosity and permeability (Fig. 13a, 13b). But this correlation is weak for samples with type A PTS, primarily because they have mainly grain support mode, and the pore-throat size is controlled by the grain size (silt or arene), the larger the grain size, the larger the pore-throat and the higher the permeability is (Fig. 13c). For example, Sample 12-H, 2-H, and 36 are 207 μm, 140 μm, and 72.7 μm in grain size respectively, and they have similar porosities, but pore-throat radii decreasing (Fig. 5) and thus permeabilities dropping successively (Table 1).

Fig. 13.

Fig. 13.

The relationships between porosity and permeability and between mean grain size and permeability of samples with different PTSs.

4.2. Impacts on fluid mobility

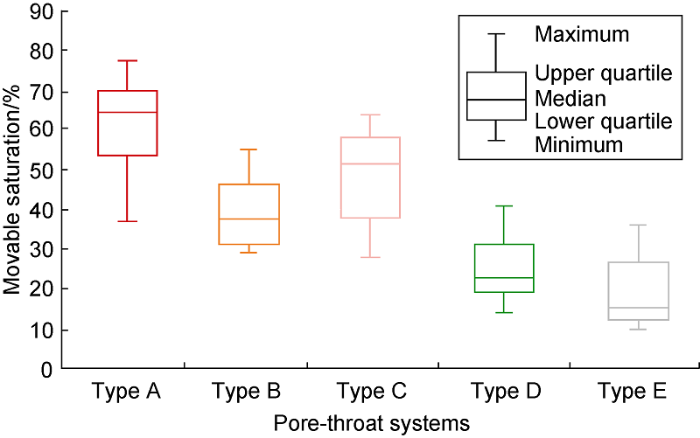

Based on the T2 spectra of samples after centrifugation (10000 r/min) and oil saturation, the movable oil saturations of the samples were calculated to analyze the control of PTS on oil mobility (Fig. 14). The samples with type E PTS have the lowest mobile oil saturation, generally lower than 35%, on average 20%, followed by samples with type D PTS (mean 25.5%). The samples with type C and type B PTS have similar mobile oil saturation range, but samples with type C PTS have slightly higher mobile oil saturation (mean 47.9%), this is because they have better sorted pore-throats (Fig. 5). The samples with type A PTS have the highest movable oil saturation, generally greater than 35% (61% on average).

Fig. 14.

Fig. 14.

Movable oil saturations of samples with different pore-throat systems.

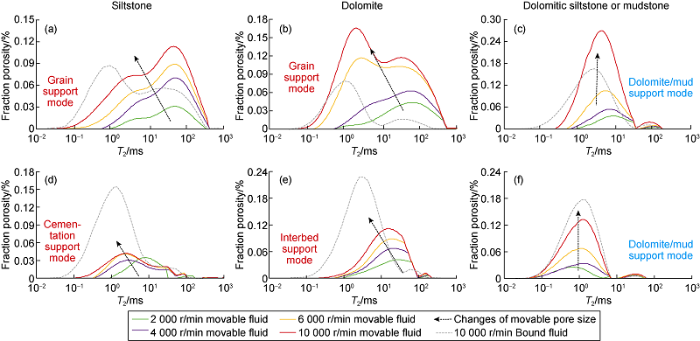

The distribution of mobile fluid is also affected by the matrix support mode (Fig. 15). For samples with grain support mode (Fig. 15a, 15b), the movable fluid is primarily distributed in larger pores, and the main peak (at 1 ms) is significantly larger than that of the bound fluid. With the increase of centrifugal force, the movable fluid increases in amplitude and distribution range (move to the small pores), and the fluid in smaller pores are produced gradually. Overall, the fluid in large pores has better mobility, indicating that large pores are commonly connected by larger pore-throats, while small pores are connected by smaller pore-throats, so fluid in small pores has poorer mobility. Grain support samples have ball-stick shaped pore-throat combination similar to conventional reservoir. For cementation support samples (Fig. 15d), the movable ratio becomes smaller, but the movable fluid is primarily concentrated in larger pores, too. Although some larger pore-throats are blocked by calcite cement, the ball-stick shaped combination of pores and throats is retained overall in this kind of samples. In samples with interbed support mode, the movable fluid distribution is similar to the samples with grain support mode, and the fluid in larger pores has better mobility than that in smaller pores too (Fig. 15e). But samples with dolomite/mud support are different in movable fluid distribution, i.e., the distribution ranges of movable fluid and bound fluid basically coincide (Fig. 15c, 15f). With the increase of centrifugal force, the distribution range of the movable fluid does not increase significantly (increase uniformly in different sizes of pores), and the fluid in larger pores has no significant advantage in mobility. For samples with dolomite/mud support, dolomicrite and argillaceous grains are primary support materials in matrix, and intercrystalline pores and feldspar dissolved pores act as primary storage and seepage channels, so the pore-throats are small in radius but well-sorted (Fig. 5), the pore-throats connecting different pores are similar in size, forming short-tube shaped combination of pores and throats. When the centrifugal force overcomes the capillary resistance of the throats, the fluid in different sizes of pores connected by these throats can flow.

Fig. 15.

Fig. 15.

Distributions of movable and bound fluid in HSR samples with different matrix support modes. (a) Sample 10-H, grain support mode, Type A PTS, calcite-bearing siltstone; (b) Sample 12-H, grain support mode, Type A PTS, dolarenite; (c) Sample 30-H, dolomite/mud support mode, Type C PTS, dolomitic siltstone; (d) Sample J43-26, cementation support mode, Type D PTS, calcareous siltstone; (e) Sample 39, interbed support mode, Type B PTS, silty dolomite; (f) Sample 30, dolomite/mud support mode, Type D PTS, silty mudstone.

Centrifugation can be regarded as the reverse process of oil charging, and the pore space with movable fluid is also the space for shale oil storage. For siltstone, dolarenite, and silty dolomite with grain or interbed support, shale oil is primarily distributed in larger pores, showing the features of "oil in large pores and water in small pores," while for dolomitic siltstone and mudstone with dolomite/mud support mode, oil and water exist in pores with similar sizes. The differences in oil and water distribution will affect the conductivity model of HSR and interpretation accuracy of NMR logging; therefore, the influence of PTS should be considered in interpretation of HSR reservoir parameters.

5. Conclusions

The Lucaogou Formation reservoirs have 5 types of PTSs, intergranular PTS (type A), intergranular-dissolved- intercrystalline mixed PTS (type B), dissolved PTS (type C), dissolved-intercrystalline mixed PTS (type D), and intercrystalline PTS (type E). The comparison method of cumulative proportions of pore-throats and pores can be used to quantitatively estimate contributions of different types of PTSs and accurately identify the PTSs.

Sedimentary environment and diagenesis jointly control PTS development. The HSR deposited near provenance has better PTS than that deposited far from provenance. In the high-energy environment such as shore sandy bar, distal bar, and dolomitic sandflat, the HSRs deposited have more coarse-grained components (silt or arene) and primarily grain or interbed support, and thus type A and type B PTSs. In the medium energy environments, such as sheet sand and sandy beach, the HSRs deposited have more mudstone or dolomite, and thus type C and type D PTSs. In the low-energy environments, such as dolomitic mudflat and shallow lake mud, the HSRs deposited have dolomite/mud support mode and thus type E and type D PTSs. Compaction and early calcite cementation destroy intergranular PTS, while dissolution enhances the proportion of dissolved PTS; but late calcite cementation would destroy dissolved PTSs and increase the proportion of intercrystalline PTS.

In the mixing deposition process of sand and mud, the PTS is affected by sandy grain and feldspar content and changes from "A to B to C to D". In the mixing deposition process of dolomite and sand, the PTS is affected by sandy grain and dolomite content and change from "A to C to D to E" and from "B to D to E". In the mixing deposition of dolomite and mud, the PTS is influenced by the ratio of feldspar to carbonate minerals and changes from "D to E".

The PTSs control the physical properties and fluid mobility of HSR reservoirs. In HSR reservoirs with grain support and interbed support mode, pores and throats take on ball-stick connection, larger pores have significant mobility edge, and large pores contain oil and small pores contain water. In contrast, the HSR with dolomite/mud support has short tube shaped pore-throat combination, so the fluid in larger pores doesn’t have much mobility priority, and oil and water exist in pores of similar sizes.

Nomenclature

d1—pore diameter, nm;

d2—pore-throat diameter, nm;

GR—gamma ray, API;

T2—transverse relaxation time, ms;

V1—pore volume per unit of mass, cm3/g;

V2—pore-throat volume per unit of mass, cm3/g.

Reference

Mixing of siliciclastic and carbonate sediments in shallow shelf environments

DOI:10.1130/0091-7613(1984)12<432:MOSACS>2.0.CO;2 URL [Cited within: 1]

Internal anatomy of a mixed siliciclastic-carbonate platform: The Late Cenomanian-Mid Turonian at the southern margin of the Spanish central system

DOI:10.1111/sed.2007.54.issue-6 URL [Cited within: 1]

Facies architecture of the mixed carbonate/siliciclastic inner continental shelf of west-central Florida: Implications for Holocene barrier development

DOI:10.1016/S0025-3227(03)00190-7 URL [Cited within: 1]

Significance, geologic characteristics, resource potential and future challenges of tight oil and shale oil. Bulletin of Mineralogy,

Characteristics of mixed sedimentary reservoir: Taking the lower cretaceous mixed sedimentary rock of Qingxi Depression in Jiuquan Basin as an example

Types and resource potential of continental shale oil in China and its boundary with tight oil

DOI:10.1016/S1876-3804(20)60001-5 URL [Cited within: 2]

Original mechanism of mixed sediments in the saline lacustrine basin

Features and model of mixed sediments of Da’anzhai Member in lower Jurassic Ziliujing Formation, Huilong area, Sichuan Basin

Depositional facies analysis on tight reservoir of Lucaogou Formation in Jimsar Sag, Junggar Basin

Identification and distribution prediction of high-quality reservoir of lacustrine carbonate rocks in Nanpu Sag

Rock types and characteristics of tight oil reservoir in Permian Lucaogou Formation, Jimsar Sag

Combining nuclear magnetic resonance and rate-controlled porosimetry to probe the pore-throat structure of tight sandstones

Development potential and technical strategy of continental shale oil in China

Formation conditions and exploration potential of tight oil in the Permian saline lacustrine dolomitic rock, Junggar Basin, NW China

Characteristics and formation mechanism of multi-source mixed sedimentary rocks in a saline lake, a case study of the Permian Lucaogou Formation in the Jimusaer Sag, northwest China

DOI:10.1016/j.marpetgeo.2019.01.016 URL [Cited within: 2]

Study on feldspar weathering and analysis of relevant impact factors

The dynamics of capillary flow

DOI:10.1103/PhysRev.17.273 URL [Cited within: 1]

Diagenesis and pore structure characteristics of carbonate component of lacustrine mixed rocks: A case study of Permian Lucaogou Formation in Jimusar Sag, Xinjiang. Fault-Block Oil &